Technical Contents

Engineering Guide: Cnc Machine Processes

Engineering Insight Precision as the Non-Negotiable Foundation of CNC Machining

In high-stakes manufacturing sectors like aerospace, medical device production, and advanced energy systems, the margin for error is effectively zero. Precision in CNC machining transcends mere dimensional accuracy; it encompasses surface integrity, geometric fidelity, thermal stability, and unwavering repeatability across production runs. The consequences of sub-micron deviations are severe: compromised component performance, accelerated wear, catastrophic system failures, and significant financial liability. Achieving true precision demands more than advanced machinery; it requires a holistic engineering philosophy integrating machine design, environmental control, process validation, and operator expertise. At Wuxi Lead Precision Machinery, we understand that precision is not an optional specification but the fundamental bedrock upon which product reliability, safety, and regulatory compliance are built. It directly dictates yield rates, total cost of ownership, and ultimately, our clients’ market reputation.

Our commitment to extreme precision is rigorously proven through mission-critical applications. We have successfully delivered components meeting the exacting standards required for Olympic Games infrastructure projects, where flawless performance under intense public scrutiny and demanding environmental conditions is paramount. Furthermore, our processes and quality systems are certified to stringent military specifications, a domain where absolute dimensional integrity and material consistency are non-negotiable for operational safety and national security. This experience translates directly to commercial clients: the same metrology protocols, environmental controls, and process discipline applied to defense or elite sporting equipment ensure unparalleled consistency and reliability for your most demanding production runs. Precision engineering at this level mitigates risk and delivers tangible competitive advantage.

The technical capability to achieve micron-level precision is embodied in our core machine specifications and process controls. The table below outlines key performance parameters representative of our high-precision machining centers, reflecting the engineering rigor applied to every project.

| Specification | Performance Metric | Significance for Precision Manufacturing |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±1.5 µm | Guarantees exact feature location across the work envelope |

| Repeatability (3σ) | ±0.8 µm | Ensures consistent part-to-part dimensional conformity |

| Volumetric Compensation | Full 21-Parameter | Corrects geometric errors inherent in machine structure |

| Thermal Stability Control | ±0.5°C Ambient | Minimizes dimensional drift due to temperature fluctuations |

| Spindle Runout (TIR) | ≤0.5 µm | Critical for achieving fine surface finishes and tight tolerances |

| In-Process Metrology | On-Machine Probing | Enables real-time correction and closed-loop process control |

True precision engineering demands viewing the CNC process as an integrated system, not isolated operations. It requires anticipating material behavior, optimizing cutting strategies to minimize residual stress, and implementing rigorous in-process verification. At Wuxi Lead Precision Machinery, our decades of experience, particularly within Olympic and military supply chains, have forged an uncompromising culture where precision is engineered into every step. We partner with clients to transform demanding specifications into reliably manufactured reality, ensuring your components perform exactly as intended, every time. This is the standard upon which critical industries depend.

