Technical Contents

Engineering Guide: Cnc Mechine

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Machining

In high-stakes manufacturing sectors like aerospace, medical device production, and advanced defense systems, precision in CNC machining transcends mere specification; it becomes the foundational pillar of product integrity, safety, and performance. Minute deviations—measured in microns—can cascade into catastrophic failures. A tolerance stack-up error in a turbine blade assembly might induce destructive harmonic vibrations. An imperceptible surface finish anomaly on a surgical implant could compromise biocompatibility. Precision is not an optional upgrade; it is the absolute prerequisite for functional reliability and regulatory compliance in mission-critical applications. Achieving this demands far more than advanced hardware; it requires deep process mastery, rigorous environmental control, and an unwavering commitment to metrology throughout the production lifecycle.

At Wuxi Lead Precision Machinery, we operate at this uncompromising threshold daily. Our engineering heritage is forged in environments where failure is not an option. We have engineered and produced components for precision timing systems deployed at the Olympic Games, where split-microsecond accuracy defines athletic legacy. Similarly, our facilities consistently meet the stringent, audited requirements of military-grade contracts, producing parts where dimensional stability under extreme conditions is paramount. This experience ingrains a unique discipline: understanding that precision is a holistic system encompassing machine calibration, thermal compensation strategies, advanced toolpath optimization, real-time in-process gauging, and the skilled interpretation of Geometric Dimensioning and Tolerancing (GD&T) by our veteran technicians. It is the difference between a part that merely fits and one that performs flawlessly for decades.

Our commitment manifests in quantifiable outcomes. The table below reflects the precision benchmarks consistently achieved across our HAAS, DMG MORI, and Makino machining centers under controlled production conditions, validated by our Zeiss CONTURA CMMs and laser interferometers:

| Specification Category | Typical Capability | Measurement Standard |

|---|---|---|

| Positional Accuracy (Linear Axes) | ±0.0025 mm (±0.0001 in) | ISO 230-2 / ASME B5.54 |

| Repeatability (3 Sigma) | ±0.0015 mm (±0.00006 in) | ISO 230-2 / ASME B5.54 |

| Surface Roughness (Ra) | As low as 0.2 µm (8 µin) | ISO 4287 / ASME B46.1 |

| Geometric Tolerances (Flatness, True Position) | Down to 0.005 mm (0.0002 in) | ISO 1101 / ASME Y14.5 |

| Material Stability (Post-Machining) | Verified per customer-specific stress-relief protocols | Internal & Customer Witness Testing |

This level of control stems from our integrated approach: continuous thermal monitoring and compensation, vibration-dampened foundations, proactive tool wear management, and a closed-loop quality system where every critical dimension is verified against the original CAD model. Precision is not an accident; it is the deliberate result of engineering rigor, disciplined process execution, and a culture shaped by the most demanding global standards. For applications where performance is measured in microns and consequences are measured in lives or legacies, Wuxi Lead Precision Machinery delivers the certified accuracy your project demands. Contact our engineering team to discuss your specific tolerance challenges and validation requirements.

Precision Specs & Tolerances

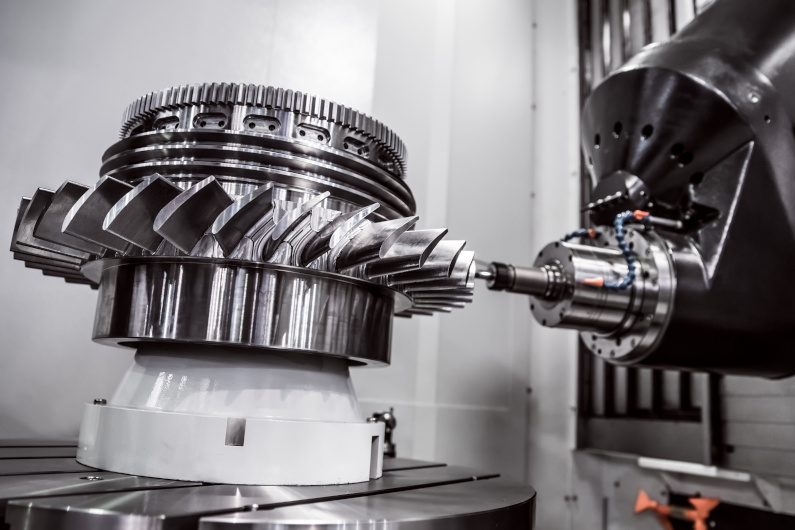

Wuxi Lead Precision Machinery delivers advanced precision CNC machining solutions engineered for the most demanding industries, including aerospace, medical, energy, and high-performance automotive sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, which enable us to produce complex, high-accuracy components with superior surface finishes and tight geometric tolerances. These multi-axis systems provide simultaneous movement across five axes, allowing for intricate contouring, undercuts, and compound angles that would be unattainable with conventional 3-axis equipment. The result is reduced setup time, improved part accuracy, and enhanced repeatability across production runs.

