Technical Contents

Engineering Guide: Cnc Machining Online Quote

Engineering Insight: Precision as the Non-Negotiable Foundation of CNC Machining Online Quotes

In high-stakes industries like aerospace, defense, and medical device manufacturing, precision is not merely a specification—it is a mission-critical requirement. A superficial online quote that fails to interrogate geometric tolerances, material behavior, or thermal stability risks catastrophic downstream failures. At Wuxi Lead Precision Machinery, we recognize that an accurate CNC machining quote must originate from deep engineering validation, not automated algorithms alone. Our quoting process embeds rigorous tolerance stack analysis and material science expertise to preempt costly iterations. This philosophy stems from decades of delivering components where deviations of even 5 microns compromise functionality—such as titanium structural elements for Olympic-grade sporting equipment and classified defense subsystems demanding MIL-STD-810 compliance.

Generic online quoting tools often overlook how complex geometries interact with machine dynamics. For instance, thin-walled aerospace housings require adaptive feed-rate strategies to prevent chatter-induced dimensional drift, while medical implant threads demand sub-micron repeatability to ensure biocompatibility. Without direct engineer-to-engineer dialogue during quoting, these nuances remain unaddressed, leading to rejected first articles or production delays. Lead Precision circumvents this by integrating our manufacturing engineers into the initial RFQ review. Each quote includes a feasibility assessment validating GD&T callouts against our machine capabilities and process controls, ensuring the quoted tolerance is achievable—not theoretical.

Our heritage in mission-critical sectors directly informs this precision-first quoting methodology. Components we produced for the Beijing 2008 Olympic bobsled tracks operated under extreme cryogenic stress, while defense contracts required zero-defect certification for inertial navigation components. These experiences forged our uncompromising approach to dimensional integrity. The table below illustrates the baseline capabilities underpinning our quotes—capabilities rigorously maintained through daily laser calibration and thermal compensation protocols.

| Parameter | Specification | Verification Standard |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ISO 230-2 |

| Repeatability | ±0.001 mm | ISO 230-2 |

| Surface Roughness (Ra) | 0.2 µm | ISO 4287 |

| Maximum Work Envelope | Ø630 x 800 mm | Customizable |

| Material Compatibility | Titanium, Inconel, PEEK, 7075-T73 | ASTM/AMS Certified |

When requesting a CNC machining online quote, insist on transparency into the supplier’s metrology infrastructure and process validation rigor. At Lead Precision, every quote references our on-site Zeiss CONTURA CMMs and 24/7 process monitoring systems—proving capability beyond datasheets. We do not treat quotes as transactional endpoints but as engineering collaborations. This commitment ensures your design transitions seamlessly from CAD model to certified physical part, eliminating the hidden costs of precision compromises. For industries where failure is not an option, the quote must be the first testament to engineering excellence.

