Technical Contents

Engineering Guide: Cnc Machine Multi Axis

Engineering Insight: The Critical Role of Precision in Multi-Axis CNC Machining

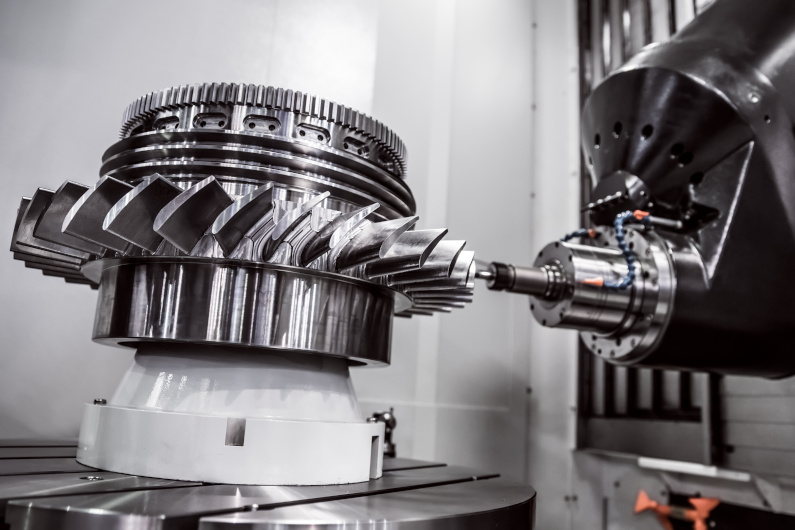

In the realm of advanced manufacturing, multi-axis CNC machines represent the pinnacle of precision engineering. These systems go beyond the conventional three-axis framework, integrating additional rotational and translational axes to enable complex geometries, tighter tolerances, and enhanced surface finishes. At Wuxi Lead Precision Machinery, we recognize that the true value of multi-axis CNC technology lies not merely in its motion capabilities, but in its ability to consistently deliver micron-level accuracy across high-complexity components.

Precision in multi-axis machining is not an incremental improvement—it is a fundamental requirement for industries where failure is not an option. Aerospace, defense, medical, and high-performance automotive sectors demand parts that conform to exacting dimensional specifications, often under extreme operational conditions. At Lead Precision, our engineering philosophy centers on achieving repeatability within ±0.002 mm and surface finishes down to Ra 0.4 µm, ensuring that every component meets or exceeds international quality benchmarks.

Our expertise in multi-axis systems is backed by over a decade of experience serving Tier-1 clients in mission-critical applications. We have contributed to projects aligned with Olympic-standard sporting equipment and supplied precision-machined components for defense-grade systems, where reliability under stress is non-negotiable. These high-stakes environments demand more than advanced machinery—they require deep process control, rigorous calibration protocols, and a culture of continuous improvement.

The integration of 4-axis and 5-axis functionality allows for single-setup machining of complex contours, reducing cumulative error from multiple fixturing stages. This not only improves geometric accuracy but also enhances productivity by minimizing manual intervention. At Lead Precision, our machines utilize high-resolution encoders, thermal compensation systems, and advanced spindle technologies to maintain stability across extended production runs.

We understand that precision is not a standalone feature but a system-wide outcome. Our CNC platforms are engineered with rigid cast iron beds, high-torque direct-drive spindles, and real-time tool monitoring to ensure consistent performance. Each machine undergoes a 72-hour endurance test under simulated production loads before shipment, validating both mechanical integrity and dimensional consistency.

Below are key specifications representative of our multi-axis CNC machining centers:

| Specification | Value |

|---|---|

| Axis Configuration | 5-Axis (X, Y, Z, A, C) |

| Positioning Accuracy | ±0.0015 mm |

| Repeatability | ±0.001 mm |

| Spindle Speed | Up to 24,000 rpm |

| Tool Capacity | 30–60 tools (automatic changer) |

| Control System | Fanuc 31i-B5 or Siemens 840D |

| Work Envelope (X×Y×Z) | 800 × 600 × 500 mm |

| Surface Finish (Typical) | Ra 0.4 µm (achievable to Ra 0.2 µm) |

At Wuxi Lead Precision Machinery, we combine cutting-edge multi-axis technology with disciplined engineering practices to deliver solutions where precision is not just measured—it is guaranteed.

