Technical Contents

Engineering Guide: Cnc Machne

Engineering Insight: The Critical Role of Precision in CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we define precision CNC machining as the convergence of advanced engineering, rigid process control, and unwavering attention to detail. Our decades of experience in serving high-demand sectors—including aerospace, defense, and Olympic-grade equipment manufacturing—underscore the non-negotiable nature of micron-level accuracy in mission-critical applications.

Precision in CNC machining directly influences part performance, especially in environments characterized by extreme stress, temperature fluctuations, or high-speed operation. A deviation of even 5 microns can lead to mechanical failure, misalignment, or compromised safety. This is particularly true in military applications, where components must endure rigorous operational conditions without failure. Our involvement in producing components for defense systems has reinforced our commitment to repeatability, material integrity, and geometric accuracy under ISO 2768 and MIL-STD-810 standards.

Similarly, our contributions to Olympic-level sports technology—such as precision components for high-performance timing systems and competition-grade equipment—highlight how exacting tolerances translate into measurable advantages. In these applications, consistency across thousands of production cycles is as vital as the initial design. Our CNC machining processes are calibrated to ensure that every component, whether a single prototype or part of a large batch, meets identical specifications.

At the core of our capability lies a combination of high-rigidity machine platforms, thermally stable work environments, and real-time in-process measurement systems. We utilize multi-axis CNC centers equipped with laser tool measurement, high-precision spindles, and closed-loop feedback to maintain tolerances down to ±0.002 mm. These systems are operated and monitored by engineers with over 15 years of specialized experience in tight-tolerance manufacturing.

Material selection and post-processing are equally critical. We machine a broad spectrum of materials—from aerospace-grade aluminum alloys to high-strength titanium and exotic superalloys—applying optimized cutting strategies to minimize residual stress and maintain dimensional stability.

Below are key performance specifications representative of our standard precision CNC machining capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 × 800 × 650 mm |

| Spindle Speed Range | 20,000 rpm (standard), 40,000 rpm (HSM) |

| Tool Change Time (ATC) | < 2.5 seconds |

| Surface Finish (Ra) | As low as 0.2 µm |

| Standard Tolerances | ISO 2768-m, DIN 7168 medium |

| In-Process Measurement | Laser probes, touch-trigger systems |

Precision is not achieved by machine alone—it is engineered into every phase of production. From initial design review to final inspection, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of performance and reliability. Our legacy in Olympic and military-grade manufacturing is not just a credential—it is a benchmark.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

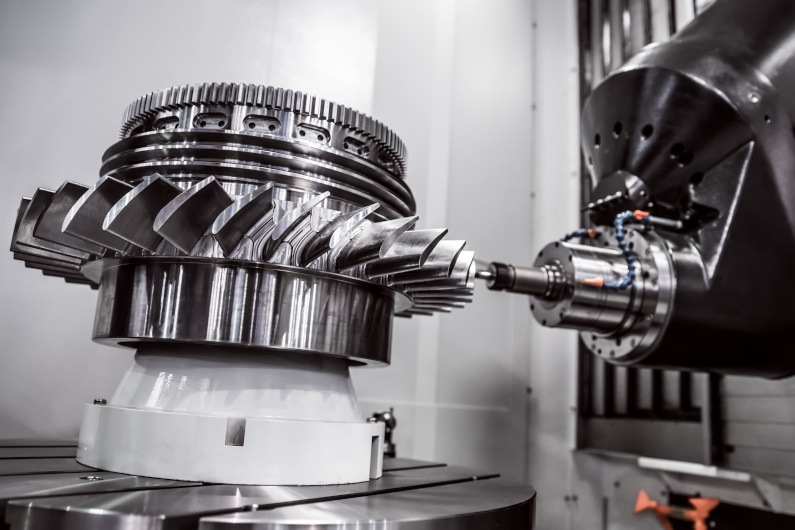

Wuxi Lead Precision Machinery delivers uncompromising precision and complex geometry fabrication through our advanced CNC machining infrastructure. Our core strength lies in mastering demanding components requiring tight tolerances, intricate contours, and superior surface finishes across diverse aerospace, medical, and energy sector applications. Central to this capability is our strategic deployment of state-of-the-art 5-axis CNC machining centers. These sophisticated systems enable simultaneous multi-axis interpolation, eliminating the need for multiple setups and significantly reducing cumulative error. This translates to the ability to machine highly complex organic shapes, deep cavities, and undercuts in a single operation, ensuring geometric integrity and dimensional accuracy unattainable with conventional 3-axis equipment. Our fleet encompasses machines from leading global manufacturers, rigorously maintained and calibrated to meet the highest standards of repeatability and thermal stability.