Precision Specs & Tolerances

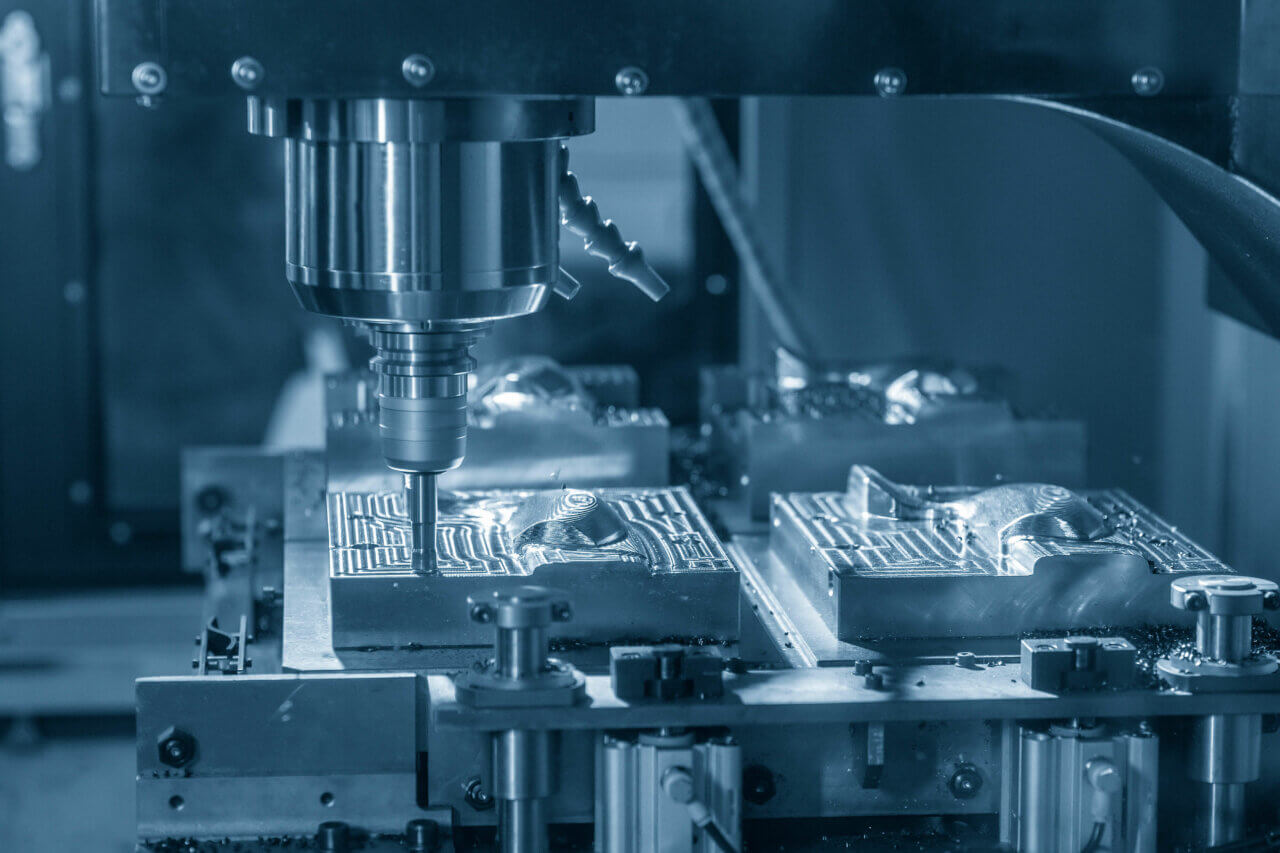

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, energy, and advanced automation. At the core of our manufacturing strength is our fleet of 5-axis CNC machining centers, which enable complex geometries, tight tolerances, and superior surface finishes on a wide range of materials including titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics. These machines provide simultaneous multi-axis motion, allowing for intricate part features to be machined in a single setup, minimizing human intervention and maximizing repeatability.

Our 5-axis platforms are equipped with high-speed spindles, automatic tool changers, and advanced coolant systems, ensuring optimal cutting performance and tool life. This capability reduces lead times and part handling while significantly improving dimensional accuracy. Complex contours, deep cavities, and undercuts that would require multiple setups on 3-axis machines can be completed efficiently and with precision on our 5-axis systems. This technological advantage is especially critical for components requiring high integrity and design complexity, such as turbine blades, surgical instruments, and structural aerospace fittings.

Quality assurance is fully integrated into our manufacturing workflow. Every critical dimension is verified using state-of-the-art Coordinate Measuring Machines (CMM) with tactile and optical probing systems. Our CMM inspection process follows ISO 10360 standards and is conducted in a temperature-controlled metrology lab to eliminate environmental variables. Full first-article inspection reports (FAIR) and production batch certifications are provided as standard, ensuring full traceability and compliance with AS9100, ISO 13485, and other industry-specific quality requirements.

Our engineering team works closely with clients during the design for manufacturability (DFM) phase to optimize part geometry, material selection, and tooling strategies. This collaborative approach ensures that components are not only manufacturable but also cost-effective and reliable in end-use applications. With in-house programming using Mastercam and Siemens NX, we maintain full control over toolpaths, cycle times, and surface finish parameters.

