Technical Contents

Engineering Guide: Cnc Machining Vs 3D Printing

Engineering Insight: CNC Machining vs 3D Printing – The Critical Role of Precision

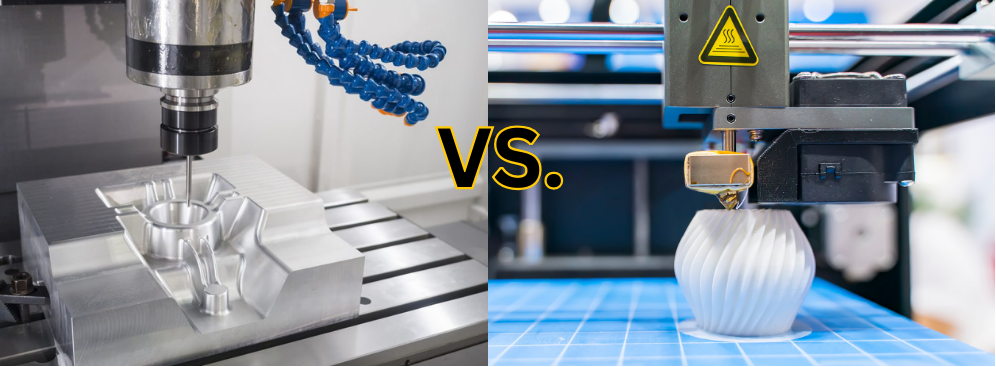

In high-end manufacturing, the choice between CNC machining and 3D printing is not merely a matter of preference—it is a strategic engineering decision driven by performance requirements, material behavior, and, above all, precision. While 3D printing has advanced significantly in recent years, offering design flexibility and rapid prototyping capabilities, CNC machining remains the gold standard for applications where dimensional accuracy, surface finish, and material consistency are non-negotiable.

Precision in manufacturing is not just about tight tolerances; it is about repeatability, structural integrity, and the ability to meet exacting specifications across production runs. CNC machining achieves this through subtractive processes that remove material from solid billets using computer-controlled cutting tools. This method ensures that every component conforms to the original CAD model with tolerances as tight as ±0.0025 mm, a level of consistency that is critical in aerospace, defense, and high-performance automotive sectors.

In contrast, 3D printing—despite its innovation—faces inherent challenges in precision due to layer-by-layer additive processes. Factors such as thermal expansion, warping, and anisotropic material properties can introduce dimensional variance, especially in larger or more complex geometries. While post-processing can mitigate some of these issues, they add time, cost, and potential for human error, undermining the efficiency gains of additive manufacturing.

At Wuxi Lead Precision Machinery, we have engineered mission-critical components for Olympic-grade equipment and military defense systems—applications where failure is not an option. Our CNC machining expertise has been validated through years of delivering parts that meet MIL-STD and ISO 2768 standards, with traceable quality control and full inspection reporting. These industries demand not just precision, but proven reliability under extreme conditions—something our clients trust us to deliver consistently.

The table below highlights key precision-related differences between CNC machining and 3D printing:

| Parameter | CNC Machining | 3D Printing |

|---|---|---|

| Typical Tolerance | ±0.0025 mm to ±0.0125 mm | ±0.1 mm to ±0.3 mm (varies by tech) |

| Surface Finish (Ra) | 0.8–3.2 µm (as-machined) | 6–25 µm (often requires finishing) |

| Dimensional Repeatability | High (consistent across batches) | Moderate (sensitive to calibration) |

| Material Integrity | Isotropic, full-density | Anisotropic, potential porosity |

| Post-Processing Needs | Minimal (deburring, coating) | Often required (support removal, curing) |

