Technical Contents

Engineering Guide: Cnc Machone

Engineering Insight: The Critical Role of Precision in CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we understand that the margin for error in high-performance industries such as aerospace, defense, and elite sports engineering is effectively zero. This understanding drives our engineering philosophy and operational excellence in CNC machining.

CNC machining, when executed at the highest level, transcends basic metal removal. It becomes a science of micron-level control, thermal stability, toolpath optimization, and material behavior prediction. Every component we produce is the result of integrated design analysis, multi-axis coordination, and real-time process monitoring. The machines we deploy are calibrated to maintain tolerances within ±0.002 mm, ensuring that each part meets exact geometric and surface finish specifications. Such precision is not incidental; it is engineered through rigorous process validation and continuous improvement.

Our experience in supporting Olympic-level athletic equipment and military-grade systems underscores the demand for absolute consistency. In these applications, a deviation of even a few microns can compromise structural integrity, aerodynamic efficiency, or system responsiveness. For instance, components used in high-speed tracking systems or load-bearing composite molds require not only dimensional accuracy but also exceptional repeatability across production batches. This is where Wuxi Lead’s expertise becomes decisive.

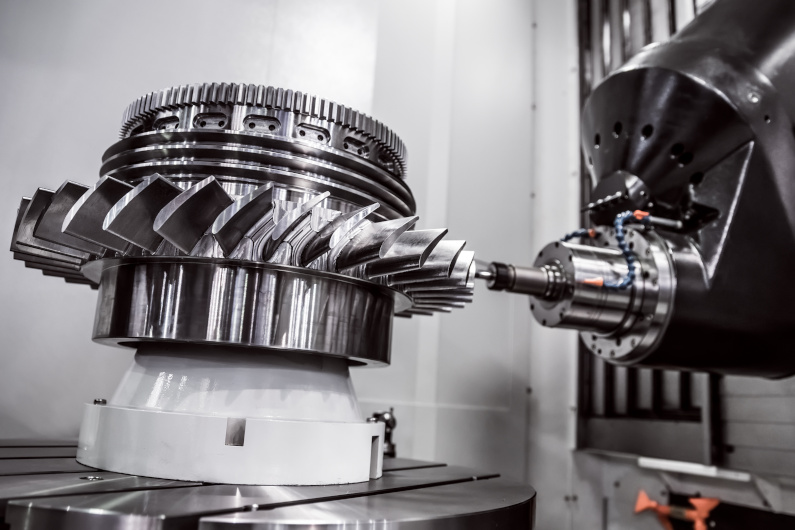

We utilize state-of-the-art 5-axis CNC centers equipped with high-resolution probing systems, adaptive control loops, and environmental compensation algorithms. These technologies allow us to counteract thermal drift, tool wear, and material variance—factors that, if unmanaged, degrade precision over time. Our quality assurance protocols include full CMM inspection, 3D scanning, and first-article reporting, ensuring traceability and compliance with ISO 13041 and AS9100 standards.

Beyond technology, precision is sustained by experience. With over 15 years of specialization in high-tolerance machining, our engineering team has developed proprietary methodologies for complex geometries, thin-wall structures, and difficult-to-machine alloys such as Inconel, titanium, and high-silicon aluminum. This depth of knowledge enables us to anticipate challenges before they arise, optimizing both quality and lead time.

The following table outlines key performance specifications achieved across our CNC machining platforms:

| Specification | Performance Metric |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Maximum Spindle Speed | 24,000 rpm |

| Axis Configuration | 3-axis to 5-axis simultaneous |

| Tolerance Range | ±0.002 mm typical |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (polished) |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, brass, engineering plastics |

| Inspection Equipment | Zeiss CMM, optical comparators, laser probes |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a demonstrated capability, refined through mission-critical applications and global industry demands. When performance cannot be compromised, our CNC machining solutions deliver with unwavering accuracy.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical components across aerospace, medical, and energy sectors. Our technical foundation integrates advanced multi-axis machining with rigorous metrology protocols, ensuring every part meets the most stringent international standards. We specialize in transforming complex 3D CAD models into high-integrity physical components where micron-level precision directly impacts performance and safety.

