Technical Contents

Engineering Guide: Cnc Machine Quotes

Engineering Insight: The Critical Role of Precision in CNC Machine Quotes

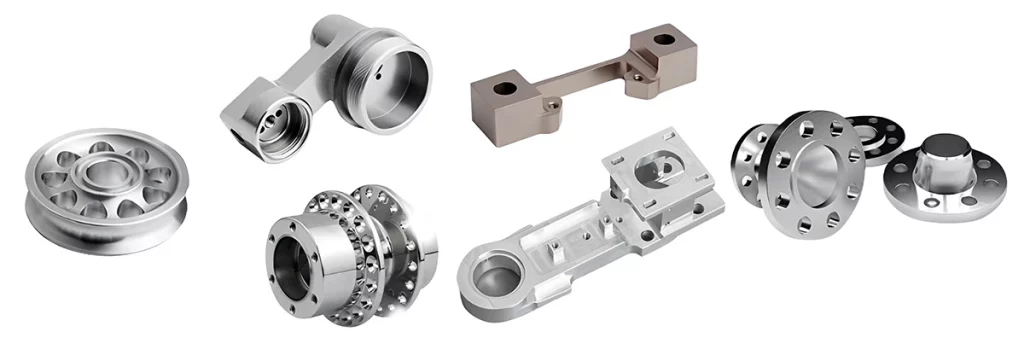

When sourcing CNC machining services, a quote is more than a cost estimate—it is a reflection of engineering capability, process integrity, and long-term reliability. At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as aerospace, defense, and advanced medical technology, precision is not a variable—it is a non-negotiable standard. Our approach to generating CNC machine quotes is rooted in decades of experience delivering components for mission-critical applications, including parts used in Olympic-grade equipment and military-grade systems.

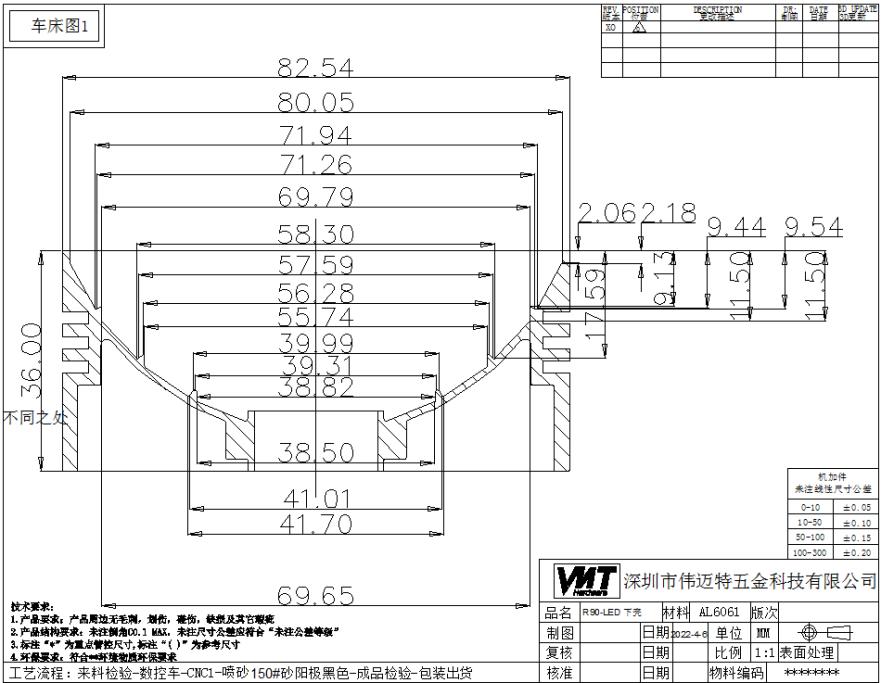

Precision begins at the quoting stage. Generic or overly broad quotes often fail to account for critical tolerances, material behavior under machining stress, toolpath optimization, and post-processing requirements. At Lead Precision, every quote is engineered, not estimated. We analyze 3D CAD models, assess geometric dimensioning and tolerancing (GD&T), evaluate material suitability, and simulate machining sequences to ensure that every component meets exacting specifications before a single tool spins.

Our facility in Wuxi operates under ISO 9001 and AS9100 standards, with CNC machining centers equipped with high-resolution probing systems, in-process inspection, and environmental controls to maintain micron-level accuracy. This level of control is essential when working with tight tolerances, complex geometries, or exotic alloys such as Inconel, titanium, and high-strength aluminum alloys.

