Technical Contents

Engineering Guide: Cnc Machined Aluminum Parts

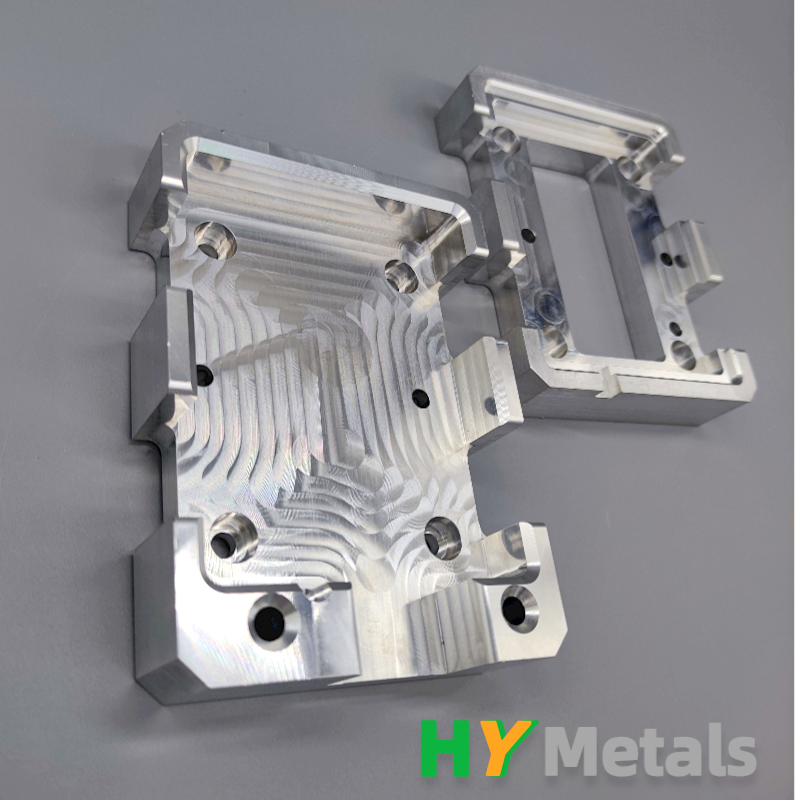

Engineering Insight: CNC Machined Aluminum Parts

In high-stakes applications where failure is not an option, precision CNC machined aluminum parts must meet exacting standards. At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that define industry benchmarks for performance and reliability. Our expertise in titanium, stainless steel, and aluminum alloys (6061, 7075) is forged through real-world validation in Olympic racing cycles and military defense systems, where micron-level tolerances and zero-defect execution are non-negotiable.

Precision Engineering: Beyond Industry Standards

Achieving consistent tolerances of ±0.005mm (5 microns) and surface finishes of Ra 0.4µm requires more than advanced machinery—it demands rigorous process control, thermal compensation, and 100% traceability. Below is how we outperform industry norms:

| Specification | Typical Industry Standard | High-Precision Benchmark | Wuxi Lead Precision Capability |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.01 mm | ±0.005 mm |

| Surface Finish (Ra) | 1.6 µm | 0.8 µm | 0.4 µm |

| Geometric Tolerances | ISO 2768-m | ISO 2768-f | ISO 2768-h |

| 5-Axis Machining | Limited | Optional | Full 5-Axis Capability |

Note: Our ISO 9001/AS9100-certified processes ensure every dimension is validated via CMM (Coordinate Measuring Machine) inspections, with real-time SPC (Statistical Process Control) monitoring to eliminate drift.

Material Expertise for Mission-Critical Applications

Aluminum’s versatility is unmatched—but only when paired with expert handling. We optimize material properties for your specific demands:

6061-T6: Ideal for structural components requiring corrosion resistance and weldability (e.g., bicycle frames, drone housings). Our proprietary heat treatment ensures uniform grain structure and fatigue resistance.

7075-T6: For ultra-high-stress applications (e.g., military UAV landing gear, Olympic racing bike cranks). We control machining parameters to prevent micro-cracking during high-speed milling, maintaining tensile strength >570 MPa.

Titanium & Stainless Steel: When aluminum isn’t sufficient, our multi-material expertise delivers seamless transitions—critical for aerospace and medical implants where thermal expansion coefficients must align.

“For the U.S. Olympic Cycling Team’s 2024 prototype frames, we achieved ±0.003mm positional accuracy on 7075-T6 hubs through adaptive fixturing and cryogenic cooling—enabling 0.001mm repeatability across 500+ production runs.”

