Technical Contents

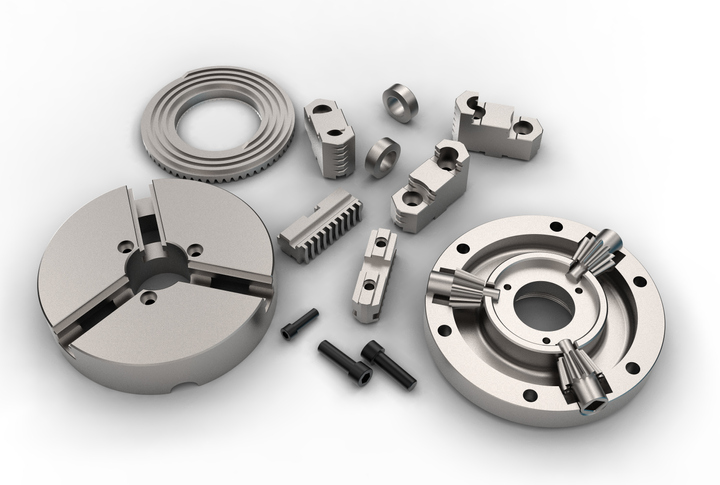

Engineering Guide: Cnc Machining Parts Usa

Engineering Insight: The Critical Role of Precision in CNC Machining Parts for the USA Market

In the high-stakes landscape of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries operating in aerospace, defense, medical technology, and high-performance automation across the United States, the demand for CNC machining parts with micron-level accuracy has never been greater. At Wuxi Lead Precision Machinery, we understand that when a component fails, the consequences extend far beyond the shop floor. This is why our engineering philosophy centers on uncompromising precision, backed by decades of experience delivering mission-critical components for applications where failure is not an option.

Our expertise has been rigorously tested in some of the most demanding environments imaginable. Wuxi Lead has contributed precision-machined components for projects aligned with Olympic-standard equipment and military-grade systems. These engagements required adherence to strict tolerances, rigorous material certifications, and full traceability—standards that mirror the expectations of U.S. manufacturers seeking dependable offshore partners. Whether producing lightweight titanium housings for unmanned aerial systems or high-torque aluminum transmission components for defense vehicles, our machining processes are engineered to meet and exceed ASTM, MIL-STD, and AS9100 requirements.

What sets true precision apart is not just the machinery, but the integration of process control, skilled craftsmanship, and advanced metrology. At our ISO-certified facility in China, we deploy state-of-the-art 5-axis CNC machining centers, coupled with real-time in-process inspection using coordinate measuring machines (CMM) and optical comparators. Every batch undergoes comprehensive dimensional analysis, surface finish verification, and material integrity testing—ensuring that each part shipped to the USA performs exactly as designed.

For American OEMs and Tier-1 suppliers, partnering with a manufacturer that understands the cultural and technical nuances of U.S. engineering standards is critical. Wuxi Lead bridges this gap with fluent technical communication, DFMA (Design for Manufacturing and Assembly) support, and rapid prototyping capabilities that align with agile development cycles common in U.S. innovation hubs.

Below are representative specifications that reflect our standard precision capabilities for CNC machining parts destined for the U.S. market:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 µm (adjustable) |

| Maximum Part Dimensions | 1200 x 800 x 600 mm |

| Minimum Achievable Tolerance | ±0.002 mm |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Brass, PEEK, Delrin |

| Standard Tolerances | ISO 2768-mK, or customer-specific GD&T |

| Quality Certification | ISO 9001, ISO 13485, MIL-STD-1312 (available on request) |

Precision is not an accident—it is engineered through discipline, experience, and an unwavering commitment to excellence. For U.S. clients seeking a trusted partner in CNC machining, Wuxi Lead Precision Machinery delivers not just parts, but performance assurance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for critical CNC machining parts serving the US market. Our advanced manufacturing ecosystem is engineered specifically to meet the stringent demands of aerospace, medical, defense, and high-tech industrial sectors where failure is not an option. Central to our capability is a robust fleet of state-of-the-art 5-axis CNC machining centers. These systems, featuring simultaneous 5-axis interpolation and high-torque spindles, enable the production of highly complex geometries in a single setup. This eliminates cumulative error from multiple fixtures, significantly enhancing part accuracy, surface finish, and overall integrity while reducing lead times. Our machines accommodate work envelopes up to 1200 x 800 x 750 mm, handling a diverse range of materials including aerospace-grade aluminum alloys, titanium, stainless steels, Inconel, and engineered plastics with equal proficiency.

