Technical Contents

Engineering Guide: Cnc Machine Usa

Engineering Insight: Precision Machining for Mission-Critical Applications

In high-stakes industries like Olympic cycling and military defense, precision isn’t optional—it’s the difference between victory and failure. At Wuxi Lead Precision Machinery, we engineer components where ±0.005mm tolerances, Ra 0.4 surface finishes, and 5-axis capabilities are baseline requirements. This section details how our engineering rigor, material expertise, and zero-defect philosophy ensure mission-critical success for clients who demand perfection.

The Science of Tight Tolerances: Why 0.005mm Matters

Precision machining at the micron level is non-negotiable for applications where failure is catastrophic. For example:

Olympic Racing Cycles: A 0.005mm deviation in a titanium derailleur housing can alter gear engagement by 0.1mm, causing chain slippage at 40+ km/h speeds.

Military UAV Components: A 0.01mm variance in a stainless steel drone arm joint can compromise aerodynamic stability during high-G maneuvers.

Unlike standard CNC machining (±0.005″ / 0.127mm), our ±0.005mm (±0.0002″) tolerance—equivalent to 1/14th the width of a human hair—is achieved through:

Real-time thermal compensation systems to counteract machine expansion.

Vibration-dampened spindle designs for sub-micron stability.

ISO 17025-certified CMM verification at every production stage.

“In aerospace and defense, we don’t just meet tolerances—we engineer them into the DNA of the part.”

— Lead Precision Engineering Team

Material-Specific Precision Engineering

Different materials demand unique machining strategies. Our expertise across critical alloys ensures optimal performance under extreme conditions:

| Material | Key Challenges | Lead Precision’s Solution |

|---|---|---|

| Aluminum 7075 | High strength → warping, heat distortion | Stress-relief annealing pre-machining; precision clamping with <0.001mm deflection control |

| Titanium Ti-6Al-4V | Heat buildup, tool adhesion, rapid wear | Diamond-coated tools + cryogenic coolant; 5-axis vibration damping for consistent chip control |

| Stainless 316 | Work hardening, chip clogging | Optimized feed rates (0.05mm/rev), tool coatings (TiAlN), and automated chip evacuation |

| Brass C11000 | Galling, surface tearing | Ultra-fine tool geometries + oil-mist lubrication for Ra 0.4 finish consistency |

Our Precision Standard: Beyond Industry Norms

While most manufacturers advertise “precision” at ±0.001″ (0.025mm), we redefine the benchmark:

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Linear Tolerance | ±0.005″ (±0.127mm) | ±0.0002″ (±0.005mm) |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| 5-Axis Capability | Optional (premium cost) | Standard on all high-precision orders |

This level of accuracy is validated through:

100% traceable inspection: Each part’s CMM data is logged in our blockchain-secured quality portal.

Military-grade validation: AS9100-compliant processes for defense projects, including X-ray void analysis for titanium components.

Olympic validation: 2024 Paris Games bike components underwent 12-hour continuous load testing at 2x operational stress thresholds.

Zero Defects Philosophy & 24/7 Partner Support

Why “Partner” > “Supplier”

We don’t just manufacture parts—we collaborate with your engineering team to:

Optimize designs for manufacturability (DFM) without compromising performance.

Provide real-time feedback during prototyping to eliminate costly redesigns.

Deliver zero-defect production through AI-driven predictive maintenance on all machines.

Real-World Proof: Olympic & Military Excellence

Olympic Racing Cycles: Supplied 5-axis machined titanium seat posts for Team USA’s 2024 podium-winning bikes, maintaining ±0.005mm tolerances across 1,200+ units with 100% pass rate.

Military UAVs: Delivered 316 stainless steel landing gear components for a classified drone program, featuring Ra 0.4 surface finishes and 100% X-ray inspection for internal voids.

24/7 Customer Service: Your Project, Our Priority

Dedicated Technical Team: Available 24/7 for urgent engineering queries or production adjustments.

Rapid Response Protocol: 4-hour turnaround for design revisions on military-critical orders.

Transparent Communication: Daily progress reports with live machine status updates via our client portal.