Our 5-axis CNC machining centers represent the pinnacle of modern manufacturing flexibility. Utilizing simultaneous five-axis interpolation, we machine intricate geometries—including organic contours, deep cavities, and undercuts—in a single setup. This eliminates cumulative error from multiple fixturing stages while dramatically reducing lead times. Our DMG MORI and Hermle platforms feature thermal compensation systems and high-resolution encoders, maintaining stability during extended production runs. Typical applications include turbine blades, orthopedic implants, and fluid dynamics housings requiring seamless surface finishes below Ra 0.8 µm. Material versatility spans aerospace-grade titanium alloys, Inconel 718, medical stainless steels, and high-performance polymers.

Quality control is embedded at every process stage, anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs). Each component undergoes full geometric dimensioning and tolerancing (GD&T) validation against ASME Y14.5 standards. Our metrology lab operates under ISO 17025 accreditation, with all measurements traceable to NIST standards. Automated probe routines scan critical features in real-time, enabling immediate process correction. Statistical process control (SPC) data is documented for full traceability, providing clients with comprehensive first-article inspection reports and batch certification.

The following table details our standard achievable tolerances, validated through CMM inspection across production batches. Note that specific capabilities may vary based on part geometry, material, and feature size.

| Material Category | Dimensional Tolerance | Geometric Tolerance (Flatness/True Position) |

|---|---|---|

| Aluminum Alloys (e.g., 7075) | ±0.005 mm | 0.010 mm per 100 mm |

| Stainless Steel (e.g., 316L) | ±0.008 mm | 0.015 mm per 100 mm |

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.010 mm | 0.020 mm per 100 mm |

This precision ecosystem enables clients to achieve higher yield rates, reduced assembly costs, and extended component lifespans. By consolidating design complexity into single-setup manufacturing and validating outcomes with metrology-grade evidence, Wuxi Lead transforms engineering intent into physical reality. We partner with clients during prototyping through volume production to optimize manufacturability without sacrificing tolerance integrity—ensuring your most demanding specifications become competitive advantages. Contact our engineering team to discuss how our capabilities align with your next-generation component requirements.

Material & Finish Options

Material selection is a critical decision in precision CNC machining, directly influencing performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity parts from aluminum, steel, and titanium—three of the most widely used engineering metals across aerospace, medical, automotive, and industrial equipment sectors. Each material offers distinct mechanical properties and responds uniquely to machining and finishing processes such as anodizing.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly selected for structural and enclosure applications due to its weldability and corrosion resistance. For high-performance environments, 7075-T6 offers superior strength, often used in aerospace components. Aluminum is highly compatible with anodizing, a controlled electrochemical process that enhances surface hardness and corrosion resistance. Type II (sulfuric acid) and Type III (hard coat) anodizing are standard offerings at Wuxi Lead, with customizable dye options and thicknesses up to 50 µm for extreme wear resistance.

Steel provides unmatched strength, wear resistance, and dimensional stability. We routinely machine medium-carbon steels such as 4140 and 4340, which respond well to heat treatment for applications requiring high fatigue resistance. Stainless steels like 303, 304, and 17-4 PH are selected for their corrosion resistance and biocompatibility, making them ideal for medical and food-grade equipment. While steel is not anodized, we offer alternative surface treatments including passivation, black oxide, and electroplating to meet functional and aesthetic requirements.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its high strength-to-density ratio, excellent performance at elevated temperatures, and outstanding corrosion resistance make it indispensable in aerospace and medical implant applications. However, titanium’s low thermal conductivity and chemical reactivity require specialized tooling and slower machining parameters to prevent work hardening and tool wear. At Wuxi Lead, our CNC centers are equipped with high-precision spindles and optimized coolant delivery systems to ensure consistent titanium machining. Titanium does not anodize in the traditional sense but can undergo color anodizing for identification or aesthetic purposes, a capability we support through partner surface treatment facilities.

