Introduction to CNC Metal Cutting

CNC metal cutting stands as a cornerstone in the realm of manufacturing, offering unparalleled precision, efficiency, and versatility in the creation of metal components. This technology leverages computerized controls to guide cutting tools and machinery, enabling the transformation of raw metal into intricately designed parts that find applications across a myriad of industries.

Significance of CNC Metal Cutting:

The advent of CNC metal cutting has revolutionized the manufacturing landscape, allowing for the production of complex geometries and designs that were once deemed unattainable. From automotive and aerospace to healthcare and consumer electronics, CNC metal cutting serves as the backbone for innovation and product development, fulfilling the diverse needs of various sectors.

Applications Across Industries:

- Automotive: The production of engine components, structural parts, and accessories relies heavily on the precision and reliability offered by CNC metal cutting.

- Aerospace: High-precision components, crafted to withstand extreme conditions and meet stringent safety standards, are made possible through advanced CNC metal cutting processes.

- Healthcare: The manufacturing of medical devices and surgical instruments necessitates the accuracy and compliance ensured by CNC metal cutting.

- Consumer Electronics: The development of compact and sophisticated electronic devices is facilitated by the scalability and precision of CNC metal cutting.

Global Reach and Impact:

CNC metal cutting has left an indelible mark on the global manufacturing sector, fostering innovation, enhancing productivity, and contributing to sustainable development. With China emerging as a manufacturing hub, companies like Wuxi Lead Precision Machinery are at the forefront of this transformation, shaping the future of CNC metal cutting and setting industry standards.

In the subsequent sections, we will delve deeper into the diverse CNC metal cutting processes, explore the synergy of CNC and laser cutting, and uncover the offerings of Wuxi Lead Precision Machinery in this domain. Join us as we navigate through the intricate world of CNC metal cutting and unravel the opportunities it presents.

Diverse CNC Metal Cutting Processes

CNC metal cutting is a multifaceted domain, encompassing a variety of processes each with its unique characteristics and applications. These processes enable manufacturers to achieve intricate designs, high precision, and efficient production, catering to the diverse requirements of different industries.

CNC Laser Cutting Process:

- Overview: CNC laser cutting is a non-contact process that utilizes a laser beam to cut metal, offering high precision and clean edges.

- Applications: Ideal for creating intricate designs in industries such as automotive, aerospace, and electronics.

- Advantages: High accuracy, smooth finishes, and the ability to handle complex geometries.

CNC Punching Process:

- Overview: This process involves the use of a CNC machine to create holes, slots, and shapes in metal sheets through punching.

- Applications: Widely used in the production of metal components for furniture, hardware, and machinery.

- Advantages: Cost-effective for high-volume production and offers versatility in creating different shapes and designs.

CNC Milling Process:

- Overview: CNC milling is a subtractive manufacturing process where rotating cutting tools remove material from a workpiece to shape it.

- Applications: Essential for crafting engine components, structural parts, and medical devices.

- Advantages: Suitable for a wide range of materials and offers high precision and versatility.

CNC Plasma Cutting:

- Overview: This process employs a plasma torch to cut metal by melting it, suitable for various thicknesses.

- Applications: Utilized in industries such as agriculture, truck manufacturing, and construction.

- Advantages: Efficient for cutting thicker materials and offers speed and adaptability.

The Synergy of CNC and Laser Cutting

The amalgamation of CNC and laser cutting technologies brings forth a synergy that enhances the capabilities of metal cutting. This combination allows for the realization of intricate designs with high precision, ensuring efficiency and quality in production.

- Precision and Detailing: The integration of CNC control with laser cutting enables the achievement of detailed designs and tight tolerances, essential for industries requiring high precision.

- Efficiency and Speed: The non-contact nature of laser cutting, coupled with CNC automation, results in faster production times and reduced material wastage.

- Versatility and Adaptability: The synergy allows for adaptability to different materials and thicknesses, offering versatile solutions for varied manufacturing needs.

Wuxi Lead Precision Machinery: A Leading CNC Metal Cutting Company in China

Wuxi Lead Precision Machinery stands as a beacon of innovation and quality in the field of CNC metal cutting. With state-of-the-art metal fabrication equipment, the company is adept at producing durable, end-use metal parts tailored to specific requirements.

- Capabilities and Services: Wuxi Lead offers a plethora of CNC metal cutting services, including laser cutting, plasma cutting, CNC punching, and CNC bending. The company works with a variety of materials such as aluminum, steel, stainless steel, brass, and copper.

- Industry Focus: Catering to diverse sectors such as agriculture, automotive, electronics, medical, furniture, hardware, and machinery, Wuxi Lead showcases its versatility and expertise.

- Commitment to Quality: The company emphasizes quality assurance, conducting 1st Piece Inspection, In-Process, and Final Inspection to ensure adherence to specifications.

