Technical Contents

Engineering Guide: Cnc Machining Basics

Precision in CNC Machining: The Foundation of High-Performance Manufacturing

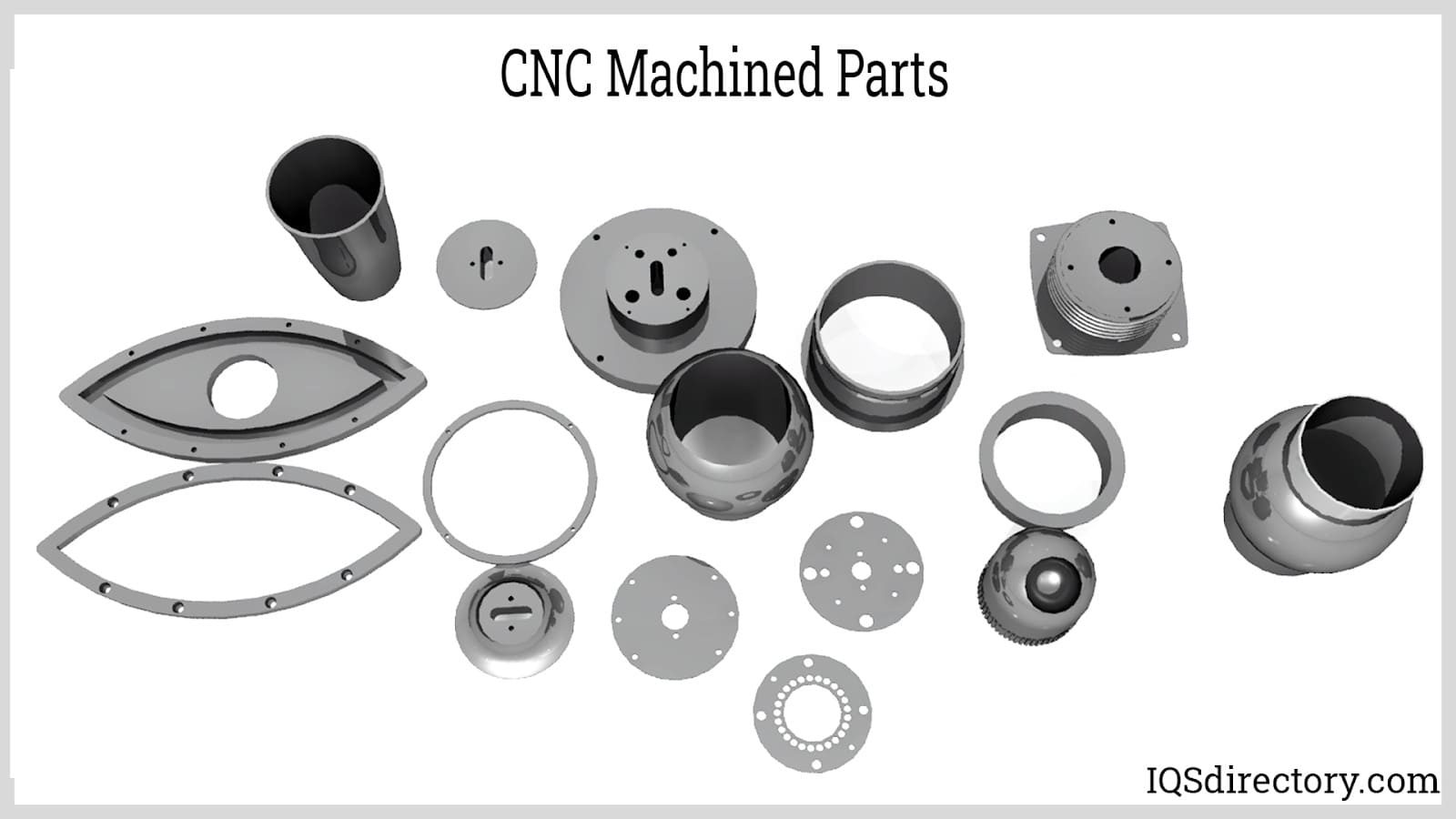

In the world of advanced manufacturing, precision is not merely a goal—it is a requirement. At Wuxi Lead Precision Machinery, we understand that the success of complex engineering systems hinges on the exactness of every machined component. CNC (Computer Numerical Control) machining forms the backbone of modern precision manufacturing, enabling the production of parts with tight tolerances, superior surface finishes, and exceptional repeatability. This level of accuracy is critical across industries such as aerospace, defense, medical technology, and high-performance automotive systems.

CNC machining operates by translating digital design data—typically from CAD (Computer-Aided Design) models—into precise machine instructions. These instructions guide cutting tools with micron-level accuracy, removing material from a workpiece to achieve the desired geometry. The process supports a wide range of materials, including aluminum alloys, stainless steel, titanium, and engineering plastics, making it indispensable for prototyping and high-volume production alike.

What separates true precision machining from standard fabrication is consistency. A single part must match its digital twin within tolerances as tight as ±0.005 mm. Such consistency ensures seamless integration into larger assemblies, reduces wear and failure rates, and enhances overall system performance. In mission-critical applications—such as components used in military hardware or Olympic-grade sporting equipment—even the smallest deviation can compromise safety, efficiency, or competitive advantage.

Wuxi Lead Precision Machinery brings over two decades of expertise in delivering such levels of precision. Our engineering team has supported projects requiring the highest standards, including components for Olympic athletic equipment and subsystems used in defense applications. These projects demand not only technical excellence but also rigorous quality control, traceability, and documentation—all of which are embedded in our manufacturing protocols.