Precision Specs & Tolerances

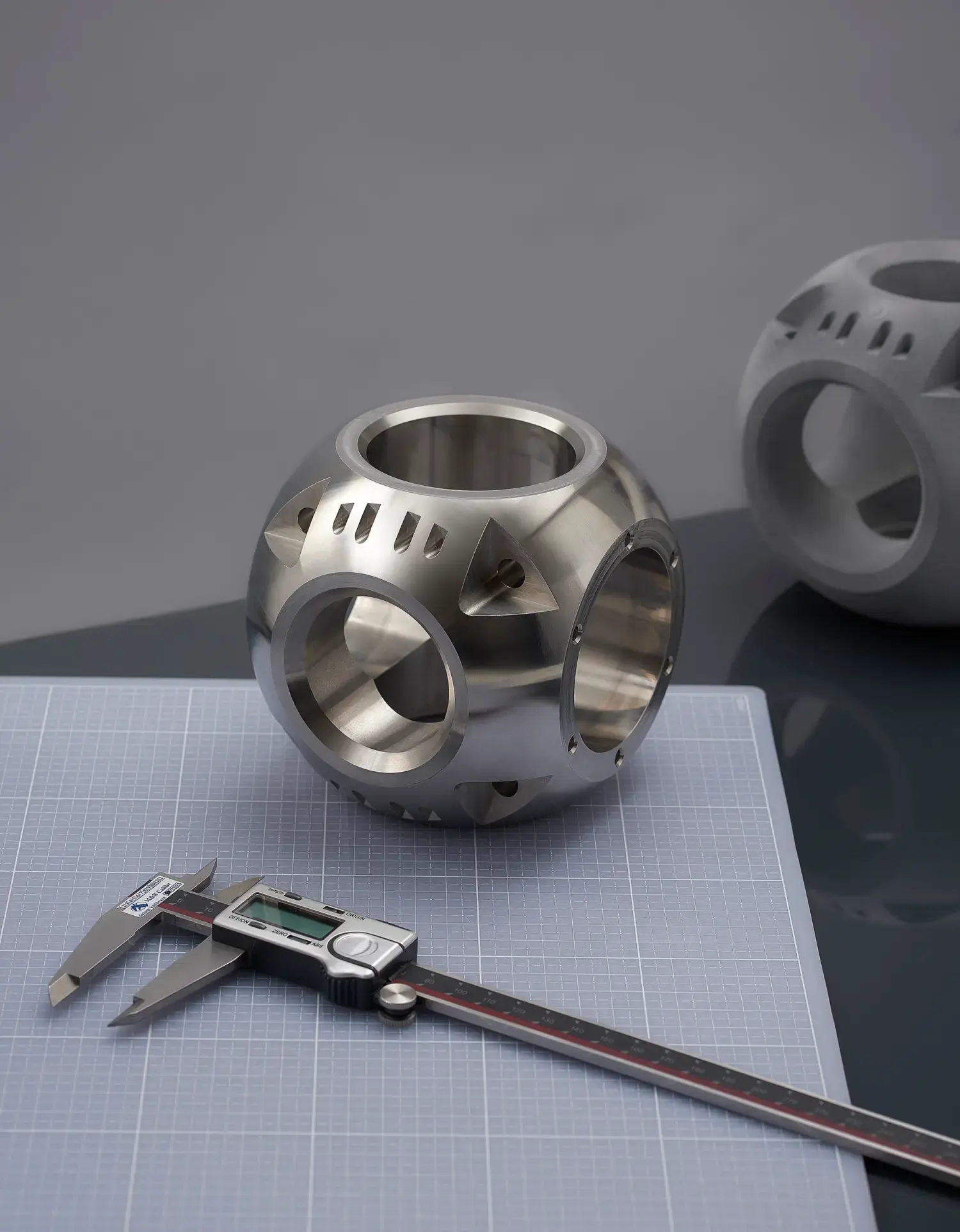

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered for high-complexity components across aerospace, medical, automotive, and industrial sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finish and dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across all five axes, minimizing setup cycles and eliminating cumulative errors associated with multiple fixturing stages. This results in faster lead times, improved part consistency, and the ability to machine deep cavities, undercuts, and organic contours that are otherwise unattainable.

Our machining fleet includes horizontal and vertical 5-axis CNC systems equipped with high-speed spindles, automatic tool changers, and real-time tool length verification. These features ensure continuous, unmanned operation while maintaining tight tolerances across extended production runs. Materials are handled with precision across a broad spectrum, including aluminum alloys, stainless steel, titanium, Inconel, brass, and engineering plastics such as PEEK and Delrin. Each job is supported by in-house CAD/CAM programming using industry-leading software, ensuring optimized toolpaths, reduced cycle times, and full digital traceability from quote to delivery.

Quality control is integrated at every stage of production. All critical dimensions are verified using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), providing micron-level inspection accuracy and full GD&T validation. Our CMM system supports both contact and optical probing, enabling non-destructive measurement of delicate features and complex freeform surfaces. Inspection reports are generated in compliance with ISO 9001 standards and can be customized to meet client-specific requirements, including First Article Inspection (FAI) and PPAP documentation.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm | Across all axes |

| Linear Dimensional Tolerance | ±0.05 mm | ±0.012 mm | Per ISO 2768-mK |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved via fine finishing passes |

| Hole Diameter Tolerance | H7 | H6 | Reamed or precision bored |

| Angular Tolerance | ±0.1° | ±0.05° | Verified with CMM and optical probes |

| Feature-to-Feature Alignment | ±0.02 mm | ±0.008 mm | Critical for multi-cavity components |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom upon request | For 5-axis machining centers |

All tolerances are achievable under controlled environmental conditions and are subject to material stability and part geometry. Our engineering team reviews every design during the quoting phase to identify potential manufacturability improvements and ensure that specified tolerances are both achievable and cost-effective. With full in-house tooling, metrology, and programming resources, Wuxi Lead Precision Machinery provides a seamless path from concept to certified production.