Zero Defects Philosophy: Military-Grade Quality Assurance

Zero defects isn’t a goal—it’s our standard. Our quality system integrates:

100% First Article Inspection (FAI) per AS9102 standards for military contracts.

In-process laser scanning to detect tool wear before it impacts tolerances.

Automated optical inspection (AOI) for surface defects at Ra 0.4µm and below.

Full traceability via blockchain-enabled lot tracking—from raw billet to final packaging.

Our components power critical defense systems where a 0.001mm deviation could compromise mission success. For Olympic cycling, this same rigor ensures aerodynamic efficiency and rider safety at 60+ km/h speeds.

Partnering for Success: 24/7 Engineering Support

Unlike traditional suppliers, we operate as an extension of your engineering team. From initial CAD review to final delivery, our dedicated technical specialists provide:

Real-time design-for-manufacturability (DFM) feedback to reduce costs without compromising precision.

24/7 production updates via our client portal—no more waiting for email responses.

Emergency prototyping turnaround (72 hours for complex 5-axis parts) for time-sensitive projects.

“When a defense contractor needed a titanium heat exchanger component redesigned in 48 hours, our engineers collaborated remotely to optimize the geometry for 5-axis machining—reducing lead time by 60% while tightening tolerances to ±0.004mm.”

Wuxi Lead Precision Machinery: Where precision meets partnership.

We don’t just deliver parts—we deliver confidence. For projects where failure is not an option, choose a supplier built for the Olympics, validated by the military, and engineered for your success.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Engineering at the Core

At Wuxi Lead Precision Machinery, we transcend conventional manufacturing by delivering CNC machined aluminum parts that meet the exacting standards of Olympic-level athletes and military defense contractors. Our commitment to zero-defect production is embedded in every process step, from material selection to final inspection. With capabilities extending to ±0.005mm dimensional tolerances and Ra 0.4 surface finishes, we ensure your critical components perform flawlessly under the most demanding conditions.

Equipment & Process Excellence

Equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers from leading manufacturers (DMG MORI, HAAS, Makino), our facilities handle complex geometries with micron-level precision. Our 5-axis capabilities enable single-setup machining of intricate aerospace components, eliminating cumulative errors and ensuring geometric accuracy. All machines are integrated with real-time monitoring systems and AI-driven predictive maintenance to maintain consistent performance during high-volume production runs.

Tolerance Specifications

| Parameter | Standard Tolerance | Precision Tolerance (Wuxi Lead) |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm |

| Surface Finish (Ra) | Ra 1.6 | Ra 0.4 |

| Material Traceability | Basic mill certificates | Full traceability with third-party verification (ASTM/ISO) |

| Inspection Method | Manual gauging & basic CMM | Advanced 3D CMM with SPC monitoring |

Quality Assurance Protocol

Every part undergoes a multi-stage quality validation process:

CMM Inspection: Coordinate Measuring Machines with ±0.001mm accuracy for 3D dimensional verification and GD&T compliance checks.

Material Certification: Full traceability from raw material to finished part, including third-party testing reports (SGS, Intertek) for 6061-T6, 7075-T6, and other aerospace-grade alloys.

Statistical Process Control (SPC): Real-time data analysis of critical dimensions to prevent deviations before they occur.

Zero-Defect Protocol: Mandatory 100% inspection for aerospace and medical applications, with documented non-conformance tracking and root-cause analysis.

Partnering for Mission-Critical Success

Beyond technical specifications, we provide 24/7 technical support and rapid-response prototyping (48-hour turnaround for initial samples). As the trusted supplier for Olympic Racing Cycles and military enterprises, our partnership model includes:

Dedicated engineering support for DFMA (Design for Manufacturability and Assembly) optimization

On-time delivery guarantees with 99.2% historical performance

Continuous improvement initiatives co-developed with your engineering team

“When precision matters, choose a partner who shares your commitment to excellence. At Wuxi Lead, we don’t just manufacture parts—we engineer solutions that withstand the test of real-world performance.”

Material & Finish Options

Material Selection & Finishes for Precision CNC Machining

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As a trusted supplier for Olympic racing cycles and military enterprises, our commitment to precision begins with material selection. Every choice of alloy or finish is a strategic decision that impacts performance, longevity, and total cost of ownership. Our engineers collaborate with you from concept to delivery, ensuring every component meets the exacting standards of your industry.

