Technical Contents

Engineering Guide: Cnc Machining Machine

Engineering Insight Precision as the Non-Negotiable Foundation of CNC Machining

In high-stakes manufacturing, precision transcends mere specification; it defines functional integrity, safety, and ultimate product success. For aerospace components operating under extreme stress, medical implants interfacing with the human body, or critical defense systems, dimensional deviations measured in microns can trigger catastrophic failure. The CNC machining machine is not merely a tool but the physical embodiment of engineering intent. Its ability to consistently achieve and maintain sub-micron tolerances across complex geometries under real-world shop floor conditions separates capable suppliers from indispensable partners. True precision demands more than a rigid machine structure; it requires integrated thermal management, advanced motion control, rigorous calibration protocols, and deep process expertise to mitigate variables like tool deflection, material instability, and environmental fluctuation. This level of control is non-negotiable when the cost of error extends far beyond scrap metal.

Wuxi Lead Precision Machinery operates at this critical threshold. Our engineering philosophy is forged in the demanding environments of Olympic timing systems and military-grade components, where absolute reliability is mandated. For the Beijing Winter Olympics, our CNC machining processes delivered timing sensor housings requiring 0.0005mm positional accuracy across multi-axis features – tolerances exceeding standard commercial requirements by an order of magnitude. Similarly, precision-machined structural elements for advanced defense platforms demand not only micron-level conformity but also documented traceability and zero-defect performance under rigorous qualification testing. These projects are not exceptions; they are the benchmark against which we calibrate every capability. They validate our machine fleet’s inherent stability, our thermal compensation systems’ effectiveness, and our engineers’ mastery of process refinement. This experience translates directly to client value: confidence that complex components will perform identically in assembly and in operation, cycle after cycle.

Our commitment is quantifiable through the core specifications enabling this precision. The following table details the performance envelope of our flagship multi-axis machining centers, engineered specifically for mission-critical applications:

| Specification Category | Performance Metric | Significance for Mission-Critical Work |

|---|---|---|

| Positioning Accuracy (ISO 230-2) | ±0.0015 mm over 500 mm travel | Ensures feature location integrity across large work envelopes |

| Repeatability (ISO 230-2) | ±0.0008 mm | Guarantees consistent output batch-to-batch |

| Thermal Growth Compensation | < 2 µm/°C ambient fluctuation (full travel) | Maintains accuracy during extended production runs |

| Spindle Runout (at tool nose) | ≤ 0.0005 mm (TIR) | Critical for fine surface finishes and tight bore tolerances |

| Control System Resolution | 0.0001 mm (Nanometer interpolation) | Enables ultra-smooth contouring of complex organic shapes |

Achieving this standard requires moving beyond basic machine capability. It demands a holistic approach where machine tool engineering, environmental control, metrology validation, and operator expertise converge. At Wuxi Lead Precision Machinery, we engineer this convergence daily. Our facility is built upon the proven requirement that in precision CNC machining, the machine is only the starting point; the relentless pursuit of dimensional truth defines the entire process. This is the standard demanded by the most exacting global industries, and it is the standard we deliver.

Precision Specs & Tolerances

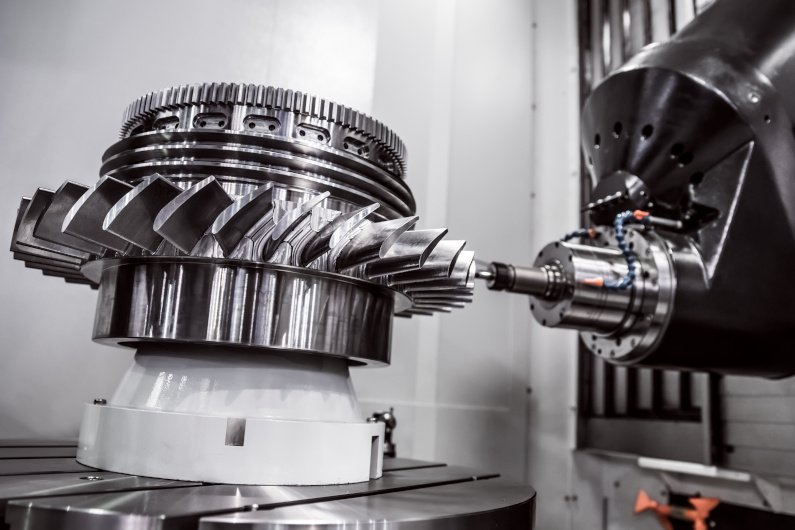

Wuxi Lead Precision Machinery delivers advanced precision CNC machining solutions tailored for high-complexity, mission-critical components across aerospace, medical, energy, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce intricate geometries with exceptional accuracy and surface integrity. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across X, Y, Z, and two rotational axes (A and B), dramatically expanding design freedom and reducing the need for multiple setups. This results in shorter lead times, improved part consistency, and superior dimensional control.