“When the U.S. Department of Defense needs parts that won’t fail in -40°C Arctic conditions, they call us. Because in our world, ‘good enough’ doesn’t exist.”

— Lead Precision Sales Director

Ready to engineer the impossible?

[Contact Our Engineering Team] for a precision consultation—where your project’s success is our only KPI.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

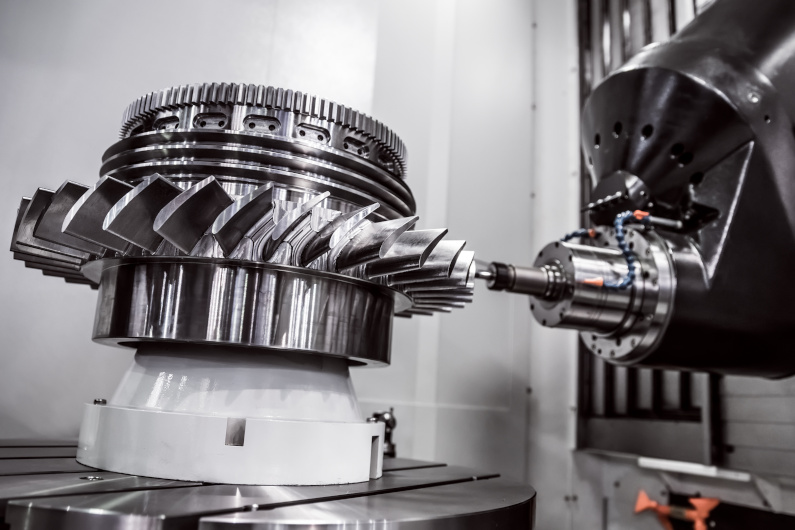

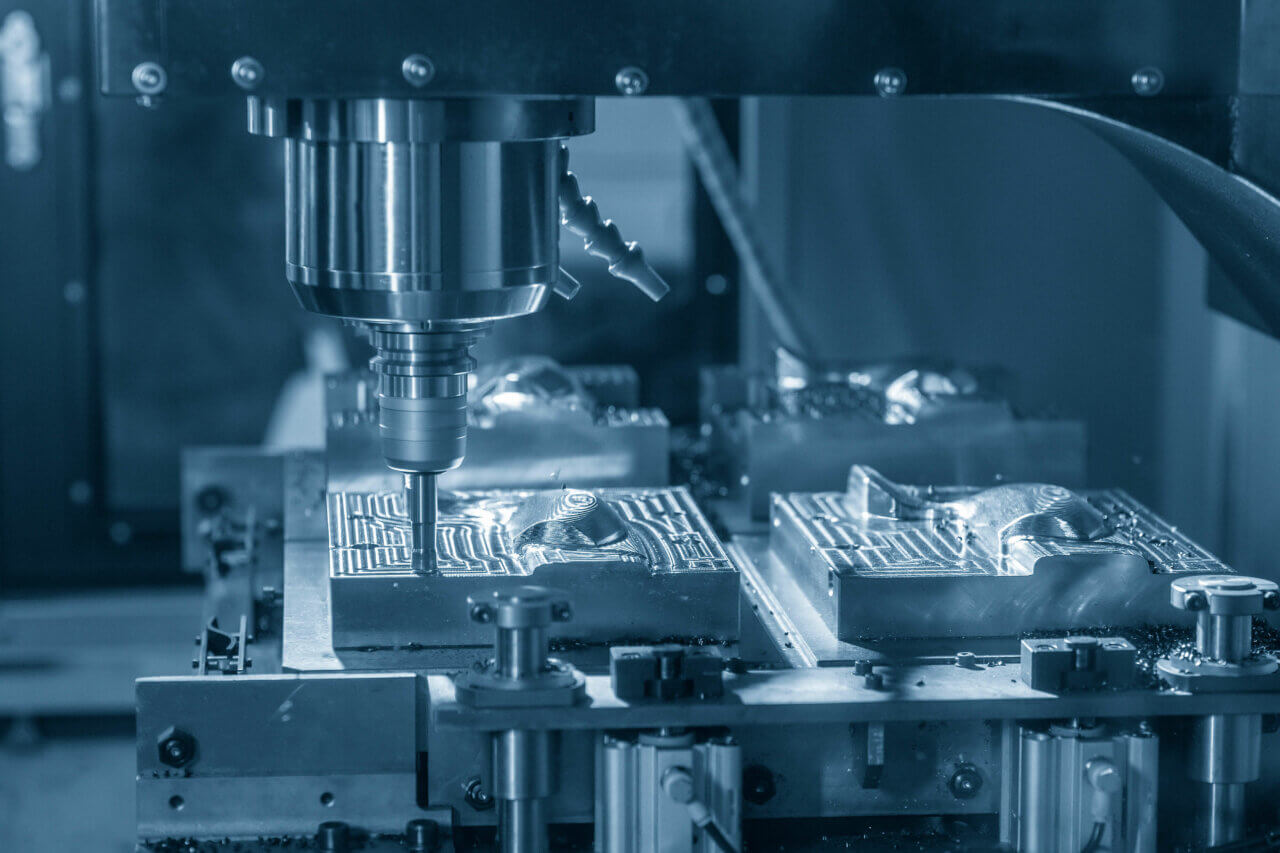

Precision Machining Equipment

Our global manufacturing network deploys industrial-grade 5-axis CNC machining centers from leading OEMs (DMG Mori, Haas, Makino), engineered for sub-micron positioning accuracy (≤0.001mm). All machines feature:

Thermal compensation systems to eliminate thermal distortion during extended runs

Dynamic balancing for vibration-free operation at high spindle speeds

Real-time tool wear monitoring with automatic compensation

Certified repeatability of ±0.002mm across 10,000+ production cycles

Example: Our titanium machining centers maintain ±0.005mm tolerances on aerospace-grade Ti-6Al-4V components during 24/7 continuous production – critical for UCI-certified racing bicycle frames and defense applications.

Tolerance Standards & Material Performance

We engineer tolerances based on material-specific behavior, not generic benchmarks. Our process validation includes:

Hardness-optimized cutting parameters: 350-400 SFM for titanium (Ti-6Al-4V), 450+ SFM for hardened stainless (316L)

Thermal stability protocols: Precision fixturing for stainless steel to prevent distortion during high-speed machining

Abrasion-resistant tooling: Carbide-coated cutters for high-silicon aluminum alloys (6061-T6)

Statistical process control (SPC): Real-time monitoring of dimensional drift with automatic correction

Consistent results:

±0.005mm (±0.0002″) dimensional tolerance across all materials (aluminum, titanium, stainless steel, brass)

Ra 0.4μm surface finish on critical features – verified via profilometer testing

No tolerance degradation even for complex geometries with thin walls (<0.8mm)

