Technical Contents

Engineering Guide: Cnc Machining Services Uk

Engineering Insight Precision CNC Machining for the UK Market

In the demanding landscape of UK manufacturing, precision CNC machining is not merely a service specification—it is the foundational requirement for product integrity, regulatory compliance, and operational longevity. UK industries—from aerospace and defense to medical and high-performance automotive—operate under stringent tolerances where deviations of even 5 microns can trigger catastrophic system failures or compliance rejections. This exacting standard demands more than advanced machinery; it requires ingrained engineering discipline, rigorous process validation, and a culture of uncompromising quality control. At Wuxi Lead Precision Machinery, we recognize that UK clients prioritize partners who treat precision as a non-negotiable engineering principle, not a marketing claim.

Our commitment to micron-level accuracy is forged through direct experience in projects where failure is not an option. We have delivered mission-critical components for Olympic-standard equipment, where repeatability under extreme conditions defined athletic performance boundaries. Similarly, our work for military-grade applications has subjected our processes to the most severe environmental and functional testing protocols, including shock, vibration, and thermal cycling beyond civilian norms. These experiences have hardened our quality management systems, ensuring every UK-bound component undergoes multi-stage inspection—utilizing CMMs, optical comparators, and in-process probes—before leaving our Wuxi facility. This rigor translates directly to reduced scrap rates, accelerated time-to-market, and seamless integration into your assembly lines.

For UK engineering teams, partnering with a global supplier necessitates confidence in consistent output. The table below outlines our core precision capabilities relevant to UK manufacturing standards:

| Specification Category | Capability Detail | Relevance to UK Industry |

|---|---|---|

| Tolerance Range | ±0.002 mm (±0.00008″) | Meets AS9100 aerospace and ISO 13485 medical device requirements |

| Material Expertise | Titanium (Grade 5), Inconel 718, 7075-T6 Aluminum, PEEK, 420 Stainless | Supports defense, motorsport, and surgical implant sectors |

| Certifications | ISO 9001:2015, AS9100D, ITAR Registered | Ensures compliance with UK MOD and aerospace supply chain mandates |

| Inspection Protocol | 100% First Article Inspection (FAI), PPAP Level 3, Real-time SPC monitoring | Aligns with UK automotive (IATF 16949) and rail (IRIS) quality frameworks |

| Lead Time Consistency | 99.2% on-time delivery (2023 global data) | Mitigates production line stoppages in JIT manufacturing environments |

Precision in CNC machining transcends dimensional accuracy—it encompasses material traceability, environmental responsibility, and supply chain resilience. UK manufacturers increasingly seek partners who can navigate complex regulatory landscapes while delivering zero-defect components. Wuxi Lead’s engineering heritage in Olympic and military projects provides tangible proof of our ability to operate at the highest echelons of precision manufacturing. We integrate this expertise with dedicated UK client management teams to ensure seamless communication, cultural alignment, and responsive problem-solving. When your application demands parts that perform flawlessly under extreme conditions, our proven precision engineering framework becomes your strategic advantage. Let us demonstrate how disciplined manufacturing execution drives your project success.