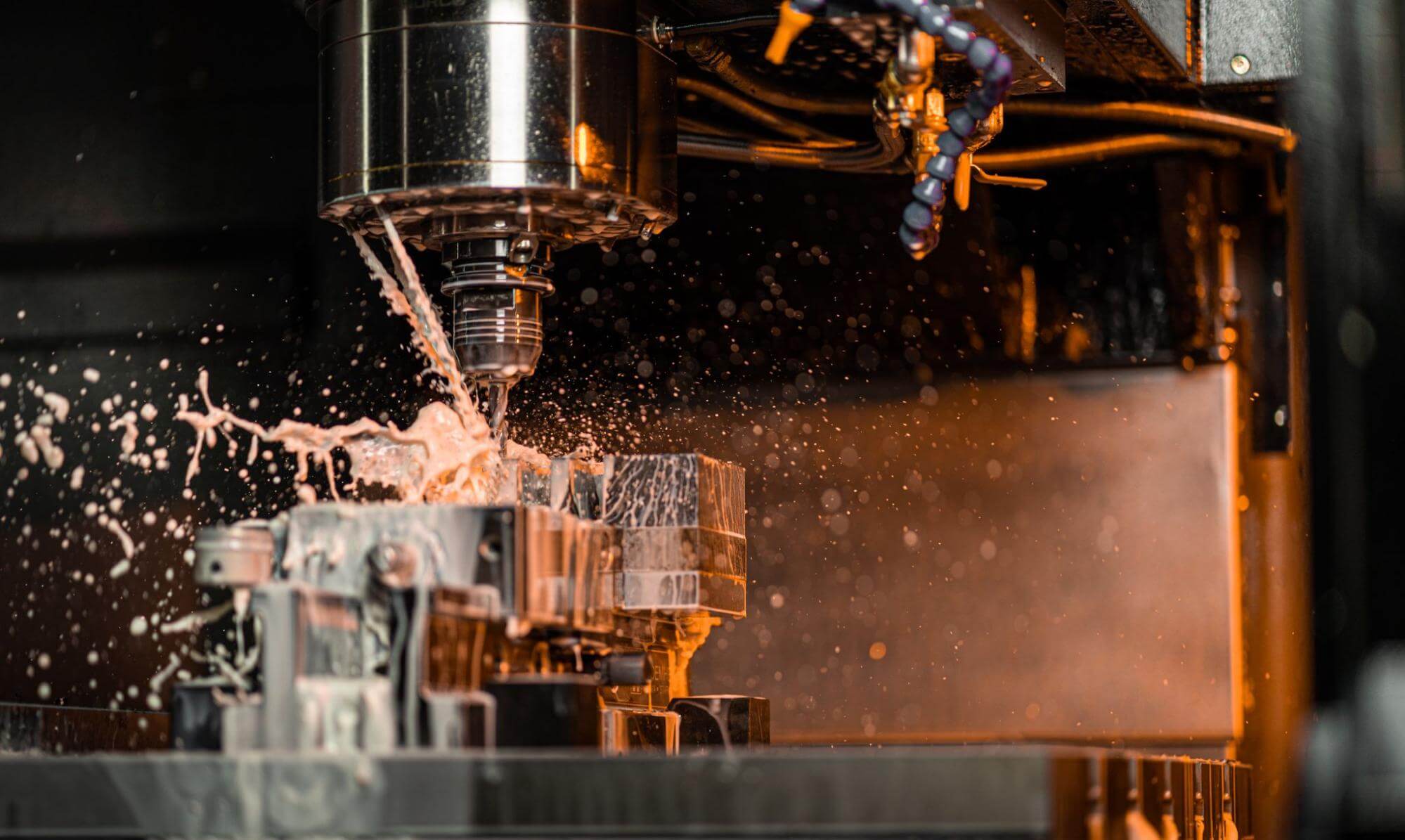

Our machining centers are equipped with high-speed spindles, automatic tool changers, and advanced coolant systems to maintain thermal stability during extended production runs. These features ensure optimal cutting performance across a wide range of materials, including titanium alloys, Inconel, aluminum, stainless steel, and high-performance engineering plastics. The integration of adaptive machining strategies and real-time tool monitoring further enhances process reliability and minimizes non-productive time.