Our 5-axis CNC platforms are operated by certified machinists with extensive experience in high-precision manufacturing. Each machine is maintained to OEM standards and equipped with high-resolution probing systems for in-process verification. This ensures dimensional consistency and minimizes human error during production. Advanced CAM software drives toolpath optimization, enabling efficient material removal while preserving critical feature integrity. From prototype development to full-scale production, our machining centers support a wide range of materials, including titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics, all processed under strict environmental controls.

Quality assurance is integral to our manufacturing philosophy. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), calibrated to international standards. These systems provide micron-level verification of geometric dimensions, positional accuracy, and surface characteristics. Our CMM inspection protocols are aligned with ISO 10360 and support full first-article inspection (FAI) reporting, including GD&T analysis. In addition to CMM, we employ optical comparators, surface roughness testers, and digital micrometry to validate conformance across all critical parameters.

The table below outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes. These values represent our typical production performance; tighter tolerances can be achieved upon request for mission-critical applications.

| Parameter | Standard Tolerance | Capability with Special Process Control |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Geometric Tolerances (GD&T) | ±0.012 mm (Position) | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Angular Tolerances | ±0.05° | ±0.02° |

| Feature-to-Feature Alignment | ±0.01 mm over 100 mm | ±0.005 mm over 100 mm |

| Repeatability (Cpk ≥ 1.67) | Achieved across batches | Cpk ≥ 2.0 with SPC monitoring |

All inspection data is documented and traceable, supporting full compliance with AS9100, ISO 9001, and customer-specific quality requirements. At Wuxi Lead Precision Machinery, our technical capabilities are not only defined by equipment but by a culture of precision, consistency, and engineering excellence.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material selection critically impacts part performance, manufacturability, and total cost in precision CNC machining. At Wuxi Lead Precision Machinery, we guide clients through optimal choices based on application demands, balancing mechanical properties, corrosion resistance, weight constraints, and production efficiency. Aluminum, steel, and titanium represent core material families, each with distinct advantages and machining considerations for high-tolerance components.

Aluminum alloys dominate aerospace, electronics, and consumer goods due to exceptional strength-to-weight ratio, high thermal and electrical conductivity, and superior machinability. Grades like 6061-T6 offer good weldability and moderate strength for structural frames, while 7075-T6 provides high strength for critical aerospace fittings. Aluminum’s softness enables high-speed machining with reduced tool wear but requires careful fixturing to prevent deformation. Steel variants, particularly 303 stainless for corrosion resistance and 4140 alloy steel for high strength and wear resistance, are essential for industrial machinery, hydraulic systems, and tooling. While harder to machine than aluminum, generating more heat and requiring robust tooling, steel delivers unmatched durability and load-bearing capacity. Titanium, especially Grade 5 (Ti-6Al-4V), is indispensable in demanding aerospace and medical applications where extreme strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility are non-negotiable. Its low thermal conductivity and high chemical reactivity pose significant machining challenges, necessitating specialized toolpaths, rigid setups, and controlled coolant application to prevent work hardening and galling.

The following table summarizes key comparative specifications for common precision machining materials:

| Material | Key Grades | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310-572 | Excellent (A) | Aerospace frames, heat sinks, enclosures |

| Stainless Steel | 303, 304, 17-4PH | 515-1310 | Moderate (C) | Valves, pumps, surgical instruments |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 345-900 | Poor (E) | Aircraft components, medical implants |

Surface finishing, particularly anodizing, is integral to maximizing material performance. Anodizing aluminum creates a durable, corrosion-resistant oxide layer that enhances wear resistance and provides electrical insulation. Type II (sulfuric acid) anodizing offers standard protection and dyeing capability for aesthetics, while Type III (hard coat) anodizing delivers significantly thicker, harder coatings for severe wear environments like hydraulic pistons or aerospace brackets. This process is non-conductive and dimensional; precise control is essential for tight-tolerance features. While primarily for aluminum, complementary finishes like passivation for stainless steel or specialized coatings for titanium address specific environmental challenges.

Selecting the optimal material-finish combination requires deep understanding of operational stresses and environmental exposure. Wuxi Lead Precision Machinery leverages decades of CNC expertise to analyze your requirements, recommend the most cost-effective solution, and execute machining with the precision your critical components demand. We ensure material properties are fully realized through controlled processes and stringent quality control.