Material & Finish Options

Precision Material Selection for CNC Machining Quoting

Material choice fundamentally impacts part performance, manufacturability, and cost in CNC machining. Selecting the optimal alloy and finish during the online quote request stage prevents delays and ensures your precision components meet exacting functional requirements. At Wuxi Lead Precision Machinery, we require precise material specifications to generate accurate, competitive quotes for your project. Generic terms like “aluminum” or “steel” are insufficient; specific grades dictate machining parameters, tooling, and secondary processes.

Aluminum Alloys dominate aerospace, automotive, and electronics due to their excellent strength-to-weight ratio and machinability. 6061-T6 is the versatile workhorse for structural components, offering good corrosion resistance and weldability. For high-stress applications demanding superior strength, 7075-T6 is the aerospace-grade solution, though it presents greater machining challenges. Aluminum’s thermal conductivity also makes it ideal for heat sinks. Specify the exact alloy and temper (e.g., 6061-T6, 7075-T6) in your quote request to enable precise cost and lead time estimation.

Steel Alloys provide exceptional strength, durability, and wear resistance. Stainless steels like 303 (free-machining) and 304/L (general purpose corrosion resistance) are common for medical, food processing, and marine hardware. For high-strength structural or tooling applications, alloy steels such as 4140 or 4340 offer superior toughness but require specialized tooling and slower machining speeds, directly influencing cost. Always state the required grade and condition (e.g., 304 Annealed, 4140 Pre-hardened) to avoid quoting inaccuracies.

Titanium Alloys, primarily Grade 5 (Ti-6Al-4V), are critical for extreme environments demanding high strength, low weight, and exceptional corrosion resistance, especially in aerospace and medical implants. However, titanium’s low thermal conductivity and high chemical reactivity make it significantly more challenging and time-consuming to machine than aluminum or steel, substantially impacting cost. Quoting requires explicit confirmation of the titanium grade.

Anodizing is the predominant surface finish for aluminum, enhancing corrosion resistance, wear properties, and allowing color coding. Type II (Sulfuric Acid) anodizing provides standard corrosion protection and dyeing capability. Type III (Hardcoat) anodizing delivers a much thicker, harder, wear-resistant surface essential for high-friction parts. Specify the anodizing type, thickness requirement (e.g., Type II 15-25µm, Type III 50µm), and color if applicable during quoting, as this affects secondary processing time and cost.

Material selection directly correlates with machining complexity and cost. The table below summarizes key properties influencing manufacturability and quoting:

| Material | Key Grades | Tensile Strength (MPa) | Primary Applications |

|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 570 | Aerospace structures, heat sinks, enclosures |

| Stainless Steel | 303, 304/L, 17-4PH | 500, 515, 1000+ | Medical devices, valves, marine hardware |

| Alloy Steel | 4140, 4340 | 655, 745 | Shafts, gears, high-stress tooling |

| Titanium | Ti-6Al-4V (Grade 5) | 900 | Aircraft components, medical implants |

Provide the exact material grade, condition, and required finish specifications within your Wuxi Lead online quote request. This precision allows our engineering team to immediately assess manufacturability, select optimal toolpaths and parameters, and deliver a technically sound, cost-competitive quotation for your precision CNC machining project. Omitting these details necessitates clarification rounds, delaying your project timeline.

Manufacturing Process & QC

From Design to Mass Production: The Wuxi Lead Precision Machining Process

At Wuxi Lead Precision Machinery, our production workflow is engineered for precision, repeatability, and zero-defect outcomes. We specialize in high-end CNC machining services for global B2B clients in aerospace, medical, automotive, and industrial automation sectors. Our process follows a disciplined progression from design validation through prototyping to full-scale mass production, ensuring every component meets exacting technical and quality standards.

The journey begins with design analysis. Our engineering team reviews customer CAD models and technical drawings to assess manufacturability, material selection, tolerances, and surface finish requirements. We conduct a comprehensive Design for Manufacturing (DFM) evaluation to identify potential issues early, recommend optimizations, and ensure cost-efficiency without compromising performance. This phase is critical in preventing downstream errors and minimizing rework.

Once the design is finalized, we proceed to prototyping. Using 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes that mirror the final product in geometry, material, and precision. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. This allows us to verify dimensional accuracy, fit, and performance under real-world conditions. Client feedback is incorporated at this stage, enabling rapid iteration before committing to mass production.