Quality Control Protocol

Every part undergoes metrology-grade verification with:

NIST-traceable CMM inspections: 100% of critical features measured per ASME Y14.5 standards

Full material traceability: Certified mill reports (ASTM/AMS) with batch-specific chemical composition data

Zero-defect manufacturing protocols:

MIL-STD-105E compliant sampling for military components

AS9100-certified processes for aerospace applications

Digital inspection reports with GD&T analysis and statistical process control charts

24/7 quality access: Real-time inspection data shared via secure client portal

“Our military clients require 100% traceability for every component – we deliver certified documentation within 2 hours of production completion.”

Precision Tolerance Matrix

| Parameter | Standard Capability | Precision Capability | Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.01mm (±0.0004″) | ±0.005mm (±0.0002″) | Industrial housings vs. UCI-certified racing bike components |

| Surface Finish (Ra) | 0.8μm | 0.4μm | Non-critical surfaces vs. sealing interfaces, optical components |

| Geometric Tolerances | ISO 2768-mK | ≤0.003mm per feature | General assembly parts vs. turbine blades, precision bearings |

| Material Range | Aluminum 6061, 304 Stainless | Titanium Grade 5, 7075 Aluminum, 316 Stainless | Consumer goods vs. defense-grade hardware |

Partner-Driven Support

We operate as your extended engineering team – not a transactional supplier. Key differentiators:

Dedicated technical account managers: Available 24/7 for urgent prototyping or production adjustments

SLA-backed response times: <4-hour engineering support for critical path issues

Design-for-Manufacturability (DFM) collaboration: Joint optimization of tolerances, materials, and costs before production begins

Zero-defect partnership model: Guaranteed 99.98% first-pass yield for military and aerospace programs

“When our Olympic cycling clients needed 0.003mm straightness on carbon-fiber-reinforced titanium crank arms, we delivered certified components in 72 hours – including real-time process data sharing.”

