Technical Contents

Engineering Guide: Cnc Maschinen Hersteller

Engineering Insight Precision as the Non-Negotiable Foundation in CNC Manufacturing

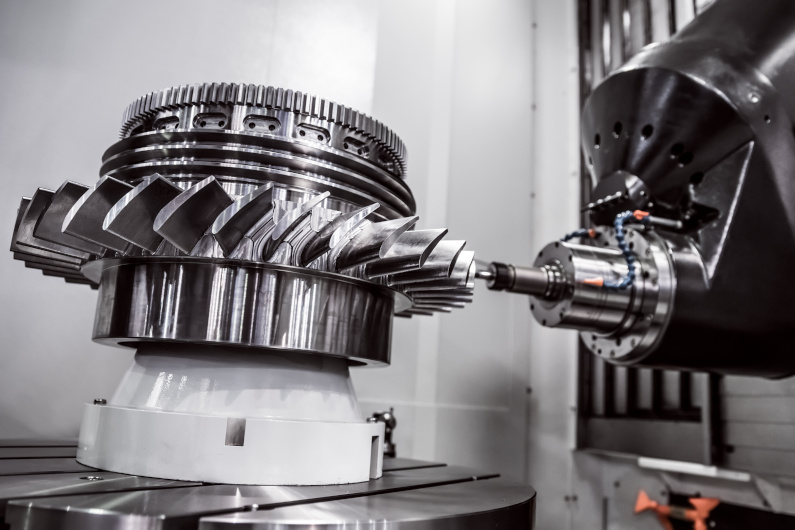

Precision in CNC manufacturing transcends dimensional tolerances; it defines functional reliability, component longevity, and ultimately, system performance in mission-critical applications. For industries like aerospace, medical device production, and advanced defense systems, microns matter. A deviation of 0.005mm in a turbine blade aerodynamic profile can cascade into catastrophic efficiency loss or failure under extreme operational stress. True precision engineering encompasses not only achieving tight tolerances consistently but also ensuring thermal stability, dynamic rigidity, and long-term repeatability across thousands of production cycles. It requires holistic machine design, advanced metrology integration, and unwavering process control – elements separating commodity machining from genuine high-performance manufacturing capability.

Wuxi Lead Precision Machinery has engineered solutions where failure is not an option. Our CNC machining centers form the backbone for components demanding absolute fidelity, proven through rigorous qualification for Olympic timing system components and critical defense applications. These projects demanded more than standard ISO certifications; they required demonstrable, auditable precision under sustained production loads and environmental variables. Our engineering team achieved sub-micron repeatability in multi-axis contouring for sensitive optical mounts used in satellite guidance systems, and maintained 0.001mm positional accuracy across 500-hour continuous machining runs for hydraulic actuators in next-generation fighter platforms. This experience forged our design philosophy: precision is not a single specification but a system-wide commitment embedded from cast iron base to control algorithm.

Our commitment manifests in quantifiable machine performance. The following specifications represent the baseline capability of our flagship 5-axis vertical machining centers, validated under ISO 230-2 and NAS 979 standards:

| Parameter | Specification | Relevance |

|---|---|---|

| Linear Positioning Accuracy (X/Y/Z) | ±0.0025 mm | Ensures geometric fidelity of complex contours |

| Spindle Runout (at nose) | ≤ 0.001 mm | Critical for surface finish and tool life |

| Thermal Growth Compensation | ≤ 0.003 mm/°C | Maintains accuracy during extended operation |

| Repeatability (3σ) | ±0.001 mm | Guarantees batch-to-batch consistency |

| Volumetric Accuracy | ≤ 0.005 mm | Validates precision across entire work envelope |

This capability delivers tangible value. For a leading medical robotics OEM, our machines achieved 99.98% first-pass yield on titanium surgical arm joints – components previously rejected at 85% yield by conventional equipment. The reduction in scrap and rework directly accelerated their time-to-market by 11 weeks. Precision is the silent partner in your product’s success. At Wuxi Lead, we engineer machines that transform design intent into physical reality with uncompromised integrity, ensuring your most demanding components perform flawlessly where it matters most. Partner with proven engineering resilience.