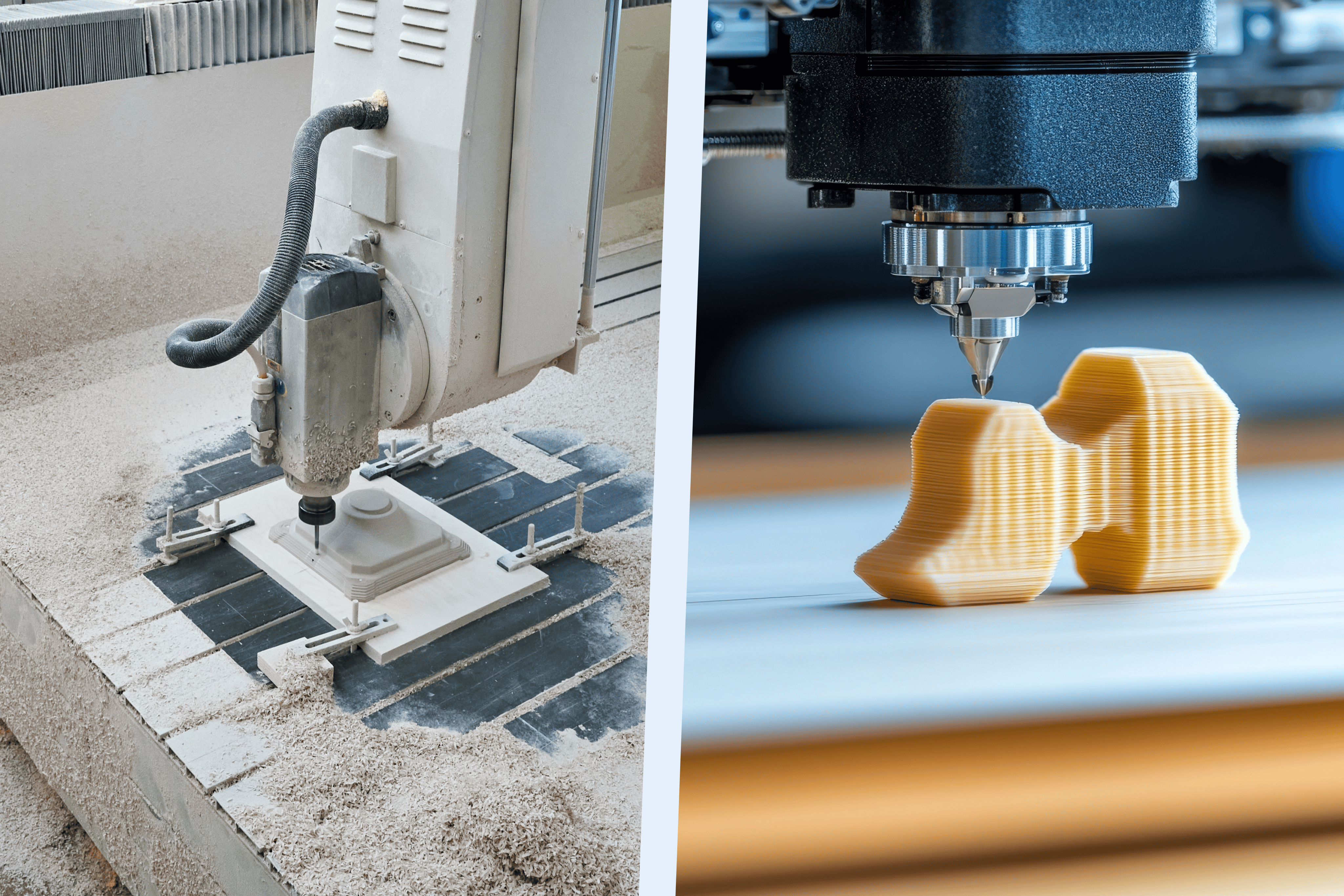

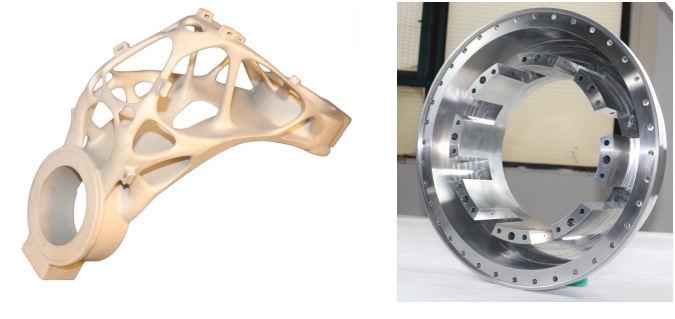

When engineering teams evaluate manufacturing methods, they must consider the lifecycle of the component. For functional prototypes, low-volume custom parts, or complex internal geometries, 3D printing offers undeniable advantages. However, for end-use parts requiring long-term reliability, high strength-to-weight ratios, and exact dimensional conformity, CNC machining is unmatched.

At Wuxi Lead, our commitment to precision is not just technological—it is cultural. With every spindle rotation, we uphold the standards demanded by the most rigorous global industries.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Machining at Scale

Wuxi Lead Precision Machinery delivers mission-critical component manufacturing through advanced 5-axis CNC machining, engineered for repeatability and structural integrity in high-performance applications. Unlike additive processes constrained by material limitations and anisotropic properties, our subtractive methodology ensures homogeneous grain structure and certified mechanical performance across aerospace, medical, and energy sectors. Our facility integrates 18 Haas UMC-750 and DMG MORI CTX beta 1250 5-axis platforms, enabling single-setup machining of complex geometries with ±0.005 mm positional accuracy. This eliminates cumulative error from multiple fixtures—a critical advantage over 3D printing’s layer-adhesion vulnerabilities in load-bearing components.