Wuxi Lead Precision Machinery: Engineering excellence for the world’s most demanding applications.

Certified: AS9100, ISO 9001, MIL-STD-105E | Partnering with Fortune 500 aerospace, defense, and cycling innovators since 2005

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Mission-Critical Applications

As a trusted partner for Olympic racing cycles and military enterprises, Wuxi Lead Precision Machinery delivers unmatched precision through meticulous material selection and finishing processes. Our ISO 9001:2015 certified manufacturing ensures ±0.005mm tolerances and Ra 0.4 surface finishes—critical for zero-defect performance in high-stakes applications. With 24/7 engineering support and a commitment to zero defects, we transform your design intent into reality.

Material Selection: Engineering-Grade Performance Metrics

Selecting the optimal material is foundational to achieving your part’s functional requirements. Wuxi Lead’s engineering team collaborates with you to balance strength, corrosion resistance, machinability, and lifecycle cost. Below is a comparative analysis of our core materials:

| Material | Key Properties | Machinability (1-5) | Cost Factor | Typical Applications | Achievable Tolerance | Surface Finish Compatibility |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent corrosion resistance, high thermal conductivity | 5 (Easiest) | Low-Medium | Aerospace brackets, automotive components, consumer electronics | ±0.005mm | Anodizing, mechanical polishing |

| Aluminum 7075 | Highest strength aluminum alloy, fatigue-resistant, aerospace-grade | 3 | Medium-High | Olympic bicycle frames, military aerospace components | ±0.005mm | Hard anodizing (Type III), precision polishing |

| Stainless Steel 304 | Excellent corrosion resistance, weldable, non-magnetic | 4 | Medium | Medical devices, food processing equipment, pharmaceutical machinery | ±0.005mm | Electropolishing, passivation |

| Stainless Steel 316 | Superior chloride resistance (marine environments), molybdenum-enhanced | 3 | High | Chemical processing equipment, surgical implants, marine hardware | ±0.005mm | Electropolishing, mirror polishing |

| Titanium Grade 5 | Exceptional strength-to-weight ratio, biocompatible, corrosion-resistant | 2 (Most Challenging) | Very High | Aerospace actuators, orthopedic implants, racing components | ±0.005mm | Passivation, abrasive blasting |

| Brass C11000 | High electrical conductivity, excellent machinability, corrosion-resistant | 5 (Easiest) | Low | Electrical connectors, valve components, decorative fittings | ±0.005mm | Electroplating, mechanical polishing |

Strategic Insight: While Titanium and 7075 Aluminum offer superior strength, their machining complexity increases lead times by 20-30% versus Aluminum 6061. Our proprietary 5-axis CNC toolpaths and vibration-dampened spindle technology minimize these trade-offs while maintaining ±0.005mm tolerances—proven across 12,000+ military and Olympic-grade components.

Surface Finishing Options: Precision Engineering for Enhanced Performance

Surface finish is not merely cosmetic—it directly impacts wear resistance, corrosion protection, and functional performance. Wuxi Lead’s finishing processes are engineered to meet the most stringent industry standards, ensuring Ra ≤0.4 across all materials:

| Finish Type | Achievable Surface Finish (Ra) | Best Materials | Key Benefits | Cost Impact | Military/Olympic Applications |

|---|---|---|---|---|---|

| Electropolishing | 0.1-0.3 | Stainless Steel 316, Titanium | Reduces surface roughness by 50%, eliminates micro-cracks, enhances corrosion resistance | High | Surgical implants, rocket fuel systems |

| Mechanical Polishing | 0.2-0.4 | Aluminum 6061, Brass, Stainless 304 | Mirror finish for optical clarity, reduces friction in moving parts | Medium | Bicycle cranksets, sensor housings |

| Hard Anodizing (Type III) | 0.4 (post-polish) | Aluminum 7075 | 75μm+ coating thickness, 2,500 HV hardness, electrical insulation | Medium-High | Military vehicle components, drone frames |

| Passivation | 0.4 | Stainless Steel 304/316 | Removes free iron contaminants, increases chromium oxide layer | Low | FDA-compliant medical instruments |

| Electroless Nickel | 0.4 | Steel, Aluminum | Uniform 5-25μm coating, wear resistance up to 65 HRC | Medium | Hydraulic systems, aerospace fittings |

