Technical Contents

Engineering Guide: Cnc Machinign

Engineering Excellence in Precision CNC Machining

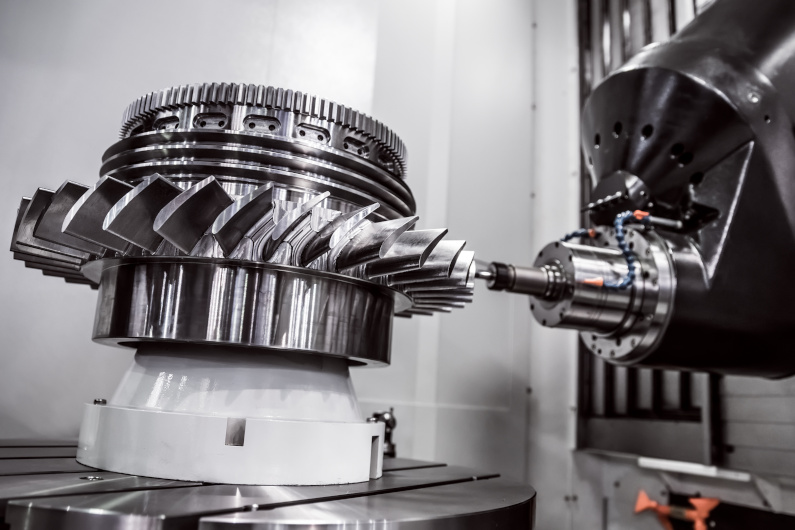

Precision in CNC machining transcends mere specification adherence; it is the foundational requirement for mission-critical components across aerospace, medical, defense, and high-performance industries. In applications where tolerances of ±0.001mm determine operational success or failure, deviations measured in microns can cascade into catastrophic system failures. At Wuxi Lead Precision Machinery, we recognize that precision engineering is not an outcome but a rigorously controlled process—from material selection and thermal stability management to vibration-dampened machine environments and closed-loop verification. Our facility operates under ISO 9001 and AS9100 standards, ensuring every micron-level tolerance is validated through calibrated CMMs, laser interferometers, and real-time in-process monitoring. This discipline eliminates guesswork, transforming design intent into physical reality with uncompromising repeatability.

Wuxi Lead’s engineering philosophy centers on proactive precision control. We deploy 5-axis simultaneous machining centers with sub-micron positioning accuracy, integrated with FEA-optimized fixturing to counteract thermal drift during extended operations. Our protocols include pre-machining material stress-relief cycles and post-process stability aging, critical for components operating under extreme loads or temperatures. Unlike standard production shops, we treat every project as a systems challenge—analyzing how micro-burrs, surface integrity, or residual stress might impact the final assembly’s lifespan. This holistic approach ensures parts perform identically in the field as they did in validation testing, a necessity for clients where failure is not an option.

Our commitment to precision is validated by demanding applications. We manufactured timing system components for the Beijing Winter Olympics, requiring ±0.0005mm geometric tolerances to ensure split-second accuracy in high-speed events. Similarly, our military-grade housings for avionics suites undergo third-party audits against MIL-STD-810G, surviving shock, vibration, and thermal cycling tests that would expose dimensional instability in lesser-machined parts. These projects exemplify how Wuxi Lead’s processes convert theoretical precision into field-proven reliability.

The table below outlines core capabilities enabling this standard of excellence:

| Parameter | Specification | Verification Method |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Laser Interferometer (ISO 230-2) |

| Repeatability | ±0.0005 mm | Ballbar Testing (ISO 230-4) |

| Geometric Tolerance | IT01 to IT5 | CMM (Zeiss CONTURA) |

| Surface Roughness | Ra 0.05 µm to Ra 1.6 µm | Profilometer (Mitutoyo SJ-410) |

| Material Range | Titanium, Inconel, PEEK, 4140 Steel | Material Certificates + Batch Testing |

Precision machining at this level demands more than advanced machinery—it requires an engineering culture where every technician is trained to interrogate variables before they impact output. At Wuxi Lead, we partner with clients during design for manufacturability (DFM) reviews to preempt precision challenges early, reducing iterations and accelerating time-to-market. For industries where performance hinges on the invisible, we deliver the tangible: components machined to the edge of possibility, validated by the world’s most exacting standards. Contact us to discuss how our precision protocols can secure your next critical application.

