Technical Contents

Engineering Guide: Cnc Machined Components

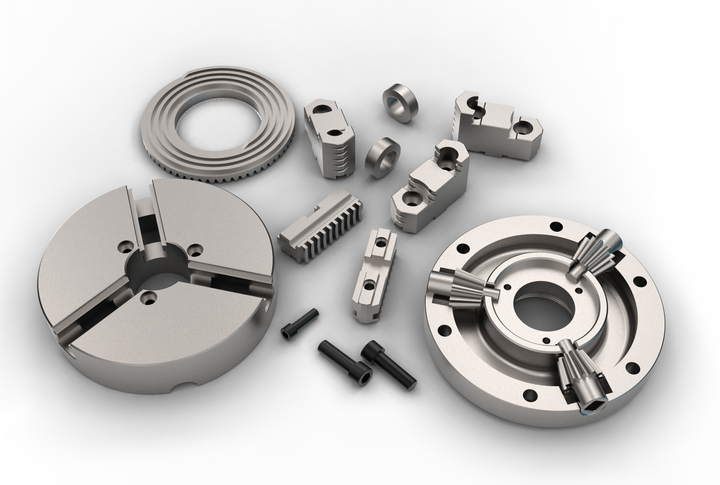

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Machined Components

In high-stakes industrial applications, precision transcends mere specification; it is the foundational element dictating system integrity, operational safety, and ultimate product viability. CNC machined components operating within aerospace propulsion systems, medical implant assemblies, or advanced defense platforms demand tolerances measured in microns. A deviation of even 0.005mm can cascade into catastrophic system failure, compromising structural integrity, inducing premature wear, or rendering critical interfaces non-functional. This extreme precision ensures seamless integration within complex assemblies, guarantees predictable performance under extreme stress and environmental conditions, and directly impacts the longevity and reliability of the final product. For industries where human safety or mission success is paramount, precision machining is not a cost center but a critical risk mitigation strategy.

Achieving this level of consistency requires more than advanced CNC equipment. It demands a holistic engineering approach encompassing meticulous material science understanding, sophisticated process planning, rigorous in-process metrology, and a deeply ingrained culture of quality control. Material behavior under cutting forces, thermal management during machining, and the strategic sequencing of operations to minimize residual stress are all critical factors mastered only through extensive practical experience. The capability to hold tight tolerances consistently across complex geometries and diverse materials – from high-temp superalloys to biocompatible titanium – separates true precision manufacturers from standard job shops. This expertise is forged through decades of solving the most demanding engineering challenges.

Wuxi Lead Precision Machinery exemplifies this mastery, honed through direct contributions to projects where failure is inconceivable. Our engineering teams possess proven experience machining mission-critical components for Olympic-grade athletic equipment, where microscopic imperfections directly impact world-record performance and athlete safety. Equally significant is our track record supplying precision-machined subsystems for specialized military applications, adhering to stringent MIL-STD requirements where environmental resilience and absolute dimensional fidelity are non-negotiable. This heritage instills a unique discipline in our processes, ensuring every component leaving our facility meets the uncompromising standards demanded by the world’s most advanced industries.

The following table outlines the precision capabilities routinely achieved by Wuxi Lead Precision Machinery for critical CNC machined components:

| Parameter | Standard Capability | High-Precision Capability | Typical Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm (2µm) | Aerospace seals, optical mounts |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.005 mm | Hydraulic manifolds, bearing races |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm – 0.4 µm | Medical implants, fuel system parts |

| Material Range | Aluminum, Steel, Stainless | Titanium, Inconel, PEEK | Critical structural, high-temp |

| Max. Part Complexity | Multi-axis prismatic | 5-axis simultaneous complex contours | Turbine blades, ergonomic medical devices |

Precision in CNC machining is the tangible expression of engineering integrity. At Wuxi Lead Precision Machinery, our decades of experience delivering components for the Olympic stage and demanding military programs provide the proven foundation to ensure your most critical applications perform flawlessly, every time. This is the standard we engineer to.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling us to produce complex, high-accuracy components with superior surface finishes and tight geometric tolerances. Our 5-axis machining centers provide simultaneous multi-axis motion, allowing for intricate contours, deep cavities, and compound angles to be machined in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times compared to traditional 3-axis methods.

All machining operations are supported by state-of-the-art CAD/CAM software, ensuring optimized toolpaths, efficient material removal, and precise feature alignment. Our engineering team works closely with clients during the design-for-manufacturability phase to identify opportunities for cost reduction, improved functionality, and faster production cycles. Materials commonly processed include aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics such as PEEK and PTFE, all machined under strict environmental and process controls.