Precision Specs & Tolerances

Advanced Multi-Axis Machining Capabilities at Wuxi Lead Precision Machinery

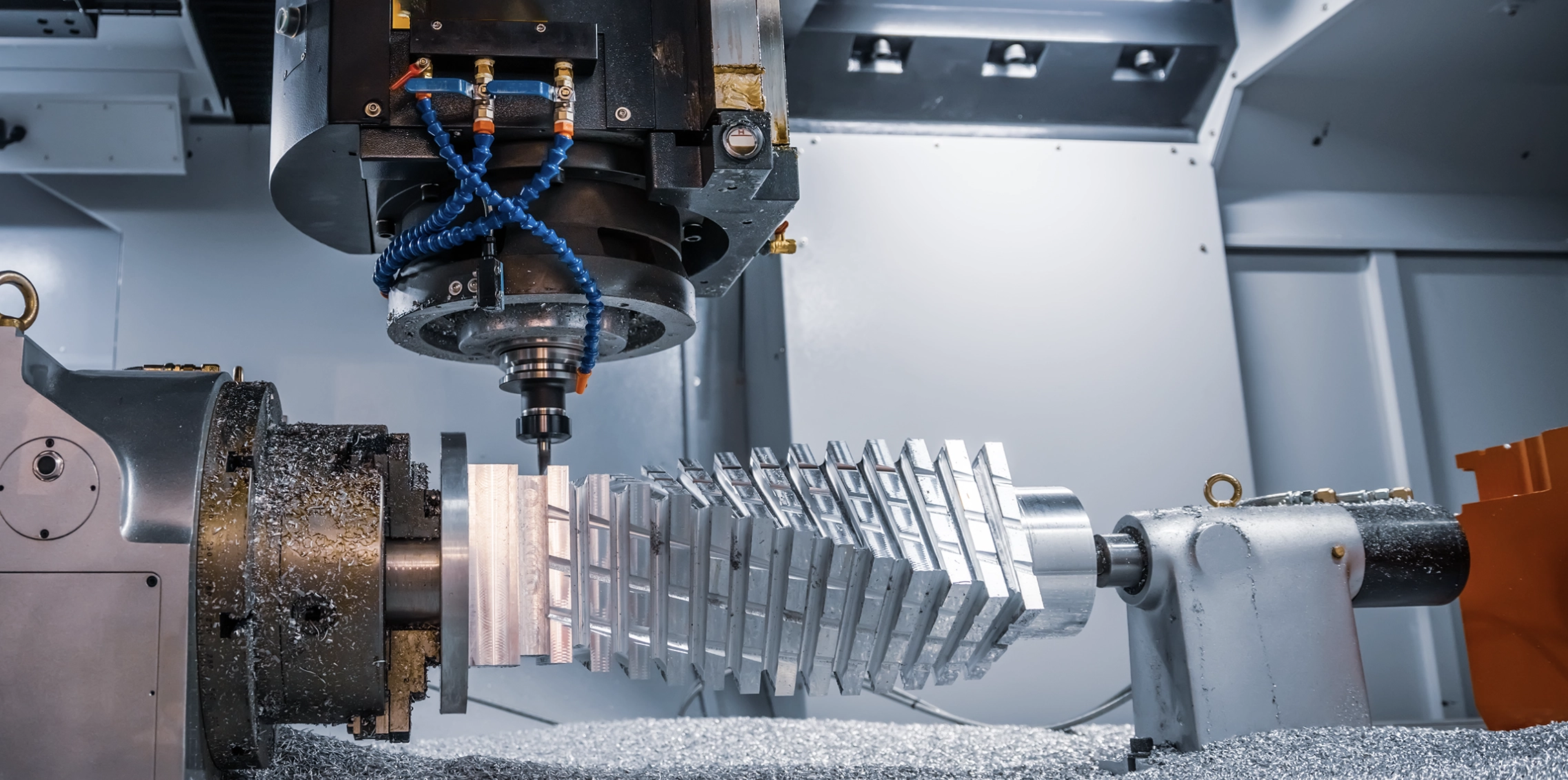

Wuxi Lead Precision Machinery delivers uncompromising precision for complex geometries through our state-of-the-art 5-axis CNC machining platforms. Our technical foundation centers on DMG MORI and Makino multi-axis systems, engineered to eliminate secondary operations and maintain micron-level accuracy across intricate contours. These machines integrate simultaneous 5-axis interpolation with high-torque spindles (up to 24,000 RPM) and thermal compensation systems, enabling single-setup production of aerospace impellers, medical orthopedic components, and energy sector turbine blades. This capability reduces cumulative error risks inherent in multi-stage processes while accelerating time-to-shipment by up to 60% versus conventional 3-axis workflows.

Critical to sustaining this precision is our closed-loop quality assurance ecosystem. Every component undergoes rigorous post-machining validation using Zeiss CONTURA G2 Coordinate Measuring Machines (CMMs) with 0.5 µm volumetric accuracy. Our metrology lab operates under ISO 17025 standards, employing automated probing routines to verify geometric dimensioning and tolerancing (GD&T) against ASME Y14.5 specifications. This ensures dimensional integrity across all critical features, from micro-cooling channels in injection molds to tight-tolerance sealing surfaces in hydraulic manifolds. Real-time SPC data from machining and inspection stages feed directly into our production control system, enabling immediate process correction without disrupting workflow continuity.

Our technical mastery extends to challenging materials including Inconel 718, titanium alloys, and carbon-fiber-reinforced polymers. Adaptive machining strategies dynamically adjust feed rates and toolpaths based on material hardness variations, preventing micro-vibrations that compromise surface finish. This results in consistent Ra values down to 0.2 µm on critical sealing faces without secondary polishing. For extreme wear applications, we implement precision-turned diamond-turned optical surfaces with sub-micron form accuracy.

