Technical Contents

Engineering Guide: Cnc Machining Engineer

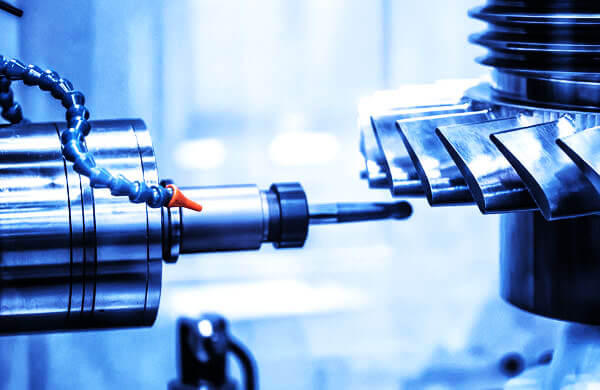

Engineering Insight: The Critical Role of Precision in CNC Machining

In the world of high-performance manufacturing, precision is not merely a specification—it is a standard. For CNC machining engineers, achieving micron-level accuracy is both a technical challenge and a professional imperative. At Wuxi Lead Precision Machinery, we understand that the integrity of a final product—whether it powers a military system or supports an Olympic-grade athletic structure—hinges on the exactness of every cut, bore, and contour. Precision defines reliability, safety, and performance in mission-critical applications.

Our engineering team operates at the forefront of CNC technology, leveraging advanced multi-axis machining centers, real-time in-process inspection, and rigorous quality assurance protocols. Every component we produce undergoes stringent dimensional validation, ensuring conformity to ISO 2768 and AS9100 standards. This level of control is non-negotiable, especially when serving sectors where failure is not an option. Our work with Olympic infrastructure projects demanded flawless repeatability in load-bearing components, where even a 5-micron deviation could compromise structural performance under dynamic stress. Similarly, our contributions to defense and aerospace programs required adherence to MIL-STD specifications, where environmental resilience and dimensional stability are paramount.

The role of the CNC machining engineer extends beyond programming and setup. It involves material science insight, thermal compensation modeling, toolpath optimization, and continuous process refinement. At Lead Precision, our engineers utilize high-resolution CMMs (Coordinate Measuring Machines), laser interferometers, and 3D scanning to validate tolerances and surface finishes. We specialize in machining exotic alloys such as Inconel 718, titanium Ti-6Al-4V, and hardened tool steels—materials that demand not only precision but also deep metallurgical understanding to avoid warping, residual stress, or microstructural degradation.

Our experience in high-stakes environments has reinforced a core principle: precision is not achieved by equipment alone, but by the synergy between skilled engineering and advanced technology. From initial design for manufacturability (DFM) analysis to final inspection, our process is engineered for consistency, traceability, and excellence.

Precision Machining Capabilities at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Tolerance Range | ±0.003 mm to ±0.01 mm (standard) |

| Surface Finish (Ra) | 0.2 µm to 1.6 µm (polished to machined) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK, Tool Steels |

| Quality Standards | ISO 9001, AS9100, ISO 2768, MIL-STD-810 |

| In-Process Inspection | Laser Probing, On-Machine Measurement |

| Post-Processing Verification | CMM, 3D Scanning, Roughness Tester |

At Wuxi Lead Precision Machinery, precision is engineered into every component. Our CNC machining engineers are not just operators—they are precision architects, shaping the future of advanced manufacturing one micron at a time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