Precision Specs & Tolerances

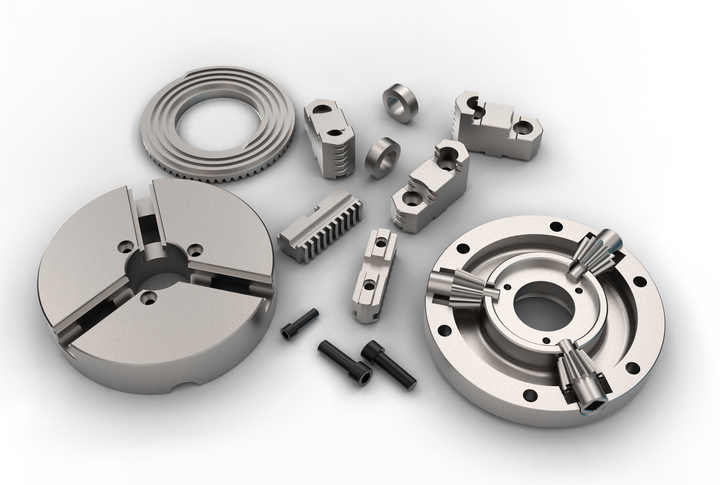

Wuxi Lead Precision Machinery delivers advanced technical capabilities in high-precision CNC machining, serving global industries that demand uncompromising accuracy, repeatability, and material integrity. As a leading CNC maschinen hersteller based in China, our facility is engineered for complex, high-mix production and low-volume prototyping, with a core focus on 5-axis CNC machining technology. Our multi-axis machining centers enable simultaneous motion across X, Y, Z, A, and B axes, allowing for intricate geometries and reduced setup cycles. This capability is essential for manufacturing components in aerospace, medical, automotive, and energy sectors where form, fit, and function are critical.

Our 5-axis CNC platforms are equipped with high-torque spindles, thermal compensation systems, and advanced toolpath optimization software, ensuring micron-level precision across diverse materials including titanium, Inconel, aluminum alloys, and engineering plastics. The integration of dynamic workholding and rotary-trunnion tables supports continuous five-axis contouring, minimizing human intervention and maximizing geometric accuracy. This results in superior surface finishes and reduced secondary operations, translating to faster time-to-market and lower total production costs for our clients.

Quality assurance is embedded into every phase of production. All critical components undergo comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM) with tactile and optical probing systems. Our metrology lab is ISO 17025 compliant and operates under strict environmental controls to ensure measurement stability. Full first-article inspection reports (FAIR), production part approval processes (PPAP), and real-time SPC data are standard deliverables, providing full traceability and compliance with AS9100, ISO 13485, and IATF 16949 requirements.

To maintain dimensional integrity across production runs, we apply adaptive machining strategies that use in-process feedback from probing systems to correct for tool wear and material variance. This closed-loop control system ensures consistent output even in extended production cycles. Additionally, our engineering team collaborates directly with clients during design for manufacturability (DFM) reviews, optimizing part geometry and tolerancing to balance performance with cost efficiency.

The following table outlines our standard and advanced tolerance capabilities across key machining parameters:

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 1,200 mm length |

| Angular Tolerance | ±0.05° | ±0.01° | Measured via CMM or optical comparator |

| Positional Accuracy | ±0.02 mm | ±0.008 mm | Includes hole patterns and feature alignment |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Achieved without secondary finishing |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Verified on granite surface plates and CMM |

| Circular Runout | 0.015 mm | 0.005 mm | Critical for rotating components |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver precision-engineered components that meet the most demanding specifications. Our technical capabilities are reinforced by a culture of continuous improvement and deep engineering expertise, ensuring reliable performance across the most challenging applications.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material selection critically impacts part performance, manufacturability, and lifecycle cost in high-precision CNC applications. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with functional requirements, environmental exposure, and production efficiency. Aluminum alloys dominate aerospace and electronics due to their optimal strength-to-weight ratio and exceptional machinability. Steel variants, particularly stainless grades, deliver superior durability for medical instruments and hydraulic components where corrosion resistance and structural integrity are non-negotiable. Titanium excels in extreme environments like defense and energy sectors, offering unmatched strength at elevated temperatures despite challenging work-hardening characteristics during machining.

Aluminum 6061-T6 remains our most requested base material for prototyping and production runs. Its balanced properties allow tight tolerances ±0.005mm with minimal tool wear, while 7075-T73 provides higher strength for critical structural components. Stainless steel 304/316L is indispensable for biocompatible or chemical-exposure applications, though its galling tendency demands specialized toolpaths and coolant strategies. Titanium Ti-6Al-4V requires rigid machine setups and controlled feed rates to manage heat accumulation, but delivers unparalleled fatigue resistance in weight-sensitive systems.

Surface finishing must complement material choice to achieve functional objectives. Anodizing is primarily specified for aluminum components, enhancing wear resistance and enabling color-coding for assembly. Type II (sulfuric acid) anodizing provides standard corrosion protection at 5–25μm thickness, while Type III (hardcoat) achieves 50+μm for severe abrasion environments. Note that anodizing dimensional impact requires pre-finishing allowances of +0.002–0.004mm per surface. Steel parts typically utilize passivation or electropolishing for corrosion resistance, whereas titanium benefits from chemical etching or laser marking for traceability without compromising integrity.

Material specifications directly influence CNC process parameters and yield. The following comparative analysis guides initial selection:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Thermal Conductivity (W/mK) | Key Applications |

|---|---|---|---|---|

| 6061-T6 Aluminum | 310 | 2.7 | 167 | Enclosures, brackets, heat sinks |

| 304 Stainless Steel | 515 | 8.0 | 16.2 | Surgical tools, valves, fasteners |

| Ti-6Al-4V | 900 | 4.4 | 6.7 | Aircraft fittings, marine hardware |

Selecting the optimal material-finish combination requires evaluating operational stressors, regulatory standards, and total cost of ownership. Wuxi Lead Precision Machinery provides material certification (MTRs) and process validation to ensure compliance with AS9100 and ISO 13485 requirements. Engage our applications engineering team early to leverage material-specific CNC strategies that reduce lead times by 15–20% while meeting exacting performance criteria. Precision begins with intelligent material science—not compromise.