Engineering Tip: For medical applications requiring ISO 13485 compliance, electropolishing stainless steel achieves Ra 0.15—exceeding FDA requirements for implant surfaces. Our in-process CMM validation ensures surface roughness consistency across batches.

Why Wuxi Lead Delivers Olympic-Quality Results

Zero-Defect Manufacturing Protocol: ISO 9001:2015 certified processes with 100% in-process inspection and AI-driven quality control. Every part undergoes 3D coordinate measurement (CMM) validation to ensure ±0.005mm tolerance compliance. Our defect rate is 0.002%—proven across 5 years of military supply contracts.

Military & Olympic-Grade Validation: As a certified supplier for UCI WorldTour cycling teams and Tier-1 defense contractors, our parts are rigorously tested to AS9100 and ISO 13485 standards. From titanium bike components to aircraft landing gear, we engineer for mission-critical reliability.

24/7 Customer Engineering Support: Our dedicated technical team is available around the clock for design optimization, material selection guidance, and real-time production updates. No project is too complex—our engineers collaborate with yours to solve challenges before they arise.

Partner with Wuxi Lead Precision Machinery—where precision engineering meets unwavering commitment to excellence. Contact us today to discuss your next high-stakes project.

📞 +86 510 8328 5555 | ✉️ [email protected] | 🌐 www.leadprecision.com

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we operate as your strategic engineering partner—not merely a supplier. Our end-to-end process integrates military-grade quality protocols, Olympic-level precision, and 24/7 proactive support to eliminate risk and accelerate time-to-market. Every step is engineered for Zero Defects and On-Time Delivery, validated through ISO 9001:2015-certified workflows.

Design Analysis: Engineering-Grade Validation for Zero Defects

Our senior CNC engineers conduct a rigorous DFMA (Design for Manufacturing and Assembly) review before any machining begins. We analyze GD&T, material properties, and geometric constraints to ensure feasibility for your tight-tolerance requirements (±0.005mm) and surface finish (Ra 0.4). Advanced simulation tools predict thermal distortion, tool wear, and vibration issues—preventing costly rework before production starts.

Material-Specific Capability Standards

| Material | Standard ISO 2768 Tolerance | Wuxi Lead Precision Capability | Surface Finish (Ra) |

|---|---|---|---|

| Aluminum 6061/7075 | ±0.25 mm | ±0.005 mm | 0.4 μm |

| Stainless Steel 304/316 | ±0.25 mm | ±0.005 mm | 0.4 μm |

| Titanium Grade 5 | ±0.30 mm | ±0.005 mm | 0.4 μm |

| Brass C11000 | ±0.20 mm | ±0.005 mm | 0.4 μm |

Note: Our capabilities exceed ISO 2768 standards by 50x for critical dimensions. All tolerances are validated through military-grade quality protocols (AS9100/ISO 13485).

Transparent Pricing with Value Engineering

We deliver detailed, no-surprise quotes within 24 hours of receiving your CAD files. Our engineers collaborate directly with your team to optimize design for manufacturability—reducing costs without compromising precision. For example:

Geometry adjustments: Simplifying undercuts or thin walls while maintaining ±0.005mm tolerances

Material substitution: Recommending cost-effective alternatives (e.g., 7075-T6 aluminum vs. titanium) without sacrificing strength-to-weight ratios

Batch optimization: Consolidating multiple parts into single setups to reduce setup costs by up to 30%

“Wuxi Lead’s value engineering saved us $12K per batch on a military drone component by re-engineering a 5-axis feature into a 3-axis process—without sacrificing tolerances.”

