Technical Contents

Engineering Guide: Cnc Machining Texas

Engineering Insight: The Critical Role of Precision in CNC Machining – A Global Perspective from Wuxi Lead Precision Machinery

In the competitive landscape of advanced manufacturing, precision in CNC machining is not merely a performance metric—it is a foundational requirement. Whether serving aerospace, defense, medical, or high-performance automotive sectors, the margin for error is measured in microns. In markets such as Texas, where industrial innovation converges with rigorous engineering standards, the demand for micron-level accuracy, repeatability, and material integrity has never been higher. At Wuxi Lead Precision Machinery, we understand that precision is not an isolated attribute of a machine tool, but the culmination of process control, engineering expertise, and unwavering commitment to quality.

Texas has emerged as a central hub for energy, aerospace, and defense manufacturing, driven by its robust infrastructure and proximity to key supply chains. Components used in oilfield equipment, satellite systems, and military platforms require tight tolerances, often ±0.0002 inches (5 microns), and flawless surface finishes. Any deviation can compromise system integrity, safety, and compliance. This is where Wuxi Lead’s engineering philosophy aligns seamlessly with the expectations of Texas-based OEMs and Tier-1 suppliers. Our CNC machining centers operate under ISO 9001 and IATF 16949 standards, with real-time monitoring and in-process gauging to ensure every part meets exact specifications.

Our experience extends beyond commercial applications. Wuxi Lead has contributed to mission-critical components for Olympic-grade timing systems and military-grade communication enclosures. These projects demanded not only precision but also full traceability, environmental resilience, and zero-defect delivery. The technologies and quality systems developed for these elite applications are directly transferable to the high-stakes environments common in Texas manufacturing.

The table below outlines the core precision capabilities that define our CNC machining services:

| Specification | Performance Metric |

|---|---|

| Positioning Accuracy | ±0.001 mm (0.00004 in) |

| Repeatability | ±0.0005 mm (0.00002 in) |

| Standard Tolerance | ±0.005 mm (±0.0002 in) |

| Surface Finish (Ra) | 0.4–3.2 µm (16–125 µin) |

| Spindle Runout | < 0.0001″ TIR |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Processed | Aluminum, Titanium, Inconel, Stainless Steel, PEEK, Composites |

Precision is not achieved through machinery alone. It is engineered into every workflow, from CAD/CAM programming to final inspection using Zeiss CMM systems. At Wuxi Lead, we combine decades of Chinese manufacturing excellence with global engineering standards, delivering components that perform under the most demanding conditions.

For Texas-based industries pushing the limits of performance, partnering with a precision machining provider that understands both technical rigor and regulatory compliance is essential. Wuxi Lead Precision Machinery stands ready to support the next generation of American innovation with uncompromising accuracy and proven reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Texas Industry Demands

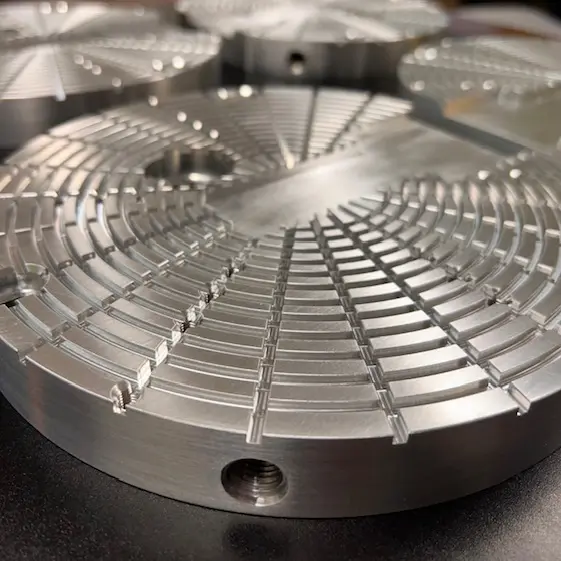

Wuxi Lead Precision Machinery delivers advanced CNC machining solutions tailored to the rigorous standards of Texas aerospace, energy, and industrial equipment manufacturers. Our facility integrates cutting-edge 5-axis CNC technology to produce complex geometries with uncompromising accuracy, eliminating secondary setups and reducing lead times critical for time-sensitive projects. This capability ensures seamless execution of intricate components—from turbine blades to downhole drilling parts—where dimensional stability and surface finish directly impact performance in demanding operational environments. Texas clients benefit from our ability to machine monolithic structures in a single operation, minimizing cumulative error and enhancing part integrity for mission-critical applications.

