Brief Overview of CNC Machining in Aerospace Manufacturing and China’s Aerospace Industry

CNC Aerospace Machining

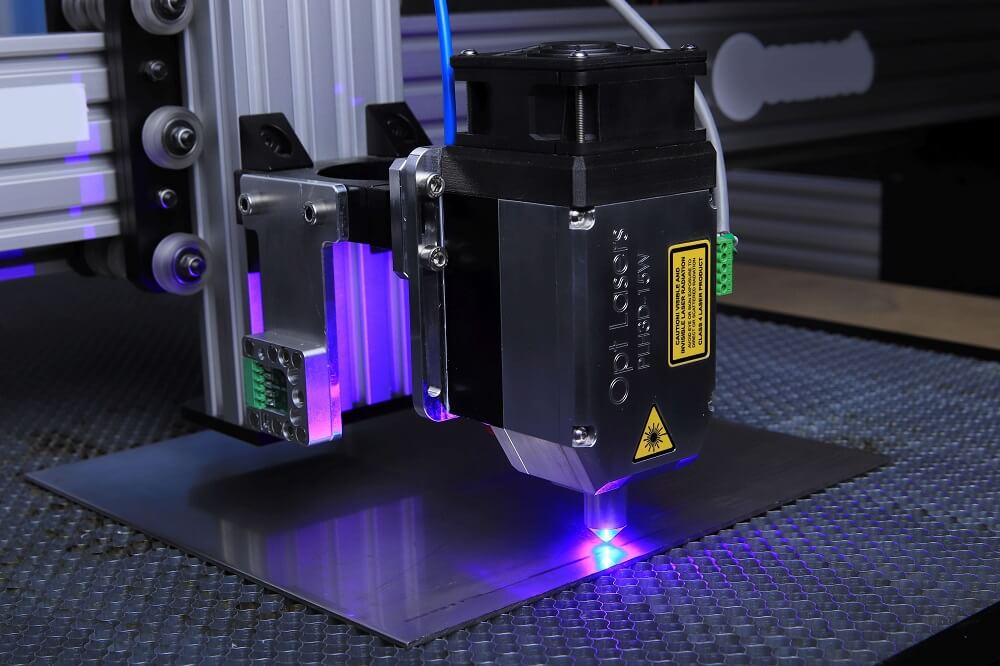

CNC machining, also known as Computer Numerical Control machining, is a manufacturing procedure that employs computerised controls and automated machinery to fabricate intricate and accurate parts and components in the manufacturing industry. This machining assumes a crucial role in multiple facets of the aerospace components production process.

The Importance of CNC Machining in Aerospace Manufacturing and China’s Involvement in the Success

High-Quality and Accurate Parts

The primary reason why CNC machining is essential in the aerospace industry is its ability to produce components with exceptional quality and precision. The aerospace industry needs parts that are very precise and have complicated designs. CNC machining is good at making highly precise things. In China, aerospace companies use special software and machines which are controlled by computers to make parts. These are very accurate and always have the same quality. This makes sure that aeroplanes are safe and work well.

Complex Geometries and Intricate Features

In addition, CNC machining allows for the creation of complicated shapes and detailed features that are often needed in aerospace applications. The aerospace industry is always pushing the limits of design and innovation, needing components with intricate shapes, curves, and internal structures. China’s CNC aerospace machining industry can accurately reproduce these complex designs, resulting in the production of lightweight and aerodynamic parts that improve aircraft performance.

Efficiency and Cost-Effectiveness

CNC machining is not only precise and complex, but it is also efficient and cost-effective in the aerospace manufacturing industry. The automated and computer-controlled features of CNC machines allow for faster production and shorter waiting times. This efficiency is especially important in the aerospace sector, where getting products to market quickly is crucial. Chinese aerospace manufacturers can improve their production processes, increase productivity, and meet deadlines by using CNC machining.

Versatility of Materials Used

CNC machining is useful in aerospace manufacturing because it can work with many different materials. This includes aluminium, titanium, composites, and exotic alloys. Chinese aerospace machining industry can choose the best materials for each part of the aircraft, which makes them work better and last longer.

Explanation of How China’s CNC Machining Industry Ensures High Precision

Investment

China has invested a lot in advanced CNC aerospace machining technology. They have access to top-notch CNC machines that have high-precision tools, advanced software, and control systems. These machines can create complex designs with great accuracy, making sure the final products meet the necessary specifications.