To uphold the highest standards of quality, every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM) with a probing system capable of micron-level measurement resolution. Our CMM cells are operated by certified metrology technicians and supported by PC-DMIS software, enabling full first-article inspection (FAI) reporting and statistical process control (SPC) data tracking. Dimensional verification includes critical features such as positional tolerances, geometric deviations, surface profiles, and thread accuracy, ensuring full compliance with ASME Y14.5 and ISO GPS standards.

We maintain a climate-controlled inspection environment to eliminate thermal drift, and all measurement equipment is calibrated traceable to national standards (NIST equivalent). In addition to post-machining inspection, we implement in-process gauging and first-piece approval protocols to detect and correct deviations early, minimizing scrap and rework.

The following table outlines our standard machining capabilities and achievable tolerances under controlled conditions:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope (5-axis) | 1200 mm × 800 mm × 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (per ISO 2768-m) | ±0.05 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | 0.02 mm / 100 mm |

| Typical Surface Roughness (Ra) | 0.8 μm (machined), down to 0.2 μm (with finishing) |

| Standard Tolerance (Machined Features) | ±0.01 mm |

| Precision Tolerance (Tight Clearance/Fits) | ±0.005 mm |

| Minimum Wall Thickness (Aluminum/Steel) | 0.5 mm |

| Minimum Hole Diameter | 0.3 mm (drilled), 0.1 mm (EDM) |

These capabilities are continuously validated through internal audits, customer-specific PPAP submissions, and third-party quality certifications. At Wuxi Lead Precision Machinery, technical excellence is not just measured in microns—it is embedded in every process, machine, and team member dedicated to precision.

Material & Finish Options

Strategic Material Selection for Precision CNC Machined Components

Material choice fundamentally impacts the performance, cost, and manufacturability of CNC machined parts. At Wuxi Lead Precision Machinery, we guide clients through critical trade-offs between mechanical properties, environmental resistance, and machining efficiency. Aluminum, steel, and titanium dominate aerospace, medical, and industrial applications, each offering distinct advantages. Selecting the optimal alloy requires alignment with functional requirements, regulatory standards, and lifecycle costs.

Aluminum alloys, particularly 6061-T6 and 7075-T6, deliver an exceptional strength-to-weight ratio and thermal conductivity. These non-ferrous metals excel in heat-sensitive applications like heat sinks, drone frames, and automotive brackets. Their low density reduces shipping costs and energy consumption in moving assemblies. While highly machinable, aluminum’s softness necessitates sharp tooling and controlled feeds to prevent burring or built-up edge. Anodizing is frequently specified to enhance surface hardness, corrosion resistance, and aesthetic uniformity. Type II (sulfuric acid) anodizing provides standard protection, while Type III (hardcoat) yields thicker, wear-resistant layers up to 50–100µm for military or aerospace components.

Carbon and stainless steels (e.g., 4140, 304, 316) are selected when ultimate strength, wear resistance, or magnetic properties are critical. Stainless grades 304 and 316 dominate medical and food processing equipment due to superior corrosion resistance from chromium and molybdenum content. Machining steel demands robust tooling and stable setups to manage higher cutting forces and heat generation compared to aluminum. Post-machining processes like passivation or electropolishing are often essential for stainless parts to maximize corrosion resistance in sterile environments.

Titanium Grade 5 (Ti-6Al-4V) is the aerospace and biomedical material of choice for extreme strength-to-weight ratios and biocompatibility. Its resistance to fatigue and corrosion in saline environments makes it ideal for surgical implants and marine components. However, titanium’s low thermal conductivity and chemical reactivity challenge machining efficiency, requiring lower RPMs, specialized carbide tools, and aggressive coolant application to prevent work hardening and galling.

