Technical Contents

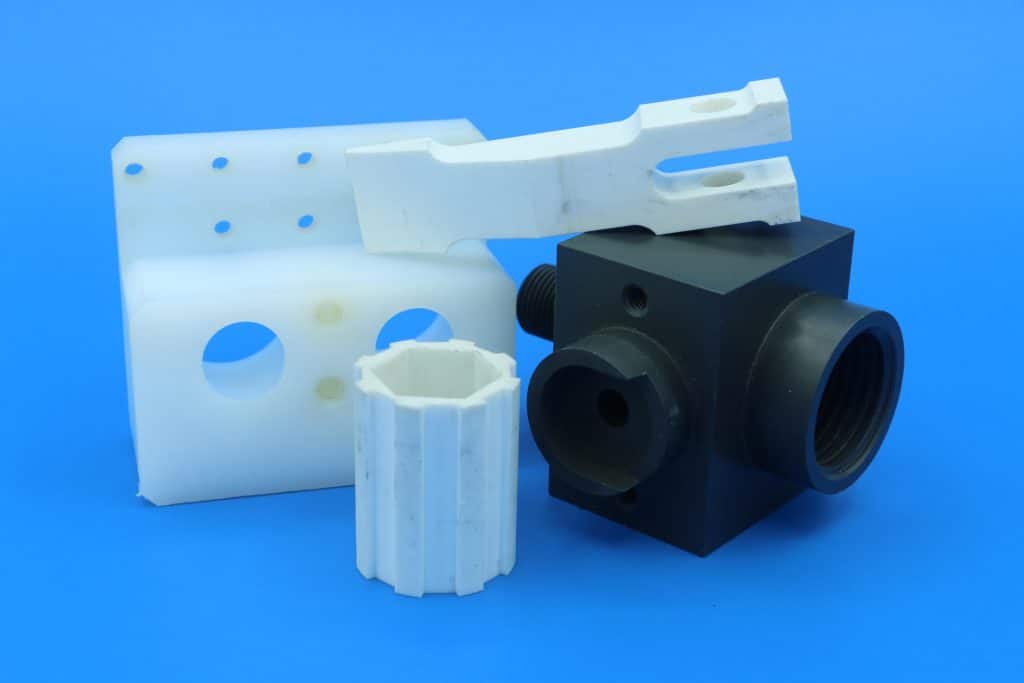

Engineering Guide: Cnc Machining Plastic Parts

Engineering Insight: Precision in CNC Machined Plastic Components

Precision in CNC machining plastic parts is non-negotiable for mission-critical applications. Unlike metals, plastics exhibit unique thermal expansion coefficients, moisture absorption rates, and variable rigidity, demanding meticulous process control. A tolerance deviation of 0.025mm can compromise sealing integrity in aerospace fluid systems or induce premature wear in medical implant components. At Wuxi Lead Precision Machinery, we treat plastic machining as a science—not an adaptation of metal protocols. Our 15-year specialization in engineering polymers ensures dimensional stability through controlled ambient environments, custom toolpath strategies, and real-time in-process metrology.

Material behavior dictates our approach. Acetal (POM) requires aggressive chip evacuation to prevent re-melting, while PEEK demands slow, consistent feeds to avoid internal stress fractures. We leverage material-specific spindle harmonics and cryogenic cooling to maintain ±0.005mm tolerances consistently. This rigor stems from direct experience machining components for Olympic-caliber sporting equipment—where aerodynamic symmetry affects podium outcomes—and classified defense systems, where polymer insulators in radar housings must perform flawlessly under extreme vibration and temperature cycling.

Our facility’s ISO 9001:2015 and AS9100D certifications underpin a workflow where every micron is accounted for. From raw bar stock conditioning to final CMM validation, we mitigate plastic’s inherent variables through empirical data libraries built across 12,000+ production runs. The table below reflects achievable precision for common engineering plastics under our controlled parameters:

| Material | Typical Tolerance (mm) | Max Part Size (mm) | Critical Consideration |

|---|---|---|---|

| PEEK | ±0.005 | 300 x 200 x 150 | Slow cooling to prevent crystallization |

| Acetal (POM) | ±0.010 | 500 x 400 x 250 | High-pressure coolant for chip control |

| Polycarbonate | ±0.015 | 600 x 450 x 300 | Low spindle speed to avoid stress cracking |

| Ultem 1000 | ±0.008 | 250 x 200 x 120 | Pre-drying mandatory (>4hrs @ 150°C) |

| PTFE | ±0.020 | 400 x 300 x 200 | Zero-clamp pressure to prevent deformation |

Military-grade projects taught us that repeatability trumps nominal accuracy. When machining polymer gears for satellite deployment mechanisms, we track thermal drift across 72-hour production cycles—adjusting offsets every 90 minutes based on laser-interferometer feedback. Similarly, Olympic bobsled runners required surface finishes under Ra 0.4µm to minimize ice friction, achieved through diamond-turned tooling and vibration-damped spindles. These experiences forged our zero-defect culture: 99.98% first-pass yield across 500+ plastic SKUs since 2020.