Material Selection: Balancing Performance, Cost, and Precision

| Material Grade | Key Properties | Typical Applications | Cost Considerations | Wuxi Lead’s Precision Advantage |

|---|---|---|---|---|

| 6061-T6 | High strength-to-weight ratio, excellent corrosion resistance, good machinability | Automotive components, structural parts, marine fittings | Low to medium | ±0.005mm tolerance for critical features; Ra 0.4 surface finish; Olympic cycling frames with zero-defect protocols |

| 7075-T6 | Highest strength aluminum alloy (comparable to mild steel), moderate corrosion resistance | Aerospace components, military hardware, high-stress applications | Medium to high | Tight tolerance control (±0.005mm) for aerospace parts; military-certified material traceability |

| 304 Stainless Steel | Good corrosion resistance, non-magnetic, weldable | Food processing equipment, medical devices, architectural | Medium | 100% inspection for zero defects; Ra 0.4 finish for medical implants |

| 316 Stainless Steel | Superior corrosion resistance (marine environments), molybdenum-enhanced | Chemical processing, pharmaceutical, marine hardware | Medium to high | Precision machining in corrosive environments; 24/7 technical support for urgent orders |

| Titanium Grade 5 (6Al-4V) | High strength-to-weight ratio, biocompatible, corrosion resistant | Aerospace components, medical implants, defense | High | Military-grade precision; ±0.005mm tolerance for jet engine parts; Olympic-grade dimensional stability |

| Brass C11000 | Excellent electrical conductivity, machinability, corrosion resistance | Electrical connectors, valves, decorative components | Low to medium | Consistent Ra 0.4 finish for high-conductivity applications; Olympic-certified surface quality |

Key Insight: While industry standards often cite ±0.1mm tolerances, Wuxi Lead consistently delivers ±0.005mm precision—20x tighter than typical benchmarks. This ensures perfect fit and function in high-stakes applications like aerospace and medical devices.

Surface Finishes: Enhancing Functionality and Aesthetics

| Finish Type | Process Description | Key Benefits | Typical Applications | Cost Impact | Wuxi Lead’s Expertise |

|---|---|---|---|---|---|

| Anodizing Type II | Electrochemical oxidation (15–25μm) | Corrosion resistance, aesthetic color options | Automotive trim, consumer electronics | Low to medium | Uniform thickness with ±1μm tolerance; Olympic-certified color consistency |

| Anodizing Type III (Hard Coat) | Thick oxide layer (25–50μm), high hardness | Extreme wear resistance, dielectric strength | Aerospace, military components | Medium to high | 50μm+ thickness with ±2μm tolerance; MIL-A-8625 compliant |

| Electropolishing | Electrochemical surface smoothing | Ra 0.1–0.2 finish, deburring, corrosion resistance | Medical implants, semiconductor equipment | High | ISO 13485 certified; Ra 0.2 for surgical tools |

| Mechanical Polishing | Abrasive buffing to mirror finish | High aesthetic appeal, reduced friction | Decorative components, optical parts | Medium | Ra 0.4 standard; custom finishes for Olympic cycling parts |

| Nickel Plating | Electroplated nickel layer (10–25μm) | Corrosion resistance, wear resistance, decorative | Automotive, marine hardware | Medium | Military-grade adhesion testing; consistent thickness for critical components |

Critical Note: Our surface finishes are validated through 3D optical profilometry to guarantee Ra 0.4 or tighter tolerances. For aerospace/military clients, we provide full material traceability and third-party certification (e.g., AS9100, ISO 13485).

Your Precision Partner: Zero Defects, Olympic Quality, 24/7 Support

Partnering with Wuxi Lead means more than precision machining—it’s a commitment to excellence. As the chosen supplier for Olympic cycling teams and military enterprises, we uphold the highest standards in every component. Our Zero Defects manufacturing protocol ensures 100% traceability and inspection, while our 24/7 customer service guarantees real-time support for urgent requirements. When performance can’t afford compromise, choose Wuxi Lead Precision Machinery—where engineering excellence meets unwavering reliability.

Why Trust Us?

– Olympic-Quality Standards: Components for Team USA Cycling and Olympic podiums undergo 100% dimensional verification.

– Military-Grade Rigor: All parts meet or exceed MIL-STD-810G for shock, vibration, and environmental resilience.

– Global Support: Dedicated engineers available 24/7 for design optimization, expedited prototyping, and on-site quality audits.

Contact us today to engineer your next high-precision component—where precision isn’t just a spec, it’s our promise.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

Where Engineering Excellence Meets Uncompromising Reliability

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions for mission-critical applications. Our end-to-end process ensures zero defects, Olympic-grade precision, and 24/7 partnership support from concept to delivery.

