Technical Contents

Engineering Guide: Cnc Machineing

Engineering Insight: The Critical Role of Precision in CNC Machining

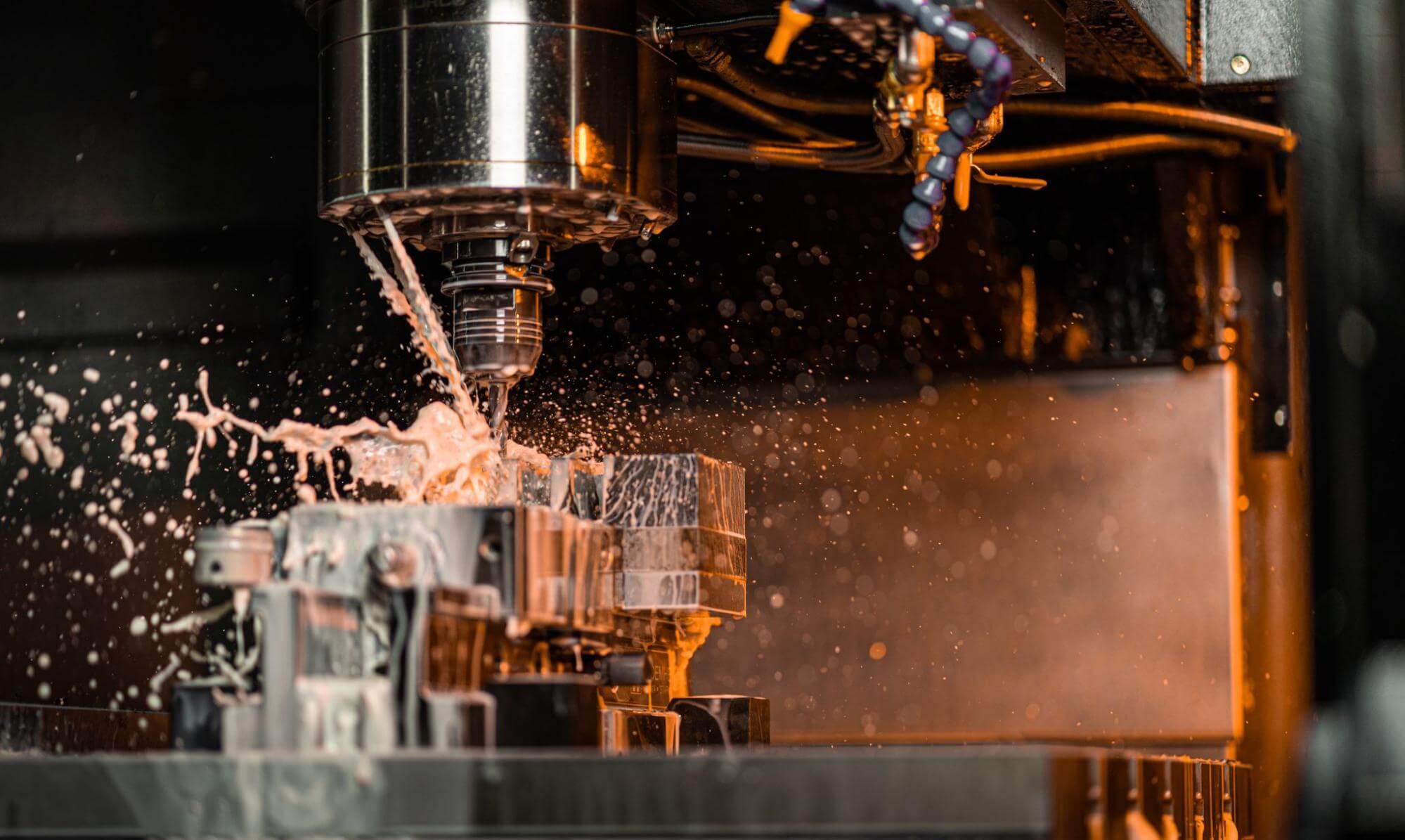

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, performance, and innovation are built. At Wuxi Lead Precision Machinery, we define precision CNC machining as the disciplined execution of micron-level accuracy across complex geometries, tight tolerances, and high-repeatability production cycles. This level of control is essential in industries where component failure is not an option—such as aerospace, defense, medical technology, and high-performance automotive systems.

