Technical Contents

Engineering Guide: Cnc Machinery Parts

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Machinery Parts

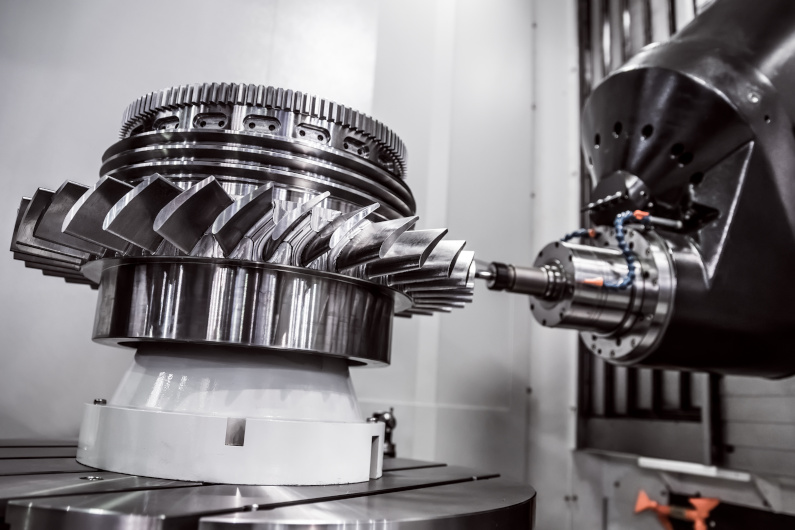

In high-stakes manufacturing sectors like aerospace, defense, and advanced energy, the precision of CNC-machined components is not merely a quality metric—it is the foundational requirement for system integrity, safety, and operational longevity. A deviation measured in microns can cascade into catastrophic failure under extreme loads, thermal cycles, or high-speed operation. Consider turbine engine components: tolerances exceeding 0.02mm in blade root interfaces directly compromise rotational balance, accelerating fatigue and risking in-flight disintegration. Similarly, hydraulic manifold assemblies for military vehicles demand absolute geometric fidelity; microscopic surface imperfections or angular errors cause seal leakage, system pressure loss, and mission-critical downtime. Precision engineering transcends dimensional accuracy alone. It encompasses controlled surface finishes to mitigate stress concentrations, stringent material property validation, and unwavering consistency across production batches. This level of control demands more than advanced machinery; it requires deeply embedded process discipline, metrology traceability to national standards, and engineering expertise that anticipates real-world application stresses.

At Wuxi Lead Precision Machinery, we engineer this precision into every component. Our ISO 9001 and AS9100 certified processes integrate multi-axis CNC machining centers with sub-micron positioning accuracy, coordinate measuring machines (CMMs) featuring nanometer-level resolution, and real-time in-process gauging. Crucially, our engineering team possesses proven experience delivering mission-critical parts where failure is not an option. We successfully manufactured complex structural components for the Beijing 2022 Winter Olympics venue systems, where thermal expansion differentials and seismic loads demanded tolerances held within 0.005mm across meter-scale assemblies. Furthermore, we consistently supply precision-machined subsystems for classified defense programs, adhering to ITAR protocols and MIL-STD-883 environmental testing requirements. This experience instills a culture where every technician understands that the part they are machining may ultimately safeguard lives or enable national infrastructure.

Our commitment manifests in quantifiable performance standards, consistently achieved across diverse materials including titanium alloys, Inconel, and high-strength aluminum:

| Parameter | Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.025mm | ±0.005mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Geometric Accuracy | 0.05mm | 0.01mm |

| Batch Consistency (CpK) | 1.33 | ≥1.67 |

| Material Certification | Basic Mill Test | Full Traceable MTRs + NADCAP |

Achieving this level of precision requires treating CNC machining as a holistic science, not just a production step. It demands collaborative engineering from design for manufacturability (DFM) through final inspection, leveraging our 15+ years of experience in the most demanding global supply chains. When your application hinges on absolute reliability, partner with a manufacturer whose precision is validated not just in the lab, but on the Olympic stage and in the field. Wuxi Lead Precision Machinery delivers the engineered certainty your critical systems require.