For sectors where polymer failure risks human safety or national security, precision is the only acceptable standard. Wuxi Lead Precision Machinery delivers it through disciplined material science, not trial-and-error. Partner with us when your plastic components must perform beyond datasheet promises. Demand precision engineered—not tolerated.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Precision Plastic Components

Wuxi Lead Precision Machinery delivers high-precision CNC machining services tailored specifically for complex plastic components used in aerospace, medical, electronics, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finishes and dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across five planes, reducing setup cycles and eliminating cumulative tolerances associated with multiple fixturing stages. This results in faster turnaround times and enhanced part consistency, critical for high-performance applications where reliability is non-negotiable.

Our facility utilizes advanced CNC equipment equipped with high-speed spindles optimized for non-metallic materials. These machines are programmed using industry-leading CAM software, ensuring precise toolpath control and material removal strategies that prevent common plastic machining challenges such as melting, warping, or delamination. We work with a broad spectrum of engineering-grade thermoplastics, including PEEK, PTFE, Delrin, Ultem, Polycarbonate, and Nylon, each processed under controlled parameters to maintain material integrity and part functionality.

Quality assurance is integrated at every stage of production. All machined plastic components undergo rigorous inspection using a coordinate measuring machine (CMM) with multi-sensor technology. This allows for full 3D verification of critical dimensions, geometric tolerances, and surface profiles against CAD models. Our CMM system is calibrated to international standards and operated by certified metrology technicians, ensuring traceable and repeatable measurement results. In addition to CMM inspection, we perform first-article inspections, in-process checks, and final batch validation to guarantee compliance with customer specifications and industry regulations.

The following table outlines typical machining tolerances achievable on plastic components using our 5-axis CNC process:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Depends on part size and geometry |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or precision drilled |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm | For machined surfaces |

| Angular Tolerance | ±0.1° | ±0.05° | Between features |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined, no secondary finish |

These tolerances reflect our commitment to precision and are consistently maintained through environmental controls, tool wear monitoring, and process validation. At Wuxi Lead Precision Machinery, we combine advanced equipment, expert programming, and metrology-grade inspection to deliver plastic components that meet the most demanding engineering requirements.

Material & Finish Options

Precision Material Selection for CNC Machined Plastic Components

Selecting the optimal polymer is paramount for achieving dimensional accuracy, functional performance, and cost efficiency in CNC machined plastic parts. Unlike metals, plastics exhibit significant variations in thermal expansion, moisture absorption, and machinability, directly impacting precision outcomes. Wuxi Lead Precision Machinery leverages deep material science expertise to guide clients toward the ideal thermoplastic or thermoset resin for demanding applications across aerospace, medical, and semiconductor industries. Critical evaluation must extend beyond basic mechanical properties to include chemical resistance, electrical characteristics, biocompatibility, and thermal stability under operational loads. Misalignment between material behavior and part function inevitably leads to premature failure or costly rework.

Common engineering plastics require distinct machining strategies. High-performance polymers like PEEK demand rigid machine setups and specialized toolpaths to manage heat generation, while softer materials such as Nylon necessitate sharp tools and controlled feeds to prevent melting or burring. Material form (rod, sheet, tube) and inherent internal stresses also influence final part geometry. We rigorously validate material certifications and conduct pre-machining analysis to mitigate warpage risks, ensuring the as-machined component meets micron-level tolerances specified in your technical drawings.

The following table outlines key properties of frequently specified engineering plastics for precision CNC work:

| Material | Tensile Strength (MPa) | Max Continuous Temp (°C) | Key Advantages | Typical Applications |

|---|---|---|---|---|

| PEEK | 90-100 | 250 | Exceptional chemical/thermal resistance | Aerospace seals, medical implants |

| Acetal (POM) | 65-75 | 100 | Low friction, high stiffness, wear res. | Gears, bearings, precision gears |

| Polycarbonate | 65-75 | 135 | High impact strength, optical clarity | Enclosures, sight glasses |

| Nylon 6/6 | 75-85 | 120 | Toughness, abrasion resistance | Bushings, rollers, fasteners |

| PTFE | 20-35 | 260 | Lowest friction, chemical inertness | Seals, linings, insulators |

Surface finish selection profoundly affects part functionality and longevity. While anodizing is exclusive to metals, plastic components benefit from specialized treatments. Bead blasting provides uniform matte textures for glare reduction or improved grip. Chemical etching enhances paint or adhesive bonding on otherwise inert surfaces like PTFE. For ESD-sensitive environments, conductive carbon-filled polymers or applied coatings are essential. We collaborate closely with certified finishing partners to apply ISO-compliant treatments that meet stringent industry standards without compromising dimensional integrity. Avoid standard metal finishing references; plastic finishing requires polymer-specific processes.

Material choice is not merely a technical specification but a strategic decision impacting the entire product lifecycle. Wuxi Lead’s engineering team provides comprehensive material consultation, including DFM analysis and prototype validation, to ensure your plastic component performs reliably in its intended environment. Contact us to discuss your specific application requirements and leverage our 15+ years of precision polymer machining expertise.