Precision Specs & Tolerances

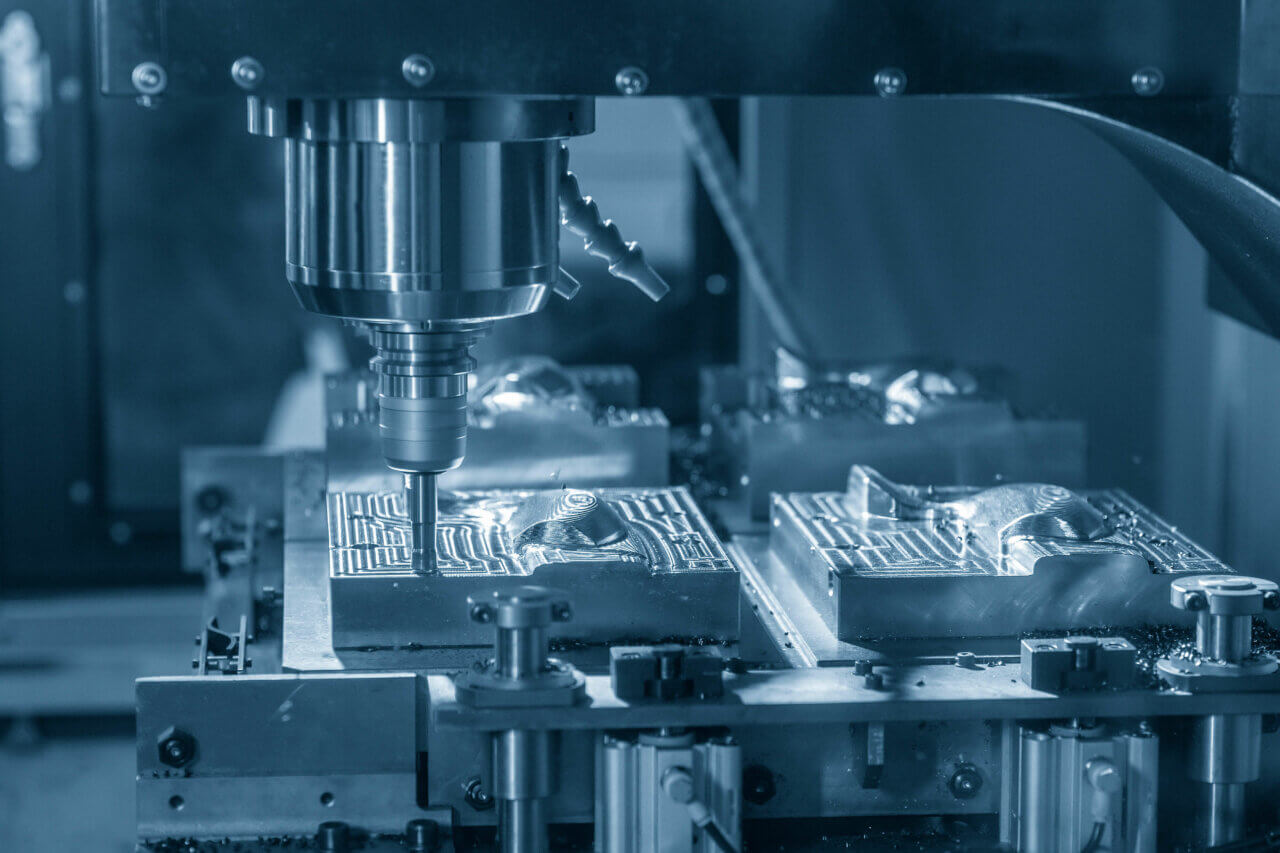

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered to meet the exacting demands of high-performance industries such as aerospace, medical, energy, and advanced automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with superior accuracy and surface finish. Our multi-axis machining centers operate with simultaneous motion control across all five axes, allowing for intricate contours, deep cavities, and compound angles to be machined in a single setup. This minimizes part handling, reduces cumulative errors, and ensures repeatability across production runs.

Our machining fleet comprises state-of-the-art CNC equipment sourced from leading global manufacturers, all maintained to stringent operational standards and operated by certified CNC engineers. These machines support a broad range of materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and high-performance engineering plastics. With rapid tool-change systems, high spindle speeds, and adaptive machining strategies, we achieve optimal cycle times without compromising dimensional integrity.