All processes are supported by a robust quality management system, with real-time monitoring of machine performance and tool wear via integrated sensors and data logging. This digital infrastructure ensures consistent output and enables rapid corrective actions when needed. With decades of experience in high-mix, low-volume production and full-scale prototyping, Wuxi Lead Precision Machinery is equipped to handle technically demanding projects from concept to delivery.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Positional Tolerance | ±0.010 mm | ±0.005 mm | Measured via CMM |

| Linear Dimensional Tolerance | ±0.012 mm | ±0.008 mm | Depending on material and geometry |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Achievable with fine finishing passes |

| Angular Tolerance | ±0.05° | ±0.02° | On complex 5-axis features |

| Feature-to-Feature Alignment | ≤ 0.015 mm | ≤ 0.008 mm | Verified with full CMM scan |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom setups available | Based on current 5-axis machine limits |

These capabilities, combined with rigorous process control and engineering expertise, position Wuxi Lead Precision Machinery as a trusted partner for mission-critical precision components in global advanced manufacturing sectors.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Machining

Selecting the optimal material is a critical engineering decision impacting part performance, manufacturability, cost, and longevity in precision CNC machining. At Wuxi Lead Precision Machinery, we emphasize aligning material properties with the application’s functional requirements and environmental demands. Aluminum, steel, and titanium represent the core structural metals for high-performance components, each offering distinct advantages and machining considerations. Understanding these differences ensures the final part meets exacting tolerances and operational specifications.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. Their relatively soft nature allows for high-speed machining, fine surface finishes, and complex geometries with minimal tool wear. However, aluminum’s lower stiffness compared to steel necessitates careful design for highly loaded structures. Steel, especially grades like 304 stainless and 4140 alloy steel, provides superior strength, hardness, and wear resistance essential for tooling, heavy machinery, and high-stress applications. Stainless variants offer excellent corrosion resistance but present greater machining challenges than aluminum, requiring robust tooling, controlled speeds/feeds, and effective chip evacuation due to work hardening tendencies. Titanium alloys, primarily Ti-6Al-4V, deliver an unparalleled combination of high strength, low density, and exceptional corrosion resistance, making them indispensable in aerospace, medical implants, and extreme environment applications. However, titanium’s low thermal conductivity and high chemical reactivity demand specialized CNC strategies: lower cutting speeds, rigid setups, sharp carbide tools with specific geometries, and ample coolant to prevent galling and excessive heat buildup.

The following table summarizes key comparative specifications for common precision machining materials:

| Material | Tensile Strength (MPa) | Machinability Rating | Key Advantages | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | Excellent (Machining Index ~100%) | Lightweight, conductive, corrosion resistant | Enclosures, brackets, heat sinks, aerospace components |

| Steel 304 Stainless | 515 | Fair (Machining Index ~45%) | High strength, corrosion resistance, durability | Valves, pumps, food processing equipment, structural parts |

| Titanium Ti-6Al-4V | 900 | Poor (Machining Index ~20-30%) | Highest strength-to-weight, extreme corrosion resistance | Aircraft structural parts, medical implants, marine components |

Anodizing is the predominant surface finish for aluminum components, significantly enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for adhesion of paints or primers. Type II (Sulfuric Acid) anodizing offers good corrosion resistance and dyeing capability for identification, while Type III (Hard Anodizing) delivers a much thicker, harder, and more wear-resistant ceramic-like layer essential for high-friction applications. It is crucial to note anodizing is specific to aluminum; steel typically requires plating (e.g., zinc, nickel) or passivation, while titanium often relies on its native oxide layer or specialized coatings like PVD for enhanced surface properties.

Material choice directly influences CNC process parameters, tooling selection, and overall production efficiency. Wuxi Lead Precision Machinery leverages extensive experience with these core materials to optimize machining strategies, ensuring your components achieve the required precision, surface integrity, and performance characteristics. Consult our engineering team early in the design phase to select the optimal material and finishing process for your demanding application.