Manufacturing Process & QC

The production process for high-precision CNC machined plastic parts at Wuxi Lead Precision Machinery follows a rigorously controlled sequence—Design, Prototyping, and Mass Production—engineered to achieve zero defects and ensure complete alignment with customer specifications. Each phase integrates advanced metrology, material science expertise, and real-time process validation to deliver components that meet the exacting demands of industries such as medical, aerospace, and semiconductor.

The process begins with Design, where our engineering team collaborates closely with clients to analyze part geometry, tolerances, material selection, and functional requirements. Utilizing CAD/CAM software and DFM (Design for Manufacturability) analysis, we optimize the design for CNC machining, identifying potential stress points, wall thickness issues, or tool access limitations early. Material compatibility is evaluated based on thermal stability, chemical resistance, and mechanical performance, with options including PEEK, PTFE, Ultem, Delrin, and polycarbonate. This phase ensures that the design is not only functional but also manufacturable with minimal waste and maximum repeatability.

Prototyping follows design finalization, serving as a critical validation step before full-scale production. Using 3-, 4-, or 5-axis CNC machines, we produce functional prototypes that mirror the final part in both geometry and material. These prototypes undergo full inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, first article inspection (FAI) documentation, and material certifications are provided to confirm compliance. Client feedback is incorporated at this stage, allowing for design refinement without impacting production timelines.

Upon approval, the process transitions to Mass Production, executed under a zero-defect quality management system. Each machine run is monitored using statistical process control (SPC), with real-time data collection on tool wear, spindle load, and dimensional drift. Automated in-process gauging ensures continuous adherence to tolerances, while 100% critical dimension checks are performed on high-risk features. Our cleanroom-compatible facilities and ISO 9001-certified workflows guarantee consistency across batches, from 10 to 10,000+ units.

The table below outlines key capabilities for CNC machining plastic parts:

| Specification | Capability |

|---|---|

| Tolerance | ±0.005 mm (±0.0002″) |

| Surface Roughness | Ra 0.4 µm to 3.2 µm (16–125 µin) |

| Maximum Part Size | 1200 × 800 × 500 mm |

| Minimum Wall Thickness | 0.5 mm (material-dependent) |

| Materials | PEEK, PTFE, Ultem (PEI), Delrin (POM), PC, PMMA, Nylon |

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Quality Standards | ISO 9001:2015, First Article Inspection, PPAP, SPC |

This end-to-end process ensures that every plastic component produced at Wuxi Lead meets the highest standards of precision, reliability, and performance—delivering zero-defect outcomes on every order.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Plastic Machining Excellence

In high-stakes industries like medical device manufacturing aerospace and semiconductor equipment the performance of plastic components directly impacts system reliability and regulatory compliance. Generic machining services cannot address the nuanced thermal stability dimensional stability and material science challenges inherent in engineering plastics. At Wuxi Lead Precision Machinery we engineer partnerships not transactions. Our dedicated engineering team collaborates from initial design review through final validation ensuring your plastic parts meet exact functional requirements while optimizing manufacturability and cost.

Our ISO 9001:2015-certified facility in Wuxi integrates 5-axis milling turning and Swiss-type capabilities with material-specific process protocols. We maintain stringent environmental controls to mitigate plastic warpage during machining and implement real-time in-process metrology using Zeiss CMMs and optical comparators. This systematic approach guarantees repeatability for critical features such as fluidic channels sealing surfaces and optical interfaces where micron-level deviations cause system failure.

The following table summarizes our core capabilities for precision plastic machining:

| Parameter | Specification | Supported Materials |

|---|---|---|

| Material Range | Engineering thermoplastics including PEEK PPSU Ultem UHMW PEI Acetal PTFE PMMA | Over 30 certified grades with full material traceability |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) standard; ±0.002 mm achievable for critical features | Validated per ASME Y14.5 for geometric tolerancing |

| Surface Finish | Ra 0.4 µm (16 µin) standard; optical-grade polishing to Ra 0.05 µm | Including ESD-safe and biocompatible finishes |

| Max Part Size | 600 x 400 x 300 mm (24″ x 16″ x 12″) | Complex geometries via 5-axis simultaneous machining |

| Lead Time | 10-15 days for prototypes; 20-25 days for production lots | Accelerated scheduling for urgent medical/aerospace needs |

We eliminate the guesswork in plastic part production through material-specific cutter path optimization cryogenic cooling for warp-sensitive polymers and post-machining stress-relief protocols. Our engineers provide DFM feedback within 24 hours identifying potential molding-to-machining transition risks or tolerance stack-up issues before cutting begins. This proactive collaboration reduces time-to-market by up to 30% while ensuring first-article approval rates exceed 98%.

When your application demands zero-defect performance in chemically resistant lightweight or electrically insulating components partner with a team that treats your specifications as engineering imperatives. Our technical account managers will connect you directly with our plastic machining specialists for a confidential design assessment. Contact us today to receive a detailed capability portfolio and schedule a facility tour via virtual or in-person consultation.

Initiate your precision plastic machining project with validated expertise. Email [email protected] with your part specifications and requirements. Our engineering team responds within 4 business hours to discuss material selection process validation and scalable production solutions tailored to your operational demands. Trust Lead Precision to transform engineering intent into flawless physical reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.