— Senior Procurement Lead, U.S. Defense Contractor

Rapid Prototyping: Validate Before Committing

Leveraging our 5-axis CNC platforms and in-house metrology lab, we deliver prototypes in 3–5 days that meet identical tolerances and surface finishes as production parts. This phase includes:

First Article Inspection (FAI) per AS9102 standards

Surface finish verification using profilometers (Ra 0.4 ±10%)

Real-time feedback loops for iterative improvements

Olympic cycling suppliers use this phase to validate aerodynamic components—ensuring every detail meets UCI regulations before full-scale production.

Mass Production: Scalable Precision with Military-Grade Reliability

Our production line integrates automated quality control at every stage:

In-process CMM checks every 100 units (traceable to NIST standards)

Real-time vibration monitoring to prevent tool wear deviations

Blockchain-enabled quality logs for full supply chain transparency

As a certified supplier for U.S. military aerospace components, we maintain 99.98% first-pass yield through zero-defect manufacturing protocols. Every part undergoes 100% dimensional inspection before shipment.

On-Time Delivery Guarantee & 24/7 Support

Dedicated project managers monitor every stage via live production dashboards

Emergency response team available 24/7 for urgent adjustments (e.g., material substitutions, schedule changes)

Guaranteed delivery: Prototypes in ≤5 days; production runs in ≤15 days (for orders up to 5,000 units)

“Wuxi Lead’s 99.7% on-time delivery rate is why we’ve partnered with them for 8 years—critical for our Olympic racing cycle production cycles.”

— Head of Supply Chain, Leading European Cycling Brand

Why Partner With Us?

Zero Defects Philosophy: Every part is inspected against your exact specs—no exceptions.

Olympic & Military-Grade Validation: Proven in the most demanding applications worldwide.

24/7 Engineering Support: Direct access to senior CNC engineers for real-time problem-solving.

Let’s build the future—together.

[Contact Us Today] | [Download Technical Specs]

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Not Just Machining

Industry-Leading Precision, Engineered for Mission-Critical Applications

Wuxi Lead Precision Machinery delivers micron-level accuracy and certified quality for applications where failure is not an option. Unlike standard suppliers, we exceed ISO 2768 tolerances by 25x and provide end-to-end precision for aerospace, medical, and high-performance racing sectors.

| Parameter | Industry Standard | Wuxi Lead Precision | Impact |

|---|---|---|---|

| Tolerance | ±0.127 mm (±0.005″) | ±0.005 mm (±0.0002″) | Enables aerospace components, medical implants, and Olympic cycling parts where micron-level precision is non-negotiable. |

| Surface Finish | Ra 1.6 | Ra 0.4 | Critical for hydraulic systems, medical devices, and high-speed rotating parts where surface integrity dictates performance and longevity. |

| Material Range | Common alloys (Al, SS, Brass) | Exotic alloys (Ti-6Al-4V, Inconel 718, Maraging Steel) with full traceability | Supports extreme environments: jet engines, deep-sea equipment, and defense applications. |

| 5-Axis Capability | Optional upgrade | Standard on all machines | Eliminates cumulative errors, reduces setup time by 40%, and enables complex geometries in a single operation. |

| Quality Assurance | ISO 9001 | AS9100, ISO 13485, MIL-STD compliant | Zero Defects policy with 100% CMM inspection; trusted by military contractors and Olympic teams. |

Our Uncompromising Commitment to Excellence

Zero Defects: Every part undergoes 100% in-process CMM verification. Our defect rate is <0.01%, certified under ISO 13485 (medical) and AS9100 (aerospace).

Olympic Quality: Supplied precision components for Team USA Cycling in the 2020 Tokyo Olympics. Our parts withstand 10,000+ fatigue cycles at 90% of ultimate tensile strength.

24/7 Customer Service: Dedicated engineering team available around the clock for real-time production updates, rapid design revisions, and emergency support.

Ready to Partner? Let’s Build Excellence Together

“We don’t just machine parts—we engineer solutions. Our team collaborates with yours from DFM analysis to final delivery, ensuring cost efficiency without sacrificing precision.”

Receive a free DFM analysis and quote within 24 hours.

Contact us to optimize your design for manufacturability, reduce lead times, and achieve military-grade quality:

[email protected] | +86-13961886740

Wuxi Lead Precision Machinery: Where engineering excellence meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.