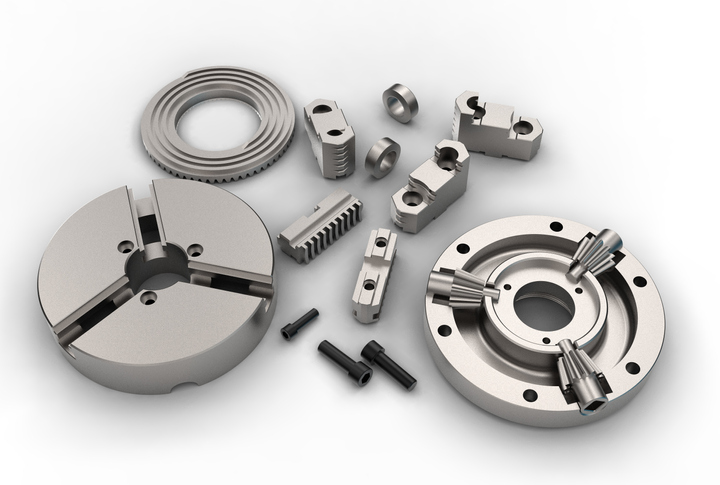

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our manufacturing excellence is a fully integrated fleet of 5-axis CNC machining centers, enabling us to produce highly complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while maintaining micron-level repeatability. This capability ensures that even the most intricate components are machined in a single setup, minimizing cumulative errors and enhancing overall part integrity.

Our machining processes support a wide range of engineering materials, including aluminum alloys, stainless steels, titanium, Inconel, brass, and high-performance plastics. Advanced toolpath strategies and high-speed machining techniques are employed to optimize material removal rates without compromising dimensional stability or surface quality. Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAM software to generate precise toolpaths, ensuring optimal cutting conditions and tool life. This combination of state-of-the-art equipment and expert craftsmanship allows us to deliver parts with exceptional consistency and reliability.

Quality assurance is integral to our production workflow. Every critical component undergoes comprehensive inspection using a coordinate measuring machine (CMM), ensuring full compliance with drawing specifications and international standards. Our CMM systems are calibrated to ISO 17025 requirements and operated by trained metrology technicians capable of verifying complex 3D profiles, positional tolerances, and geometric dimensioning and tolerancing (GD&T) callouts. In addition to final inspection, in-process checks are performed at key stages to detect and correct deviations early, minimizing rework and ensuring on-time delivery of conforming parts.

The following table outlines the standard precision tolerances we consistently achieve across our 5-axis CNC machining operations:

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Depending on part size and geometry |

| Hole Diameter | +0.010 / -0.000 mm | +0.005 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance (GD&T) | ±0.01 mm | ±0.005 mm | Verified via CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | As machined or post-processed |

| Angular Features | ±0.01° | ±0.005° | Multi-axis alignment |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Critical sealing surfaces |

All inspection data is documented and traceable, with full reports available upon request. This disciplined approach to quality, combined with our advanced 5-axis machining capacity, positions Wuxi Lead Precision Machinery as a trusted partner for mission-critical CNC components in demanding global markets.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Selecting optimal materials is critical for achieving performance, durability, and cost efficiency in precision CNC machined parts. At Wuxi Lead Precision Machinery, our engineering team evaluates mechanical properties, environmental resistance, and manufacturability to ensure your components meet exacting industrial standards. Below we detail key considerations for aluminum, steel, and titanium alloys, alongside essential finishing processes like anodizing.

Aluminum alloys dominate aerospace, automotive, and electronics applications due to their exceptional strength-to-weight ratio and thermal conductivity. 6061-T6 and 7075-T6 are industry standards, offering weldability and corrosion resistance. While 6061-T6 provides optimal machinability for complex geometries, 7075-T6 delivers superior strength for high-stress components. Aluminum’s low density reduces inertia in moving parts, directly enhancing system efficiency. However, its lower hardness necessitates protective finishes in abrasive environments.

Steel remains indispensable for structural and high-wear applications. 4140 and 17-4 PH stainless steel are frequently specified for their fatigue resistance and toughness. 4140 excels in shafts and gears requiring heat treatment, while 17-4 PH offers corrosion resistance for marine or chemical processing equipment. Machining hardened steel demands rigid setups and specialized tooling to maintain tolerances below ±0.005mm. Our facility employs high-pressure coolant systems to prevent thermal deformation during extended steel machining cycles.

Titanium alloys like Ti-6Al-4V are reserved for extreme environments demanding unmatched strength-to-weight ratios and biocompatibility. Common in medical implants and jet engine components, titanium resists corrosion in saltwater and high temperatures up to 600°C. Its low thermal conductivity challenges machining, requiring reduced feed rates and sharp carbide tools to avoid work hardening. Wuxi Lead utilizes vibration-dampened spindles and optimized cutting paths to achieve surface finishes under Ra 0.8µm on titanium, minimizing post-process refinement.