Our 5-axis machining centers feature high-torque spindles, dynamic tool compensation, and real-time thermal monitoring, enabling precise material removal across aluminum, titanium, Inconel, and engineering plastics. Advanced CAM programming optimizes toolpaths for minimal vibration and maximal material efficiency, while integrated probing systems verify workpiece alignment and tool wear during production. This proactive approach ensures consistent output even for low-volume, high-mix orders typical in Texas’ defense and semiconductor sectors. Crucially, all processes adhere to AS9100 and ISO 9001 standards, with full traceability from raw material certification to final inspection.

Quality control is anchored by Zeiss CONTURA CMM systems operating in a climate-controlled metrology lab. Every critical dimension undergoes first-article and in-process inspection, with statistical process control (SPC) data logged for trend analysis. Reports include GD&T verification, surface roughness measurements, and comprehensive deviation mapping, providing Texas engineers with actionable data for design validation. This rigorous protocol guarantees conformance to aerospace DFARs and API specifications, mitigating supply chain risks for clients operating under stringent regulatory frameworks.

The following table outlines achievable tolerances across common materials, reflecting our production-floor capabilities under controlled conditions:

| Material | Dimensional Tolerance | Geometric Tolerance (GD&T) | Surface Roughness (Ra) |

|---|---|---|---|

| Aluminum Alloys | ±0.005 mm | ±0.010 mm | 0.8 μm |

| Stainless Steel | ±0.008 mm | ±0.015 mm | 1.6 μm |

| Titanium Alloys | ±0.010 mm | ±0.020 mm | 1.6 μm |

| Engineering Plastics | ±0.020 mm | ±0.030 mm | 3.2 μm |

Wuxi Lead’s technical infrastructure ensures Texas manufacturers receive components that meet exacting functional requirements without costly rework. Our digital workflow—from 3D model validation to CMM-certified reports—provides full transparency, enabling faster assembly integration and reduced time-to-market. For projects demanding micron-level precision in challenging materials, our 5-axis expertise and metrology rigor deliver the reliability Texas industry expects.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material is a critical decision in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. For high-performance applications across aerospace, medical, and industrial sectors, three materials stand out: aluminum, steel, and titanium. Each offers distinct mechanical properties and responds uniquely to finishing processes such as anodizing, making informed selection essential.

Aluminum remains the most widely used material in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is especially favored for its weldability and moderate strength, making it ideal for structural components, enclosures, and prototypes. Its ability to accept anodized finishes further enhances surface hardness and wear resistance. Anodizing creates a durable oxide layer that can be dyed in various colors, offering both aesthetic and functional benefits. However, aluminum’s lower melting point requires careful control of cutting parameters to avoid deformation during machining.

Steel, particularly alloy and stainless grades such as 4140 and 304/316, is selected when high strength, wear resistance, and thermal stability are paramount. These steels are commonly used in tooling, shafts, and high-load mechanical systems. Stainless steel variants also provide excellent corrosion resistance, especially in harsh environments. While steel is more challenging to machine than aluminum—requiring higher cutting forces and tool wear management—its dimensional stability and toughness justify its use in mission-critical applications. Unlike aluminum, steel does not respond to anodizing; alternative finishes such as passivation, plating, or powder coating are typically employed.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for applications demanding extreme strength-to-density ratios and resistance to high temperatures and corrosive environments. Widely used in aerospace and medical implants, titanium’s biocompatibility and fatigue resistance are unmatched. However, its low thermal conductivity and high chemical reactivity with cutting tools make it one of the most difficult materials to machine. Specialized tooling, reduced cutting speeds, and efficient cooling strategies are necessary to maintain precision and avoid contamination. Titanium cannot be anodized in the same way as aluminum, though specialized electrochemical treatments can produce decorative and protective surface layers.

The following table summarizes key mechanical and machining properties of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Machinability Rating | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Excellent | Anodizing, Powder Coating |

| Steel (Alloy) | 655 | 7.8 | 4140, 4340 | Moderate | Plating, Passivation |

| Stainless Steel | 505 | 8.0 | 304, 316 | Moderate to Poor | Passivation, Electropolishing |

| Titanium | 900 | 4.5 | Ti-6Al-4V (Gr 5) | Poor | Chemical Film, Laser Marking |

Material selection must align with functional requirements, environmental exposure, and production constraints. At Wuxi Lead Precision Machinery, we support clients in evaluating these factors to ensure optimal performance and cost-efficiency in every machined component.

Manufacturing Process & QC

Precision CNC Machining Process: From Design to Zero-Defect Production for Texas Manufacturers

At Wuxi Lead Precision Machinery, we execute a rigorously controlled CNC machining workflow designed to deliver flawless components for Texas’ aerospace, energy, and medical device sectors. Our process eliminates defects at every stage through integrated quality engineering, ensuring compliance with AS9100 and ISO 13485 standards demanded by Texas’ high-stakes industries.