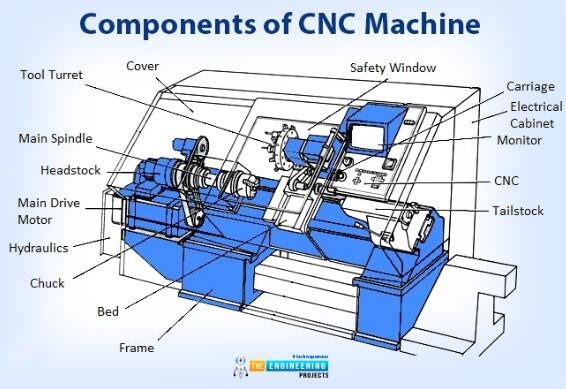

Our facility is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, allowing us to produce complex geometries with minimal setup changes. Coupled with in-process inspection systems and post-machining metrology using coordinate measuring machines (CMM), we ensure every part meets or exceeds client specifications.

The following table outlines typical capabilities at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Spindle Speed Range | Up to 24,000 rpm |

| Tolerance Range | ±0.01 mm (standard), ±0.005 mm (high) |

| Surface Finish (Ra) | 0.8–3.2 µm (standard), down to 0.4 µm |

| Materials Processed | Aluminum, Steel, Stainless Steel, Titanium, Brass, Engineering Plastics |

Precision is not an add-on—it is engineered into every stage of production. At Wuxi Lead Precision Machinery, we combine advanced technology, strict process controls, and deep engineering insight to deliver CNC-machined components that perform under the most demanding conditions. Whether supporting innovation in elite sports or national defense, our commitment to excellence remains unwavering.

Precision Specs & Tolerances

Technical Capabilities: Precision Beyond Standard Machining

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions centered on high-precision 5-axis CNC machining and rigorous quality control. Our technical foundation is built to meet the exacting demands of aerospace, medical, energy, and complex industrial components where dimensional accuracy and geometric complexity are non-negotiable. We operate a modern fleet of multi-tasking 5-axis CNC machining centers, including DMG MORI CMX and Makino D-Series platforms. These machines feature simultaneous 5-axis interpolation, enabling the production of intricate contours, deep cavities, and organic shapes in a single setup. This capability significantly reduces part handling errors, improves surface finish consistency, and achieves critical positional tolerances unattainable with 3-axis systems. Our programming leverages advanced CAM software (Mastercam, Siemens NX) to optimize toolpaths for maximum efficiency and surface integrity, while high-precision spindles and thermal compensation systems ensure stability during extended production runs.