Material versatility is fundamental to our service offering. We expertly machine a comprehensive range of engineering alloys including titanium grades (Ti-6Al-4V, CP Ti), high-temperature nickel alloys (Inconel 718, Hastelloy), aluminum alloys (7075-T6, 6061), stainless steels (17-4PH, 316L), and specialized plastics like PEEK and Vespel. Each material program is optimized for specific cutting parameters, tooling strategies, and fixturing solutions to maximize part quality and process efficiency while minimizing cycle times. Our engineers possess deep expertise in managing the unique challenges presented by each material, from the galling tendencies of titanium to the thermal sensitivity of high-performance polymers.

Quality assurance is intrinsically woven into every manufacturing step, not merely a final check. Our comprehensive Quality Control system is anchored by multiple Coordinate Measuring Machines (CMMs), including bridge-type and portable arm systems equipped with high-precision probes and advanced metrology software. Full first-article inspection reports (FAIR) and detailed dimensional reports are standard deliverables, providing clients with absolute verification against print specifications. Statistical Process Control (SPC) methodologies are implemented on critical features during production runs to ensure consistent conformance and enable proactive process adjustments. This integrated approach guarantees that every component shipped meets or exceeds the stringent tolerance requirements demanded by high-integrity industries.

Our standard and achievable tolerance capabilities reflect this commitment to precision, as summarized below:

| Feature Type | Standard Capability | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Diameter (Reamed) | ±0.008 mm | ±0.003 mm |

| Hole Location | ±0.010 mm | ±0.005 mm |

| Surface Flatness | 0.010 mm | 0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| True Position | ±0.015 mm | ±0.008 mm |

This technical foundation – combining cutting-edge 5-axis machining, broad material expertise, and rigorous CMM-based quality control – ensures Wuxi Lead Precision Machinery consistently delivers components of exceptional accuracy, reliability, and performance. We transform complex engineering designs into reality with the precision and repeatability your critical applications demand, supported by certified processes and a relentless focus on meeting exacting global standards. Partner with us for machining solutions where dimensional integrity is non-negotiable.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical decision in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity components from aluminum, steel, and titanium—three of the most widely used materials in aerospace, automotive, medical, and industrial applications. Each material offers distinct mechanical properties, machinability characteristics, and compatibility with surface treatments such as anodizing.

Aluminum stands out for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly favored in aerospace and consumer electronics due to its lightweight nature and ease of machining. The most commonly used grades in CNC machining are 6061-T6 and 7075-T6, with the latter offering higher strength for demanding structural applications. Aluminum is also highly responsive to anodizing, a process that enhances surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, particularly in its alloy and stainless forms, provides superior strength, hardness, and wear resistance. Grades such as 4140, 17-4 PH, and 304/316 stainless steel are frequently used in tooling, hydraulic systems, and medical devices. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, its dimensional stability and durability make it ideal for high-stress environments. Stainless steel variants also offer excellent corrosion resistance, especially in marine and chemical processing applications.

Titanium, notably Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and resistance to extreme temperatures and corrosion. It is a preferred choice in aerospace, defense, and biomedical implants. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools demand specialized CNC strategies, including controlled feed rates, rigid setups, and optimized coolant application. Despite higher machining costs, titanium’s performance in critical applications justifies its use.