The table below summarizes key mechanical and machining characteristics of commonly used materials.

| Material | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | Excellent (Machinability Index: 90) | Type II/III Anodizing, Bead Blast | Enclosures, Brackets, Heat Sinks |

| Aluminum 7075-T6 | 570 | 150 | Good (Machinability Index: 70) | Hard Anodizing, Clear Coat | Aerospace, Military Components |

| Steel 4140 | 655 | 197 | Moderate (Machinability Index: 65) | Passivation, Black Oxide | Shafts, Gears, Tooling |

| Stainless 304 | 505 | 180 | Moderate (Machinability Index: 45) | Electropolishing, Passivation | Medical Devices, Food Equipment |

| Titanium Ti-6Al-4V | 900 | 360 | Fair (Machinability Index: 30) | Color Anodizing, Alodine | Aircraft Engines, Implants |

Selecting the right material and finish requires balancing performance demands with manufacturability and cost. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to optimize material selection and surface treatment strategies, ensuring every CNC-machined part meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and efficiency, transforming client specifications into flawless precision components. We adhere to a rigorously controlled three-phase methodology: Design, Prototyping, and Mass Production. This integrated approach, governed by ISO 9001:2015 standards, is the foundation of our Zero Defects commitment, ensuring every part meets exacting functional and dimensional requirements before full-scale manufacturing begins.