Precision Specs & Tolerances

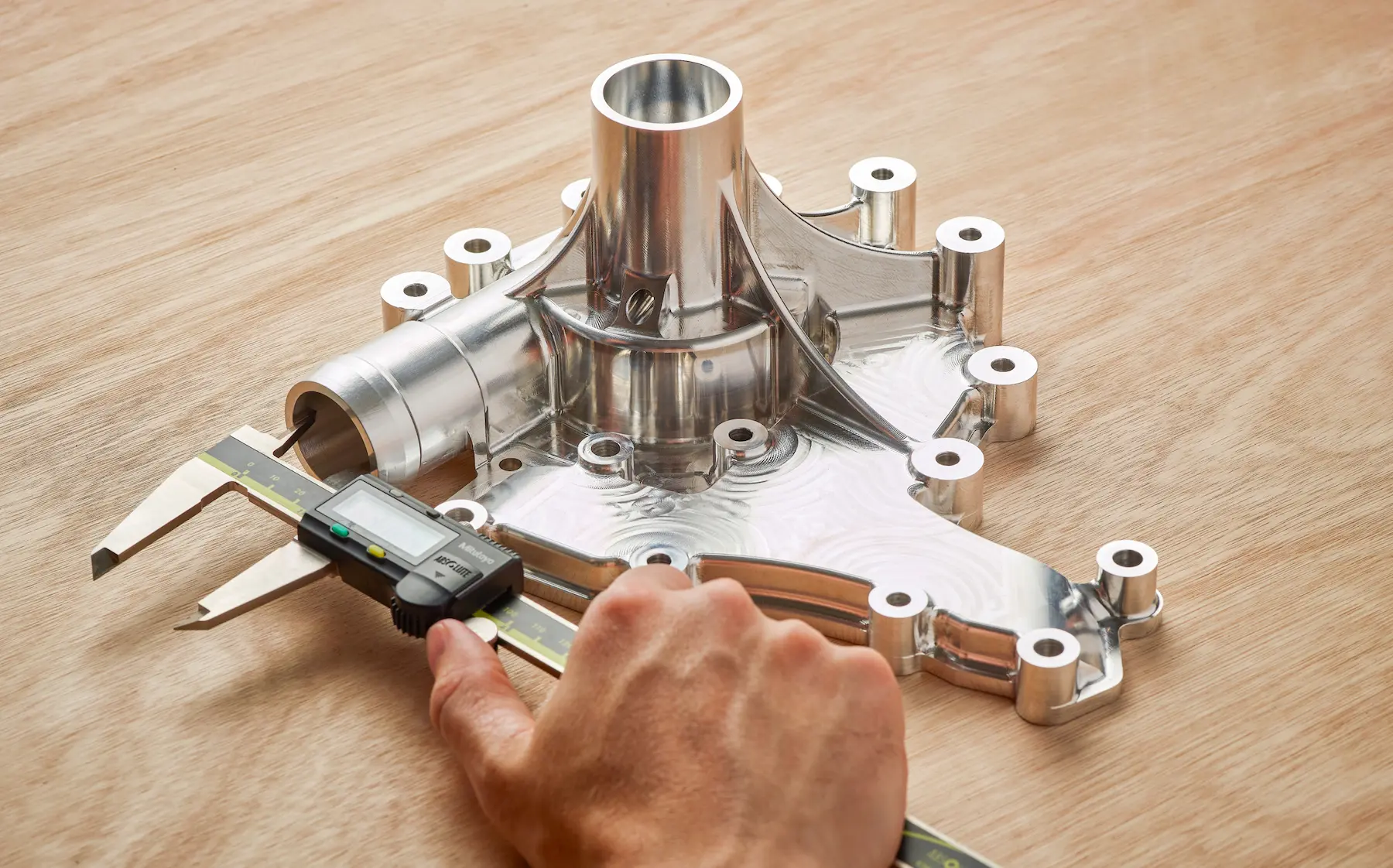

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored for high-performance industries including aerospace, medical, energy, and advanced automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across all five axes, significantly reducing setup time and improving part consistency. This capability supports the production of intricate components such as turbine blades, surgical instruments, and high-tolerance housings with compound angles and organic contours.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring consistent performance across large and small production runs. We work with a broad range of engineering materials, including aluminum alloys, stainless steels, titanium, Inconel, PEEK, and engineering plastics, adapting cutting strategies to maintain material integrity and dimensional stability. In addition to milling, our 5-axis capabilities integrate precision turning operations where applicable, allowing for complete machining in a single setup—minimizing human intervention and reducing potential error sources.

To guarantee the highest level of quality, every critical dimension is verified through comprehensive inspection protocols. Our quality control process is anchored by a Zeiss DuraMax and a蔡司 CONTURA G2 Coordinate Measuring Machine (CMM), providing non-contact and tactile probing with micron-level resolution. These systems ensure full compliance with geometric dimensioning and tolerancing (GD&T) requirements as defined in ASME Y14.5 and ISO 1101 standards. All inspection reports are documented and archived for full traceability, supporting industries with strict regulatory demands such as ISO 13485 and AS9100.

We maintain tight control over environmental conditions in our metrology lab, including temperature stabilization and vibration isolation, to ensure measurement repeatability. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and calibrated handheld instruments for first-article and in-process checks. This multi-layered quality assurance system ensures that every component shipped meets or exceeds customer specifications.