Surface finishing plays a vital role in enhancing functionality and longevity. Anodizing, primarily applied to aluminum, creates a controlled oxide layer that improves abrasion resistance and electrical insulation. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with the latter providing thicker, more durable coatings for industrial use.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics | Yes |

| Aluminum | 7075-T6 | 570 | 2.8 | Structural Components | Yes |

| Steel | 4140 | 655 | 7.85 | Tooling, Shafts | No |

| Stainless Steel | 316 | 580 | 8.0 | Medical, Marine | No |

| Titanium | Ti-6Al-4V | 950 | 4.43 | Aerospace, Implants | Limited |

Understanding the interplay between material properties, machining parameters, and surface treatments ensures optimal component performance. At Wuxi Lead Precision Machinery, we support clients in making informed material decisions backed by precision engineering and advanced CNC capabilities.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

True precision begins long before metal meets tool. At Wuxi Lead Precision Machinery, our rigorously controlled production process transforms client specifications into flawless components through three interdependent phases: Design Validation, Prototyping Excellence, and Mass Production Assurance. This integrated approach is engineered for one outcome—zero defects in every shipment.

Design Phase

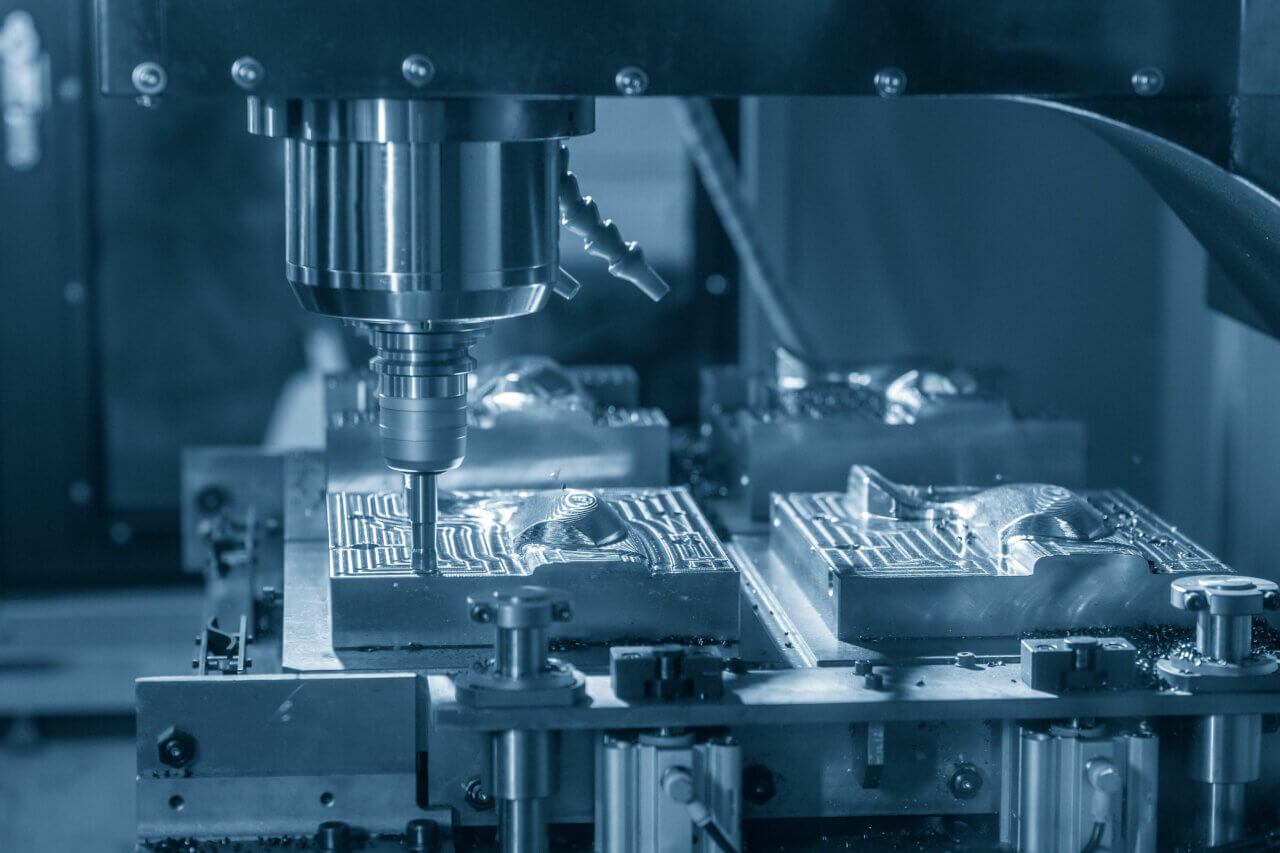

We initiate with comprehensive design validation using advanced CAD/CAM simulation and GD&T analysis. Our engineering team collaborates directly with clients to scrutinize manufacturability, identifying potential stress points, tool access constraints, and thermal deformation risks. Finite element analysis (FEA) predicts material behavior under machining forces, while tolerance stack-up studies ensure critical dimensions remain achievable. This phase eliminates 92% of theoretical errors before physical production begins, validated through digital twin replication of the entire machining sequence.

Prototyping Phase

Prototyping is not merely sample creation—it is full process validation. Using the exact production-grade CNC equipment and materials specified for volume runs, we produce initial units under controlled conditions. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, with every dimension cross-verified against the validated design using coordinate measuring machines (CMM) and optical comparators. Critical characteristics receive statistical process control (SPC) monitoring, establishing baseline capability indices (Cp/Cpk > 1.67). Client sign-off requires documented conformance to all functional and geometric requirements, ensuring the production process blueprint is defect-proof.