Our engineering philosophy centers on the integration of advanced CNC technology with rigorous quality assurance protocols. Every machining process at Lead Precision is calibrated to maintain tolerances as tight as ±0.002 mm, ensuring that each component meets or exceeds international standards. This capability is not accidental; it is the result of over a decade of refinement, strategic investment in 5-axis CNC systems, and a deep-rooted culture of engineering excellence.

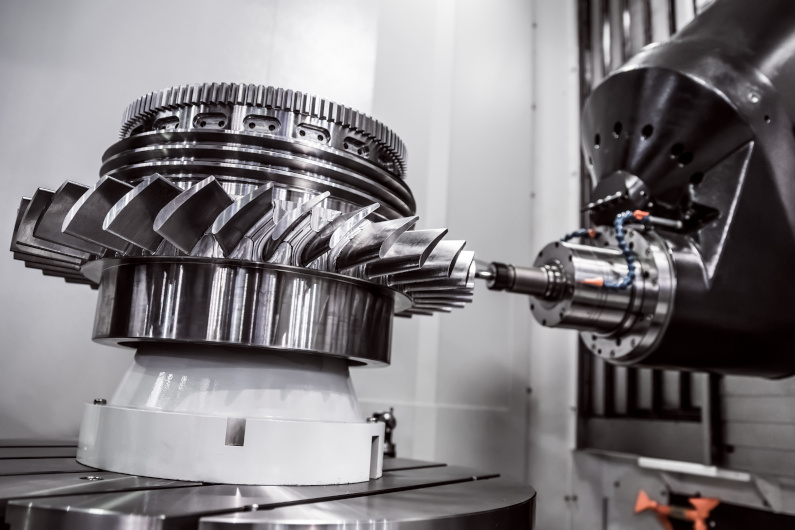

The importance of precision extends beyond dimensional accuracy. It directly influences part functionality, assembly integrity, and long-term durability. For example, in aerospace applications, even a micron-scale deviation in a turbine blade can lead to imbalanced rotation, increased wear, and catastrophic system failure. Similarly, in military-grade electronics enclosures, precise fitment ensures electromagnetic shielding and environmental resistance under extreme conditions.

Wuxi Lead Precision Machinery has been entrusted with projects of national and global significance, including components used in Olympic-standard timing systems and mission-critical defense equipment. These applications demand not only technical precision but also full traceability, material certification, and compliance with ISO 9001 and AS9100 standards. Our involvement in such high-stakes projects underscores our capability to deliver under the most stringent requirements.

Our CNC machining centers utilize Siemens, Fanuc, and Heidenhain controls, enabling dynamic tool path optimization and real-time error compensation. Coupled with in-process probing and post-machining CMM inspection, we ensure that every workpiece is verified for geometric accuracy before shipment.

Below are representative specifications from our precision machining capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Spindle Speed | Up to 24,000 rpm |

| Tolerance Range | ±0.002 mm to ±0.01 mm (depending on part) |

| Surface Finish | Ra 0.2 to Ra 1.6 µm |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, PEEK, brass |

| Quality Standards | ISO 9001, AS9100, RoHS compliance |

Precision in CNC machining is not a singular achievement—it is a continuous commitment to engineering integrity. At Wuxi Lead Precision Machinery, we combine technical mastery with real-world application experience to deliver components that perform flawlessly in the most demanding environments.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