The following table details our standard production tolerances for critical parameters:

| Parameter | Standard Capability | Tight-Tolerance Option | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.010 mm | ±0.005 mm | CMM / Air Gaging |

| Flatness | 0.008 mm | 0.003 mm | Laser Interferometer |

| True Position | ±0.015 mm | ±0.008 mm | CMM GD&T Analysis |

| Circular Runout | 0.010 mm | 0.005 mm | Precision Spindle Probe |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

This technical infrastructure supports industries where failure is not an option. We transform complex 3D CAD models into mission-critical components with documented traceability from raw material certification to final inspection reports. Our engineering team collaborates with clients during DFM stages to optimize part geometry for multi-axis efficiency, reducing material waste while maximizing structural integrity. By integrating cutting-edge 5-axis technology with uncompromising metrology, Wuxi Lead Precision Machinery ensures every component meets the exacting demands of advanced manufacturing applications worldwide. Partner with us to convert your most challenging designs into precision realities.

Material & Finish Options

Material Selection for High-Precision Multi-Axis CNC Machining

Selecting the appropriate material is critical in multi-axis CNC machining, where complex geometries and tight tolerances demand optimal machinability, structural integrity, and finish quality. At Wuxi Lead Precision Machinery, we specialize in high-accuracy machining of advanced engineering materials, with aluminum, steel, and titanium representing the core metals used in aerospace, medical, and industrial applications. Each material presents unique advantages and challenges that must be carefully evaluated based on the functional requirements of the final component.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Its low density makes it ideal for lightweight structural components, particularly in aerospace and automotive sectors. Aluminum alloys such as 6061 and 7075 are highly machinable on multi-axis CNC platforms, allowing for intricate contours and fine surface finishes. However, aluminum’s softness requires careful tool selection and cutting parameters to prevent burring and tool adhesion.