Rigorous quality control is not an afterthought but the foundation of every process. Every critical dimension on every component undergoes meticulous verification using industry-standard Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, operating within a climate-controlled metrology lab, provide sub-micron repeatability and full traceability to NIST standards. This is complemented by in-process inspection using Renishaw probes on machining centers, ensuring deviations are identified and corrected in real-time. Comprehensive First Article Inspection Reports (FAIRs) and Production Part Approval Process (PPAP) documentation are standard deliverables, providing full transparency and adherence to AS9100 and ISO 13485 requirements where applicable.

Our commitment to dimensional excellence is quantifiable. We consistently achieve and verify the following tolerance capabilities across production runs, validated by our CMM infrastructure. These specifications represent our standard production capability for features within typical size ranges for the materials processed; tighter tolerances are achievable for specific applications upon engineering review.

| Feature Type | Standard Capability (Metric) | Standard Capability (Imperial) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.0002″ | Up to 100 mm / 4″ |

| ±0.012 mm | ±0.0005″ | 100-300 mm / 4-12″ | |

| ±0.025 mm | ±0.001″ | 300-600 mm / 12-24″ | |

| Geometric Tolerances | ±0.005 mm | ±0.0002″ | Flatness, Perpendicularity, Runout |

| ±0.010 mm | ±0.0004″ | Position, Profile (Complex Geometries) | |

| Surface Finish (Ra) | 0.4 µm (16 µin) | 16 µin | Typical machined finish |

| 0.2 µm (8 µin) | 8 µin | Achievable with fine finishing passes |

Material selection, part geometry complexity, and specific feature locations influence achievable tolerances. Our engineering team collaborates proactively with US clients during the Design for Manufacturability (DFM) phase to optimize designs for precision, cost-efficiency, and seamless integration into your supply chain. This integrated approach, combining cutting-edge 5-axis technology, NIST-traceable metrology, and deep process expertise, ensures Wuxi Lead delivers CNC machining parts that consistently meet or exceed the exacting standards required by the most demanding US industries. We provide not just components, but certified precision you can build upon.