The following table summarizes key properties and applications for common CNC machining materials:

| Material | Key Properties | Typical Applications | Machinability Rating |

|---|---|---|---|

| Aluminum 6061-T6 | Lightweight, high thermal conductivity, weldable | Enclosures, brackets, heat sinks | Excellent |

| Steel 304/316 | High strength, corrosion-resistant (stainless), magnetic (304) | Medical instruments, valves, shafts | Good (304), Moderate (316) |

| Titanium Grade 5 | Extreme strength-to-weight, biocompatible, corrosion-proof | Aircraft components, implants | Moderate |

Material selection directly influences tool life, cycle time, and final part quality. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to optimize cutting parameters, tool paths, and post-processing for each alloy. We collaborate with clients during the design phase to balance performance targets with manufacturability, ensuring cost-effective production of mission-critical components. Consult our engineering team to validate your material and finish specifications against real-world production constraints.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for uncompromising precision, consistency, and quality. Rooted in decades of advanced CNC machining expertise, our workflow follows a disciplined progression: Design, Prototyping, and Mass Production—each stage governed by strict protocols to achieve zero defects and optimal performance for high-end industrial clients.

Design begins with a deep collaboration between our engineering team and the client. Utilizing advanced CAD/CAM software, we transform conceptual requirements into detailed 3D models and technical drawings. Finite element analysis (FEA) and geometric dimensioning and tolerancing (GD&T) are applied to ensure structural integrity and functional accuracy. Every design is reviewed for manufacturability, material compatibility, and compliance with international standards such as ISO 2768 and ASME Y14.5. This phase establishes the foundation for precision, minimizing risk before any material is cut.