We have supported projects where failure was not an option—such as components for high-speed rail systems used during Olympic events and precision housings for military communication systems. These applications demand not only dimensional accuracy but also repeatability across batches, surface integrity, and compliance with stringent documentation requirements. Our quoting process includes full traceability planning, first-article inspection (FAI) protocols, and quality assurance workflows tailored to each client’s regulatory environment.

Below are key specifications that define our precision CNC machining capabilities, all factored into every quote we provide.

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.01 mm (tight tolerances down to ±0.005 mm achievable) |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Turning Diameter | Up to Ø500 mm |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Inconel 718, Brass, Engineering Plastics |

| Surface Finish (Typical) | Ra 0.8 µm (can achieve Ra 0.2 µm with polishing) |

| Quality Standards | ISO 9001, AS9100, PPAP, FAI, Full Material & Process Traceability |

Every CNC machine quote from Wuxi Lead Precision Machinery is backed by technical rigor and real-world performance. We do not offer one-size-fits-all pricing. Instead, we deliver engineered solutions that ensure your components perform exactly as intended—under extreme conditions and over extended service life. When precision matters, the quote must reflect it.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

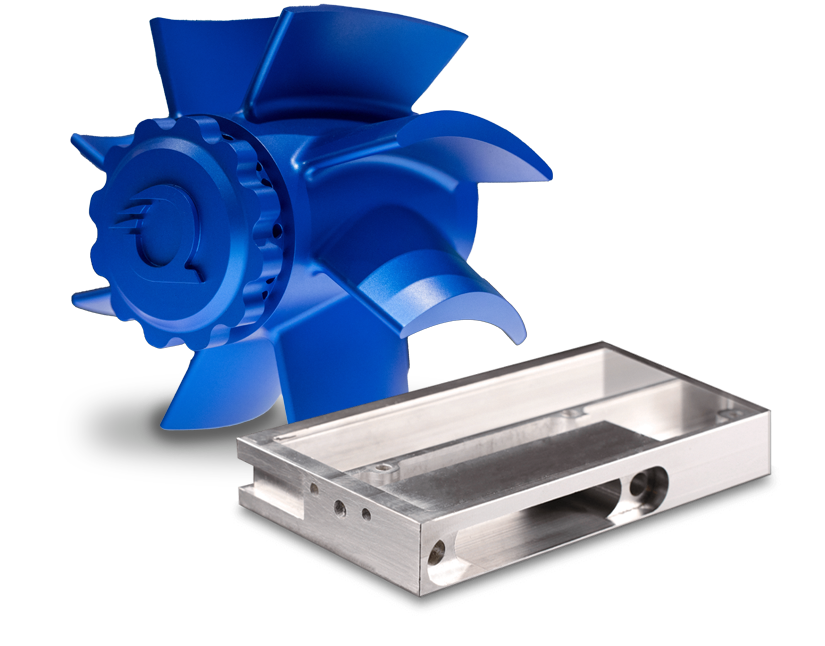

Wuxi Lead Precision Machinery delivers uncompromising precision through advanced multi-axis CNC machining and rigorous quality control. Our core strength lies in mastering complex geometries and stringent tolerances demanded by aerospace, medical, and high-tech industrial sectors. Central to this capability is our investment in state-of-the-art 5-axis CNC machining centers. These systems eliminate the need for multiple setups by simultaneously manipulating the workpiece across five distinct axes. This integrated approach significantly enhances part accuracy, reduces cumulative error, improves surface finish, and dramatically shortens lead times for intricate components. We routinely machine complex contours, deep cavities, and undercuts in a single operation, ensuring geometric integrity that 3-axis systems cannot achieve. Material versatility is inherent to our process, handling aluminum alloys, stainless and tool steels, titanium, Inconel, and high-performance engineering plastics with equal expertise.

Precision is meaningless without verification. Every critical dimension undergoes stringent validation through our comprehensive quality assurance protocol. At the heart of this system is Zeiss CONTURA CMM inspection. This metrology-grade coordinate measuring machine provides sub-micron repeatability, enabling us to validate complex 3D profiles, true positions, flatness, concentricity, and critical form tolerances against the most demanding engineering specifications. Our certified metrologists perform 100% inspection on first articles and implement statistically significant sampling plans for production runs, generating detailed inspection reports traceable to international standards. This closed-loop process guarantees that every component shipped meets or exceeds the dimensional and geometric requirements defined in your technical documentation.