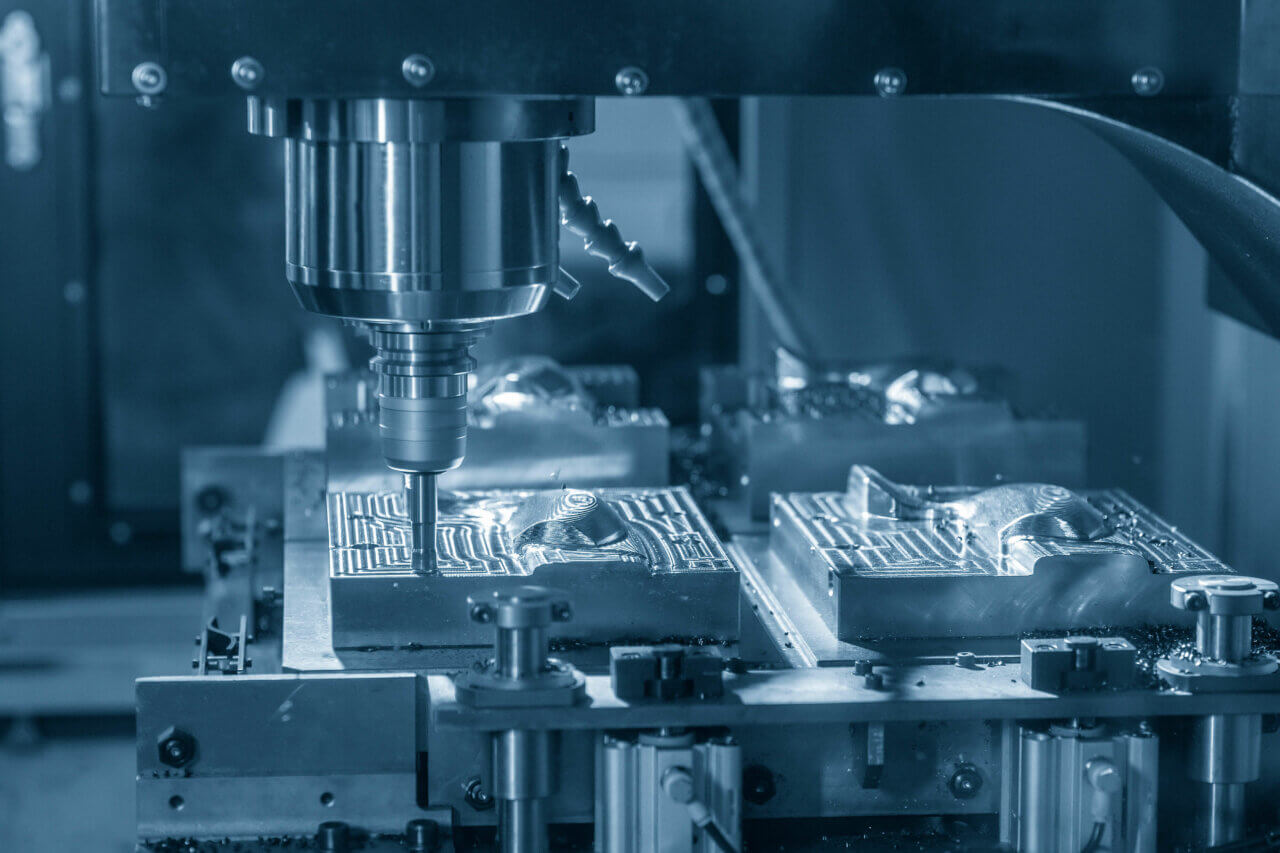

Wuxi Lead Precision Machinery delivers uncompromising precision through a foundation of advanced equipment and rigorous process control. Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers, strategically selected for their exceptional rigidity, thermal stability, and sub-micron positioning accuracy. We operate a modern fleet featuring leading brands including DMG MORI CTX beta 2500 linear and Makino D200Z VCP models, equipped with high-speed spindles (up to 24,000 RPM) and integrated probing systems. This technology enables the complete machining of complex geometries – intricate contours, deep cavities, and multi-faceted components – in a single setup. The elimination of secondary operations significantly reduces cumulative error, accelerates lead times, and ensures superior part-to-part consistency critical for aerospace structural components, medical implants, and high-performance automotive systems. Our machines are maintained to OEM specifications under a strict preventative maintenance schedule, guaranteeing sustained peak performance.

Quality assurance is intrinsically woven into our manufacturing workflow, not merely a final checkpoint. Every critical dimension and feature undergoes verification using calibrated Coordinate Measuring Machines (CMMs), specifically the蔡司 CONTURA G2 series with VAST XT gold probe technology. This provides metrology-grade accuracy traceable to national standards (NIST equivalent). Our inspection process is proactive; first-article inspection (FAI) per AS9102 is standard for new programs, and in-process checks are implemented based on Statistical Process Control (SPC) principles for high-volume runs. Comprehensive inspection reports, including full GD&T analysis and 3D deviation maps, are generated and provided with every shipment, offering complete transparency and data-driven confidence in component conformity. This integrated approach ensures defects are identified and corrected at the source, preventing non-conforming product from progressing.