Material & Finish Options

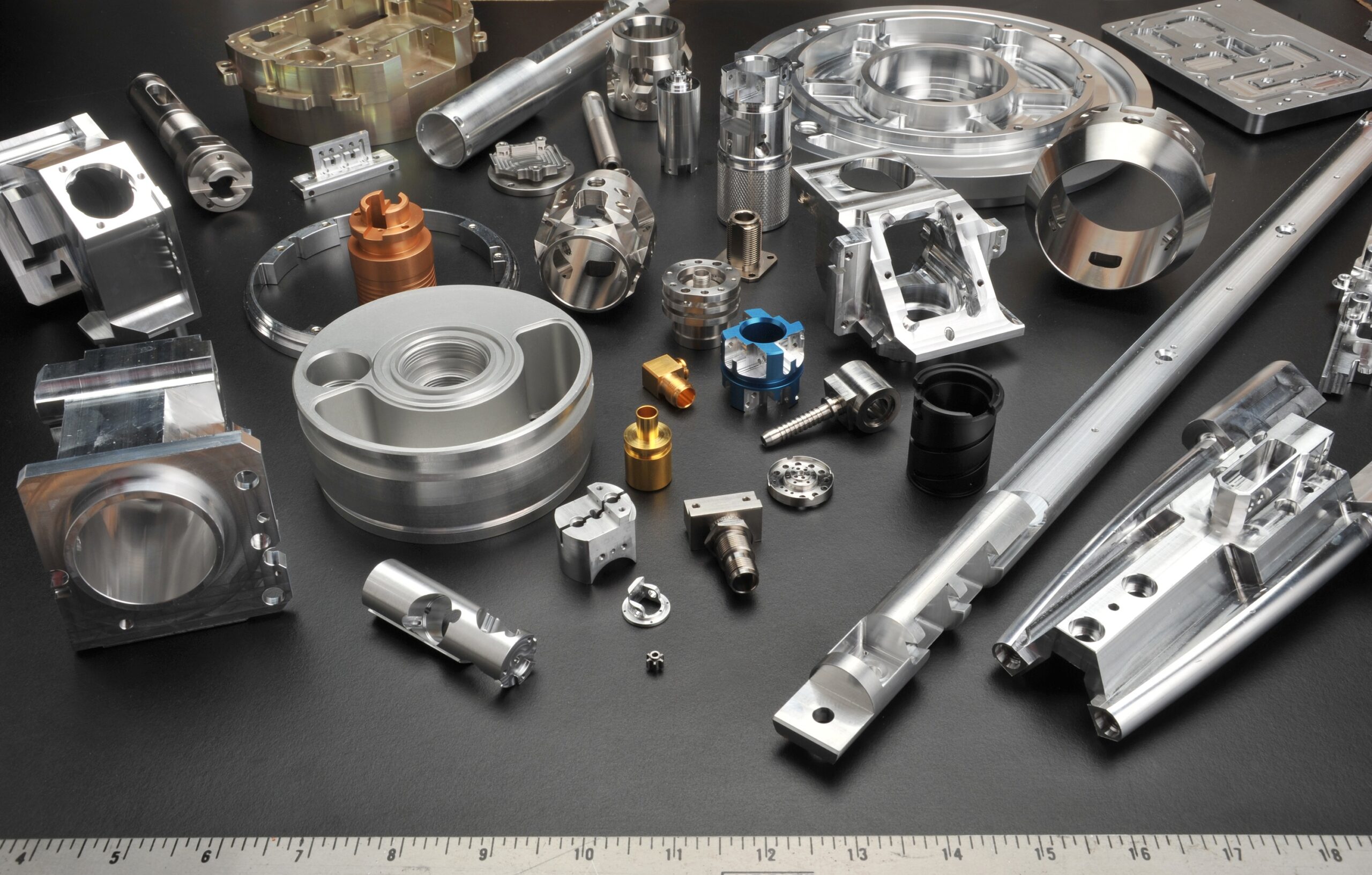

Material Selection for High-Precision CNC Machined Components

Selecting the appropriate material is critical in delivering CNC machined parts that meet performance, environmental, and longevity requirements. For industries such as aerospace, medical, automotive, and industrial automation, the choice between aluminum, steel, and titanium directly impacts part functionality, weight, strength, and cost-efficiency. At Wuxi Lead Precision Machinery, we guide our North American clients through optimal material selection based on application demands and design specifications.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly common in structural and prototype applications due to its weldability and moderate strength. For more demanding environments, 7075-T6 offers higher tensile strength, making it suitable for aerospace components. Aluminum’s natural oxide layer provides inherent corrosion protection, but when enhanced surface properties are required, anodizing is recommended.

Steel remains the standard for applications requiring high strength, wear resistance, and dimensional stability. 4140 and 4340 alloy steels are frequently used in high-stress mechanical systems, such as shafts and gears, due to their toughness and fatigue resistance. Stainless steel grades like 304 and 316 offer superior corrosion resistance, making them ideal for medical devices and food processing equipment. While heavier than aluminum, steel’s durability ensures long service life under extreme loads and temperatures.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an unmatched combination of high strength, low density, and exceptional resistance to heat and corrosion. It is the material of choice in aerospace, defense, and medical implant applications where weight reduction and biocompatibility are paramount. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s performance in aggressive environments justifies its use in mission-critical components.

Surface Finishing: The Role of Anodizing

Anodizing is a key post-machining process for aluminum parts, enhancing surface hardness, wear resistance, and aesthetic quality. Type II (sulfuric acid) anodizing provides a clear or dyed protective layer, while Type III (hardcoat anodizing) delivers a thicker, more durable finish suitable for industrial and aerospace applications. Anodized layers are electrically insulating and highly resistant to corrosion, making them ideal for components exposed to harsh environments.

Below is a comparative overview of key material properties for common CNC machining alloys.

| Material | Grade | Tensile Strength (MPa) | Density (g/cm³) | Key Properties | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Lightweight, corrosion resistant, weldable | Enclosures, brackets, prototypes |

| Aluminum | 7075-T6 | 570 | 2.8 | High strength, fatigue resistant | Aerospace, defense |

| Steel | 4140 | 655 | 7.85 | High toughness, wear resistant | Shafts, tooling, machinery |

| Stainless Steel | 316 | 580 | 8.0 | Corrosion resistant, biocompatible | Medical, marine, food processing |

| Titanium | Ti-6Al-4V | 950 | 4.43 | High strength-to-weight, heat resistant | Aerospace, implants, racing |

At Wuxi Lead Precision Machinery, we ensure material traceability, strict process control, and compliance with international standards. Our expertise in machining and finishing enables seamless delivery of high-performance components tailored to U.S. manufacturing demands.

Manufacturing Process & QC

Precision CNC Machining Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our CNC machining process for the US market is engineered for uncompromising quality and seamless integration into demanding supply chains. We adhere strictly to a three-phase methodology—Design, Prototyping, Mass Production—each stage fortified with rigorous quality controls to achieve zero defects. This structured approach ensures your precision components meet exacting aerospace, medical, and industrial specifications while minimizing time-to-market.