Steel, particularly alloy and stainless grades, offers superior strength, durability, and wear resistance. Materials like 4140 alloy steel and 304/316 stainless steel are commonly used in high-stress environments such as tooling, hydraulic systems, and medical devices. While steel is more challenging to machine due to higher hardness and heat generation, modern multi-axis CNC machines equipped with high-torque spindles and advanced cooling systems can achieve precise results with excellent surface integrity. Post-machining treatments such as passivation or heat treatment are often recommended to enhance performance.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments requiring high strength, corrosion resistance, and biocompatibility. Its use is prevalent in aerospace, defense, and implantable medical devices. Despite its excellent mechanical properties, titanium poses significant machining challenges due to low thermal conductivity, which leads to heat concentration at the cutting zone, and high chemical reactivity with tool materials. Successful titanium machining requires rigid setups, specialized carbide tools, and controlled feed rates to prevent work hardening and tool failure.

Surface finish treatments further enhance the functionality and longevity of machined parts. Anodizing, particularly for aluminum, provides a durable, corrosion-resistant oxide layer that can also be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior wear resistance for high-performance applications.

The following table summarizes key properties and machining considerations for these materials:

| Material | Typical Alloy | Tensile Strength (MPa) | Machinability Rating | Common Finishes | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Excellent | Anodizing, Bead Blast | Aerospace, Automotive, Enclosures |

| Steel | 4140 | 655 | Moderate | Passivation, Painting | Tooling, Shafts, Industrial |

| Stainless Steel | 316L | 580 | Fair | Electropolishing, Passivation | Medical, Marine, Food Processing |

| Titanium | Ti-6Al-4V | 950 | Poor | Anodizing (Type II/III) | Aerospace, Medical Implants |

At Wuxi Lead Precision Machinery, we combine advanced multi-axis CNC technology with deep material expertise to deliver precision components tailored to your application. Proper material and finish selection ensures optimal performance, reliability, and cost-efficiency in every project.

Manufacturing Process & QC

Precision Multi-Axis CNC Production: Achieving Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our multi-axis CNC production process is engineered for uncompromising quality, ensuring zero defects from initial design through high-volume manufacturing. This integrated workflow leverages advanced technology and rigorous methodology to transform complex geometries into flawless components for aerospace, medical, and energy sectors. The foundation is a closed-loop system where design intent directly informs machining strategy and real-time quality control.

Design Phase: Engineering Precision at the Source

The process begins with meticulous CAD/CAM integration. Our engineering team utilizes Siemens NX and Mastercam to develop 3D models incorporating stringent geometric dimensioning and tolerancing (GD&T) per ASME Y14.5 standards. Critical focus is placed on multi-axis toolpath simulation, analyzing potential collisions, optimizing cutter engagement, and simulating thermal growth effects to preempt machining errors. Material-specific cutting parameters are defined, and fixture design is validated virtually to ensure absolute component stability during 5-axis simultaneous operations. This phase establishes the blueprint for defect prevention, targeting tolerances as tight as ±0.001mm.

Prototyping Phase: Validation and Process Refinement

Physical validation commences with precision prototyping using the exact multi-axis CNC equipment designated for production. Each prototype undergoes comprehensive first-article inspection (FAI) against the approved CAD model using coordinate measuring machines (CMM) and optical comparators. We perform rigorous material property verification and functional testing under simulated operational conditions. Any deviation triggers immediate root cause analysis and iterative refinement of the CAM program, tooling, or fixturing. This phase is not merely about part validation; it is the critical step for locking a proven, repeatable process capable of sustaining zero defects at scale. Material waste and rework are minimized through this disciplined verification cycle.