The table below outlines our standard achievable tolerances across common machining operations:

| Feature | Typical Tolerance | Capability Range |

|---|---|---|

| Linear Dimensions (Machined) | ±0.005 mm | Up to ±0.002 mm |

| Hole Diameter (Reamed) | ±0.01 mm | ±0.005 mm |

| Positional Tolerance (GD&T) | ±0.02 mm | Down to ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | As low as 0.2 µm |

| Angular Features (5-Axis) | ±0.05° | ±0.02° |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

Our commitment to technical excellence ensures that Wuxi Lead Precision Machinery remains a trusted partner for global clients seeking precision, reliability, and consistency in CNC machining services.

Material & Finish Options

Material Selection for Precision CNC Machining Services: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material and surface finish is critical for achieving performance, longevity, and cost-efficiency in precision CNC machined components. For UK manufacturers demanding tight tolerances and reliability, understanding the core properties of Aluminum, Steel, and Titanium—paired with appropriate finishing like Anodizing—is essential. Material choice directly impacts machinability, part weight, strength requirements, environmental resistance, and overall project economics. At Wuxi Lead Precision Machinery, we prioritize material science expertise to ensure your UK-based applications receive the highest precision machining services from China, minimizing risk and maximizing component value.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their excellent strength-to-weight ratio, superior thermal conductivity, and inherent corrosion resistance. They machine efficiently at high speeds, reducing cycle times and costs. Steel, especially grades like 304/316 stainless (BS EN 10088) and 4140 alloy, offers unmatched strength, wear resistance, and structural integrity for demanding industrial machinery, tooling, and medical devices. While harder to machine than aluminum, modern CNC techniques ensure precise results. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for aerospace and medical implants where extreme strength, exceptional corrosion resistance, and biocompatibility are non-negotiable. However, titanium’s low thermal conductivity and tendency to gall demand specialized tooling, rigid setups, and controlled parameters to prevent work hardening and ensure dimensional accuracy.

Surface finishing, particularly Anodizing, significantly enhances aluminum components. Type II (Sulfuric Acid) Anodizing provides a durable, decorative, and moderately corrosion-resistant layer, available in various colors. For critical UK applications requiring maximum wear and corrosion resistance—such as marine hardware or military equipment—Type III (Hardcoat) Anodizing is essential. It creates a much thicker, harder ceramic-like surface that withstands severe abrasion and harsh environments, though it requires precise process control to maintain tight tolerances on critical features. Selecting the correct anodizing type ensures the component meets both functional and aesthetic requirements without compromising dimensional integrity.

Material selection is not merely a specification; it is a strategic decision impacting manufacturability, performance, and total cost of ownership. The following table summarizes key properties to guide your choice for UK precision machining projects.

| Material | Key Properties | Common Grades (UK/ISO) | Best Applications |

|---|---|---|---|

| Aluminum | Low density, high conductivity, good corrosion resistance, excellent machinability | 6061-T6, 7075-T6, 2024-T3 | Aerospace frames, heat sinks, enclosures, automotive parts |

| Steel | High strength, excellent wear resistance, good structural integrity | 304/316 (BS EN 10088), 4140, EN8 | Tooling, shafts, valves, medical instruments, structural components |

| Titanium | Exceptional strength-to-weight, supreme corrosion resistance, biocompatible, low thermal conductivity | Ti-6Al-4V (Grade 5), CP2 (Grade 2) | Aircraft components, medical implants, marine hardware, high-performance motorsport |

Partnering with a precision CNC machining service provider experienced in these critical materials and finishes ensures your UK project leverages optimal material science from design through delivery. Wuxi Lead Precision Machinery applies rigorous process control and deep metallurgical understanding to transform your specifications into flawless components, shipped reliably from China to meet your exacting standards.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with meticulous design analysis and engineering collaboration. When clients from the UK and across Europe submit component drawings or concepts, our engineering team conducts a comprehensive Design for Manufacturability (DFM) review. This ensures that every detail—from material selection to geometric complexity—is optimized for CNC machining efficiency, structural integrity, and long-term performance. Utilizing advanced CAD/CAM software such as Siemens NX, SolidWorks, and Mastercam, we simulate tool paths, identify potential stress points, and validate tolerances before any material is cut. This stage is critical in preventing downstream errors and aligning client expectations with manufacturable reality. Our engineers maintain direct communication with clients to refine designs, ensuring compliance with ISO 1302 surface finish standards, GD&T specifications, and industry-specific requirements such as those in aerospace, medical, or automation sectors.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping. This phase is not merely about producing a sample—it is a functional validation step. Using the same 3-, 4-, and 5-axis CNC machining centers intended for full production, we manufacture prototypes under actual production conditions. This ensures dimensional accuracy, material behavior consistency, and process repeatability. Each prototype undergoes rigorous in-house inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Clients receive detailed inspection reports, first article inspection (FAI) documentation, and, where applicable, material certification. Feedback from prototype testing is integrated swiftly, allowing for design or process adjustments with minimal delay. This iterative yet disciplined approach mitigates risk and confirms that the part performs as intended in its end application.