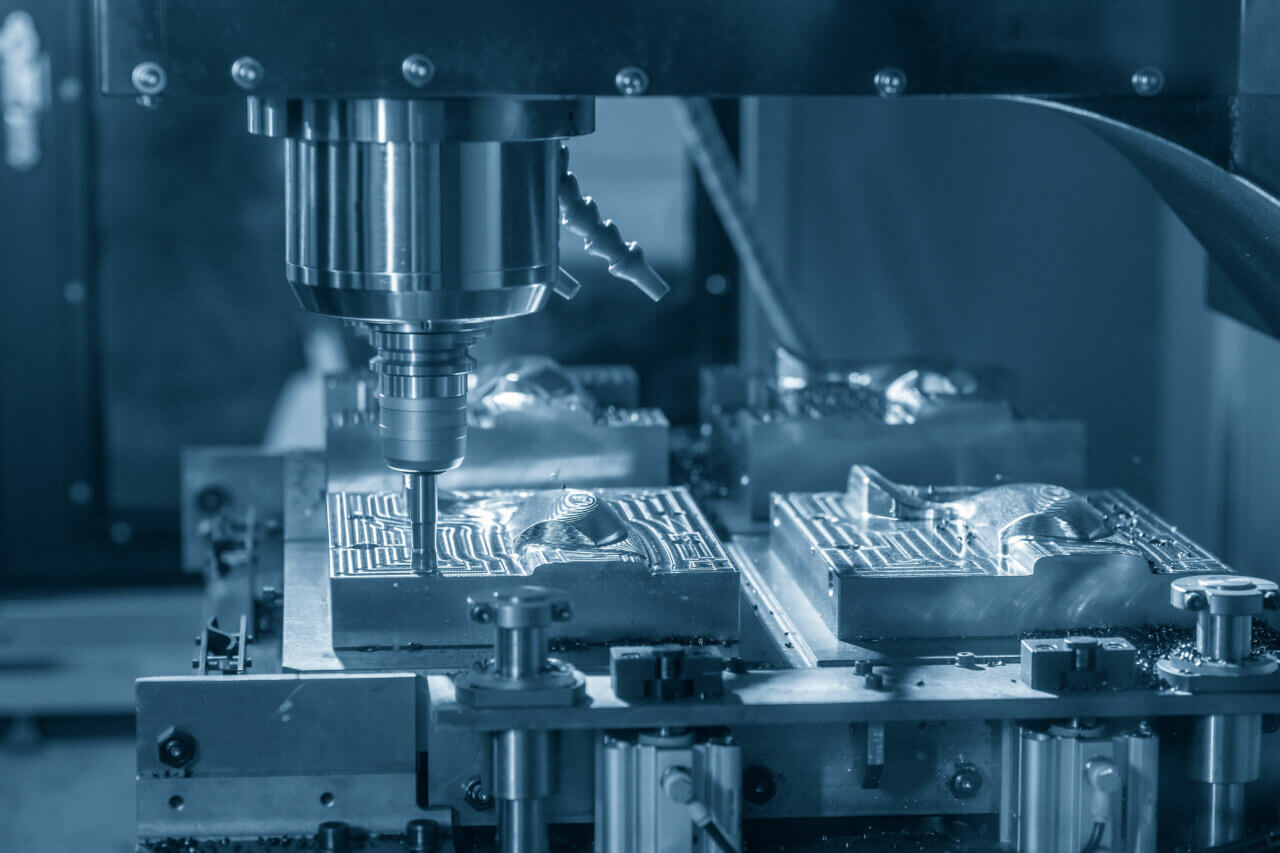

The Design phase is where quality is proactively built in. Our engineering team collaborates closely with clients to review CAD models, perform comprehensive Design for Manufacturability (DFM) analysis, and optimize toolpaths using advanced CAM software. Critical factors such as material selection, geometric complexity, and achievable tolerances are meticulously evaluated. Finite Element Analysis (FEA) simulates machining stresses to prevent distortion, while virtual machine simulation verifies collision-free operation and process efficiency. This deep technical validation eliminates potential errors at the source, establishing a robust blueprint for production and significantly reducing downstream rework risks.

Prototyping serves as the critical physical validation step. Utilizing the same high-precision CNC equipment and materials designated for final production, we manufacture initial sample units. These prototypes undergo exhaustive metrology using calibrated CMMs, optical comparators, and surface roughness testers against the original design intent. Dimensional accuracy, surface finish, material properties, and functional fit are rigorously assessed. Any deviations trigger immediate root cause analysis and process refinement. Client approval of these validated prototypes is mandatory before proceeding, ensuring complete alignment and de-risking the transition to volume manufacturing.