Quality assurance is integrated at every stage, not merely a final checkpoint. All critical dimensions undergo verification using state-of-the-art Coordinate Measuring Machines (CMM), including Hexagon GLOBAL and Leitz PMM-C systems. Our CMM inspection protocol follows ASME Y14.5 and ISO 1101 standards, providing full geometric dimensioning and tolerancing (GD&T) validation with traceable NIST-certified reports. Statistical Process Control (SPC) methodologies are applied to key characteristics, ensuring process capability (Cp/Cpk) meets or exceeds customer requirements. Material certifications, first-article inspection (FAI) reports per AS9102, and comprehensive dimensional data packages are standard deliverables, guaranteeing full traceability and compliance with stringent industry regulations.

Our machining capabilities consistently achieve tight tolerances across diverse materials including titanium, Inconel, stainless steels, aluminum alloys, and engineering plastics. The following table details our standard achievable tolerance ranges for critical features under controlled production conditions. Note that specific tolerances are always confirmed during the engineering review phase based on part geometry, material, and functional requirements.

| Feature Type | Standard Tolerance Range | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Up to 300 mm; tighter over shorter lengths |

| Geometric (Flatness) | 0.025 mm (0.001″) | 0.005 mm (0.0002″) | Per ISO 2768-mK / ASME Y14.5 |

| Geometric (Roundness) | 0.012 mm (0.0005″) | 0.0025 mm (0.0001″) | Cylindrical features |

| Positional (Holes) | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Relative to datum; simultaneous 5-axis |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) | As-machined; post-process can improve |

These specifications represent our core production capability under optimal conditions. Achieving the tightest tolerances requires collaborative design for manufacturability (DFM) analysis. We partner with clients early in the development cycle to optimize part geometry, material selection, and fixture strategy, ensuring manufacturability without compromising performance. Contact our engineering team to discuss specific project requirements and receive a detailed capability assessment for your critical components. Wuxi Lead Precision Machinery transforms complex designs into reality with uncompromising precision.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical step in the CNC machining process, directly influencing part performance, durability, cost, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC machining of engineering-grade metals, with aluminum, steel, and titanium being among the most commonly specified materials for industrial applications. Each offers distinct mechanical properties and responds differently to machining and finishing processes such as anodizing.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061 and 7075 are commonly used in aerospace, automotive, and consumer electronics due to their corrosion resistance and weldability. Aluminum is particularly well-suited for high-speed machining, allowing for tight tolerances and complex geometries. It is also highly compatible with anodizing, a surface treatment that enhances wear and corrosion resistance while allowing for color customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with hardcoat providing superior durability for industrial components.

Steel, particularly alloy and stainless variants like 4140 and 304/316, offers superior strength, hardness, and resistance to wear and deformation under load. These properties make steel ideal for structural components, tooling, and applications requiring long-term reliability in harsh environments. While more challenging to machine than aluminum due to higher tool wear and cutting forces, modern CNC systems equipped with carbide tooling and optimized parameters can achieve excellent surface finishes and dimensional accuracy. Stainless steels also offer inherent corrosion resistance, though secondary treatments such as passivation may be applied for enhanced performance.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments where strength, lightweight, and resistance to high temperatures and corrosion are paramount. Commonly used in aerospace, medical implants, and high-performance automotive sectors, titanium presents unique machining challenges due to its low thermal conductivity and tendency to gall. Successful CNC machining of titanium requires rigid setups, controlled feed rates, and specialized cooling strategies to prevent work hardening and tool failure.