Quality assurance is embedded throughout our production workflow. Every component undergoes comprehensive dimensional verification using a Zeiss Coordinate Measuring Machine (CMM), capable of sub-micron level accuracy. The CMM inspection process ensures full compliance with geometric dimensioning and tolerancing (GD&T) requirements as specified in engineering drawings. Additional quality controls include first-article inspection reports (FAIR), in-process checks, and final inspection documentation, all traceable to individual production lots.

Our facility maintains ISO 9001:2015 certification, reflecting our commitment to consistent quality, continuous improvement, and customer satisfaction. All operators and quality technicians are trained in precision measurement techniques and adhere to standardized work instructions to ensure repeatability across production runs, whether prototyping or high-volume orders.

The following table outlines the standard and precision tolerance capabilities achievable across common machining features:

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | Up to 300 mm |

| Diameter | ±0.03 mm | ±0.008 mm | Turning & milling |

| Positional Tolerance | ±0.05 mm | ±0.01 mm | GD&T compliant |

| Flatness | 0.05 mm | 0.005 mm | Per ISO 1101 |

| Surface Roughness | Ra 3.2 µm | Ra 0.4 µm | Achievable with fine finishing passes |

| Angular Features | ±0.1° | ±0.05° | 5-axis simultaneous machining |

These capabilities, combined with our technical expertise and quality infrastructure, position Wuxi Lead Precision Machinery as a trusted partner for mission-critical CNC machined components requiring the highest levels of accuracy and reliability.

Material & Finish Options

Material Selection for Precision CNC Machined Components

Selecting the optimal material for CNC machined components is critical to balancing performance, cost, and manufacturability. At Wuxi Lead Precision Machinery, we prioritize materials that align with your application’s mechanical demands, environmental exposure, and lifecycle requirements. Aluminum, steel, and titanium represent the core alloys for high-precision parts, each offering distinct advantages. Understanding their properties ensures cost-effective production without compromising integrity.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace and electronics due to their high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. These grades machine efficiently at high speeds, reducing lead times and tool wear. Aluminum’s lightweight nature is indispensable for weight-sensitive applications, though it may lack the wear resistance required for high-stress mechanical interfaces.

Steel variants like 4140 and 304 stainless provide superior hardness, tensile strength, and durability for industrial machinery, automotive, and tooling. 4140 offers exceptional fatigue resistance when heat-treated, while 304 stainless excels in corrosive environments. Steel’s machinability is moderate compared to aluminum, requiring optimized toolpaths and slower feeds to maintain precision. Its higher density increases part weight and material costs but delivers unmatched longevity under load.

Titanium Ti-6Al-4V is the premium choice for extreme conditions—such as aerospace structural components or medical implants—where strength, corrosion resistance, and biocompatibility are non-negotiable. Despite its challenging machinability (noted for work hardening and low thermal conductivity), titanium’s performance in high-temperature or saline environments justifies its use. Production demands rigid setups and specialized tooling to avoid contamination and ensure dimensional accuracy.

Surface finishes further enhance functionality. Anodizing is the industry-standard post-process for aluminum, creating a hard, corrosion-resistant oxide layer that accepts dyes for identification. Type II (sulfuric acid) anodizing offers economical wear resistance, while Type III (hardcoat) delivers superior abrasion tolerance for hydraulic or marine parts. We strictly control anodizing thickness, adhesion, and pore sealing to meet MIL-A-8625 or ISO 12670 standards.

Material properties directly impact CNC machining efficiency and final part performance. The table below summarizes critical specifications for common alloys:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Excellent (65) | Enclosures, brackets, heat sinks |

| Steel 4140 | 655 | 7.85 | Good (60) | Shafts, gears, tooling |

| Stainless 304 | 515 | 8.0 | Moderate (45) | Valves, food processing |

| Titanium Ti-6Al-4V | 900 | 4.43 | Fair (20) | Aircraft fittings, medical |

Material selection is never one-size-fits-all. Our engineering team collaborates with clients to evaluate load requirements, environmental factors, and total cost of ownership—ensuring your CNC machined components exceed operational expectations. For complex projects, we recommend prototyping with candidate materials to validate performance before full-scale production. Contact Wuxi Lead Precision Machinery to optimize your material strategy with data-driven insights and precision manufacturing expertise.