Manufacturing Process & QC

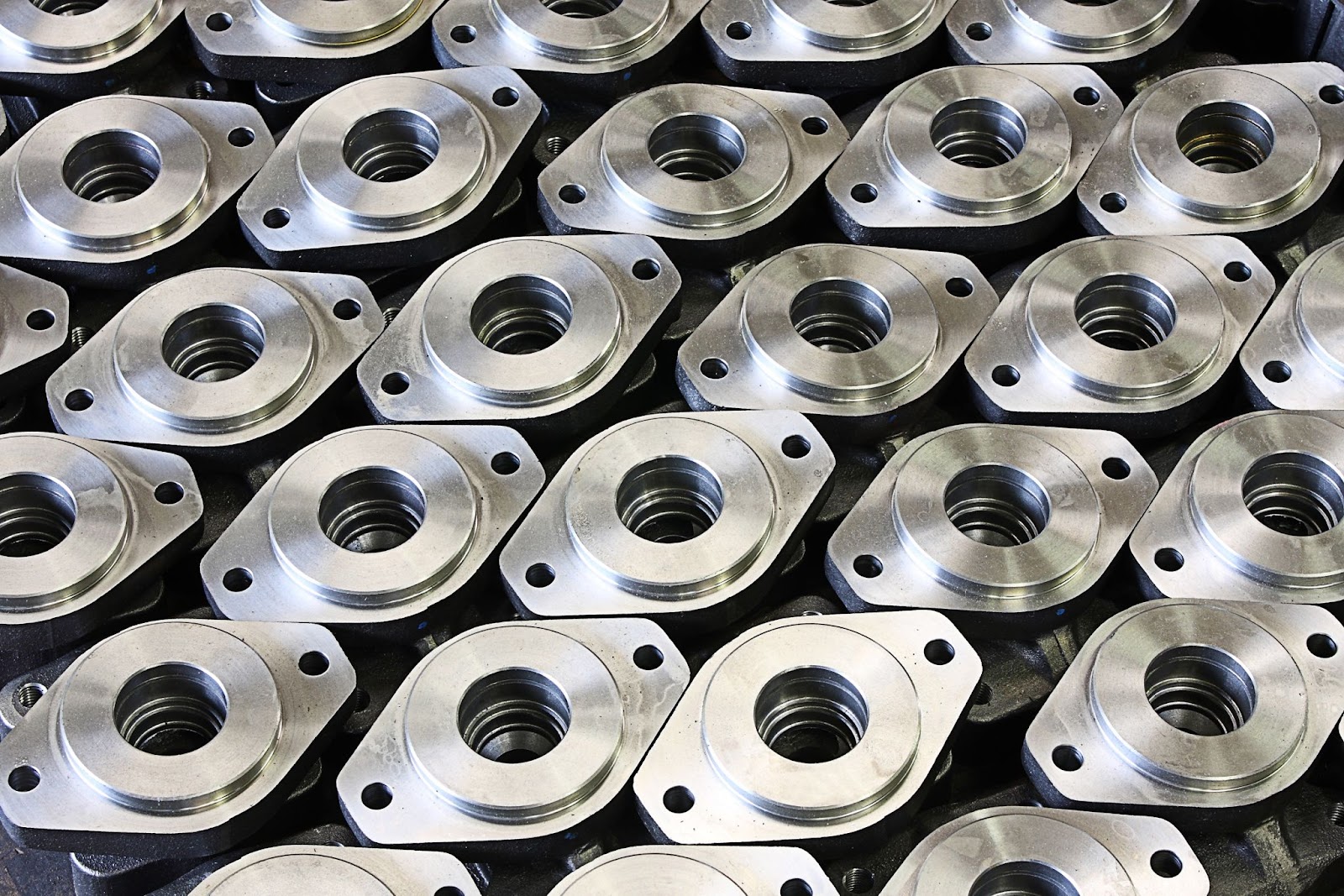

From Design to Mass Production: The Zero-Defect CNC Manufacturing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we integrate precision engineering with disciplined process control to deliver flawless CNC-machined components from concept to full-scale production. Our end-to-end manufacturing workflow—encompassing design validation, prototyping, and mass production—is engineered to achieve zero defects, ensuring every part meets the highest standards of dimensional accuracy, surface integrity, and functional reliability.