- Additional Services: Beyond CNC metal cutting, Wuxi Lead also provides additional services like CNC machining, CNC milling, CNC turning, metal stamping, and various finishes.

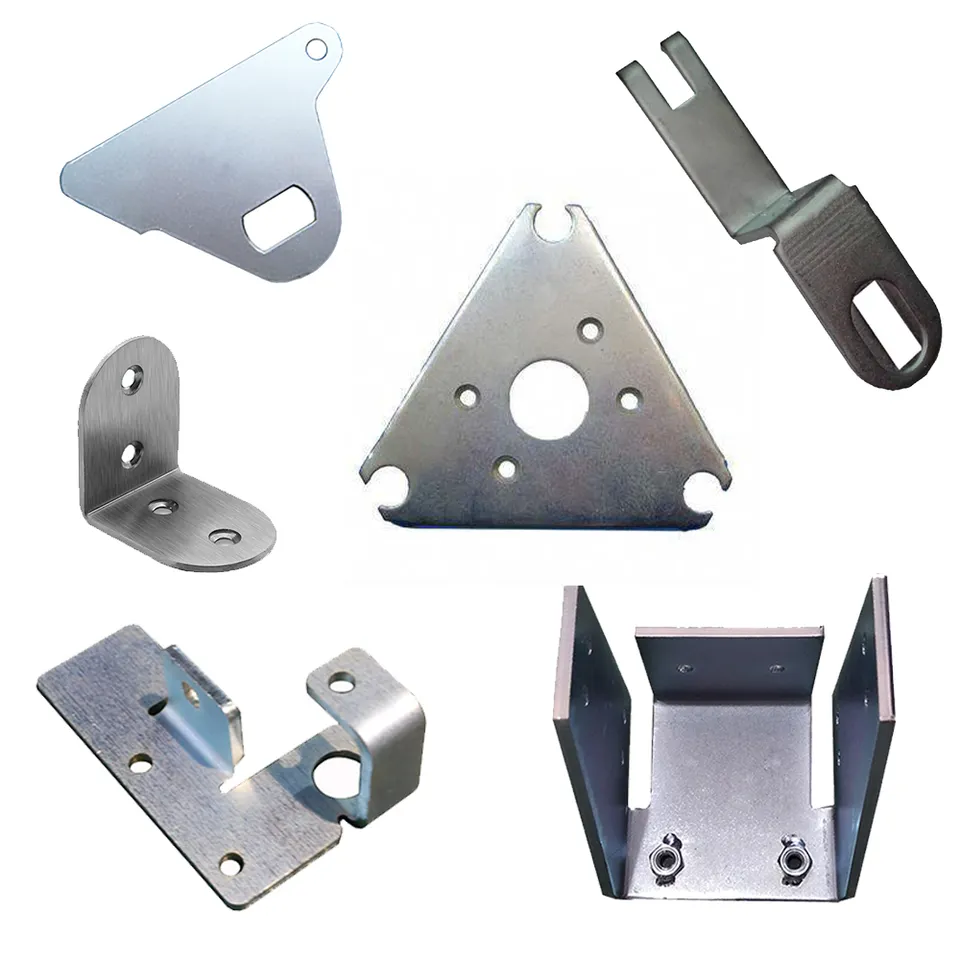

Custom CNC Metal Cutting Services by Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery excels in delivering custom CNC metal cutting services, tailored to meet the unique needs and specifications of each client. With a focus on versatility and precision, the company crafts end-use metal parts that are both durable and compliant with industry standards.

Tailored Solutions for Diverse Needs:

- Overview: Wuxi Lead specializes in creating customized metal parts through processes such as laser cutting, plasma cutting, CNC punching, and CNC bending.

- Material Variety: The company handles a wide range of materials including aluminum, steel, stainless steel, brass, and copper, offering diverse solutions.

- Industry Applications: Wuxi Lead’s custom services cater to various industries such as agriculture, automotive, electronics, medical, furniture, hardware, and machinery.

Quality and Compliance:

- Quality Assurance: Rigorous inspection processes including 1st Piece Inspection, In-Process, and Final Inspection are conducted to ensure zero defects and adherence to client specifications.

- Compliance with Standards: Wuxi Lead is committed to maintaining compliance with international quality standards, ensuring the reliability and safety of the produced metal parts.

Additional Services and Finishes:

- Complementary Services: Beyond metal cutting, the company offers additional services like CNC machining, CNC milling, CNC turning, and metal stamping to provide comprehensive solutions.

- Finishes: Various finishes such as anodized, sandblasted, polished, powder coated, and electroplated are available to enhance the aesthetic and functional properties of the metal parts.

