Technical Contents

Engineering Guide: Cnc Machined Plastic

Engineering Insight: Precision Imperatives in CNC Machined Plastics

Precision in CNC machined plastics transcends dimensional accuracy—it defines functional reliability in mission-critical applications. Unlike metals, engineering plastics exhibit unique thermal expansion coefficients, moisture absorption rates, and elastic behaviors that demand granular process control. A tolerance deviation of ±0.025 mm may seem negligible but can trigger catastrophic assembly failures in fluid dynamics systems or optical housings where material creep or swelling compromises seal integrity. At Wuxi Lead Precision Machinery, we treat plastic machining not as subtractive manufacturing but as predictive material science. Our protocols account for resin-specific stress relaxation during cutting, toolpath-induced thermal gradients, and post-machining dimensional stabilization—ensuring parts perform identically in -40°C aerospace hydraulics or 150°C medical sterilization cycles.

Material selection initiates precision. We reject one-size-fits-all approaches, instead matching polymer crystallinity, filler content, and molecular weight to the operational envelope. For instance, machining PEEK for satellite components requires rigid moisture preconditioning and diamond-coated tools to prevent micro-fractures, while Delrin gears demand cryogenic cooling to avoid gear tooth profile distortion. Our 18-year refinement of these parameters stems from validating components under extreme conditions: from Olympic bobsled aerodynamic fairings tested at 140 km/h wind tunnels to MIL-STD-810G compliant drone structural brackets surviving 50G shock loads. This heritage ingrains rigor—every lead screw, every coolant pressure setting, every vibration-dampened spindle rotation is calibrated to neutralize plastic’s inherent variability.

Our facility leverages ISO 2768-mK geometric tolerancing with real-time CMM verification at critical stages, not merely final inspection. This prevents scrap rates common in high-precision plastic work, where residual stress release during secondary operations can shift dimensions by 0.1 mm. The table below illustrates how our process mastery achieves tighter tolerances than industry norms:

| Material | Typical Industry Tolerance (mm) | Lead Precision Tolerance (mm) | Critical Application Factor |

|---|---|---|---|

| PEEK | ±0.05 | ±0.012 | Moisture absorption stability |

| Ultem 1000 | ±0.04 | ±0.010 | Thermal deflection resistance |

| Acetal (Delrin) | ±0.03 | ±0.008 | Creep under cyclic load |

| PPSU | ±0.06 | ±0.015 | Gamma radiation dimensional hold |

Precision in plastic machining is ultimately a commitment to predictable failure avoidance. When your design tolerates zero deviation—whether in a life-support valve or a semiconductor handling arm—material behavior must be as calculable as the toolpath. Wuxi Lead Precision Machinery delivers this certainty through disciplined process physics, not trial-and-error. Our military and Olympic project validations prove that in high-stakes environments, precision isn’t measured in microns alone but in unwavering operational readiness. Partner with us to transform plastic from a compromise material into a precision-engineered asset.

Precision Specs & Tolerances

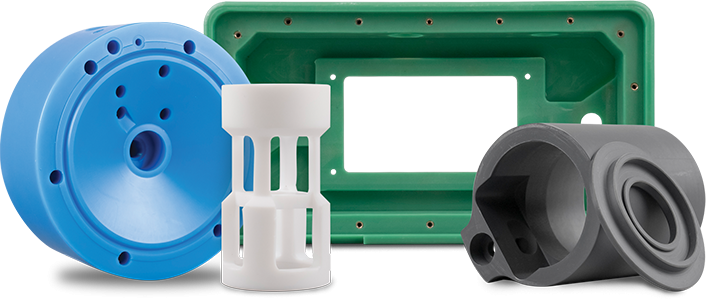

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services specializing in high-complexity plastic components for demanding industries including medical, aerospace, automation, and semiconductor. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce intricate geometries with superior surface finishes and exacting dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across all axes, minimizing setup changes and ensuring optimal tool positioning. This results in reduced cycle times, improved part consistency, and the ability to machine undercuts, deep cavities, and contoured surfaces that are otherwise unattainable with standard equipment.