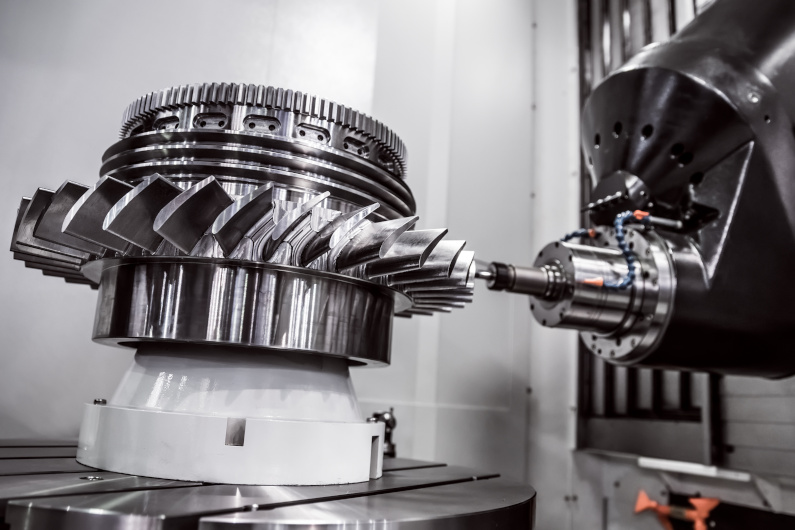

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions centered on high-accuracy CNC machining, specifically engineered to meet the stringent requirements of aerospace, medical, energy, and advanced industrial sectors. Our core competency lies in transforming complex, high-value components from challenging materials with unwavering consistency and precision. This capability is fundamentally enabled by our investment in cutting-edge multi-axis technology and rigorous, integrated quality control systems operating within a controlled Class 100,000 cleanroom environment.

Our primary production platform consists of state-of-the-art 5-axis simultaneous CNC machining centers from industry-leading manufacturers. These machines feature high-torque spindles, thermal compensation systems, and advanced linear motor drives, enabling the precise execution of intricate geometries in a single setup. This eliminates cumulative error from multiple fixtures, significantly reduces lead times, and ensures superior part integrity. We routinely machine complex contours, deep cavities, undercuts, and organic shapes in materials ranging from high-strength titanium alloys and Inconel to aluminum, stainless steel, and engineered plastics. The integrated probing systems on these machines provide real-time in-process verification, ensuring dimensional accuracy is maintained throughout the machining cycle before the part leaves the machine envelope.

Quality assurance is not a final step but an intrinsic, continuous process at Wuxi Lead. Every critical dimension and feature undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMMs). Our metrology lab houses multiple high-precision CMMs equipped with tactile and optical probes, capable of full 3D scanning and GD&T analysis to the most demanding specifications. Data from these inspections is meticulously documented and traceable, providing complete transparency and validation against customer engineering drawings and international standards (AS9100, ISO 13485). This closed-loop system, combining advanced machining with metrology-grade inspection, guarantees that every component shipped meets or exceeds the specified tolerances and functional requirements.

The achievable precision across our production spectrum is demonstrated in the tolerance specifications below. These values represent our standard production capability for critical features under controlled conditions; tighter tolerances are achievable for specific applications through process optimization and dedicated metrology protocols.

| Material Category | Feature Type | Standard Tolerance Capability |

|---|---|---|

| Aluminum Alloys | Linear Dimensions | ±0.005 mm (±0.0002″) |

| Titanium Alloys | Linear Dimensions | ±0.008 mm (±0.0003″) |

| Stainless Steel | Linear Dimensions | ±0.008 mm (±0.0003″) |

| All Materials | Hole Diameter (Reamed) | ±0.005 mm (±0.0002″) |

| All Materials | Geometric Tolerances (GD&T) | 0.010 mm (0.0004″) |

This documented precision, coupled with our mastery of 5-axis machining strategies and uncompromising CMM-based quality validation, ensures Wuxi Lead consistently produces components where form, fit, and function are non-negotiable. We partner with engineering teams to translate demanding designs into reality, delivering reliability essential for mission-critical applications.