Our machining precision consistently meets the stringent demands of global Tier 1 suppliers and OEMs. The following table details our standard achievable tolerances across common engineering materials, reflecting our process capability under controlled production conditions:

| Material Category | Dimensional Tolerance (mm) | Dimensional Tolerance (inch) | Typical Surface Finish (Ra µm) | Typical Surface Finish (Ra µin) |

|---|---|---|---|---|

| Aluminum Alloys | ±0.010 | ±0.0004 | 0.8 | 32 |

| Engineering Plastics | ±0.025 | ±0.0010 | 1.6 | 63 |

| Stainless Steels | ±0.012 | ±0.0005 | 0.8 | 32 |

| Titanium Alloys | ±0.015 | ±0.0006 | 1.6 | 63 |

| High-Temp Alloys | ±0.020 | ±0.0008 | 1.6 | 63 |

These capabilities are not theoretical; they are proven daily in our ISO 9001:2015 certified facility. We understand that true precision machining transcends simple part production. It requires the seamless integration of cutting-edge 5-axis technology, metrology-grade inspection, and a culture of continuous process validation. Partnering with Wuxi Lead means your most complex components are manufactured with the dimensional integrity and surface quality essential for optimal performance and longevity in mission-critical applications. We provide not just parts, but guaranteed precision and supply chain reliability.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-performance materials including aluminum, steel, and titanium—each offering distinct advantages depending on the application requirements. Understanding the mechanical properties, machinability, and compatibility with surface treatments such as anodizing enables engineers and procurement teams to make informed decisions for mission-critical components.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grade 6061-T6 is particularly popular for structural components, offering good weldability and machinability. Its ability to accept anodized finishes enhances surface hardness and wear resistance, making it ideal for parts exposed to abrasive environments. Type II and Type III (hardcoat) anodizing are commonly applied, with the latter providing a thicker, more durable oxide layer suitable for high-wear applications.

Steel, particularly alloy and stainless grades such as 4140, 17-4 PH, and 304/316, delivers superior strength, toughness, and temperature resistance. These properties make steel the material of choice for industrial tooling, hydraulic systems, and high-stress mechanical components. While more challenging to machine than aluminum, modern CNC processes at Wuxi Lead ensure tight tolerances and excellent surface finishes. Stainless steels also offer inherent corrosion resistance, though additional passivation or electropolishing may be recommended for medical or food-grade applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and resistance to extreme environments. It is extensively used in aerospace, defense, and medical implant manufacturing. Despite its high cost and demanding machining characteristics—such as low thermal conductivity and high chemical reactivity—our precision CNC platforms are optimized to maintain dimensional accuracy while minimizing tool wear. Titanium does not anodize in the conventional sense but can undergo specialized surface treatments to improve wear and oxidation resistance.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Excellent | Anodizing (Type II/III), Powder Coat | Aerospace frames, heat sinks, enclosures |

| Steel 4140 | 655 | 7.85 | Good | Passivation, Zinc Plating | Shafts, tooling, automotive components |

| Stainless 316 | 580 | 8.0 | Moderate | Electropolishing, Bead Blasting | Medical devices, marine hardware |

| Titanium Ti-6Al-4V | 900 | 4.43 | Fair | Plasma Spray, Nitriding | Jet engines, implants, high-performance racing |

Selecting the right material involves balancing performance demands with manufacturability and lifecycle costs. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to recommend optimal material and finish combinations based on functional requirements, environmental exposure, and production volume. This technical partnership ensures that every machined component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability. We integrate advanced CNC technology with rigorous quality management systems to ensure zero defects across all phases—design, prototyping, and mass production. This disciplined approach minimizes waste, accelerates time-to-market, and guarantees components meet the most stringent aerospace, medical, and industrial specifications.

Design Phase

Our process begins with collaborative design analysis. Engineers review 3D CAD models for manufacturability, identifying potential stress points, material constraints, and tolerance conflicts. We employ simulation software to validate thermal dynamics, toolpath efficiency, and fixture requirements, ensuring designs translate flawlessly to production. Material selection is critical; we prioritize aerospace-grade aluminum alloys, titanium, and high-performance polymers with certified mill test reports. This phase eliminates 80% of potential defects before metal cutting begins, reducing rework and accelerating project timelines.