Quality assurance is embedded throughout our manufacturing process. Every critical component undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. The CMM system provides traceable, high-accuracy metrology data, supporting first-article inspections, process validation, and batch certification. All inspection reports are documented in accordance with ISO 9001 standards and can be provided in multiple formats including PDF, DMIS, and IGES.

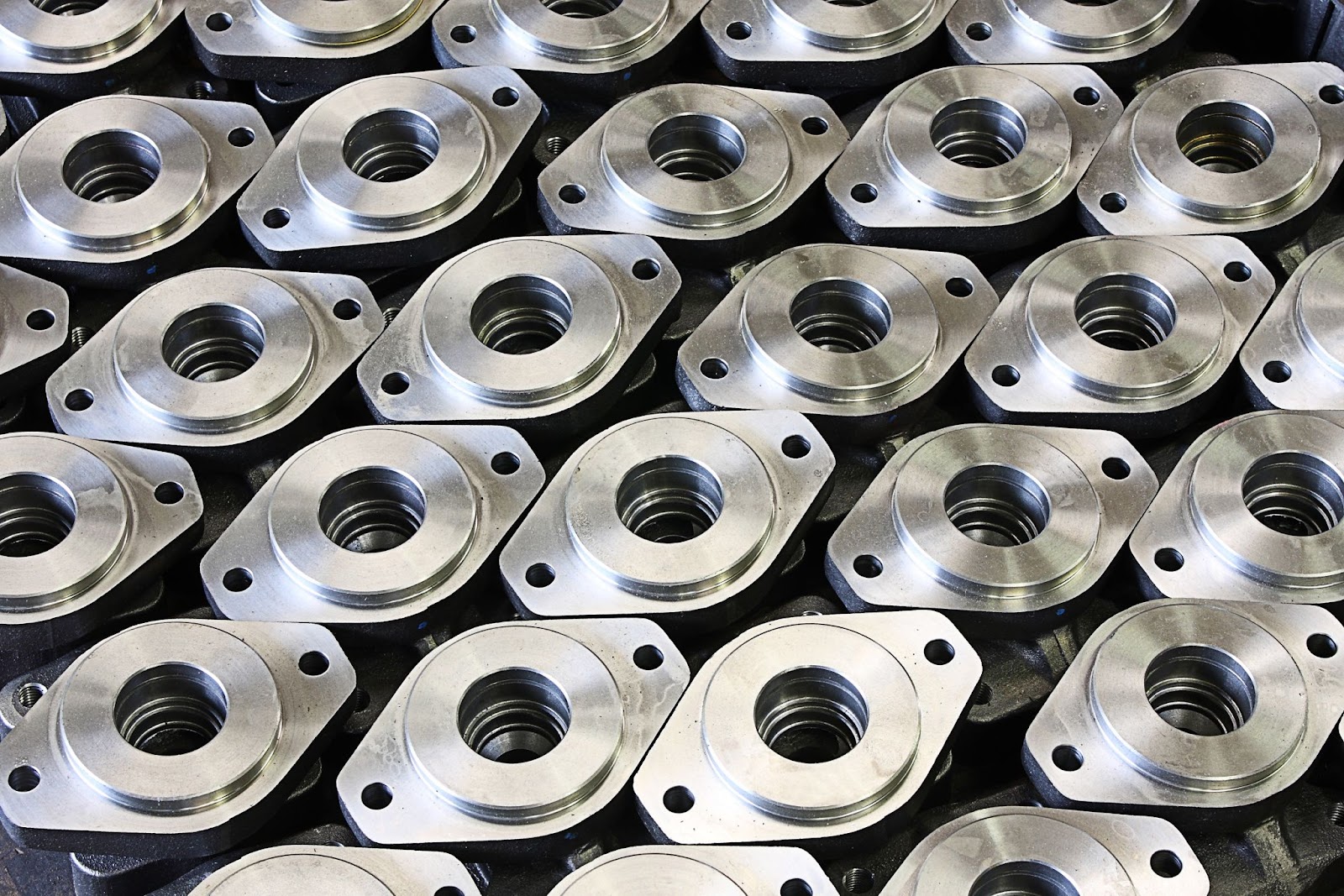

In addition to 5-axis milling, our technical infrastructure supports precision turning, milling-turning with live tooling, and secondary operations such as deburring, passivation, and precision cleaning. We specialize in low to medium volume production of high-complexity parts where precision, material integrity, and on-time delivery are paramount.