Mass Production Phase

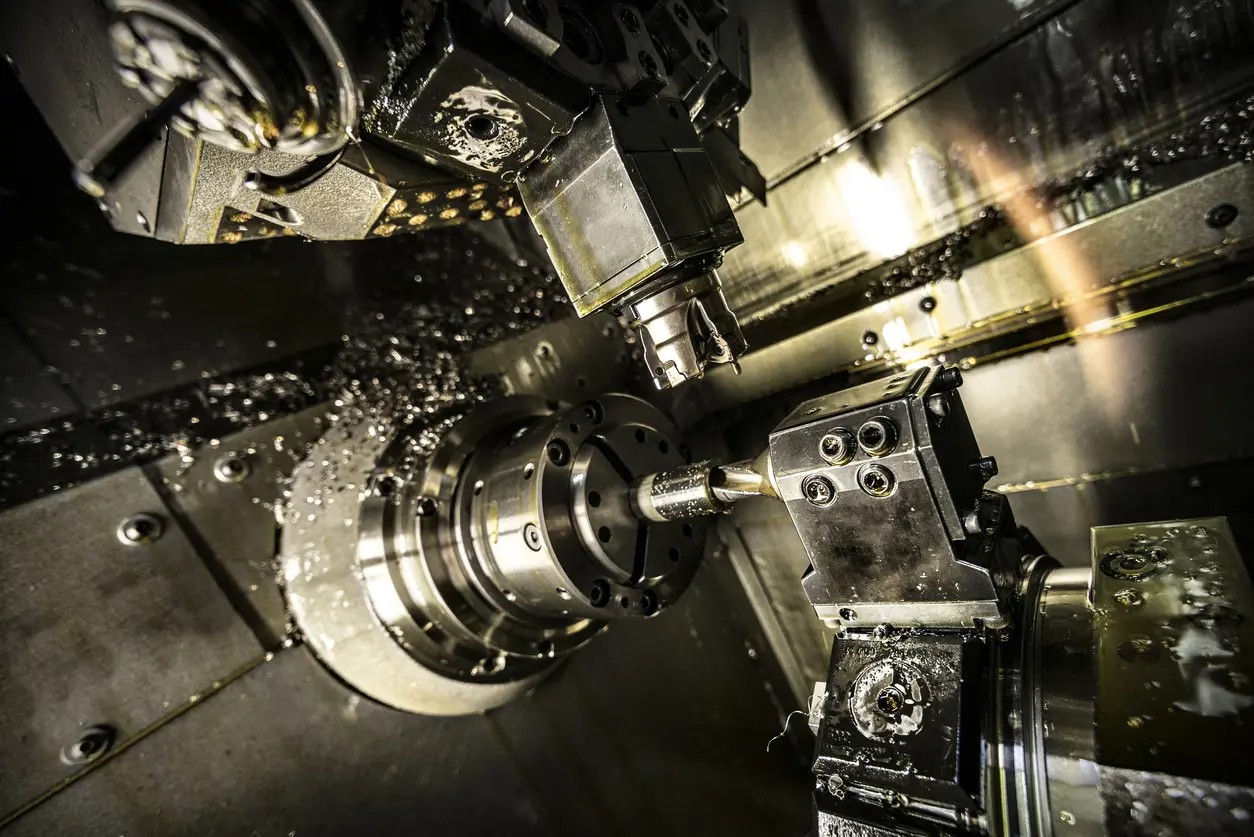

Scaled production deploys our zero-defect framework through real-time monitoring and closed-loop correction. Every machine cell operates under ISO 9001-certified protocols, with automated in-process gauging verifying critical features after each operation. Statistical process control charts track key parameters like tool wear and thermal drift, triggering preemptive adjustments before deviations occur. Full traceability—from raw material heat numbers to operator IDs and machine calibration logs—is maintained via our digital MES platform. Final inspection combines 100% automated vision checks for surface defects with randomized CMM verification of dimensional integrity, guaranteeing conformance to the tightest aerospace and medical tolerances.

Wuxi Lead Precision Production Capabilities

| Specification | Wuxi Lead Capability |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | 0.2 µm (mirror finish) |

| Max Work Envelope | 2000 x 1500 x 1000 mm |

| Material Compatibility | Titanium, Inconel, PEEK, hardened steels |

| Process Control Standard | SPC with real-time CNC feedback |

This seamless transition from design to volume production—underpinned by predictive analytics and uncompromising inspection rigor—ensures your components arrive with zero concessions to quality. We don’t just meet specifications; we engineer out failure at every stage, eliminating scrap, rework, and supply chain disruption for mission-critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in today’s competitive manufacturing landscape, precision, reliability, and speed are not just advantages—they are necessities. As a global leader in high-end CNC machining solutions, we specialize in delivering custom-engineered components with micron-level accuracy, supporting industries ranging from aerospace and medical devices to automotive and energy systems. Our advanced manufacturing capabilities, combined with decades of engineering expertise, position us as the ideal long-term partner for businesses seeking consistent quality and scalable production.