Mass Production Phase: Sustained Excellence at Volume

Transitioning to volume production, Wuxi Lead implements real-time process control. Our Haas and DMG MORI 5-axis centers operate under continuous in-process monitoring, utilizing spindle power analysis, tool wear sensors, and automated part probing. Statistical Process Control (SPC) charts track critical dimensions on every batch, with automatic machine tool compensation applied for thermal drift or tool deflection. Every component undergoes 100% dimensional verification via automated CMM routines or vision systems before shipment. This closed-loop manufacturing environment, combined with our ISO 9001:2015 and AS9100D certified quality management system, guarantees consistent output meeting the most demanding specifications without compromise.

Key Process Specifications Across Production Stages

| Phase | Critical Parameter | Target Specification | Verification Method |

|---|---|---|---|

| Design | Geometric Tolerance | ±0.001mm to ±0.005mm | CAD/CAM Simulation & GD&T Analysis |

| Prototyping | First-Article Conformance | 100% to CAD Model | CMM, Optical Comparator, FAI |

| Mass Production | Process Capability (Cpk) | ≥1.67 | Real-time SPC, Automated Probing |

This seamless integration of design foresight, prototype validation, and intelligent production execution forms the core of Wuxi Lead’s zero-defect philosophy. We deliver not just parts, but guaranteed performance and reliability, making us the trusted partner for mission-critical multi-axis CNC components worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Multi-Axis CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in today’s competitive manufacturing landscape, precision, efficiency, and reliability are non-negotiable. As a global leader in advanced CNC solutions, we specialize in high-performance multi-axis CNC machines engineered to meet the exacting demands of aerospace, automotive, medical, and high-tech industrial sectors. Our machines are not just tools—they are strategic assets designed to elevate your production capabilities, reduce cycle times, and deliver micron-level accuracy across complex geometries.

When you partner with Lead Precision, you gain more than equipment—you gain a technology ally. Our multi-axis CNC systems integrate seamless 4-axis and 5-axis synchronization, enabling simultaneous machining from multiple angles without manual repositioning. This translates into faster throughput, superior surface finishes, and the ability to produce components once deemed too intricate for conventional machining. Every machine is built with high-rigidity castings, precision spindle technology, and advanced control systems to ensure long-term stability and minimal downtime.

We design our solutions with scalability in mind. Whether you are a contract manufacturer handling low-volume, high-mix jobs or a tier-one supplier requiring lights-out automation, our machines adapt to your workflow. Our engineering team works closely with your operations to customize configurations, tooling interfaces, and automation integration—ensuring optimal performance from day one. With a focus on Industry 4.0 readiness, our CNC platforms support real-time monitoring, predictive maintenance, and digital twin compatibility, empowering data-driven decision-making on the shop floor.

Our commitment extends beyond the sale. Lead Precision offers comprehensive technical support, on-site installation, operator training, and 24/7 service response to minimize disruptions. With a global footprint and a network of certified service engineers, we ensure your investment remains productive for years to come.

Choose a partner who combines Chinese manufacturing efficiency with German-level precision engineering standards. At Wuxi Lead Precision Machinery, innovation is not an add-on—it’s our foundation.

Contact us today to discuss your next-generation machining requirements. Let our engineers help you select the right multi-axis solution tailored to your production goals.

Email: [email protected]

| Specification | Detail |

|---|---|

| Axis Configuration | 4-Axis, 5-Axis Simultaneous |

| Spindle Speed | Up to 24,000 RPM (optional) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Control System | Fanuc, Siemens, or Heidenhain (customizable) |

| Table Size Range | 600 mm × 500 mm to 1,200 mm × 1,000 mm |

| Rapid Traverse Rate | 60 m/min (X, Y, Z) |

| Tool Magazine Capacity | 24 to 60 Tools (optional) |

| Automation Ready | Yes (Robotic & Pallet System Compatible) |

| Coolant & Chip Management | Integrated High-Pressure System |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.