Skilled Workforce

Moreover, China’s CNC aerospace machining industry benefits from a highly skilled workforce. The country has a large pool of trained engineers, technicians, and operators who possess extensive knowledge and experience in CNC machining. These professionals undergo rigorous training programs and are well-versed in operating and programming CNC machines. Their expertise allows them to effectively utilize the advanced features of the machines, resulting in precise and consistent output.

Quality Control System

In addition, China’s CNC aerospace machining industry has a highly standardised quality control system. They have achieved this with trained engineers, technicians, and operators who have a lot of knowledge and experience in the industry. This system helps to maintain highly accurate output promptly.

Cost-Effective Production Capabilities

Furthermore, China’s CNC aerospace machining industry offers cost-effective production capabilities. The country has a vast network of suppliers and manufacturers, allowing for efficient sourcing of raw materials and components at competitive prices. Additionally, China’s large-scale production capabilities enable economies of scale, reducing overall production costs. This cost advantage allows Chinese manufacturers to invest in advanced CNC machining technology and quality control measures, further enhancing the precision of the final products.

Well-Established Supply Chain

China has a wide range of suppliers and manufacturers, making it easy to find raw materials and components at competitive prices. Moreover, China’s ability to produce on a large scale helps to lower production costs. This cost advantage allows Chinese aerospace machining industries to invest in advanced CNC machining technology and quality control measures, resulting in highly precise final products.

Examples of Precision-Driven Aerospace Components Produced in China

Turbine Blades

Turbine blades for aeroplane engines need to be very precise and accurate to work their best. In China, CNC aerospace machining is used to make turbine blades with complicated shapes and very small differences, which helps the air flow well and makes the engine work as efficiently as possible.

Aircraft Structural Components

Various structural components of an aircraft, such as wing spars, fuselage frames, and landing gear components, are manufactured through CNC aerospace machining in China. These components require precise machining to meet stringent safety standards and ensure the structural integrity of the aircraft.

Aerospace Fasteners

In China, they use CNC aerospace machining to make important parts for aeroplanes like wings, bodies, and landing gear. These parts need to be made very carefully to keep the aeroplane safe and strong.

Avionics Enclosures

Avionics enclosures protect important electronic parts in an aeroplane, like flight control, navigation, and communication systems. In China, CNC machining makes strong and accurate enclosures that keep these electronics safe from the environment and working well.

Satellite Components

China is a big player in making satellites. They use CNC machines to make important parts like antenna reflectors, solar panels, and structural supports. These parts need to be very precise so they can work well in space.

Rocket Engine Components

In China, CNC aerospace machining is used to make different parts of rocket engines, like combustion chambers, nozzles, and fuel injectors. These parts have to handle very high temperatures and pressures, so it’s important to machine them with great precision to ensure they work well and are dependable.

Aircraft Interior Components

China uses CNC machining to make aerospace interior parts like seat frames, overhead bins, and cabin panels. These parts need accurate machining to fit well, last long, and look good.

Helicopter Rotor Blades

In China, CNC machining is used to make rotor blades for helicopters. These blades must be machined with great precision to ensure they rotate smoothly, generate lift efficiently, and enable smooth flight.

UAV (Unmanned Aerial Vehicle) Components

China is a top producer of UAVs. They make many parts for these unmanned aircraft, like airframes, wings, and control surfaces, using CNC machining. Precision machining is very important to make sure these UAVs are stable, easy to control, and perform well.

Conclusion

CNC machining for aerospace plays a pivotal role in the aerospace manufacturing sector in China. It facilitates the production of components with exceptional quality and precision, enables the fabrication of intricate designs and intricate features, provides efficiency and cost-effectiveness, and permits the utilisation of a diverse array of materials.

China’s investments in cutting-edge technology, highly skilled workforce, rigorous quality control system, cost-efficient production capabilities, and well-established supply chain all contribute to the exceptional precision and reliability of CNC machining within the country. Noteworthy examples of precision-driven aerospace components manufactured in China encompass turbine blades, aircraft structural components, aerospace fasteners, avionics enclosures, satellite components, rocket engine components, aircraft interior components, helicopter rotor blades, and UAV components.