The following table summarizes key properties and machining characteristics of these materials:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Typical Applications | Compatible Finishes |

|---|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310–570 | 2.7 | Excellent | Aerospace, electronics, enclosures | Anodizing (Type II/III), powder coat |

| Steel | 4140, 304, 316 | 500–900 | 7.8 | Moderate to Good | Tooling, structural parts | Passivation, plating, painting |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1,170 | 4.5 | Challenging | Aerospace, medical, motorsports | Anodizing, plasma spray, polishing |

Understanding the interplay between material properties, machining parameters, and surface treatments ensures optimal performance and cost-efficiency. At Wuxi Lead Precision Machinery, we work closely with clients to select the right material and finish combination tailored to the functional and environmental demands of their applications.

Manufacturing Process & QC

Precision CNC Production: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our production process is engineered for one uncompromising outcome: Zero Defects. This requires a rigorously controlled sequence from initial design through to high-volume manufacturing, eliminating errors before they reach the shop floor. We integrate advanced planning with real-time verification at every phase, ensuring your components meet exact specifications consistently.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the CAD stage, scrutinizing geometry, material selection, and tolerances. We identify potential machining challenges early—such as thin walls, complex undercuts, or stringent surface finishes—and propose optimized solutions. This proactive review prevents costly revisions later and ensures the design is inherently suited for high-precision CNC execution. Concurrently, we develop a comprehensive process plan detailing toolpaths, fixture strategies, and critical inspection points, establishing the blueprint for defect prevention.

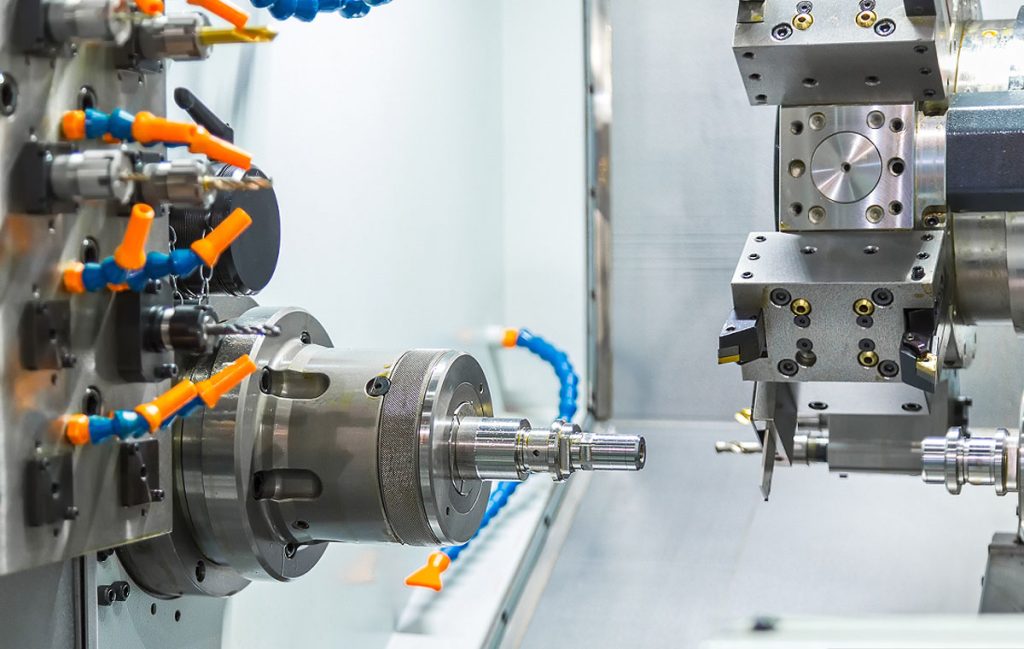

Prototyping is not merely a validation step; it is the critical proving ground for our Zero Defects system. Using the same high-accuracy CNC centers (5-axis mills, turning centers) intended for production, we manufacture initial parts under controlled conditions. Every prototype undergoes exhaustive first-article inspection against the original CAD model using calibrated CMMs and optical comparators. Dimensional accuracy, surface integrity, and material properties are verified against the tightest specified tolerances. Process parameters are fine-tuned based on this data, and statistical process control (SPC) baselines are established. Only when prototypes consistently meet all requirements do we proceed.