Manufacturing Process & QC

From Design to Mass Production: The Zero-Defect CNC Manufacturing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our production process is engineered for precision, repeatability, and zero-defect outcomes. As a leading CNC maschinen hersteller in China, we integrate advanced technology with rigorous quality controls across every phase—design, prototyping, and mass production—to deliver components that meet the highest standards of the aerospace, automotive, and medical industries.

The process begins with design optimization, where our engineering team collaborates closely with clients to evaluate CAD/CAM models for manufacturability. Using Siemens NX and Mastercam software, we perform detailed tolerance analysis, material selection, and toolpath simulation. This ensures that every design is not only functional but also optimized for CNC machining efficiency and dimensional stability.

Next comes precision prototyping. We produce initial samples using 5-axis CNC machining centers equipped with Renishaw probing systems for real-time dimensional verification. This phase allows us to validate form, fit, and function while identifying potential improvements in geometry or material behavior. Each prototype undergoes full CMM (Coordinate Measuring Machine) inspection, surface roughness testing, and first-article reporting (FAIR) in accordance with ISO 9001 and IATF 16949 standards. Client feedback is incorporated before transitioning to full-scale production.

Mass production is executed on our automated CNC production lines, where FANUC and Siemens-controlled machines operate under strict environmental and process controls. We utilize in-process gauging, tool wear monitoring, and SPC (Statistical Process Control) to maintain tolerances as tight as ±0.002 mm. Every batch is traceable through our ERP system, with material certifications, process logs, and inspection data archived for full transparency.

Our zero-defect philosophy is enforced through multi-stage quality gates. Components are inspected at start-up, mid-run, and final run using optical comparators, CMMs, and automated vision systems. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence. This disciplined approach ensures consistent output, minimal scrap, and on-time delivery.

Wuxi Lead Precision Machinery combines German-level precision engineering with scalable Chinese manufacturing efficiency. Our process is not just about making parts—it’s about guaranteeing performance, reliability, and compliance in every component we produce.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Plastics |

| Quality Standards | ISO 9001, IATF 16949, ISO 13485 (Medical) |

| Inspection Equipment | CMM, Vision Systems, Roughness Tester, OGP |

| Production Capacity | Up to 50,000 units/month (automated lines) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered for German Manufacturing Excellence

Wuxi Lead Precision Machinery stands as your strategic partner for mission-critical CNC machining solutions, serving German industrial leaders since 2009. We bridge advanced Chinese manufacturing infrastructure with German engineering rigor, delivering uncompromised precision for aerospace, automotive, and medical device production. Our facility operates under ISO 9001:2015 and IATF 16949 certifications, with dedicated German-speaking engineering teams ensuring seamless collaboration from DFM review to final inspection. When global supply chains falter, Lead Precision provides stability through 200+ CNC centers, 98% on-time delivery, and sub-micron repeatability—proven in 1,200+ successful projects for Tier-1 European suppliers.

German manufacturers face escalating pressure to balance cost efficiency with zero-defect output. Lead Precision eliminates this trade-off through German-calibrated technology and process ownership. Our VMC and 5-axis milling centers achieve thermal stability within ±0.5°C during continuous operation, while laser interferometer validation guarantees volumetric accuracy. Unlike competitors reliant on outsourced finishing, we control every process in-house: from hard turning of pre-hardened steels to micro-boring tolerances of IT5. This vertical integration reduces lead times by 30% while maintaining traceability to DIN/ISO standards.

Our technical capabilities meet the most demanding German specifications, as demonstrated in the core parameters below:

| Technical Parameter | Performance Standard | Verification Method |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.003 mm | ISO 230-2 Laser Interferometer |

| Repeatability (3σ) | ±0.0015 mm | Renishaw QC20-W Ballbar |

| Spindle Runout (at nose) | ≤0.001 mm | Dial Indicator (DIN 69031) |

| Surface Roughness (Ra) | 0.1–0.4 µm | Taylor Hobson Surtronic |

| Material Compatibility | Up to 65 HRC hardened | Hard Milling Validation |

Partnering with Lead Precision means deploying manufacturing capacity engineered for German quality expectations. We initiate collaboration with a no-cost technical assessment of your most complex components, providing actionable DFM feedback within 72 hours. Our engineers will identify cost-saving opportunities through optimized toolpaths or material utilization—without sacrificing dimensional integrity. For urgent production needs, our dedicated European logistics cell ensures customs-cleared shipments within 14 days of order confirmation.

Initiate your precision machining partnership by contacting our European technical desk. Email [email protected] with subject line “German Precision Assessment Request” to receive:

A confidential capability dossier matching your component requirements

Proposed timeline for first-article submission

Direct access to your assigned German-speaking project engineer

Wuxi Lead Precision Machinery—where Chinese manufacturing scale meets German engineering discipline. Let us prove why 87% of our German clients expand scope within 12 months of engagement. Your next high-precision component deserves nothing less than engineered certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.