Evaluating Price and Cost: What to Expect from CNC Metal Cutting Services in China

Understanding the pricing and cost factors associated with CNC metal cutting services in China is essential for clients seeking to make informed decisions and optimize their investment.

Price Determinants:

- Material Type and Thickness: The type and thickness of the metal used can significantly impact the overall cost of CNC metal cutting services.

- Complexity of Design: Intricate designs and tight tolerances may necessitate additional time and resources, influencing the price.

- Volume of Production: The scale of production, whether low-volume or high-volume, can affect the unit cost of the manufactured parts.

Cost-Effective Solutions:

- Comparative Analysis: Evaluating the offerings and pricing of different CNC metal cutting companies in China can help clients identify cost-effective solutions.

- Customization and Flexibility: Opting for customized services and flexible production options can allow clients to align the services with their budget and requirements.

Choosing the Right CNC Metal Cutting Supplier and Manufacturer

Selecting a reliable and high-quality CNC metal cutting supplier and manufacturer in China involves considering several factors to establish a successful partnership.

- Quality Assurance: Ensuring that the manufacturer adheres to strict quality control measures and international standards is vital.

- Technical Capabilities: Assessing the technical capabilities of the manufacturer, including their ability to handle diverse materials and intricate designs, is essential.

- Customer Service: Excellent customer service and support throughout the project lifecycle are crucial for smooth collaboration.

- Price and Cost Evaluation: Conducting a thorough evaluation of the price and cost factors associated with the services offered can aid in making an informed decision.

Frequently Asked Questions about CNC Metal Cutting

1. What is CNC Metal Cutting and Why is it Important?

- Answer: CNC metal cutting is a technology that utilizes computerized controls to operate cutting tools and machinery, enabling the creation of precision-engineered metal parts. It is crucial for producing complex components for various industries, fostering innovation, and enhancing productivity.

2. How Do CNC and Laser Cutting Technologies Work Together?

- Answer: CNC and laser cutting technologies synergize to achieve high precision and intricate designs. CNC controls the movement and operation of the laser cutter, allowing for accurate and efficient cutting of metal materials, suitable for various applications.

3. What Sets Wuxi Lead Precision Machinery Apart in CNC Metal Cutting?

- Answer: Wuxi Lead Precision Machinery stands out for its commitment to quality, diverse CNC metal cutting services, industry-specific solutions, and adherence to international standards. The company offers customized services and works with a variety of materials to meet the unique needs of clients across different sectors.

4. How to Evaluate the Price and Cost of CNC Metal Cutting Services in China?

- Answer: Evaluating the price and cost involves considering factors such as material type and thickness, design complexity, and production volume. Comparative analysis of different companies’ offerings and customization options can help identify cost-effective solutions aligned with budget and requirements.

5. What Considerations Should be Made When Choosing a CNC Metal Cutting Supplier and Manufacturer?

- Answer: Key considerations include quality assurance, technical capabilities, customer service, and price and cost evaluation. Ensuring that the manufacturer adheres to quality standards, possesses the necessary technical expertise, offers excellent customer support, and provides value for money is essential for a successful partnership.

Different Metal Materials for Various CNC Cutting Processes

| Metal Material | CNC Laser Cutting Process | CNC Punching Process | CNC Milling Process | CNC Plasma Cutting |

|---|---|---|---|---|

| Aluminum | Suitable: Offers clean and precise cuts. | Suitable: Can handle thin to medium thickness. | Highly Suitable: Aluminum is soft, making it ideal for milling. | Suitable: Can handle thicker sheets. |

| Stainless Steel | Highly Suitable: Provides smooth finishes and high precision. | Suitable: Ideal for thinner sheets. | Suitable: Requires specific tools to handle hardness. | Highly Suitable: Effective for various thicknesses. |

| Carbon Steel | Highly Suitable: Laser can cut thick sheets with precision. | Suitable: Best for medium thickness. | Suitable: Can be milled with proper tooling. | Highly Suitable: Ideal for a wide range of thicknesses. |

| Brass | Suitable: Requires specific laser settings for clean cuts. | Less Suitable: Might cause tool wear. | Highly Suitable: Brass is relatively soft. | Less Suitable: Might result in uneven edges. |

| Copper | Less Suitable: Reflective nature can pose challenges. | Less Suitable: Can wear out tools quickly. | Suitable: Requires specific tools and settings. | Less Suitable: Might not achieve clean cuts. |

| Titanium | Suitable: Requires controlled settings for precision. | Less Suitable: Hard on tools. | Suitable: Needs coolant due to heat generated. | Suitable: Can handle thicker sheets with proper settings. |

This table provides a general overview of the suitability of different metal materials for various CNC cutting processes. It’s essential to note that the actual suitability can vary based on the specific alloy, equipment, and conditions used. Always consult with CNC experts or manufacturers for specific projects.