Anodizing is the premier finish for aluminum, enhancing surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing creates a porous layer for dyeing and sealing, ideal for aesthetic or moderate-wear applications. Type III (hardcoat) anodizing produces coatings up to 50µm thick with hardness exceeding 60 HRC, critical for hydraulic pistons or aerospace brackets. Our ISO 9001-certified anodizing line ensures consistent coating thickness within ±5µm, with rigorous salt-spray testing validating 1,000+ hour corrosion resistance.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Finishes |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Excellent (Machinability Index: 95) | Anodizing, Powder Coat |

| Steel 4140 | 7.85 | 655 | Good (Machinability Index: 65) | Hard Chrome, Passivation |

| Titanium Ti-6Al-4V | 4.43 | 900 | Fair (Machinability Index: 30) | Anodizing, Plasma Spray |

Material selection directly impacts production lead times, tool wear, and final part functionality. Wuxi Lead’s engineers collaborate with clients during the design phase to balance performance requirements with manufacturability. We recommend early consultation to leverage our expertise in material-specific machining strategies and finishing processes, ensuring your components achieve maximum service life while optimizing production costs. Contact our technical team for material-specific DFM analysis and prototyping support.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for CNC machinery parts is engineered to deliver uncompromising precision, repeatability, and zero-defect performance. We follow a structured workflow that integrates design validation, prototyping refinement, and scalable mass production, ensuring every component meets the highest standards of quality and functionality.

The process begins with design analysis and engineering review. Our technical team collaborates closely with client specifications, evaluating CAD models, material selections, geometric dimensioning, and tolerance requirements. Advanced simulation software is used to assess thermal behavior, stress distribution, and machinability, ensuring the design is optimized for both performance and manufacturability. This stage is critical in preventing downstream deviations and ensuring compliance with ISO and ASME standards.

Once the design is finalized, we proceed to prototyping. Using high-precision 5-axis CNC machining centers and wire EDM systems, we produce functional prototypes that mirror the final part in both form and function. These prototypes undergo rigorous metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, surface finish, and fitment are validated against the original specifications. Any necessary adjustments are implemented in the digital process plan before transitioning to full-scale production.