We specialize in machining a wide range of engineering-grade thermoplastics such as PEEK, PTFE, Ultem (PEI), PPS, Acetal (POM), and Polycarbonate. These materials are selected for their thermal stability, chemical resistance, mechanical strength, and electrical insulation properties. Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time tool wear compensation systems, ensuring precision and repeatability across both prototyping and high-volume production runs. In-process probing and adaptive machining strategies further enhance accuracy by allowing dynamic corrections based on real-time feedback.

Quality assurance is integral to our manufacturing process. Every machined plastic component undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system captures high-density point cloud data for dimensional validation, surface profile analysis, and feature position verification. All inspection reports are documented and archived for full traceability, meeting ISO 9001 standards and customer-specific quality protocols.

Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and machining strategy. This collaborative approach reduces lead times, minimizes material waste, and ensures functional performance in end-use environments. With in-house programming using Mastercam and Siemens NX, we maintain full control over toolpaths, cutting parameters, and fixturing solutions tailored to each unique plastic material’s behavior under machining conditions.

The table below outlines our standard machining tolerances for CNC-machined plastic components. Tighter tolerances are achievable based on part geometry, material, and customer requirements.

| Feature Type | Standard Tolerance | Typical Achievable | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | Up to 300 mm |

| Diameter (Internal/External) | ±0.05 mm | ±0.02 mm | For bores, pins, shafts |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm surface |

| Parallelism | 0.05 mm | 0.02 mm | Between opposing faces |

| Perpendicularity | 0.05 mm | 0.03 mm | Relative to datum |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Hole patterns, slots |

| Surface Roughness (Ra) | 3.2 µm | 1.6–0.8 µm | Machined finish; polish available |

All tolerances are subject to material stability and part geometry. Final specifications are confirmed during the DFM review.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Selecting the optimal material is foundational to achieving performance, durability, and cost-efficiency in precision CNC machined parts. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, balancing application demands with manufacturability. While plastics serve specific roles, metals like aluminum, steel, and titanium remain indispensable for structural integrity, thermal management, and extreme environment performance. Understanding their distinct properties ensures the right match for aerospace, medical, automotive, and industrial automation applications.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate where strength-to-weight ratio and thermal conductivity are paramount. They machine exceptionally well, enabling complex geometries with tight tolerances while minimizing cycle times and tool wear. Aluminum’s natural corrosion resistance is often enhanced through finishing processes, making it ideal for enclosures, heat sinks, and structural frames. Its lower density significantly reduces component weight without sacrificing rigidity.

Steel, especially stainless grades like 303, 304, and 17-4 PH, delivers superior strength, hardness, and wear resistance. These properties are critical for high-stress components such as shafts, valves, and surgical instruments. Stainless steel inherently resists corrosion across diverse environments, though specific grades offer tailored performance for marine or chemical exposure. Machining stainless steel requires optimized parameters and tooling due to work hardening tendencies, a capability our advanced CNC centers are engineered to handle precisely.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), provide an unparalleled strength-to-weight ratio combined with exceptional corrosion resistance and biocompatibility. This makes titanium essential for aerospace structural parts, medical implants, and high-performance marine components. However, its low thermal conductivity and chemical reactivity present significant machining challenges, demanding specialized expertise, rigid setups, and controlled cutting parameters to prevent galling and ensure dimensional accuracy. The material cost and machining complexity necessitate careful justification against performance requirements.

Material properties directly influence both function and production economics. The table below summarizes key characteristics for common precision machining alloys.

| Material | Typical Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Machinability Rating |

|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | 6061, 7075, 2024 | Excellent (9/10) |

| Stainless Steel | 7.9 | 620 (304) | 303, 304, 17-4 PH | Moderate (5/10) |

| Titanium | 4.4 | 900 (Ti-6Al-4V) | Gr2, Gr5 (Ti-6Al-4V) | Challenging (3/10) |

Anodizing is the premier surface treatment for aluminum components, significantly enhancing corrosion resistance, wear properties, and aesthetic options. Type II (Sulfuric Acid) anodizing provides a standard protective layer with dye capability for identification. For mission-critical applications demanding maximum hardness and abrasion resistance, Type III (Hardcoat) anodizing delivers a thicker, denser ceramic-like surface. Both processes are fully compatible with tight tolerance machining, as we precisely control dimensional impact during treatment.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and state-of-the-art CNC technology to transform these materials into components meeting the most stringent specifications. Our engineering team collaborates closely with clients during the design phase to recommend the optimal material and finishing solution, ensuring performance, reliability, and value. Contact our technical sales department to discuss your specific application requirements and receive a tailored material selection analysis.

