Technical Contents

Engineering Guide: Cnc Machine Moving

Engineering Insight: CNC Machine Moving and the Critical Role of Precision

In the realm of high-end manufacturing, the relocation of CNC machines is not a logistical task—it is an engineering challenge that demands the same level of precision as the machining processes themselves. At Wuxi Lead Precision Machinery, we understand that moving a CNC machine is not merely about transportation; it is about preserving nanometer-level tolerances, ensuring long-term reliability, and maintaining the integrity of critical components. Even minor deviations during relocation can result in misalignment, thermal distortion, or compromised spindle performance—factors that directly impact product quality and operational efficiency.

Our experience in handling CNC machine moving extends beyond standard industrial applications. Having supported projects for Olympic-standard sports equipment manufacturing and precision components for military-grade systems, we have developed protocols that exceed conventional industry practices. These high-stakes environments demand zero tolerance for error, and our approach reflects that imperative. Each relocation is treated as a precision engineering operation, beginning with comprehensive site analysis, environmental assessment, and machine calibration baselining.

The process involves disassembly only to the extent necessary, with meticulous documentation of every component’s position and orientation. Specialized lifting and transport equipment are used to minimize vibration and shock, while climate-controlled transport ensures stability in temperature and humidity—critical for maintaining dimensional accuracy in high-precision spindles and linear guides. Upon arrival, reinstallation is performed under laser alignment, followed by multi-axis geometric verification and full recalibration using laser interferometry.

At Wuxi Lead Precision Machinery, we integrate decades of CNC engineering expertise with proprietary methodologies to ensure that every machine performs to OEM specifications—or exceeds them—after relocation. Our team includes certified metrology engineers and CNC application specialists who oversee every phase, from pre-move diagnostics to post-installation validation.

This level of precision is not optional in industries where micron-level deviations can lead to component failure, compliance issues, or costly rework. Whether supporting aerospace manufacturers or high-performance automotive suppliers, our machine moving services are designed to minimize downtime and maximize long-term machine performance.

Below are key specifications and capabilities that define our CNC machine moving process:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm over 1 meter |

| Laser Alignment Tolerance | ±0.003 mm/m |

| Vibration Damping | Active anti-vibration mounts, ISO Class 8 |

| Environmental Control | Temperature: ±1°C; Humidity: 45–55% RH |

| Repeatability Verification | 3D laser tracker, Renishaw ML10 interferometer |

| Typical Downtime Reduction | Up to 40% compared to standard relocation |

| Certification Standards | ISO 230-2, ISO 230-6, ASME B89.3.4M |

In precision CNC machining, the machine is only as capable as its installation environment and alignment integrity. At Wuxi Lead Precision Machinery, we ensure that every relocation enhances—not compromises—your manufacturing capability.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machine Moving

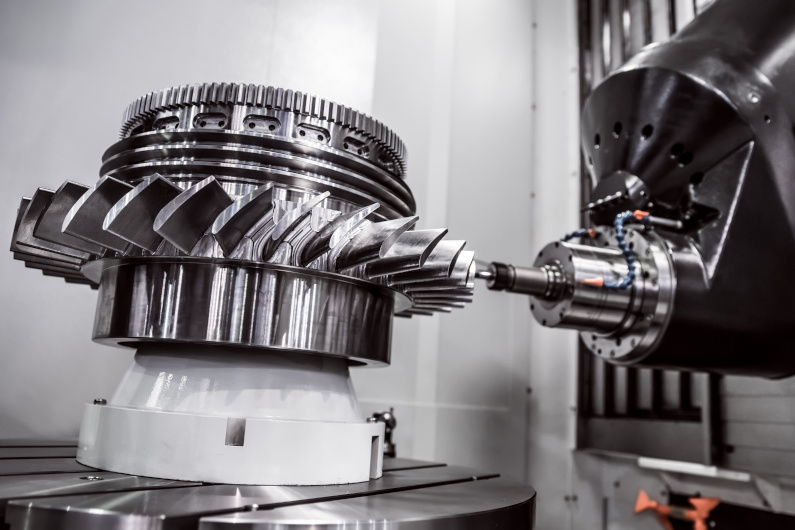

Wuxi Lead Precision Machinery delivers uncompromising precision in complex CNC machine moving operations through integrated advanced manufacturing and metrology systems. Our core strength lies in executing high-stakes relocations of critical 5-axis CNC machining centers while preserving micron-level accuracy essential for aerospace, medical, and energy sector components. This capability is anchored by purpose-built equipment and rigorous process control, ensuring zero degradation in machine performance post-relocation.