Manufacturing Process & QC

From Concept to Perfection: The Precision CNC Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence through a rigorously structured production workflow that transforms design concepts into high-precision, zero-defect components. Our approach integrates advanced CNC technology with disciplined process control, ensuring every phase—from initial design to mass production—delivers unmatched quality and repeatability.

The journey begins with design engineering, where our technical team collaborates closely with clients to interpret specifications, material requirements, and functional intent. Utilizing industry-leading CAD/CAM software, we develop 3D models and simulate machining paths to optimize tooling strategies, minimize cycle times, and preempt potential manufacturing challenges. This digital validation phase ensures geometric accuracy and process feasibility before any material is cut.

Next, we move to prototyping. A small batch of components is produced under full production conditions, allowing for real-world performance evaluation. These prototypes undergo comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We validate dimensional conformance, material integrity, and assembly fit, providing clients with physical samples for functional testing. Any deviations trigger immediate design or process refinement, ensuring the final production run is flawless.

Once approved, the project transitions to mass production. Our CNC machining centers—equipped with high-speed spindles, automated tool changers, and real-time monitoring systems—operate under strict environmental and procedural controls. Each machine runs pre-validated G-code, with in-process gauging and statistical process control (SPC) continuously tracking critical dimensions. Our production floor integrates IoT-enabled sensors that detect anomalies in vibration, temperature, and tool wear, enabling predictive maintenance and instant corrective action.

Quality is embedded at every stage. Our zero-defect philosophy is enforced through a closed-loop quality management system compliant with ISO 9001:2015 standards. Every batch is traceable, with full documentation of machine parameters, inspection reports, and material certifications. Final inspection includes 100% visual checks and random sampling against AQL 1.0 standards, ensuring consistency across tens of thousands of parts.

This disciplined progression from design to prototyping to mass production enables Wuxi Lead Precision Machinery to deliver components that meet the exacting demands of aerospace, medical, and high-end industrial sectors.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, PEEK, Brass |

| Production Capacity | Up to 50,000 units/month (per project) |

| Quality Standard | ISO 9001:2015, Full First Article Inspection |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (varies by volume) |

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership with Lead Precision

In the demanding landscape of high-precision component manufacturing, selecting a machining partner transcends mere cost considerations. It demands a strategic alliance grounded in unwavering technical capability, rigorous process control, and a shared commitment to exceeding the most stringent industry specifications. Wuxi Lead Precision Machinery stands as your definitive partner for mission-critical CNC machining, where theoretical potential translates into measurable, repeatable results. We engineer reliability into every spindle rotation, ensuring your complex geometries and tight-tolerance requirements are met with absolute consistency, directly impacting your product performance and market success. Our integrated approach, from initial feasibility analysis through final inspection, mitigates risk and accelerates time-to-market for applications where failure is not an option.

Our technical foundation is built upon a modern fleet of advanced multi-axis CNC machining centers, operated and maintained by certified engineers with deep domain expertise in aerospace, medical device, and energy sector requirements. We specialize in transforming challenging materials like titanium alloys, Inconel, and high-performance composites into components meeting sub-micron tolerances and exceptional surface finishes. The table below outlines our core production capabilities, reflecting the infrastructure dedicated to delivering your most demanding projects:

| Capability Parameter | Specification Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 750 mm (5-Axis) |

| Positioning Accuracy | ≤ ±0.003 mm |

| Repeatability | ≤ ±0.002 mm |

| Spindle Speed Range | 20 – 24,000 RPM |

| Core Materials Processed | Titanium, Inconel, Stainless Steels, Aluminum Alloys, High-Performance Plastics, Composites |

| Key Certifications | ISO 9001:2015, ISO 13485, AS9100D |

| In-Process Metrology | Integrated Renishaw Probes, CMM Verification (0.0001mm resolution) |

Beyond equipment, our value lies in proactive collaboration. We engage early in your design phase, providing actionable Design for Manufacturability (DFM) feedback to optimize part geometry, reduce waste, and enhance producibility without compromising function. Our closed-loop quality management system, featuring real-time SPC data and full traceability from raw material to finished part, ensures complete transparency and compliance with your exacting standards. This systematic rigor eliminates costly rework and supply chain disruptions, providing the operational stability your production schedule requires.

Partnering with Lead Precision means investing in a supplier whose performance directly strengthens your competitive position. We understand the criticality of your components and the operational consequences of inconsistency. Let us demonstrate how our precision engineering discipline and responsive partnership model can resolve your most complex manufacturing challenges. Contact our engineering team directly to initiate a technical consultation and receive a detailed capability assessment tailored to your specific project requirements. The path to assured precision begins with a single step.

Schedule your technical consultation today. Contact us at [email protected] to discuss your precision machining needs and secure a competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.