Manufacturing Process & QC

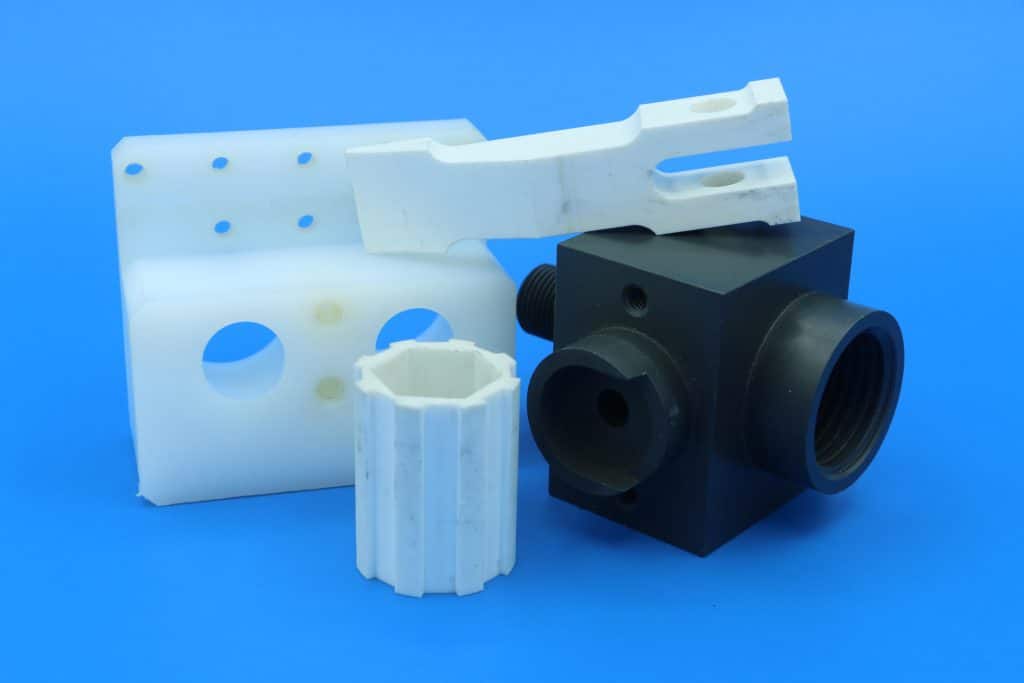

The production process for high-precision CNC machined plastic components at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects from concept to mass production. Each stage—design, prototyping, and full-scale manufacturing—is engineered for repeatability, dimensional accuracy, and material integrity, meeting the demands of aerospace, medical, and industrial automation sectors.

Design begins with a detailed analysis of the client’s CAD models and functional requirements. Our engineering team evaluates material selection, wall thickness, tolerances, and geometric complexity to optimize for machinability and performance. Thermoplastics such as PEEK, PTFE, Ultem, and Acetal are assessed for thermal stability, chemical resistance, and mechanical load. Using advanced simulation software, we perform stress and deformation analysis to preempt potential failure points and ensure long-term reliability. Design for manufacturability (DFM) feedback is provided early, minimizing downstream risks and reducing time-to-market.

Prototyping is executed on the same high-accuracy CNC machining centers used in mass production—ensuring process consistency. This approach eliminates variability between prototype and final parts. Components are machined using 3-, 4-, and 5-axis CNC mills with sub-micron repeatability. Each prototype undergoes full dimensional inspection using coordinate measuring machines (CMM) and optical comparators, validating conformity to ±0.005 mm tolerances. First-article inspection reports (FAIR) and material certifications are provided. Functional testing, including fit checks and environmental exposure, confirms performance under real-world conditions. Only after client approval does the project advance to mass production.