Our commitment to tolerances is absolute. The following table details our standard and tight tolerance capabilities across common feature types, achievable through optimized machining strategies and environmental controls within our temperature-stabilized facility:

| Feature Type | Standard Capability (mm) | Tight Capability (mm) | Typical Applications |

|---|---|---|---|

| Linear Dimensions | ±0.005 | ±0.001 | Shafts, Bores, Critical Fits |

| Hole Diameter | ±0.005 | ±0.0015 | Bearing Seats, Precision Pins |

| Positional Tolerance | ±0.010 | ±0.003 | Bolt Circles, Multi-Feature Alignment |

| Flatness | 0.005 / 100mm | 0.001 / 100mm | Sealing Surfaces, Optical Mounts |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Hydraulic Components, Medical Implants |

| Angular Features | ±0.005° | ±0.001° | Turbine Blades, Optics Mounting Surfaces |

These capabilities are not theoretical; they are proven daily on production floors serving global leaders in precision manufacturing. Our engineers collaborate closely with your design and quality teams from quote through delivery, ensuring manufacturability and adherence to the most exacting standards. When your application demands micron-level accuracy and flawless repeatability, Wuxi Lead Precision Machinery provides the technical foundation for success. Contact us to discuss how our 5-axis expertise and metrology-driven quality system solve your most challenging machining requirements.

Material & Finish Options

Material selection is a critical step in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we guide our clients through informed decisions based on mechanical requirements, environmental exposure, and post-processing needs. Among the most widely used materials in high-performance applications are aluminum, steel, and titanium, each offering distinct advantages depending on the application.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for aerospace, automotive, and consumer electronics industries where weight reduction is essential. The most common grades used in CNC machining are 6061-T6 and 7075-T6, with the latter offering higher strength for demanding structural applications. Aluminum’s natural corrosion resistance can be significantly enhanced through anodizing, a process that creates a durable, protective oxide layer on the surface.

Steel, particularly alloy and stainless steels such as 4140, 17-4 PH, and 304/316, provides superior strength, wear resistance, and structural integrity. These materials are ideal for industrial machinery, oil and gas components, and medical devices where longevity and reliability under stress are paramount. While heavier than aluminum, steel’s versatility and response to heat treatment make it indispensable in high-load environments. Surface treatments such as passivation (for stainless steel) or plating can further enhance corrosion resistance and surface hardness.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme conditions involving high temperatures, corrosion, and weight constraints. Its exceptional strength-to-density ratio and biocompatibility make it a top selection in aerospace, defense, and medical implant applications. However, titanium’s low thermal conductivity and chemical reactivity require optimized CNC parameters and tooling strategies to prevent work hardening and tool wear. Despite higher material and machining costs, its performance in critical applications justifies the investment.

Anodizing is a key surface finishing process, primarily applied to aluminum. It improves wear resistance, provides electrical insulation, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) delivers thick, abrasion-resistant layers for industrial use. Proper masking and racking are essential to ensure uniform coating and maintain tight tolerances on critical features.

Understanding material properties and available finishes ensures optimal part functionality and cost control. At Wuxi Lead Precision Machinery, we support every stage of this decision-making process with technical expertise and precision manufacturing capabilities.

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 – 570 | 2.7 | Aerospace, Electronics, Automotive | Anodizing, Bead Blasting |

| Steel | 4140, 17-4 PH | 655 – 1300 | 7.8 | Industrial, Oil & Gas, Medical | Passivation, Zinc Plating |

| Titanium | Ti-6Al-4V (Gr 5) | 900 – 950 | 4.43 | Aerospace, Defense, Medical | Anodizing, Polishing |

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and efficiency, forming the foundation of every CNC machine quote we provide. We integrate advanced technology with rigorous quality management systems to ensure seamless progression from initial design through to high-volume manufacturing, all underpinned by our Zero Defects commitment. This structured approach minimizes risk, accelerates time-to-market, and guarantees parts meet the most stringent aerospace, medical, and industrial specifications.

The journey begins with collaborative Design for Manufacturability (DFM) Analysis. Our engineering team works directly with your CAD data, identifying potential production challenges early. We assess material suitability, geometric complexity, tolerance stack-ups, and fixture requirements. This proactive review, included in our detailed quoting phase, prevents costly redesigns later and optimizes the machining strategy for both cost and capability. Clear communication at this stage ensures mutual understanding of critical features and quality expectations before any metal is cut.