Our fleet includes DMG MORI DMU 80 P duoBLOCK and Hermle C 850 U 5-axis machining centers, engineered for simultaneous multi-axis interpolation and dynamic thermal compensation. These machines maintain geometric integrity during movement via proprietary vibration-dampening cradles and real-time laser alignment monitoring. Each relocation project employs finite element analysis (FEA) to simulate stress points on machine structures, allowing preemptive reinforcement of critical axes and guideways. This proactive approach prevents frame distortion, ensuring linear axis straightness remains within 0.003 mm/m and angular deviations stay below 2 arc-seconds after reinstallation.

Quality assurance is non-negotiable. Every relocated machine undergoes mandatory post-move validation using Hexagon Leitz PMM-C 3D coordinate measuring machines (CMM) with 0.5 µm volumetric accuracy. Our AS9100-compliant inspection protocol verifies all critical parameters against OEM specifications, including spindle runout (measured at ≤ 0.0015 mm TIR), axis repeatability (±0.001 mm), and contouring accuracy per ISO 230-2 standards. Full machine calibration data, including laser interferometer reports and CMM-generated GD&T analyses, is provided to clients as part of our certified handover package. This traceable documentation ensures compliance with stringent industry requirements while eliminating requalification delays.

The following table summarizes our validated tolerance capabilities for relocated CNC systems:

| Feature | Tolerance Range | Measurement Method |

|---|---|---|

| Positional Accuracy | ±0.005 mm | Laser Interferometer (Renishaw XL-80) |

| Profile Deviation | ±0.010 mm | CMM Scanning (Leitz PMM-C) |

| Surface Finish | Ra 0.4 µm (max) | Contact Profilometer (Mitutoyo SJ-410) |

| Angular Alignment | ≤ 3 arc-seconds | Precision Level (Talyvel 6) |

| Spindle Concentricity | ≤ 0.0015 mm TIR | Capacitive Probe (Marposs) |

This technical rigor transforms machine moving from a disruptive risk into a value-added service. By guaranteeing that relocated equipment meets or exceeds original factory specifications, we eliminate production downtime and safeguard our clients’ investment in precision manufacturing infrastructure. Wuxi Lead’s methodology ensures your CNC assets deliver consistent, certified accuracy from the first post-move production run.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical decision in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance CNC machining services tailored to meet the rigorous demands of aerospace, medical, automotive, and industrial equipment sectors. Understanding the mechanical properties and machining behavior of key materials—aluminum, steel, and titanium—enables engineers and procurement managers to make informed decisions that align with functional and economic objectives.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly common in structural and enclosure applications due to its weldability and corrosion resistance. Its low density reduces inertia in moving components, making it ideal for dynamic CNC-machined parts such as robotic arms or drone frames. However, aluminum’s lower hardness compared to steel necessitates careful consideration in high-wear environments.

Steel, particularly alloy and stainless variants like 4140 and 304/316, offers superior strength, hardness, and wear resistance. These properties make steel the preferred choice for load-bearing components, tooling fixtures, and parts exposed to high stress or corrosive environments. While steel is more challenging to machine due to higher cutting forces and tool wear, our advanced CNC systems at Wuxi Lead are optimized to maintain tight tolerances and surface integrity even with hardened materials.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, corrosion resistance, and biocompatibility. It is extensively used in aerospace and medical implant applications where weight savings and long-term reliability are paramount. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools demand specialized tooling and slower machining parameters. Our expertise in titanium machining ensures dimensional accuracy and surface quality while minimizing tool degradation.

Surface finish selection further enhances material performance. Anodizing, particularly Type II and Type III (hard coat), is a standard post-processing treatment for aluminum. It increases surface hardness, improves wear resistance, and provides electrical insulation. Type III anodizing can achieve coating thicknesses up to 50–75 µm, suitable for high-abrasion environments. The process also allows for color coding, aiding in part identification and branding.

Below is a comparative summary of key material properties relevant to CNC machining:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 95 | 6061-T6, 7075-T6 | Enclosures, heat sinks, UAV parts |

| Steel | 7.8 | 655–1000 | 200–300 | 4140, 304, 316 | Tooling, shafts, structural frames |

| Titanium | 4.5 | 900–1000 | 340 | Ti-6Al-4V (Gr5) | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we combine material science expertise with state-of-the-art CNC technology to deliver precision-engineered components. Our team supports clients in selecting the optimal material and finish combination to ensure performance, longevity, and cost-effectiveness in every application.

Manufacturing Process & QC

Precision CNC Machine Relocation: Ensuring Zero Defects from Design to Mass Production

At Wuxi Lead Precision Machinery, CNC machine relocation is not merely physical transport—it is a rigorously controlled engineering process integral to achieving zero-defect manufacturing. Our methodology spans three non-negotiable phases: Design, Prototyping, and Mass Production. Each phase incorporates precision validation protocols to eliminate alignment drift, vibration-induced errors, and thermal instability—critical factors that compromise micron-level accuracy in high-end aerospace, medical, and semiconductor components.