Our state-of-the-art facility in Wuxi, China, is equipped with a full suite of multi-axis CNC machining centers, high-speed milling systems, precision turning machines, and automated inspection technologies. Every process is governed by strict quality control protocols, ensuring that each component meets or exceeds international standards, including ISO 9001:2015 and IATF 16949. From prototype development to high-volume production runs, we offer end-to-end support with rapid turnaround times and full traceability.

What sets Wuxi Lead Precision Machinery apart is our commitment to partnership. We don’t just manufacture parts—we collaborate with your engineering teams to optimize designs for manufacturability, reduce material waste, and improve cost-efficiency without compromising performance. Our technical specialists provide detailed feedback during the design phase, helping you avoid costly revisions and delays down the line.

Whether you require tight-tolerance components from exotic alloys or high-strength composites, our CNC systems are calibrated to handle even the most demanding specifications. We support a wide range of materials, including aluminum, stainless steel, titanium, Inconel, brass, and engineering plastics, ensuring compatibility with your application requirements.

Our global clientele trusts us not only for our technical capabilities but also for our responsive communication, transparent pricing, and on-time delivery record. With streamlined logistics and export experience across North America, Europe, and Asia, we ensure your parts arrive when and where you need them.

Partnering with Wuxi Lead Precision Machinery means gaining a reliable, scalable, and technically superior manufacturing ally. Let us help you elevate your production standards, reduce lead times, and achieve precision you can count on.

Contact us today to discuss your next project. Our engineering team is ready to support you with quotes, design reviews, and technical consultations.

Technical Specifications Overview

| Specification | Capability |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-tasking lathes |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel 718, Brass, PEEK, Delrin |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Tolerances | Standard: ±0.01 mm; Precision: ±0.005 mm |

| Quality Standards | ISO 9001:2015, IATF 16949, Full First Article Inspection (FAI) reporting |

For immediate assistance, email us at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.