Material versatility defines our production edge. We machine titanium Grade 5, Inconel 718, and hardened tool steels up to 65 HRC—materials where 3D printing often compromises fatigue resistance or requires costly post-processing. Our 5-axis simultaneous interpolation capability produces fluid contours and undercuts unattainable via layer-based deposition, while high-pressure coolant systems prevent thermal distortion in thin-walled features. Crucially, CNC machining delivers as-machined surface finishes of Ra 0.8 µm without secondary polishing, whereas 3D printed surfaces typically require extensive media blasting or machining to meet functional requirements.

Quality assurance is non-negotiable. Every component undergoes full CMM inspection using Zeiss CONTURA systems calibrated to ISO 17025 standards, with traceable reports validating geometric dimensioning and tolerancing (GD&T) compliance. This closed-loop verification—impossible in batch-oriented 3D printing workflows—ensures first-article conformity and statistical process control for volumes exceeding 10,000 units. Our AS9100D-certified protocols mandate 100% critical feature inspection, directly addressing the porosity and residual stress risks inherent in metal additive manufacturing.

The following table details achievable tolerances across common production scenarios:

| Feature Type | Standard Capability | Precision Capability | Material Dependent |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | All metals |

| Geometric Tolerances | ±0.015 mm | ±0.003 mm | Steels, Al, Ti |

| Hole Diameter | ±0.010 mm | ±0.002 mm | Non-ferrous |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machinable alloys |

| Angular Features | ±0.005° | ±0.001° | All materials |

For production runs demanding certified material properties, fatigue life, and zero-defect delivery, CNC machining remains the industrial benchmark. While 3D printing serves prototyping niches, Wuxi Lead’s integrated CNC ecosystem—combining multi-axis precision, rigorous metrology, and material science expertise—delivers the reliability required for end-use parts in safety-critical assemblies. Contact our engineering team to validate tolerances against your specific application requirements.

Material & Finish Options

Material Selection in CNC Machining: Aluminum, Steel, and Titanium

When evaluating CNC machining versus 3D printing for high-precision industrial applications, material selection plays a decisive role in performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we emphasize the importance of selecting the right base material based on mechanical requirements, environmental exposure, and finishing needs. Among the most widely used materials in precision CNC machining are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum stands out for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly favored in aerospace, automotive, and electronics industries where lightweight components with high dimensional stability are critical. The most common grade used in CNC machining is 6061-T6, known for its weldability and corrosion resistance. When enhanced with anodizing, aluminum achieves improved surface hardness and wear resistance while allowing for color coding and aesthetic refinement. Type II and Type III (hardcoat) anodizing are standard options, with the latter providing a thicker, more durable oxide layer suitable for high-wear environments.

Steel, particularly in its alloy and stainless forms, delivers superior strength, hardness, and resistance to deformation under load. Grades such as 4140, 1018, and 304/316 stainless steel are routinely machined for industrial tooling, hydraulic components, and medical devices. Stainless steels offer inherent corrosion resistance, making them ideal for food processing, pharmaceutical, and marine applications. While steel is less conducive to anodizing, it benefits from alternative surface treatments such as passivation, plating, and powder coating to enhance longevity and performance.

Titanium, though more challenging to machine due to its low thermal conductivity and high reactivity at elevated temperatures, offers an unmatched strength-to-density ratio and exceptional resistance to corrosion—especially in saline or acidic environments. Grade 5 (Ti-6Al-4V) is the most prevalent in aerospace, defense, and biomedical implants. CNC machining allows precise control over titanium’s tight tolerances and complex geometries, which additive methods often struggle to replicate consistently at scale.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics, Automotive | Anodizing (Type II/III), Powder Coat |

| Steel (Alloy) | 4140 | 655 | 7.85 | Tooling, Shafts, Machinery | Passivation, Zinc Plating |

| Steel (Stainless) | 304 | 505 | 8.0 | Medical, Food Processing | Electropolishing, Passivation |

| Titanium | Ti-6Al-4V | 950 | 4.43 | Aerospace, Implants, Marine | Anodizing (Medical Grade), Passivation |

In high-end manufacturing, the choice between these materials should align with functional demands and lifecycle expectations. While 3D printing offers design flexibility, CNC machining remains superior in achieving tight tolerances, superior surface finishes, and the use of fully dense, certified industrial materials. At Wuxi Lead, we support clients in selecting the optimal material and finish combination to ensure performance under real-world operating conditions.