The following table outlines the standard precision tolerances we consistently achieve across typical production scenarios:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.005 mm (reamed/ground) |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished/ground) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Runout (diameter) | 0.02 mm | 0.01 mm |

These capabilities are not theoretical benchmarks but proven performance metrics validated through daily production and customer audits. At Wuxi Lead Precision Machinery, we combine advanced hardware, rigorous quality protocols, and engineering expertise to deliver components that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in CNC-machined components. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, mechanical properties, and environmental resistance. Aluminum, steel, and titanium dominate high-end applications, each serving distinct engineering requirements. Understanding their characteristics ensures your design aligns with functional demands and production feasibility.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are ideal for lightweight structural parts requiring high strength-to-weight ratios and excellent corrosion resistance. 6061 offers superior weldability and moderate strength for enclosures or brackets, while 7075 delivers aerospace-grade strength for critical load-bearing components. Aluminum machines rapidly with minimal tool wear, reducing lead times and costs. Its natural oxide layer provides baseline protection, though anodizing is recommended for enhanced durability in harsh environments.

Carbon and stainless steels provide unmatched hardness and wear resistance for heavy-duty applications. 4140 alloy steel excels in high-stress mechanical systems like shafts and gears due to its fatigue resistance and heat-treatability. For corrosive or sanitary settings, 304 and 316 stainless steels offer robust oxidation resistance without secondary coatings. Steel machining demands rigid setups and slower feeds to manage heat and tool deflection, but yields exceptional dimensional stability and surface integrity.

Titanium Grade 5 (Ti-6Al-4V) is the solution for extreme conditions—high temperatures, aggressive chemicals, or weight-critical aerospace/medical systems. Its biocompatibility and 40% lower density than steel make it indispensable despite challenging machinability. Titanium requires specialized tooling, low cutting speeds, and strict thermal control to prevent work hardening and galling. While costly to machine, its lifecycle value in mission-critical parts justifies the investment.

Key material properties are summarized below for rapid comparison:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 572 | 75% | Aerospace fittings, military |

| Steel 4140 | 7.85 | 655 | 65% | Shafts, tooling, machinery |

| Titanium Gr5 | 4.43 | 900 | 22% | Aircraft components, implants |

Surface finishing further refines performance. Anodizing is the premier post-process for aluminum, creating a hard, non-conductive oxide layer that resists wear and corrosion. Type II (sulfuric acid) anodizing offers economical color dyeing for aesthetics, while Type III (hardcoat) delivers 50–100µm thickness for severe abrasion resistance. Note that anodizing applies exclusively to aluminum; steels require plating or passivation, and titanium benefits from laser etching or chemical polishing.

Material choice directly impacts CNC programming, tool selection, and cycle time. We advise validating your selection against operational stressors, regulatory standards, and total cost of ownership. Consult our engineering team early in design to optimize material compatibility with precision machining capabilities and avoid costly revisions. Wuxi Lead Precision Machinery ensures every material decision translates into a component that meets exacting performance benchmarks.

Manufacturing Process & QC

From Design to Mass Production: A Zero-Defect CNC Machining Workflow

At Wuxi Lead Precision Machinery, our precision CNC machining process is engineered for consistency, accuracy, and zero-defect outcomes. We follow a structured workflow that integrates design validation, iterative prototyping, and scalable mass production. Every stage is governed by strict quality protocols to ensure compliance with international standards and client specifications.

The process begins with design analysis and manufacturability review. Our engineering team collaborates closely with clients to evaluate CAD/CAM models, verify geometric dimensioning and tolerancing (GD&T), and assess material suitability. Finite element analysis (FEA) and CNC toolpath simulation are employed to anticipate stress points, minimize material waste, and optimize machining cycles. This pre-production phase ensures that theoretical designs are translated into practical, high-precision components.

Prototyping follows design approval and serves as a critical validation step. Using 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes in the intended production material. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, fit, and performance under operational conditions are verified. Any deviations trigger immediate engineering feedback loops, enabling rapid design adjustments. This stage not only confirms design integrity but also certifies the process capability for full-scale production.