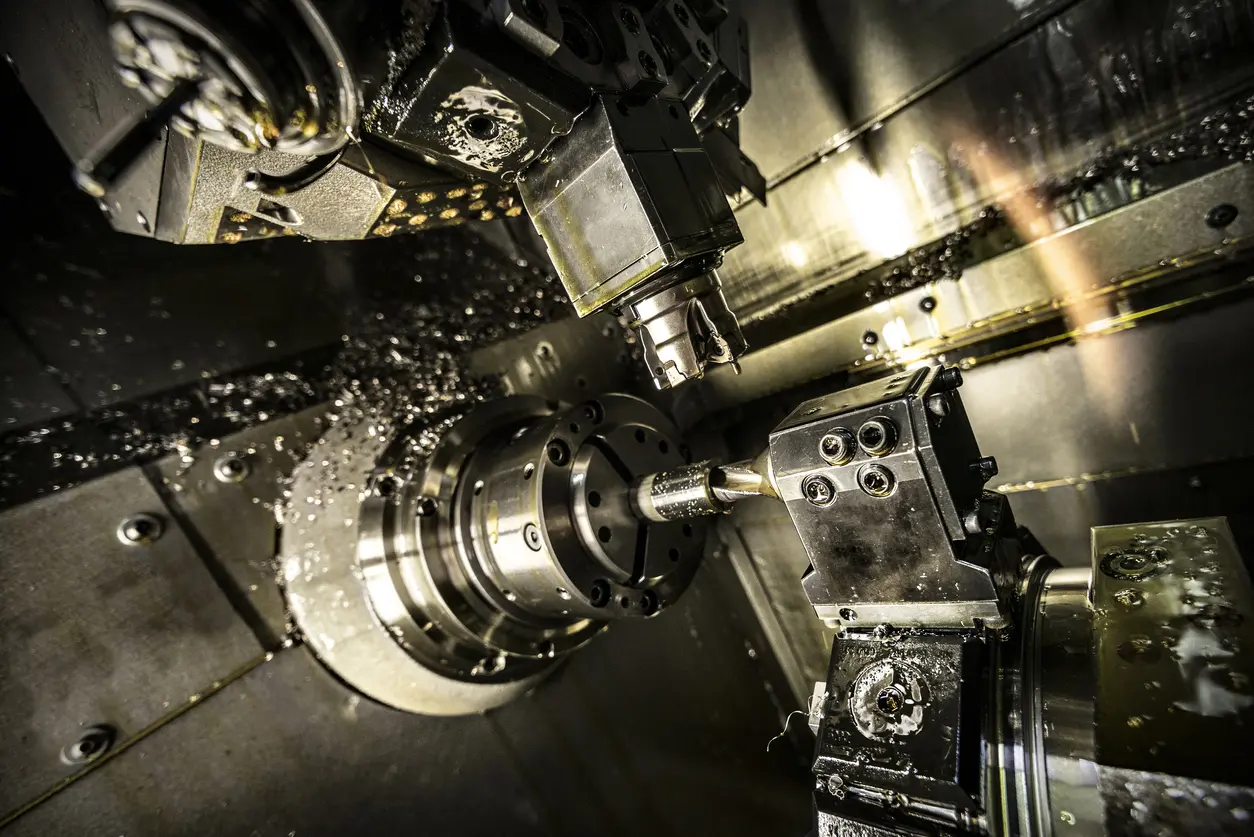

Prototyping follows with the creation of a functional sample using the same CNC machining centers intended for full-scale production. This ensures process consistency and enables real-world validation of form, fit, and function. We employ 5-axis milling, precision turning, and multi-axis grinding to replicate final production conditions. The prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, material properties, and surface finish are verified against design specifications. Feedback from this stage is integrated into final process optimization, ensuring readiness for mass production.

Mass Production is executed on our fully automated CNC machining lines, where process control is maintained through real-time monitoring and statistical process control (SPC). Each machine operates under standardized tooling, fixturing, and cutting parameters, with automated in-process gauging to detect deviations instantly. Our production floor is certified to ISO 9001:2015, and every component is traceable through serialized lot tracking. Final inspection includes 100% critical dimension checks and random sampling for non-critical features, ensuring every part meets the zero-defect standard.

We specialize in high-mix, low-to-medium volume production, serving industries where failure is not an option—medical, aerospace, semiconductor, and automation. Our integrated approach eliminates silos between design, validation, and manufacturing, delivering precision-engineered components with unmatched reliability.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| CNC Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (milling) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanners, Roughness Tester |

| Production Volume Range | Prototype to 10,000 units/year |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), AS9100 (aerospace) |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Capabilities Through Strategic Partnership

At Wuxi Lead Precision Machinery, we recognize that selecting a CNC machining partner is a critical strategic decision impacting product quality, time-to-market, and operational efficiency. Our commitment extends beyond delivering precision-machined components; we integrate as an extension of your engineering and production teams to solve complex manufacturing challenges. With 15 years of specialization in high-tolerance CNC machining for aerospace, medical, and energy sectors, we consistently achieve sub-micron repeatability and zero-defect batch production. Our ISO 9001:2015 and AS9100D certified facility in Wuxi, China, operates 42 state-of-the-art CNC centers under stringent environmental controls, ensuring your components meet the most demanding global standards. Partnering with us means accessing not just machinery, but engineered manufacturing intelligence.

Our technical capabilities are engineered for mission-critical applications. Below are core specifications defining our machining excellence:

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | ±0.005 mm |

| Repeatability | 0.0005 mm | 0.002 mm |

| Max Work Envelope | 2000 x 1200 x 1000 mm | 1500 x 1000 x 800 mm |

| Spindle Speed Range | 20 – 24,000 RPM | 20 – 15,000 RPM |

| Surface Finish (Ra) | 0.1 – 0.8 µm | 0.8 – 1.6 µm |

| Material Compatibility | Titanium, Inconel, PEEK, Tool Steels | Standard Alloys |

This precision translates directly to your bottom line through 30% reduced scrap rates, 25% faster prototyping cycles, and seamless scalability from 1-off prototypes to 50,000-unit production runs. Our engineers collaborate during your design phase to optimize manufacturability, preventing costly revisions and accelerating certification processes. Unlike transactional suppliers, we implement dedicated project management with real-time production visibility via our secure client portal, ensuring complete transparency from raw material traceability to final inspection documentation.

The next-generation components driving your industry forward demand manufacturing partners who operate at the bleeding edge of precision. Wuxi Lead Precision Machinery delivers this through continuous investment in Siemens-controlled 5-axis milling, Swiss-type turning, and multi-tasking platforms paired with metrology-grade CMM validation. Your success is our operational imperative—whether resolving thermal distortion in thin-walled aerospace manifolds or achieving biocompatible finishes for surgical implants.

Initiate your precision advantage today. Contact our engineering team directly at [email protected] to schedule a technical consultation. Include your component drawings or performance requirements, and we will provide a detailed capability analysis within 24 business hours. Let us demonstrate how our partnership approach transforms machining challenges into competitive differentiators. Your precision journey starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.