Manufacturing Process & QC

Precision Manufacturing Process: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, CNC machining delivers unmatched repeatability and quality for mission-critical components, where 3D printing often falls short in structural integrity and dimensional stability. Our integrated production process eliminates defects through rigorous phase transitions, ensuring every part meets aerospace and medical-grade specifications.

The journey begins with Design Validation, where our engineering team collaborates with clients to optimize CAD models for manufacturability. Finite element analysis (FEA) identifies stress points, while material selection—spanning titanium, Inconel, and high-strength alloys—is validated against thermal and load requirements. Unlike additive methods, CNC leverages subtractive precision from the outset, avoiding layer adhesion weaknesses inherent in 3D printing. Critical tolerances are embedded into CAM toolpaths, with simulations verifying collision-free machining.

Prototyping transitions seamlessly into production intent. Using the same 5-axis DMG MORI and Makino centers deployed for volume runs, we produce functional prototypes under identical thermal and mechanical conditions. This eliminates process-variable discrepancies common when shifting from 3D-printed prototypes to CNC mass production. Each prototype undergoes CMM inspection against GD&T callouts, with first-article reports documenting surface roughness (Ra ≤ 0.8 µm) and geometric deviations. Iterations are resolved in hours, not days, through digital twin adjustments.

Mass Production executes with zero-defect discipline. Automated bar feeders and pallet systems ensure 24/7 operation, while in-process probing checks critical features after each machining stage. Statistical process control (SPC) monitors tool wear in real time, triggering replacements before tolerances drift beyond ±0.005 mm. Every component undergoes final inspection via Zeiss CONTURA CMMs, with full traceability from raw material certs to post-process deburring. This closed-loop system—impossible with layer-based 3D printing—achieves ≤50 PPM defect rates consistently.

CNC Machining vs. 3D Printing: Critical Production Specifications

| Parameter | CNC Machining (Wuxi Lead) | Typical 3D Printing |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.1 mm to ±0.5 mm |

| Material Strength | 100% of bulk material | 40-80% of bulk material |

| Surface Finish (Ra) | 0.4–1.6 µm (as-machined) | 10–25 µm (post-processed) |

| Production Speed | Minutes per part | Hours per part |

| Material Options | Metals, composites, plastics | Limited metal alloys |

| Structural Integrity | Isotropic, no layer lines | Anisotropic, layer delamination risk |

Wuxi Lead’s process transforms design intent into flawlessly consistent production. By anchoring prototyping and volume runs within a unified CNC ecosystem, we eliminate the quality gaps that arise when bridging 3D-printed concepts to high-stress applications. This is precision engineering without compromise—where every rotation of the spindle advances zero-defect certainty.

Why Choose Wuxi Lead Precision

When evaluating advanced manufacturing technologies for your next production run, the decision between CNC machining and 3D printing goes beyond initial cost or speed. It hinges on precision, repeatability, material performance, and long-term scalability. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining solutions designed for industries where tolerances matter—medical, aerospace, automotive, and industrial automation.

While 3D printing offers advantages in rapid prototyping and complex geometries, CNC machining remains the gold standard for end-use parts requiring tight tolerances, superior surface finishes, and structural integrity in engineering-grade materials. Our 3-, 4-, and 5-axis CNC systems deliver micron-level accuracy across a broad spectrum of metals and high-performance polymers, ensuring your components meet exact design specifications—batch after batch.

Partnering with Wuxi Lead Precision means aligning with a team that understands the nuances of precision manufacturing at scale. We don’t just produce parts—we engineer solutions. From DFM analysis and material selection to final inspection and global shipping, our integrated workflow reduces lead times and eliminates production bottlenecks. Our ISO 9001-certified facility in Wuxi, China, is equipped with state-of-the-art HAAS, DMG MORI, and Makino machines, supported by a quality control system that includes CMM, optical comparators, and surface roughness testers.

Our clients choose us not only for our technical capabilities but for our commitment to transparency, communication, and continuous improvement. Whether you’re transitioning from prototype to production or optimizing an existing supply chain, we offer scalable CNC services with full traceability and real-time project updates.

Below are key performance specifications that define our CNC machining capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.025 mm (0.001″) |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, PEEK, Delrin, and more |

| Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation |

| Lead Times | 7–15 days (standard production) |

We invite engineering teams, procurement managers, and product developers to contact us directly for a technical consultation. Let us help you determine whether CNC machining or hybrid manufacturing approaches will deliver the best balance of performance, durability, and cost-efficiency for your application.

For project inquiries, material recommendations, or a free quote, email us at [email protected]. Our engineering support team responds within 12 business hours. Partner with Wuxi Lead Precision Machinery—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.