Mass production is conducted under strict ISO 9001-certified quality protocols. Each batch is traceable, with documented process parameters, tool wear monitoring, and real-time in-process inspections. Automated tool length and diameter compensation ensures consistent cutting performance across long runs. Our facility utilizes climate-controlled machining environments to prevent thermal expansion errors, especially critical in hygroscopic plastics. Every component is 100% visually inspected and spot-measured using calibrated instruments. Non-conforming parts are immediately quarantined and root-cause analyzed.

Throughout the entire workflow, Wuxi Lead applies a zero-defect philosophy. Preventive controls, statistical process control (SPC), and continuous operator training minimize human error. Our closed-loop feedback system integrates inspection data directly into machine programs, enabling real-time adjustments and sustained precision.

Key production capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Materials Supported | PEEK, PTFE, Ultem, Acetal, Nylon, PC, PEI |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| CNC Axes | 3, 4, and 5-axis machining |

| Surface Finish (Ra) | 0.8 µm to 6.3 µm (custom finishes available) |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

| Quality Standards | ISO 9001:2015, FAIR, PPAP, RoHS compliant |

This end-to-end process ensures that every CNC machined plastic component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Plastic Component Performance Through Strategic Partnership

When your application demands uncompromising precision in CNC machined plastics—from aerospace seals to life-saving medical implants—the selection of your manufacturing partner becomes a critical engineering decision. At Wuxi Lead Precision Machinery, we operate at the intersection of advanced material science and micron-level machining capability, specifically engineered for the most demanding thermoplastic and thermoset components. Our ISO 9001:2015 certified facility in Wuxi, China, leverages a strategic blend of German-engineered DMG MORI and MAKINO 5-axis CNC centers, coupled with proprietary process validation protocols, to deliver parts where dimensional stability and material integrity are non-negotiable. We understand that tolerances measured in thousandths of an inch directly impact your product’s function, longevity, and regulatory compliance.

Our technical mastery spans the full spectrum of engineering plastics, including challenging materials like PEEK, PPSU, Ultem, and custom-filled composites. We do not merely machine plastic; we optimize the entire process for each unique polymer’s thermal behavior, chip formation, and stress-relief characteristics. This material-specific expertise ensures your components meet exacting functional requirements without hidden compromises. Below outlines our core machining capabilities for critical plastic applications:

| Material Category | Typical Tolerance Range | Max Feature Size | Standard Lead Time | Common Applications |

|---|---|---|---|---|

| High-Performance (PEEK, PEI) | ±0.005 mm to ±0.025 mm | Ø 350 mm x 250 mm | 10-15 working days | Medical implants, semiconductor |

| Engineering (POM, PA, PPS) | ±0.01 mm to ±0.05 mm | Ø 500 mm x 400 mm | 7-12 working days | Fluid handling, automotive |

| Standard (PVC, ABS, PMMA) | ±0.02 mm to ±0.1 mm | Ø 600 mm x 500 mm | 5-10 working days | Prototyping, enclosures |

Beyond specifications, our partnership model delivers tangible engineering value. We integrate early in your design phase through DFM analysis focused explicitly on plastic behavior, preventing costly revisions and material waste. Our dedicated application engineers collaborate directly with your R&D team, providing material selection guidance and process validation data—such as CTE reports and non-destructive testing results—to de-risk your qualification process. This proactive technical engagement ensures manufacturability without sacrificing performance, translating your design intent into flawless physical components. Our operational excellence provides a strategic cost position without compromising the precision your application requires.

Choosing Wuxi Lead Precision Machinery means selecting a partner invested in your product’s success, not just fulfilling a purchase order. We commit to transparent communication, rigorous documentation traceability, and scalable capacity to support your growth from prototype to high-volume production. When the performance of your plastic component directly impacts safety, efficiency, or innovation, settle for nothing less than engineered precision backed by deep material expertise.

Initiate a technical consultation today. Email our engineering team directly at [email protected] with your design files or material specifications. We will respond within 24 business hours with actionable DFM feedback and a precise capability assessment tailored to your project’s critical requirements. Let us demonstrate how precision plastic machining becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.