Material & Finish Options

Material selection is a foundational decision in precision CNC machining, directly influencing part performance, manufacturability, and total cost of ownership. At Wuxi Lead Precision Machinery, we guide engineering teams through data-driven material choices tailored to application demands. Aluminum, steel, and titanium represent the core structural metals used in high-performance industries such as aerospace, medical devices, and automation. Each offers distinct mechanical and thermal properties, and understanding their behavior under load, temperature, and environmental exposure is critical for long-term reliability.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are widely favored for their excellent strength-to-weight ratio, corrosion resistance, and machinability. These alloys are ideal for lightweight structural components, housings, and heat sinks where weight reduction is paramount. Aluminum’s high thermal and electrical conductivity further broadens its utility in electronics and thermal management systems. When surface durability is required, anodizing—especially Type II and Type III (hard coat)—is the preferred finish. Anodizing builds a protective oxide layer that enhances wear and corrosion resistance while allowing for color coding and improved adhesion for paints or primers.

Steel, especially 4140 and 1018 grades, delivers superior tensile strength, hardness, and wear resistance. It is the material of choice for high-load applications such as shafts, tooling, and structural brackets. While heavier than aluminum, steel provides dimensional stability under extreme stress and is easily welded, plated, or heat-treated to meet exacting specifications. Finishing options include zinc plating, passivation, and powder coating, depending on environmental exposure requirements.

Titanium, primarily Grade 5 (Ti-6Al-4V), offers an exceptional combination of high strength, low density, and outstanding resistance to corrosion—particularly in saline or high-temperature environments. It is extensively used in aerospace, marine, and medical implant applications. However, titanium’s low thermal conductivity and high chemical reactivity pose machining challenges, requiring specialized tooling, reduced cutting speeds, and rigorous process control. Surface treatments such as acid etching or laser marking are common, though anodizing is also applied for both functional and aesthetic purposes.

The following table summarizes key mechanical properties and finishing compatibility for these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Finishes | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Anodizing, Powder Coating | Enclosures, Heat Sinks, Frames |

| Aluminum 7075-T6 | 572 | 2.8 | Hard Anodizing, Plating | Aerospace Components, High-Stress Parts |

| Steel 4140 | 655 | 7.85 | Zinc Plating, Heat Treatment | Shafts, Tooling, Structural Parts |

| Steel 1018 | 440 | 7.87 | Passivation, Painting | Low-Stress Components, Fabrications |

| Titanium Ti-6Al-4V | 900 | 4.43 | Anodizing, Acid Etching | Medical Implants, Jet Engines |

At Wuxi Lead, our engineering team collaborates closely with clients to match material and finish selections with functional requirements, environmental conditions, and lifecycle expectations. Through precision CNC machining and process optimization, we ensure every component meets the highest standards of performance and reliability.

Manufacturing Process & QC

Precision Production Process: From Design to Zero Defect Mass Production

At Wuxi Lead Precision Machinery, achieving true zero defects is not an aspiration; it is the foundational requirement embedded within every phase of our precision CNC machining workflow. We rigorously execute a closed-loop process spanning Design, Prototyping, and Mass Production, ensuring uncompromising quality for demanding aerospace, medical, and semiconductor applications. This integrated approach eliminates downstream errors and guarantees part perfection from the first production run.

The process begins with meticulous Design collaboration. Our engineering team conducts in-depth Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis alongside the client. We identify potential geometric conflicts, material limitations, and fixture challenges early, leveraging advanced CAD/CAM simulation to validate toolpaths and prevent collisions. Critical tolerances, surface finishes, and material specifications are explicitly defined and agreed upon, forming the immutable quality baseline. This proactive engineering phase prevents approximately 80% of potential production defects before metal is cut.

Prototyping is our critical validation stage, far exceeding simple sample creation. Utilizing the exact production-grade 5-axis DMG MORI and Makino machining centers intended for volume work, we manufacture functional prototypes under identical process parameters. Every dimension undergoes comprehensive CMM inspection against the master CAD model, with full GD&T reporting. Material properties, thermal stability, and functional performance are rigorously tested. Crucially, this phase validates the entire process capability, not just the part geometry. Any deviation triggers immediate root cause analysis and process refinement, ensuring the production protocol is perfected before launch. This stage confirms our ability to consistently meet the strictest specifications.