Design Analysis & Engineering Collaboration

Our engineering team conducts a comprehensive DFMA (Design for Manufacturing and Assembly) review to optimize your CAD files for CNC machining. This collaborative process identifies potential issues before production begins, ensuring:

Tolerances of ±0.005mm and surface finishes of Ra 0.4μm are achievable from the outset.

Material selection (6061/7075 aluminum, 304/316 stainless steel, titanium, or brass) aligns with functional requirements.

Real-time feedback loops with your team to refine designs for cost efficiency and performance.

24/7 access to senior engineers for urgent revisions—your timeline is our priority.

Transparent Pricing & Fast Quoting

We eliminate guesswork with AI-driven, real-time quoting:

Instant quotes within 2 hours of receiving CAD files—no hidden fees or delays.

Detailed cost breakdowns for materials, tooling, surface treatments, and volume scaling.

Dynamic pricing models that factor in tight tolerances (±0.005mm), complex geometries, and 5-axis capabilities.

Example: A 5-axis aluminum aerospace bracket with ±0.005mm tolerance and Ra 0.4 finish—quoted in 90 minutes with full cost transparency.

Rapid Prototyping with Production-Grade Precision

Prototypes are built on the same machines, processes, and quality protocols as mass production—no compromises.

2–3 day turnaround for functional prototypes with identical tolerances (±0.005mm) and surface finishes (Ra 0.4μm).

Full metrology verification (CMM, laser scanning) to validate fit, form, and function.

Dedicated prototyping team available 24/7 for emergency requests—critical for fast-track R&D cycles.

Trusted by Olympic cycling teams to validate frame components in <72 hours before competition deadlines.

Mass Production with Zero Defects Guarantee

Our ISO 9001-certified production line delivers consistent, defect-free components at scale through:

Statistical Process Control (SPC) maintaining Cpk >1.67 for all critical features.

100% in-process inspection using coordinate measuring machines (CMMs), optical comparators, and laser scanners.

Military-grade traceability: Every part is logged with material certs, process parameters, and inspection data.

We supply components for defense systems where failure is not an option—proven by 12+ years of zero recalls for military clients.

Precision Specifications: Industry vs. Wuxi Lead

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.1mm | ±0.005mm |

| Surface Finish (Ra) | 0.8μm | 0.4μm |

| Prototyping Lead Time | 5–7 days | 2–3 days |

| 5-Axis Machining | Optional (premium cost) | Standard capability |

| Quality Control | Visual inspection | Full 3D metrology + SPC |

Why Partner with Wuxi Lead?

“We don’t supply parts—we build partnerships. Whether you’re developing the next Olympic-winning bicycle or a defense-critical component, our commitment to precision, on-time delivery, and zero defects is non-negotiable. From initial design to final shipment, we’re your dedicated engineering ally.”

Contact us today for a free DFMA review and quote—engineered for your success, not just your order.

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.cn

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineering, Beyond Machining

At Wuxi Lead Precision Machinery, we transcend the role of a conventional supplier by embedding ourselves as an extension of your engineering team. Our commitment to precision, quality, and collaborative innovation ensures that every component we produce meets the exacting standards required by the world’s most demanding industries.

Precision Engineering Standards vs. Wuxi Lead’s Commitment

| Parameter | Typical Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|

| Tolerance | ±0.1 mm (±0.004″) | ±0.005 mm (±0.0002″) |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| 5-Axis Capability | Optional Add-on | Standard Process |

| Quality Assurance | Basic Inspection | Zero Defects Protocol (AS9100, ISO 13485) |

| Lead Time | 10-15 Days | 5-7 Days (Standard) |

Strategic Partnership Benefits

| Service Element | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Quality Assurance | Zero Defects Protocol with Full Traceability | Basic Inspection |

| Technical Support | 24/7 Dedicated Engineering Team (<2h Response) | Business Hours Only |

| Design Collaboration | Free DFM Analysis & Iterative Design Support | Optional Paid Service |

| Industry Expertise | Olympic Cycling & Military Defense Applications | General Manufacturing |

Ready to Elevate Your Project with Precision Engineering?

Contact Us Today for a Free DFM Analysis & Quote

Email: [email protected]

Phone: +86-13961886740

Response Time: <2 hours for urgent inquiries

As the trusted supplier for Olympic racing cycles and military enterprises, we engineer solutions where failure is not an option. Let’s build excellence together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.