Prototyping Phase

Rapid prototyping transforms validated designs into tangible components within 72 hours. Using 5-axis milling centers with sub-micron positioning accuracy, we produce functional prototypes for dimensional, fit, and performance validation. Every prototype undergoes 100% inspection via coordinate measuring machines (CMM) and optical comparators against original CAD data. Critical features are verified to ±0.001mm tolerances, with surface roughness measured to Ra 0.4μm. Client feedback is incorporated iteratively, with design adjustments documented and re-validated. This phase confirms process capability and secures approval for mass production, ensuring no latent issues propagate downstream.

Mass Production Phase

Full-scale production leverages statistical process control (SPC) and automated in-process inspection. CNC machines operate under real-time monitoring of tool wear, vibration, and thermal drift, with parameters adjusted via closed-loop feedback systems. Each component is traceable via laser-etched serial numbers, linking material certificates, machine logs, and inspection records. Final quality gates include automated vision systems for surface integrity and CMM revalidation of critical dimensions on every 10th part. Our zero-defect mandate is enforced through a multi-stage checkpoint system: pre-machining material verification, mid-process feature checks, and 100% post-production validation.

Quality Performance Metrics

The following table reflects our standard production capabilities for critical components:

| Parameter | Specification | Measurement Method |

|---|---|---|

| Dimensional Accuracy | ±0.001 mm | CMM (Zeiss CONTURA) |

| Surface Roughness | Ra 0.4 μm | Profilometer (Mitutoyo) |

| Process Capability (Cpk) | >1.67 | SPC Charts |

| First Pass Yield | 99.8% | In-Process Inspection |

This integrated workflow—rooted in proactive defect prevention—delivers consistent precision at scale. Wuxi Lead’s commitment to zero defects is not aspirational; it is systematically executed through engineering rigor, cutting-edge metrology, and unwavering adherence to ISO 9001 and AS9100 standards. Partner with us to transform complex designs into flawless, high-volume reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer long-term partnerships built on trust, performance, and technological leadership. As a global leader in high-end CNC machining, we specialize in delivering complex, mission-critical parts for industries where failure is not an option. From aerospace and medical devices to advanced automation and energy systems, our clients rely on us to bring their most demanding designs to life with micron-level accuracy and uncompromising quality.

Our commitment begins with a deep understanding of your engineering challenges. Whether you require rapid prototyping, low-volume custom runs, or high-volume production, our team of experienced CNC engineers collaborates closely with your design and manufacturing teams to optimize every phase of the process. We integrate advanced 5-axis milling, precision turning, multi-tasking machining, and automated inspection systems to ensure repeatability, efficiency, and compliance with international standards including ISO 9001 and AS9100.

We understand that today’s manufacturing environment demands more than just precision—it requires agility, transparency, and responsive support. That’s why we’ve built a customer-centric operational model focused on short lead times, real-time project tracking, and proactive communication. When you partner with Lead Precision, you gain a true extension of your engineering team, equipped with the technical depth and manufacturing scalability to adapt as your needs evolve.

Our facility in Wuxi, China, combines cutting-edge CNC equipment with a culture of continuous improvement. Every process is monitored through integrated quality management systems, ensuring that each component meets exacting specifications. From material sourcing to final packaging, we maintain full traceability and documentation, providing you with complete confidence in every shipment.

Below are key capabilities that define our precision machining services:

| Capability | Specification |

|---|---|

| Machining Types | 3-axis to 5-axis CNC milling, CNC turning, mill-turn with Y-axis and live tooling |

| Tolerances | As tight as ±0.002 mm |

| Materials | Aluminum, stainless steel, titanium, brass, copper, PEEK, Delrin, and exotic alloys |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), turning up to Ø400 mm |

| Surface Finishes | As-machined, anodizing, plating, passivation, polishing, coating |

| Quality Standards | ISO 9001:2015, AS9100D, full CMM inspection, first-article reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Your next breakthrough component starts with the right manufacturing partner. At Wuxi Lead Precision Machinery, we are ready to support your success with engineering expertise, scalable capacity, and unwavering attention to detail.

Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let’s build the future—precisely.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.