Design Phase

Our engineering team initiates collaboration during the conceptual stage, conducting thorough Design for Manufacturability (DFM) analysis. We identify potential machining constraints early, optimizing geometries for material efficiency and process stability. Using advanced CAD/CAM software (Siemens NX, Mastercam), we validate toolpaths, simulate cuts, and preemptively resolve collision risks. Critical tolerances, surface finishes, and material specifications are cross-referenced against AS9100 and ISO 13486 standards. This phase culminates in a finalized digital twin, approved by your engineering team, ensuring absolute alignment before physical production begins.

Prototyping Phase

Rapid prototyping transforms validated designs into tangible test articles within 7–10 days. We employ high-precision 5-axis milling and turning centers to produce functional prototypes mirroring final production conditions. Each prototype undergoes First Article Inspection (FAI) per AS9102 standards, with full CMM reporting and material certification. Dimensional accuracy, concentricity, and surface integrity are scrutinized against your blueprint. Client feedback drives immediate design iterations—no prototype is deemed approved until it passes your functional validation. This phase de-risks mass production by verifying process capability and component performance under real-world stress.

Mass Production Phase

Zero-defect mass production leverages statistical process control (SPC) and automated in-process inspection. Every machine cell operates under real-time monitoring: laser probes verify workpiece alignment before machining, while integrated sensors detect tool wear deviations exceeding 0.0002″. Critical dimensions are measured via coordinate measuring machines (CMM) after every 50 units, with Cp/Cpk values maintained above 1.67. All components undergo final 100% visual and dimensional inspection against your master drawing, with traceable material certs and heat-treat documentation. Non-conforming parts are quarantined via our closed-loop corrective action system—never reworked. Shipments include full inspection reports, ensuring seamless integration into your assembly line with zero incoming QC rejects.

Our process guarantees dimensional stability across volumes, as demonstrated in the core specifications below:

| Material Type | Standard Tolerances | Surface Finish (Ra) | Max Part Size (mm) |

|---|---|---|---|

| Aluminum Alloys | ±0.005 mm | 0.8 µm | 1200 x 800 x 600 |

| Stainless Steel | ±0.003 mm | 0.4 µm | 1000 x 600 x 500 |

| Titanium Alloys | ±0.005 mm | 0.8 µm | 800 x 500 x 400 |

Wuxi Lead delivers US-bound CNC machining parts with military-grade repeatability. Our process isn’t just about meeting drawings—it’s about embedding zero defects into every spindle rotation, ensuring your production line never stops. Partner with us for precision that accelerates your time-to-market while eliminating quality risk.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence in the USA

When sourcing high-precision CNC machining parts for demanding industrial applications, reliability, accuracy, and consistency are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical components that meet the exacting standards of U.S. manufacturers across aerospace, medical, automotive, and advanced industrial sectors. Our integrated manufacturing ecosystem combines cutting-edge CNC technology with rigorous quality assurance to ensure every part exceeds expectations.

Our strategic position in China does not compromise proximity or responsiveness. With optimized logistics, dedicated account management, and real-time project tracking, we provide U.S. clients seamless access to world-class manufacturing capabilities. Whether you require rapid prototyping, low-volume custom runs, or high-volume production, our flexible machining platforms adapt to your timeline and technical requirements.

We operate a full-spectrum CNC facility equipped with 3-axis, 4-axis, and 5-axis milling centers, precision turning, and multi-tasking machines capable of handling complex geometries with tight tolerances down to ±0.001 mm. Our materials expertise spans aluminum alloys, stainless steel, titanium, brass, PEEK, and engineered plastics—ensuring compatibility with functional and regulatory demands.

What sets Lead Precision apart is our commitment to partnership. We don’t just manufacture parts—we collaborate. From initial design review to final inspection, our engineering team works alongside yours to optimize manufacturability, reduce lead times, and lower total cost of ownership. Every component undergoes comprehensive dimensional verification using CMM, optical comparators, and surface roughness testers, with full traceability and documentation provided.

For U.S. businesses navigating supply chain volatility, we offer a stable, scalable alternative without sacrificing quality. Our ISO 9001-certified processes, combined with decades of precision machining experience, ensure that your components are produced with the highest level of control and consistency.

Explore how Wuxi Lead Precision Machinery can become your trusted offshore manufacturing partner. Contact us today at [email protected] to discuss your next project with our engineering team.

Key Technical Capabilities

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning, multi-axis milling/turning |

| Tolerances | ±0.001 mm (±0.00004 in) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Brass, PEEK, Delrin, and more |

| Surface Finishes | As-machined, anodizing (Type II, Type III), plating, passivation, polishing, powder coating |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, Full CMM reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Reach out to us at [email protected] and experience precision engineering without borders.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.