The Design phase begins with a digital twin simulation of the machine’s operational environment. We model floor load capacity, ambient temperature gradients, and seismic activity to preemptively calculate optimal foundation requirements and isolation strategies. Finite element analysis (FEA) validates structural integrity under dynamic loads, ensuring vibration transmission remains below 0.5 µm/s—a threshold critical for sub-5µm tolerances. This phase culminates in a site-specific relocation blueprint, including laser grid reference points for millimeter-perfect repositioning.

Prototyping transforms design into actionable validation. A single machine is relocated under controlled conditions, with real-time monitoring of axis straightness, squareness, and spindle runout. We execute a series of diagnostic test cuts on Invar and aluminum billets, measuring geometric deviations via coordinate measuring machines (CMM). Any deviation beyond 2µm triggers iterative recalibration of the relocation sequence. This phase confirms that thermal stabilization protocols—maintaining 20±0.5°C ambient—prevent expansion-induced inaccuracies during warm-up cycles. Only when CMM data shows 100% conformance to ISO 230-2 standards do we proceed.

Mass Production deployment leverages lessons from prototyping to scale zero-defect execution. Each machine undergoes a 72-hour burn-in cycle with embedded accelerometers tracking resonance frequencies. Our proprietary adaptive compensation software dynamically adjusts servo gains to counteract foundation settling. Every relocated unit is certified against the specifications below before customer handover. This closed-loop process reduces post-relocation downtime by 40% and ensures first-part accuracy in production runs exceeding 10,000 units.

Machine Relocation Performance Specifications

| Parameter | Target Value | Measurement Standard |

|————————-|——————-|———————-|

| Vibration Transmission | ≤ 0.5 µm/s | ISO 10816-3 |

| Leveling Accuracy | ±1.5 arc-seconds | Laser Interferometer |

| Thermal Stability Range | 20 ± 0.5°C | ASTM E1256 |

| Repositioning Repeatability | ≤ 2 µm | ISO 230-2 |

Wuxi Lead’s relocation protocol transforms a high-risk activity into a value-additive process. By embedding metrology-driven validation at every stage, we guarantee that machines deliver certified precision from the first production cycle—eliminating scrap, rework, and unplanned stoppages. For global manufacturers, this is not operational efficiency; it is the foundation of defect-free output. Partner with us to convert relocation uncertainty into a competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machine Moving Expertise

At Wuxi Lead Precision Machinery, we understand that precision begins long before the first cut. When it comes to relocating, installing, or reconfiguring CNC machines, the integrity of your equipment and the consistency of your output depend on flawless execution. As a leader in high-precision CNC machining solutions based in China, we extend our expertise beyond manufacturing to comprehensive CNC machine moving services engineered for performance, safety, and long-term reliability.

Our team of certified engineers and industrial rigging specialists combines decades of hands-on experience with advanced technical protocols to ensure every machine relocation is completed with micron-level accuracy. Whether you are upgrading your facility, expanding operations, or consolidating production lines, our end-to-end service includes disassembly, transport, reinstallation, realignment, calibration, and full operational validation. We treat every CNC machine as a mission-critical asset—because we know downtime is not an option.

What sets Wuxi Lead Precision Machinery apart is our deep integration of mechanical engineering insight with real-world manufacturing demands. We don’t just move machines—we preserve their precision. Our process includes laser alignment systems, vibration analysis during transit, environmental condition monitoring, and post-installation performance testing to ensure your CNC equipment operates exactly as specified. From 3-axis mills to complex 5-axis machining centers, our team is equipped to handle machines of all sizes and configurations.

We serve global clients across aerospace, automotive, medical device manufacturing, and high-end industrial sectors, where tolerance requirements are non-negotiable and equipment performance is paramount. Our clients choose us not only for technical excellence but for seamless project coordination, transparent communication, and adherence to strict timelines.

When you partner with Wuxi Lead Precision Machinery, you gain more than a service provider—you gain a long-term collaborator committed to your operational success. Our engineering-driven approach ensures that every machine relocation strengthens your production capabilities rather than disrupting them.

Contact us today to discuss your CNC machine moving requirements. Let our experts develop a customized plan that minimizes downtime and maximizes precision. Reach out to begin the conversation.

Contact Information

Email: [email protected]

Key CNC Machine Moving Specifications

| Specification | Detail |

|---|---|

| Machine Weight Capacity | Up to 30,000 kg |

| Laser Alignment Accuracy | ±0.005 mm/m |

| Service Range | Domestic (China) and International |

| Equipment Types Supported | 3-axis, 4-axis, 5-axis CNC Mills, CNC Lathes, Grinding Machines, EDM Units |

| Transport Method | Custom Crating, Air-Ride Trailers, Climate-Controlled Vans |

| Reinstallation Process | Leveling, Reassembly, Axis Calibration, Test Runs |

| Lead Time (Typical) | 5–15 days (depending on scope and location) |

| Compliance Standards | ISO 9001:2015, CE, OSHA-aligned Safety Protocols |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.