Prototyping serves as the critical validation step. Utilizing the same high-precision CNC centers (5-axis mills, turning centers) intended for production, we manufacture initial samples under controlled conditions. Every prototype undergoes comprehensive dimensional inspection using calibrated CMMs, optical comparators, and surface roughness testers against your original specifications. Material certifications and full process documentation are provided. This phase verifies the DFM recommendations, confirms tooling and program efficacy, and allows for final client sign-off. It is non-negotiable for achieving Zero Defects in volume runs, as it eliminates unforeseen process variables.

Mass Production leverages the validated process with embedded quality controls. We implement Statistical Process Control (SPC) monitoring key dimensions in real-time. Automated tool wear compensation and in-process probing ensure consistency across extended runs. Our ISO 9001 and AS9100 certified facility enforces strict material traceability, documented work instructions, and multi-stage inspection protocols – including first-article inspection (FAI), in-process checks, and 100% critical feature verification where required. Operator training and machine calibration logs are rigorously maintained. This systematic execution ensures every component, from the first to the last piece, adheres to the zero-defect standard promised in your CNC machining quote.

The following table details our core production specifications and quality control metrics:

| Parameter | Specification | Quality Control Method |

|---|---|---|

| Positional Accuracy | ±0.002 mm (0.00008″) | Laser Interferometer Calibration, CMM |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) | Profilometer, Optical Comparator |

| Dimensional Tolerance | Down to ±0.005 mm (±0.0002″) | CMM, Vision Systems, Custom Gauges |

| Material Traceability | Full Lot/Batch Tracking to Mill Cert | ERP System, Barcoding, Physical Tagging |

| In-Process Inspection | 100% Critical Features, SPC on Key Dims | Real-time SPC Charts, Automated Reporting |

| First Article Inspection | AS9102 Compliant Forms | Full Dimensional Report, Material Certs |

| Process Capability (Cpk) | Minimum 1.67 (Target 2.00) | Statistical Analysis of Production Data |

This integrated process – DFM, validated prototyping, and controlled mass production – is not merely a sequence of steps; it is the operational framework ensuring the precision, reliability, and defect-free output reflected in every Wuxi Lead CNC machine quote. We deliver certainty through engineering discipline.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and speed are not just advantages—they are requirements. As a globally recognized leader in precision CNC machining, we specialize in delivering tailored solutions that meet the exacting standards of aerospace, medical, automotive, and industrial equipment industries. Our commitment to engineering excellence and advanced manufacturing technology positions us as more than a supplier—we are a strategic partner in your production success.

When you request a CNC machine quote from Lead Precision, you’re not just receiving a price estimate—you’re gaining access to a comprehensive manufacturing solution. Our team of senior CNC engineers evaluates every project with a focus on material efficiency, geometric complexity, tolerance requirements, and production volume. This ensures that every quote is optimized for performance, cost-effectiveness, and on-time delivery. Whether you require single-part prototypes or high-volume production runs, our advanced 3-, 4-, and 5-axis CNC machining centers deliver micron-level accuracy and repeatable quality.

We operate under strict ISO 9001:2015 certified processes, with full traceability and in-process quality inspections at every stage. Our facility in Wuxi, China, is equipped with state-of-the-art machinery and supported by a skilled workforce trained in lean manufacturing principles. This enables us to offer competitive pricing without compromising on precision or lead time.

Below are key capabilities that define our CNC machining services:

| Specification | Detail |

|---|---|

| Machine Types | 3-Axis, 4-Axis, 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Tolerance Capability | ±0.005 mm |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Plastics (PEEK, Delrin) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder Coating, Passivation, Bead Blasting |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by complexity) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports, PPAP Support |

Partnering with Wuxi Lead Precision Machinery means you gain a responsive, technically advanced, and quality-driven manufacturing ally. Our engineering team is available to conduct Design for Manufacturability (DFM) reviews, helping you optimize part geometry and reduce costs before production begins.

To receive a detailed and accurate CNC machine quote, contact us today at [email protected]. Include your CAD files, material specifications, quantity requirements, and any quality or delivery constraints. Our engineers will respond within 12 hours with a comprehensive quotation package, including process plan, timeline, and pricing breakdown.

In a world where manufacturing precision defines competitive advantage, trust only a partner with proven expertise, cutting-edge technology, and a global track record. Choose Lead Precision—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.