With prototype approval, we transition seamlessly into high-volume manufacturing. Our facility in Wuxi is equipped with over 120 CNC machines, including automated pallet systems and robotic loading for 24/7 continuous operation. Production runs are managed under strict ISO 9001:2015 and IATF 16949 quality systems, with real-time process monitoring and Statistical Process Control (SPC) to maintain consistency. Every batch is traceable, with full documentation of material certificates, inspection reports, and process parameters.

Zero defects is not a goal—it is our standard. We enforce multi-stage quality gates: incoming material inspection, in-process checks at critical stages, and 100% final inspection for high-risk features. Non-conforming parts are immediately quarantined and analyzed using root cause corrective action (RCCA) protocols. This systematic approach ensures that every component shipped meets or exceeds customer specifications.

Wuxi Lead combines advanced technology, disciplined process control, and deep engineering expertise to deliver precision-machined parts with unmatched reliability. Whether producing a single prototype or managing a million-part annual volume, our process guarantees consistency, speed, and quality.

Key Production Capabilities

| Parameter | Specification |

|---|---|

| CNC Machining Types | 3-axis, 4-axis, 5-axis milling, turning |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.4 μm to 3.2 μm (custom finishes available) |

| Materials Supported | Aluminum, stainless steel, titanium, brass, PEEK, Delrin, and engineered plastics |

| Max Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Production Capacity | Up to 500,000 units annually per product line |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP, APQP, SPC |

| Lead Time (Prototype) | 7–15 days (express options available) |

| Lead Time (Mass Production) | 20–35 days depending on complexity and volume |

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

Selecting a CNC machining partner transcends transactional quoting; it demands a strategic alliance grounded in engineering excellence and unwavering reliability. At Wuxi Lead Precision Machinery, we engineer partnerships for global enterprises where dimensional accuracy, material integrity, and on-time delivery are non-negotiable. Our ISO 9001-certified facility in Wuxi, China, operates at the convergence of advanced multi-axis technology and rigorous quality control, ensuring every component meets aerospace, medical, and industrial OEM specifications. We transform complex 3D CAD models into mission-critical parts with engineered tolerance compliance down to ±0.005mm, eliminating supply chain vulnerabilities through vertical integration and real-time process validation.

Core Capabilities Driving Your Success

Our infrastructure supports the most demanding precision applications. The table below details our primary machining platforms and their performance envelope:

| Machine Type | Axis Configuration | Max Travel (X/Y/Z) | Positioning Accuracy | Key Material Capabilities |

|---|---|---|---|---|

| 5-Axis Milling | 5+2 Rotary | 1200 x 800 x 600mm | ±0.003mm | Titanium, Inconel, PEEK, Hardened Steels |

| High-Speed Milling | 3-5 Axis | 1500 x 1000 x 750mm | ±0.005mm | Aluminum Alloys, Magnesium, Composites |

| Precision Turning | 2-4 Axis (Y-axis) | Ø400 x 500mm | ±0.002mm | Stainless Steel, Brass, Plastics |

| Swiss-Type Lathes | 7-12 Axis | Ø32 x 200mm | ±0.001mm | Medical Implants, Micro-Components |

Unlike automated online quote systems that prioritize speed over feasibility, our engineering team conducts proactive manufacturability analysis during quotation. We identify potential secondary operation risks, material waste reduction opportunities, and fixture optimization—delivering not just a price, but a validated production pathway. This preemptive engineering review reduces time-to-prototype by 30% and prevents costly revisions in serial production. All processes are monitored via SPC (Statistical Process Control) with full traceability from raw material certification to final inspection reports, including CMM, optical comparator, and surface roughness data.

Your Next Step in Precision Execution

The true value of a machining partnership emerges when technical challenges arise. Wuxi Lead Precision Machinery provides dedicated engineering support from RFQ through volume production, ensuring design intent is preserved at every machining stage. Our clients gain direct access to application specialists fluent in GD&T, material science, and high-mix/low-volume production economics—no call centers, no language barriers. When your project requires more than a quote, it demands a precision collaborator.

Initiate your precision workflow today. Email detailed drawings and requirements to [email protected]. Our engineering team will respond within 4 business hours with a comprehensive technical quotation, process plan, and lead time commitment—not an automated estimate. Partner with the precision standard in Chinese manufacturing, where every micron is engineered with purpose.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.