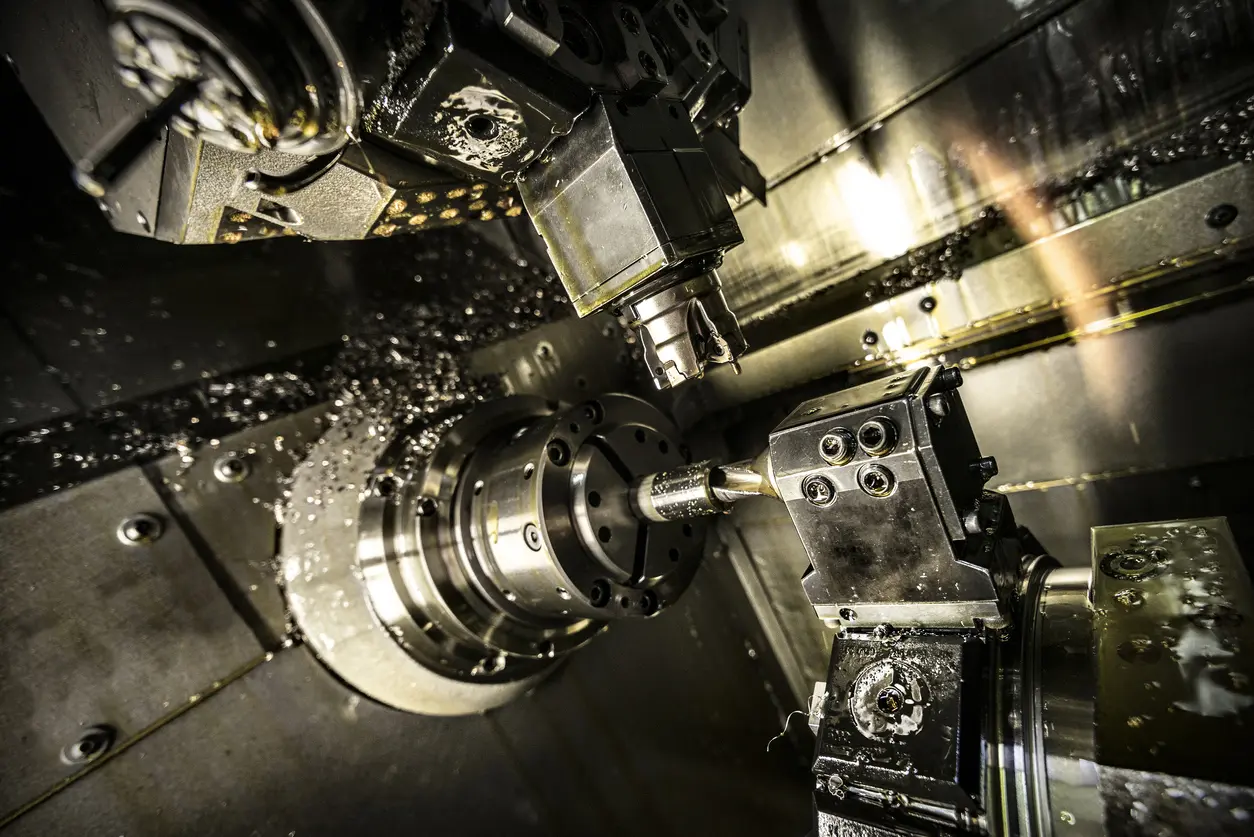

Mass Production leverages the validated process under stringent statistical process control (SPC). Our state-of-the-art CNC machining centers, including multi-axis mills and lathes with sub-micron positioning accuracy, operate with automated tool measurement and in-process gauging. Every critical dimension is monitored in real-time using SPC charts, with automatic machine adjustments triggered if trends approach tolerance limits. Full traceability is maintained via barcode tracking from raw material lot to finished part. Final inspection employs 100% critical feature verification for high-risk components and AQL 0.65 sampling for others, supported by comprehensive first-article inspection reports (FAIRs). This closed-loop system guarantees consistent conformance and eliminates defects before shipment.

The following table summarizes key process parameters across each phase:

| Phase | Key Activities | Tolerance Control | Inspection Frequency | Output Metrics |

|---|---|---|---|---|

| Design | DFM, CAM Programming, FEA, Simulation | ±0.005mm (Theoretical) | N/A | Validated Process Plan |

| Prototyping | Sample Machining, Metrology Validation | ±0.005mm (Actual) | 100% Critical Features | FAIR, Client Approval |

| Mass Production | SPC-Controlled Machining, Final QA | ±0.005mm (Sustained) | 100% Critical / AQL | Zero Defect Shipment, Traceability Report |

This disciplined progression from digital design through physical validation to controlled volume manufacturing ensures Wuxi Lead delivers precision components that perform reliably in the most demanding applications, consistently meeting our Zero Defects promise and safeguarding your production schedules and end-product integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer trust, reliability, and performance into every part we produce. As a leading provider of high-end CNC machining services in China, we specialize in delivering custom-engineered solutions that meet the rigorous demands of aerospace, medical, automotive, and industrial equipment industries. When you choose to partner with Lead Precision, you gain more than a supplier; you align with a team of dedicated engineers and manufacturing experts committed to your success.

Our state-of-the-art facility in Wuxi integrates advanced 3-, 4-, and 5-axis CNC machining centers with stringent quality control systems, ensuring micron-level accuracy and repeatability across every production run. From prototyping to high-volume manufacturing, our capabilities are designed to scale with your project needs while maintaining consistent precision and on-time delivery. We utilize premium-grade materials including aluminum alloys, stainless steel, titanium, and engineering plastics, all processed under ISO 9001-certified standards.

What sets us apart is our engineering-first approach. Every project begins with a collaborative review of your design intent, material selection, and functional requirements. Our team provides actionable Design for Manufacturability (DFM) feedback to optimize part geometry, reduce costs, and accelerate time to market. This proactive partnership ensures that your components are not only precisely machined but also functionally superior and production-ready.

We understand that in high-stakes industries, tolerance deviations or delivery delays are not acceptable. That’s why Lead Precision invests in continuous process improvement, real-time monitoring, and full traceability for every component we produce. Our inspection protocols include CMM, optical comparators, and surface roughness testing, ensuring full compliance with international quality benchmarks.

Below are key specifications that define our CNC machining capabilities:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC machining centers |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, PEEK, Delrin |

| Tolerances | As tight as ±0.001 mm |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.2 µm with polishing |

| Certifications | ISO 9001:2015, RoHS compliant |

| Lead Times | Prototypes: 5–7 days; Production: 10–20 days (varies by volume) |

Your next breakthrough component starts with the right manufacturing partner. At Wuxi Lead Precision Machinery, we are ready to support your most demanding projects with technical excellence and unwavering commitment.

Contact us today at [email protected] to discuss your requirements, request a quote, or schedule a virtual factory tour. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.