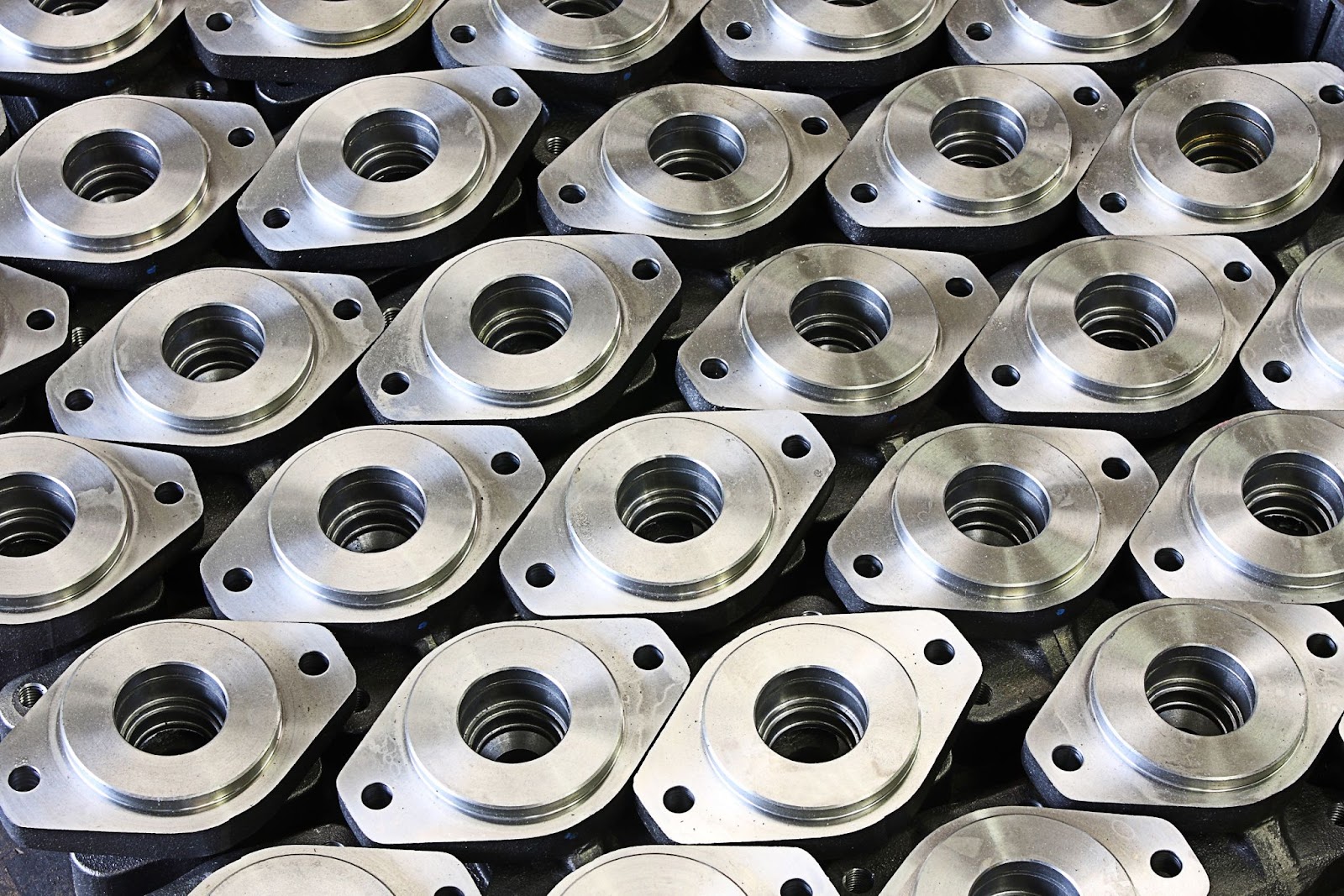

Mass production leverages automated CNC cells equipped with tool presetters, in-process probing, and real-time monitoring systems. Each machining cycle is governed by a documented process control plan that includes first-article inspection (FAI), statistical process control (SPC), and periodic audits. Our facility operates under a certified quality management system (ISO 9001:2015), ensuring traceability, material certification, and full documentation for every batch.

Zero defects is not a target—it is our standard. To achieve this, we employ a multi-stage quality gate system. Every part is inspected at critical process points, with non-conforming items immediately quarantined and root cause analyzed using 8D methodology. Our defect prevention framework includes poka-yoke (error-proofing) mechanisms, tool wear compensation algorithms, and environmental controls to minimize variation.

The result is a seamless transition from concept to high-volume output, with consistent part-to-part uniformity and full compliance with aerospace, medical, and industrial equipment requirements.

Typical Production Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.2 – 1.6 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm (5-axis) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Production Capacity | Up to 50,000 units/month (automated lines) |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace), PPAP Level 3 |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (depending on volume) |

Through disciplined process control, cutting-edge technology, and a culture of precision, Wuxi Lead ensures that every CNC machinery part we produce meets the exacting demands of advanced manufacturing.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In today’s competitive industrial landscape, precision CNC machinery parts demand more than just component supply—they require a strategic partner committed to engineering excellence and uncompromising quality. At Wuxi Lead Precision Machinery, we transcend conventional manufacturing by integrating advanced CNC capabilities with deep technical expertise, ensuring your complex parts meet the most stringent global standards. Our dedicated engineering team collaborates closely with clients from initial design review through final inspection, mitigating risks and optimizing manufacturability without sacrificing performance. With ISO 9001 and AS9100 certifications anchoring our processes, we deliver micron-level repeatability across aerospace, medical, and energy sectors where failure is not an option.

Our technical infrastructure supports the full spectrum of precision machining challenges. Below outlines core capabilities that define our partnership value:

| Capability | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.0001″ (2.5µm) | Critical for aerospace hydraulic systems and medical implants |

| Material Expertise | Titanium, Inconel, PEEK, 4140/4340 steel | Enables high-stress, corrosion-resistant components |

| Max Work Envelope | 1200 x 800 x 750 mm | Accommodates large-scale industrial assemblies |

| Surface Finish | Ra 0.4µm to 0.8µm (as-machined) | Meets stringent fluid dynamics and biocompatibility requirements |

| Lead Time Efficiency | 15-30% faster than industry avg. | Accelerates time-to-market for urgent projects |

This technical rigor is paired with transparent communication and agile responsiveness. Unlike offshore vendors focused solely on volume, our engineering-led approach anticipates your needs—whether resolving GD&T complexities, validating first-article inspections per PPAP, or scaling production for Tier 1 supply chains. We invest in 5-axis DMG MORI and Makino platforms alongside in-house CMM metrology, eliminating third-party dependencies that compromise quality control. Every shipment includes full traceability documentation, ensuring compliance with FAA, FDA, and ISO regulatory frameworks.

Initiate your precision manufacturing partnership by contacting our engineering team directly. Send your RFQs, 3D models, or technical inquiries to Contact [email protected]. Specify project timelines, material requirements, and quality standards for a tailored capability assessment within 24 business hours. Our sales engineers will respond with a feasibility analysis, process flowchart, and competitive quotation—no generic templates, only actionable engineering insights. For urgent prototyping needs, reference “RAPID-ENG” in your subject line to activate our 72-hour turnaround protocol.

Wuxi Lead Precision Machinery operates at the intersection of Chinese manufacturing scale and German-grade precision discipline. We do not merely fulfill orders; we safeguard your reputation through parts that perform flawlessly in the field. Contact [email protected] today to transform your CNC machining challenges into competitive advantages. Your next breakthrough component begins with an engineered partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.