The process begins with design analysis and engineering collaboration. Our technical team reviews customer CAD models and engineering specifications to assess manufacturability, material suitability, and geometric complexity. Using advanced simulation software, we perform CNC toolpath optimization and interference checks to eliminate potential errors before any metal is cut. This proactive design validation reduces risk and accelerates time-to-market.

Next, we move into precision prototyping. Utilizing high-speed 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes that mirror final production conditions. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify conformance to tolerances as tight as ±0.002 mm. Feedback from prototype testing is used to refine tooling, fixturing, and machining strategies, ensuring process stability prior to scale-up.

Once design and prototype approval are confirmed, we transition seamlessly into mass production. Our facility operates a fleet of automated CNC machining centers with integrated robotic loading systems, enabling 24/7 unattended operation while maintaining consistent quality. Each production batch is governed by a documented Quality Control Plan that includes first-article inspection, in-process checks, and final audit protocols. Statistical process control (SPC) is implemented to monitor critical dimensions and detect process drift in real time.

To guarantee zero defects, we enforce a multi-layered quality assurance system. Every component is traceable through our ERP system, with full documentation of machine parameters, tool life, inspection data, and operator logs. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence.

Our commitment to precision, repeatability, and continuous improvement ensures that every product shipped from Wuxi Lead Precision Machinery exceeds customer expectations in performance and reliability.

Key Process Specifications

| Parameter | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Tolerances (Typical) | ±0.005 mm (standard), ±0.002 mm (tight) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Production Volume Range | 1 – 500,000+ units annually |

| Quality Standards | ISO 9001:2015, PPAP, APQP, SPC, CMM Reports |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Capabilities Through Strategic Partnership

At Wuxi Lead Precision Machinery, we recognize that precision CNC machining is not merely a service—it is the cornerstone of product reliability, innovation velocity, and market leadership. For over 15 years, we have engineered mission-critical components for aerospace, medical device, and industrial automation leaders who demand uncompromising accuracy and zero-failure performance. Our ISO 9001:2015 and IATF 16949-certified facility in Wuxi integrates German-engineered machinery with proprietary process controls, transforming complex designs into tangible assets that exceed global tolerance standards. When you partner with us, you gain more than a supplier; you secure a dedicated engineering ally committed to de-risking your production lifecycle through proactive quality assurance and agile scalability.

Our technical infrastructure eliminates the trade-offs between precision and throughput. Below are core capabilities driving measurable ROI for clients:

| Capability | Specification | Impact for Your Operations |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Zero scrap in micro-features |

| Spindle Speed Range | 20,000 RPM (HSC models) | 40% faster cycle times |

| Work Envelope | 1,200 x 800 x 600 mm | Single-setup large assemblies |

| Material Compatibility | Titanium, Inconel, CFRP | Complex material mastery |

| Thermal Compensation | Real-time laser calibration | Sub-micron stability 24/7 |

This foundation enables us to tackle your most stringent challenges—from 5-axis contouring of turbine blades to burr-free machining of surgical implants—while maintaining full traceability via our digital twin monitoring system. Unlike transactional vendors, we embed our engineers within your NPI phase to optimize manufacturability, reducing time-to-market by up to 30%. Our dedicated project managers provide live dashboards tracking first-pass yield, tool wear analytics, and delivery milestones, ensuring transparency at every micro-step.

The cost of precision miscalculation extends beyond rework—it erodes brand equity and market trust. With supply chain volatility intensifying, your choice of machining partner directly impacts resilience. Wuxi Lead Precision Machinery mitigates this risk through dual-sourcing strategies, 12-month raw material hedging, and a 99.2% on-time delivery rate sustained since 2020. We invest in your success through shared technology roadmaps, not just purchase orders.

Initiate your precision partnership today. Email [email protected] with your component specifications and target volume. Within 24 hours, our applications engineering team will provide a detailed feasibility analysis—including DFM recommendations, cost-per-part breakdown, and capacity allocation timeline. For urgent RFQs, reference code LEAD-CTA2024 to fast-track technical review. Let us prove why global innovators trust Wuxi Lead to turn engineering ambition into certified reality. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.