Once prototype approval is obtained, we transition seamlessly into mass production. Our facility leverages automated pallet systems, robotic part handling, and real-time process monitoring to maintain throughput without compromising precision. Each production run is supported by Statistical Process Control (SPC) and First Article Inspection (FAI) reporting. In-process inspections occur at predefined intervals, and final quality audits are conducted before shipment. All data is documented and traceable, ensuring full compliance with ISO 9001 and IATF 16949 standards.

Our zero-defect philosophy is enforced through continuous operator training, preventive maintenance of CNC equipment, and a closed-loop corrective action system. Any non-conformance is immediately quarantined, analyzed, and resolved at the root cause level. This proactive quality culture minimizes rework, reduces lead times, and enhances customer confidence.

The table below outlines our core production capabilities and inspection tolerances:

| Parameter | Specification |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, mill-turn |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.8 µm to 6.3 µm |

| Materials | Aluminum, stainless steel, titanium, brass, PEEK, Delrin |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Inspection Equipment | CMM, optical comparator, micrometers, calipers, surface roughness tester |

| Quality Standards | ISO 9001, IATF 16949, RoHS |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Mass Production) | 15–25 days, scalable |

Through this disciplined, technology-driven approach, Wuxi Lead Precision Machinery delivers precision components that meet the most demanding requirements in aerospace, medical, automotive, and industrial automation sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Manufacturing Excellence

In today’s competitive manufacturing landscape, selecting a precision CNC partner transcends cost considerations. It demands a strategic alliance rooted in technical mastery, unwavering quality control, and proactive engineering collaboration. Wuxi Lead Precision Machinery stands as your definitive solution for mission-critical components where micron-level accuracy directly impacts product performance and market success. We engineer partnerships, not transactions, ensuring your most demanding designs transition seamlessly from CAD model to flawless physical reality. Our ISO 9001:2015-certified facility in Wuxi, China, leverages cutting-edge machinery and a culture of continuous improvement to eliminate production risk and accelerate time-to-market for global innovators in aerospace, medical devices, and advanced industrial equipment.

Our technical infrastructure delivers measurable advantages for complex, high-value projects. The table below summarizes core capabilities driving client success:

| Capability Category | Specification Detail | Performance Benchmark |

|---|---|---|

| Machine Technology | 5-Axis Milling/Turning Centers | Travel: 1200 x 800 x 600 mm |

| High-Speed Vertical Machining Centers | Spindle Speed: 24,000 RPM | |

| Multi-Tasking Turning Centers | Max. Turning Diameter: 500 mm | |

| Precision Tolerance | Standard Capability | ±0.005 mm (±0.0002″) |

| Advanced Capability (Special Processes) | ±0.001 mm (±0.00004″) | |

| Material Expertise | Metals | Titanium, Inconel, Stainless Steels, Aluminum Alloys |

| Engineering Plastics | PEEK, Delrin, Ultem | |

| Quality Assurance | In-Process Metrology | On-Machine Probing Systems |

| Final Inspection | CMM, Optical Comparators |

This foundation enables us to solve challenges others cannot. When your project requires sub-5µm tolerances on hardened tool steels, complex geometries in reactive alloys, or zero-defect batches for life-critical applications, our engineering team engages early. We conduct Design for Manufacturability (DFM) reviews to optimize toolpaths, reduce cycle times, and prevent costly revisions—transforming potential production bottlenecks into competitive advantages. Our closed-loop quality systems provide full traceability from raw material certification to final inspection reports, meeting stringent aerospace AS9100 and medical ISO 13485 requirements without negotiation.

Choosing Lead Precision means gaining an extension of your engineering department. We invest in understanding your end-use application, regulatory environment, and volume ramp-up strategy to deliver not just parts, but risk-mitigated manufacturing solutions. Our clients consistently achieve 30% faster prototyping cycles and 25% lower total cost of ownership through our integrated approach to precision machining.

Initiate your precision manufacturing partnership with confidence. Contact our engineering sales team directly at [email protected] to schedule a technical consultation. Provide your component specifications, target tolerances, and volume requirements, and we will deliver a detailed capability assessment within 24 business hours. Let Lead Precision become the strategic manufacturing pillar your innovation roadmap requires—where engineering rigor meets execution certainty. Your next breakthrough component starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.