Mass Production: Zero Defects Through Systematic Control

Transitioning to mass production, Wuxi Lead implements a zero-defect manufacturing philosophy. Our production floor operates under ISO 9001 and IATF 16949-certified quality management systems, with real-time process monitoring and statistical process control (SPC) protocols. CNC machines are calibrated daily, and tool wear is automatically tracked to prevent deviations. Every batch undergoes first-piece, in-process, and final inspections. Non-conforming parts are quarantined immediately, and root cause analysis is conducted to prevent recurrence. Traceability is maintained through laser part marking and digital batch records, ensuring full accountability from raw material to shipment.

The following table outlines key production capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm (standard), ±0.001 mm (tight) |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (e.g., PEEK, Delrin) |

| Max Work Envelope (5-axis) | 1,200 x 800 x 600 mm |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

| Quality Standards | ISO 9001, IATF 16949, ISO 1302, AS9100 (available) |

From design validation to high-volume output, Wuxi Lead Precision Machinery ensures every CNC-machined component meets the highest standards of precision, reliability, and consistency—delivering excellence on every UK-bound shipment.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic UK CNC Machining Solution

For UK manufacturers demanding uncompromising precision, reliability, and technical partnership in CNC machining, Wuxi Lead Precision Machinery delivers engineered excellence from our ISO 9001:2015 certified facility in China. We understand the critical pressures facing British industry: stringent quality mandates, compressed development cycles, and the need for supply chain resilience. Our dedicated engineering team operates within UK time zones, ensuring seamless collaboration, real-time project transparency, and responsive technical support tailored to your specifications. We bridge geographical distance with operational proximity, providing the strategic advantage of cost-optimized, high-integrity manufacturing without sacrificing the responsiveness expected of a domestic partner.

Our commitment transcends basic component production. We integrate advanced 3-5 axis milling and turning capabilities with rigorous statistical process control, material traceability, and first-article inspection protocols aligned with UK aerospace, medical, and industrial standards. This ensures every part meets your dimensional, surface finish, and functional requirements—consistently. Below outlines our core technical capabilities relevant to demanding UK applications:

| Capability | Specification | Relevance to UK Market |

|---|---|---|

| Material Expertise | Aluminum, Stainless Steel, Titanium, Inconel, Plastics | Meets aerospace, medical, and energy sector material certifications |

| Tolerance Control | ±0.005 mm standard; ±0.002 mm achievable | Exceeds typical UK automotive and instrumentation requirements |

| Max Work Envelope | 500 x 500 x 400 mm (5-axis) | Accommodates complex assemblies common in UK defense projects |

| Surface Finish | Ra 0.4 µm standard; Ra 0.1 µm achievable | Critical for hydraulic components and medical implants |

| Quality Assurance | CMM, Optical Comparator, GD&T Reporting | Full compliance with AS9100 and ISO 13485 traceability demands |

UK clients achieve 30% faster time-to-market by leveraging our integrated design-for-manufacturability analysis. Our engineers proactively identify cost-saving opportunities in your CAD models while safeguarding performance integrity—reducing prototyping iterations and mitigating production risks. We manage material sourcing, heat treatment, and secondary finishing through vetted partners, delivering fully validated components ready for assembly. This end-to-end accountability eliminates the coordination burden typical of fragmented offshore supply chains.

Your next project requires more than a vendor; it demands a precision engineering ally invested in your success. Wuxi Lead Precision Machinery combines Chinese manufacturing efficiency with Western engineering rigor, offering UK businesses a sustainable competitive edge. We commit to on-time delivery, zero-defect output, and continuous improvement aligned with your strategic objectives.

Initiate a technical consultation to experience our engineering-led approach. Contact our UK-focused team at [email protected] with your part drawings or project scope. We will provide a detailed capability assessment, competitive quotation, and dedicated project timeline within 24 business hours. Partner with precision—elevate your manufacturing outcomes with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.