Manufacturing Process & QC

From Concept to Completion: The Precision CNC Machining Workflow at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, the production of high-performance CNC machined components follows a rigorously controlled workflow designed to ensure zero defects and unmatched consistency. Our process spans three critical phases: Design, Prototyping, and Mass Production. Each stage integrates advanced engineering insight, cutting-edge technology, and stringent quality assurance to deliver components that meet the exacting standards of aerospace, medical, and industrial automation sectors.

The journey begins with Design, where our engineering team collaborates closely with clients to interpret technical specifications and functional requirements. Utilizing industry-leading CAD/CAM software, we develop detailed 3D models and generate optimized toolpaths tailored to the selected material and geometry. Design for Manufacturability (DFM) analysis is conducted at this stage to identify potential challenges in machining, assembly, or performance, allowing for proactive refinement before any material is cut. This collaborative approach ensures that every component is not only precise in form but also efficient to produce at scale.

Next, we move to Prototyping, a phase critical to validating both design integrity and process reliability. Using high-precision 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes in the actual production-grade material. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers to verify dimensional accuracy and surface quality. Feedback from testing is incorporated into final design or process adjustments, ensuring that the transition to full-scale production is seamless and risk-free.

The final phase, Mass Production, leverages automated CNC cells, real-time process monitoring, and Statistical Process Control (SPC) to maintain consistency across large volumes. Each component is machined under controlled environmental conditions, with tool wear monitored and compensated dynamically. Our zero-defect philosophy is enforced through 100% in-process inspection for critical dimensions and full batch traceability. Every part is documented with a certificate of conformance, including material certification and inspection reports.

Our production capabilities support a wide range of materials and tight tolerances, ensuring adaptability across industries.

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC Milling, CNC Turning, Mill-Turn |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin |

| Tolerances | ±0.005 mm (±0.0002″) standard; down to ±0.001 mm with special controls |

| Surface Finish | Ra 0.8 µm standard; down to Ra 0.2 µm with fine finishing |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Quality Standards | ISO 9001:2015 certified, full inspection reporting, PPAP documentation available |

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer trust through precision, transparency, and total process control.

Why Choose Wuxi Lead Precision

Elevate Your Supply Chain with Precision Engineering Partnership

Selecting a CNC machining partner transcends transactional procurement; it demands a strategic alliance built on unwavering technical capability and collaborative problem-solving. At Wuxi Lead Precision Machinery, we engineer this partnership through decades of mastery in high-complexity, tight-tolerance component manufacturing. Our ISO 9001:2015 and IATF 16949-certified facility in Wuxi, China, serves global leaders in aerospace, medical device, and industrial automation sectors where failure is not an option. We integrate advanced 5-axis milling, precision turning, and multi-spindle Swiss machining with rigorous in-process metrology to transform your most demanding designs into flawless physical reality. This commitment ensures your components meet exacting functional and regulatory requirements while optimizing total cost of ownership.

Our technical capabilities are engineered for mission-critical applications. The table below details core specifications governing our production ecosystem:

| Specification | Capability Range |

|---|---|

| Tolerance Range | ±0.0002″ (5µm) to ±0.001″ (25µm) |

| Max Work Envelope | 2000 x 1000 x 800 mm (78.7 x 39.4 x 31.5 in) |

| Material Expertise | Titanium, Inconel, 17-4PH SS, PEEK, Aluminum 7075-T6, Tool Steels |

| Quality Certifications | ISO 9001:2015, IATF 16949, AS9100D (in progress) |

| Typical Lead Time | 15-25 days for complex prototypes; 20-35 days for production runs |

Beyond machinery and metrics, we mitigate your operational risks through proactive engineering engagement. Our cross-functional teams collaborate during your design phase to identify manufacturability enhancements, reducing scrap rates and accelerating time-to-market. Real-time SPC data tracking and full FAI documentation provide auditable quality assurance, while our dedicated logistics coordination ensures on-time delivery to your assembly line—critical for JIT manufacturing environments. We understand that inconsistent quality or delayed shipments disrupt entire value chains; our structured NPI process and contingency planning eliminate these vulnerabilities.

Partnering with Lead Precision means securing a single source for components requiring micron-level precision across diverse material families and geometries. We invest in your success through transparent communication, flexible capacity allocation, and continuous improvement initiatives aligned with your evolving technical roadmaps. Our export experience spans 32 countries, with stringent adherence to ITAR, REACH, and RoHS compliance frameworks.

Initiate your precision advantage today. Contact our engineering team directly at [email protected] to discuss your specific requirements. Share your CAD files or technical drawings for a rapid manufacturability assessment and competitive quotation. Let us demonstrate how our technical rigor and partnership ethos become your strategic differentiator in the global marketplace. Your next breakthrough component begins with an engineered collaboration.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.