Mass Production leverages the validated process with unwavering discipline. Our automated production cells operate under continuous closed-loop verification. In-process probing with Renishaw systems checks critical features mid-machining, automatically compensating for tool wear or thermal drift. Post-machining, 100% critical dimensions are verified via SPC charts, with non-critical features sampled per AQL standards. Real-time data from machine sensors and inspection equipment feeds into our centralized quality management system, triggering immediate containment if any parameter drifts outside control limits. This relentless focus on process stability, not just final inspection, is how we achieve true Zero Defects output at scale.

The table below summarizes key process parameters and verification methods across phases:

| Parameter | Prototyping Phase | Mass Production Phase | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.005 mm (maintained) | CMM, Optical Comparator |

| Surface Finish (Ra) | 0.4 µm (as specified) | 0.4 µm (controlled) | Profilometer, Visual Inspection |

| Critical Feature Check | 100% First Article | 100% In-Process Probing | Machine-Integrated Touch Probes |

| Process Stability | SPC Baseline Established | Real-Time SPC Monitoring | Statistical Control Charts |

| Material Verification | Certificates + Lab Test | Batch Certificates + Spot Check | Material Test Reports (MTRs) |

This seamless integration of design insight, prototype validation, and statistically controlled mass production forms the core of Wuxi Lead’s Zero Defects commitment. We transform complex requirements into flawless physical components, de-risking your supply chain and ensuring absolute confidence in every part delivered.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-end manufacturing. As a globally recognized leader in CNC machining, we specialize in delivering custom-engineered components with micron-level accuracy, supporting industries ranging from aerospace and medical devices to energy and automation. When you partner with Lead Precision, you are not just sourcing parts—you are gaining a strategic manufacturing ally committed to quality, innovation, and on-time delivery.

Our state-of-the-art facility in Wuxi, China, is equipped with advanced multi-axis CNC machining centers, high-speed milling systems, and precision turning equipment. Combined with our ISO 9001:2015-certified quality management system, this enables us to handle complex geometries, tight tolerances, and a wide range of engineering materials—from aluminum and stainless steel to titanium and high-performance alloys. Our engineering team collaborates closely with clients from prototype development through full-scale production, ensuring design optimization, cost efficiency, and rapid turnaround.

We pride ourselves on transparency, technical expertise, and responsive service. Whether you require low-volume precision prototypes or high-volume serial production, our agile manufacturing model adapts to your project’s scale and timeline. Our in-house capabilities include CNC milling, CNC turning, grinding, EDM, and comprehensive inspection using CMM, optical comparators, and surface finish testers—ensuring every component meets the highest standards of dimensional accuracy and surface integrity.

To illustrate our core capabilities, the following table outlines key technical specifications we routinely achieve:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Surface Roughness | Ra 0.2 – 1.6 µm (adjustable) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Minimum Feature Size | 0.1 mm (milling), 0.2 mm (turning) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, PEEK, Delrin, and more |

| Tolerances | IT6 to IT8 (ISO 286-1) |

| Production Capacity | Prototypes to 50,000+ units annually |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, SPC |

Partnering with Wuxi Lead Precision Machinery means access to a vertically integrated supply chain, real-time production tracking, and dedicated engineering support—all designed to reduce lead times and mitigate risk. We speak your language, literally and technically, with fluent English-speaking project managers and engineers ready to collaborate across time zones.

Take the next step toward precision manufacturing excellence. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual tour of our facility. Let Lead Precision be the foundation of your next high-performance component.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.