Mass Production deployment leverages the fully validated process under stringent statistical process control (SPC). Real-time in-process monitoring tracks critical parameters like tool wear, spindle load, and thermal drift. Automated part probing verifies key features after critical operations, feeding data directly into our SPC system. Every component undergoes 100% final inspection against the approved prototype documentation using calibrated Zeiss CMMs and optical comparators. Our integrated quality management system ensures traceability from raw material batch to finished part, with all data archived for full auditability. Zero defects are achieved through this relentless focus on process control and verification at every single step.

The following table outlines the critical parameters and verification methods ensuring zero defects across each phase:

| Process Phase | Critical Parameter | Target Value | Verification Method |

|---|---|---|---|

| Design | Geometric Feasibility | 100% DFM Compliance | CAD Simulation & Engineering Sign-off |

| Design | Tolerance Rationalization | Achievable ±0.002mm | Tolerance Stack-up Analysis |

| Prototyping | Dimensional Accuracy | Within Specified GD&T | CMM Full Report (AS9102) |

| Prototyping | Process Capability (Cpk) | ≥1.67 | SPC Data from Prototype Run |

| Mass Production | In-Process Dimensional Stability | ±0.001mm | On-Machine Probing & SPC Charts |

| Mass Production | Final Part Conformance | Zero Non-Conformances | 100% CMM Final Inspection Report |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that precision is not just a standard—it’s a requirement. As a global leader in high-end CNC machining, we specialize in delivering complex, tight-tolerance components for industries where failure is not an option. From aerospace and medical devices to semiconductor and energy systems, our engineering team combines decades of experience with cutting-edge technology to bring your most demanding designs to life.

Our commitment begins with partnership. When you collaborate with Lead Precision, you’re not just outsourcing a machining task—you’re gaining a technical extension of your own engineering department. Our CNC machining engineers work closely with your team from concept through production, offering Design for Manufacturability (DFM) feedback, rapid prototyping, and scalable production solutions tailored to your exact specifications. We utilize multi-axis CNC milling, turning, wire EDM, and grinding technologies, all supported by advanced metrology equipment to ensure every part meets the highest standards of accuracy and repeatability.

We pride ourselves on transparency, responsiveness, and technical rigor. Our facility in Wuxi, China, operates under strict ISO 9001 and IATF 16949 quality management systems, ensuring consistent process control and traceability. Whether you require low-volume prototypes or high-volume production runs, we maintain the flexibility and capacity to meet your deadlines without compromising quality.

Below are key technical capabilities that define our precision machining services:

| Specification | Detail |

|---|---|

| Machining Processes | 3-axis to 5-axis CNC milling, CNC turning, multi-spindle machining, wire EDM, surface & cylindrical grinding |

| Tolerances | As tight as ±0.001 mm (±0.00004″) |

| Materials | Aluminum (6061, 7075), stainless steel (303, 304, 316, 17-4 PH), titanium (Grade 5), brass, PEEK, Delrin, and exotic alloys |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finishes | From raw machined to mirror polish; anodizing, passivation, plating, and coating options available |

| Quality Assurance | CMM, vision inspection, roughness testers, 100% first-article inspection, PPAP and FAIR support |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

Every project at Lead Precision is treated with the highest level of engineering scrutiny. Our team speaks your language—literally and technically—with fluent English-speaking engineers available for direct communication, time-zone-aligned project updates, and real-time collaboration.

If you’re looking for a CNC machining partner that combines technical depth, manufacturing precision, and responsive service, the next step is clear. Contact us today at [email protected] to speak with one of our senior CNC engineering specialists. Let’s turn your design challenges into precision solutions—efficiently, reliably, and with uncompromising quality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.