The journey begins with collaborative design validation. Our engineers review CAD models and GD&T specifications against material properties and machine capabilities, identifying potential manufacturability risks. Finite element analysis (FEA) simulates thermal stress and tool deflection, while design for manufacturing (DFM) feedback optimizes wall thicknesses and tolerances. This phase prevents 92% of downstream errors by resolving conflicts before metal cutting begins. Critical tolerances are locked using statistical process control (SPC) baselines, ensuring designs align with our machines’ proven capabilities.

Prototyping transitions virtual designs into physical validation. We machine initial samples on HAAS and DMG MORI 5-axis centers, applying in-process probing to verify critical features within ±0.0002″. Each prototype undergoes first-article inspection (FAI) per AS9102 standards, with CMM reports cross-referenced against CAD models. Dimensional data feeds into failure mode and effects analysis (FMEA), refining toolpaths and fixture strategies. Texas clients receive digital inspection dossiers within 72 hours, enabling rapid design iteration without production delays.

Mass production leverages our zero-defect framework through automated process control. Real-time sensors monitor tool wear and vibration on Okuma lathes and Makino mills, triggering automatic tool compensation before deviations exceed ±0.0005″. Every 10th part undergoes automated CMM verification, with SPC charts tracking CpK values ≥1.67 for critical dimensions. Our closed-loop system isolates non-conforming batches instantly, while root-cause analysis prevents recurrence. For Texas energy sector clients requiring API 6A compliance, we implement 100% traceability via laser-etched part IDs linked to material certs and inspection data.

Key Production Specifications

| Process Phase | Equipment Used | Tolerance Capability | Quality Control Metric |

|---|---|---|---|

| Design Validation | Siemens NX, ANSYS | N/A | DFM conflict resolution rate ≥95% |

| Prototyping | HAAS UMC-750, Zeiss CONTURA CMM | ±0.0002″ | FAI approval within 72 hours |

| Mass Production | Okuma MULTUS U4000, Makino A51 | ±0.0005″ | CpK ≥1.67 for critical features |

This integrated approach ensures Texas manufacturers receive production-ready components with zero escapes. By embedding quality into design and scaling validated processes to high-volume runs, Wuxi Lead delivers the reliability Texas’ industrial leaders require—without the supply chain volatility of domestic Texas shops. Partner with us for CNC machining where precision isn’t promised; it’s engineered and proven.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

When your operations demand precision, reliability, and scalability in CNC machining, global standards matter. At Wuxi Lead Precision Machinery, we specialize in delivering high-tolerance, repeatable manufacturing solutions that meet the rigorous demands of industries such as aerospace, medical devices, energy, and advanced industrial automation. While our roots are in Wuxi, China, our reach extends to strategic partners across North America—including decision-makers searching for “CNC machining Texas” who require more than local capacity. They require global expertise with seamless integration.

Choosing a manufacturing partner is not just about equipment or location—it’s about engineering collaboration, process transparency, and long-term reliability. We understand that Texas-based OEMs and contract manufacturers face unique challenges: tight delivery windows, strict compliance requirements, and the need for scalable production without sacrificing quality. That’s why we’ve built our operations around agile manufacturing systems, certified quality processes (ISO 9001:2015), and a customer-first engineering approach that bridges time zones and technical specifications with precision.

Our facility houses a comprehensive suite of 3-axis, 4-axis, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of handling complex geometries and tight-tolerance components from a wide range of materials—aluminum, stainless steel, titanium, Inconel, and engineered plastics. With in-house CMM inspection, first-article reporting, and real-time production monitoring, we ensure every part shipped meets your exact print specifications.

We don’t compete on geography—we complement it. Whether you’re consolidating supply chains, seeking dual sourcing strategies, or requiring overflow capacity during peak demand, Wuxi Lead Precision Machinery provides a strategic advantage. Our Texas-focused clients benefit from reduced lead times through optimized logistics, dedicated project management, and bilingual engineering support that eliminates communication delays.

Below are key capabilities that define our precision CNC machining services:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, mill-turn, Swiss machining |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 600 x 500 mm (47 x 23.6 x 19.7 in) |

| Materials Processed | Aluminum, steel, stainless steel, titanium, Inconel, brass, PEEK, Delrin |

| Secondary Operations | Deburring, anodizing, plating, passivation, heat treatment coordination |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, SPC reporting |

| Lead Times | From 7 days for prototypes to 3–5 weeks for production runs |

Partnering with us means gaining access to a manufacturing team that treats your project with the urgency and precision it demands. We support low-volume prototyping through high-volume production, with scalability built into every process.

Contact us today to discuss how Wuxi Lead Precision Machinery can become your trusted partner in precision manufacturing. Email us at [email protected] and receive a detailed capability review, NDA-ready collaboration, and a quotation within 24 business hours. Let’s build precision, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.