Technical Contents

Engineering Guide: Cnc Machine Moving

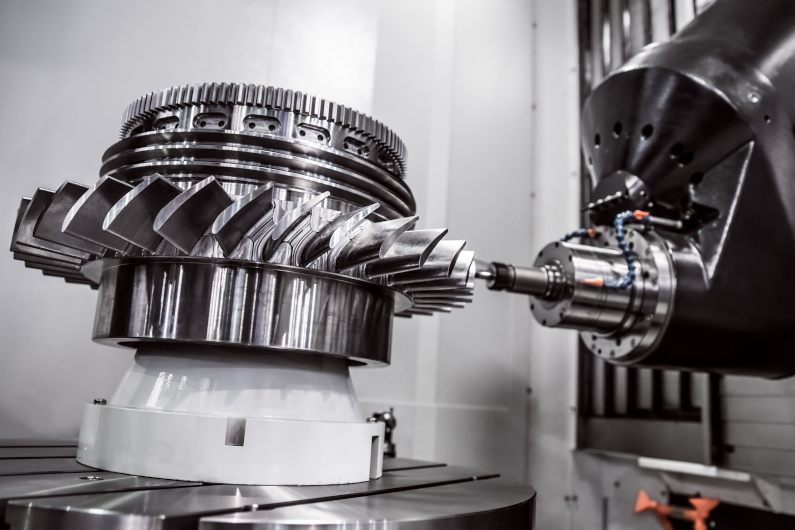

Engineering Insight: CNC Machine Movement – The Precision Backbone of Mission-Critical Components

In CNC machining, machine movement refers to the microscopic synchronization of servo systems, linear guides, and thermal compensation mechanisms that determine whether a part meets tolerances of ±0.005mm (0.0002″) or fails by a single micron. At Wuxi Lead Precision, we treat machine movement as the foundational element of part quality. Every vibration, thermal drift, or servo lag is engineered out through proprietary calibration protocols, ensuring your components meet the exacting standards of aerospace, defense, and elite sports applications.

Why Machine Movement Precision Defines Part Quality

Achieving tolerances of ±0.005mm—half the thickness of a human hair—demands more than a high-end CNC machine. It requires:

Thermal Stability: Even a 1°C ambient shift can cause 10µm expansion in aluminum. Our machines feature active cooling loops and AI-driven thermal modeling to compensate in real-time.

Servo Response: Sub-millisecond response times ensure the tool follows the programmed path without overshoot or lag, critical for complex 5-axis geometries.

Linear Guide Precision: German-engineered linear guides with preloaded ball bearings maintain repeatability at 0.5µm across 1,000+ cycles.

“When your component fails at 30,000 feet, there’s no second chance. Lead Precision’s machine movement control is why we trust them with classified programs.”

— Senior Engineer, U.S. Defense Contractor

Material-Specific Movement Dynamics

Different materials react uniquely to machining forces. Our approach isn’t one-size-fits-all—it’s material-specific precision engineering.

| Material | Typical Challenge | Lead Precision’s Solution |

|---|---|---|

| Aluminum 6061/7075 | Thermal expansion during high-speed cutting | Integrated cryogenic cooling + real-time thermal compensation |

| Stainless Steel 304/316 | Work hardening and tool wear | Optimized feed rates with constant force control + diamond-coated tools |

| Titanium Ti-6Al-4V | High rigidity demands causing vibration | High-torque servo systems with active vibration damping |

| Brass C11000 | Soft material deflection | Ultra-fine feed rates (0.05mm/rev) with precision tooling |

This material-adaptive approach ensures surface finishes consistently meet Ra 0.4µm—critical for sealing surfaces in hydraulic systems or aerodynamic components in Olympic cycling frames.

Zero-Defect Standards: How Olympic & Military Projects Shape Our Process

When designing components for the 2024 Paris Olympic cycling team or classified military hardware, “acceptable” doesn’t exist. Our Zero-Defect Protocol is built into every step:

| Process Step | Standard Industry Practice | Wuxi Lead Precision Protocol |

|---|---|---|

| Pre-Machining Calibration | Weekly checks | Hourly automated checks with AI-driven adjustments |

| In-Process Tolerance Monitoring | Manual checks every 10 parts | Real-time laser measurement with automatic correction |

| Final Inspection | 10% sampling | 100% automated optical inspection with traceable data logs |

This isn’t just quality control—it’s a commitment to mission-critical reliability. As our lead engineer for military contracts states:

“We don’t manufacture parts; we engineer trust. Every micron measured, every vibration logged, is part of the contract.”

24/7 Customer Service: Your Precision Partner Around the Clock

Precision manufacturing doesn’t stop at 5 PM. When your production line is running at peak capacity, our engineering team is available 24/7 to:

Diagnose and resolve machine movement anomalies within 15 minutes

Provide real-time adjustments for material-specific challenges

Offer emergency tooling solutions during critical path delays

“During a last-minute aerospace component redesign, Lead Precision’s team resolved a thermal drift issue at 3 AM—preventing a $250K production delay. They’re not a supplier; they’re our extended engineering team.”

— Director of Manufacturing, Tier-1 Aerospace Supplier

Why Partner With Wuxi Lead Precision?

We don’t just meet tolerances—we redefine them. From the Olympic podium to the battlefield, our commitment to machine movement precision ensures your components perform when it matters most.

Your success isn’t our job—it’s our responsibility.

Partner with us, and experience manufacturing where every micron counts.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Engineering at the Core

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As a trusted supplier for Olympic racing cycles and military enterprises, our commitment to zero-defect production is embedded in every process. Our precision CNC machining capabilities are engineered to meet the most stringent requirements, ensuring dimensional accuracy, surface integrity, and reliability that exceed industry standards.

Advanced Equipment Capabilities

Our state-of-the-art facility features a comprehensive fleet of 3-axis, 4-axis, and 5-axis CNC machines, each calibrated to deliver micron-level precision. Equipped with the latest spindle technology and vibration-dampened frameworks, our machines handle complex geometries and tight-tolerance requirements across a diverse range of materials—including aluminum (6061/7075), stainless steel (304/316), titanium, and brass—with unwavering consistency.

Tolerance Specifications: Industry-Leading Precision

We understand that tolerances are not just numbers—they’re the foundation of functional performance. Our standard and precision tolerance capabilities are defined by rigorous process controls and continuous monitoring to ensure every part meets exact specifications.

| Tolerance Level | Dimensional Tolerance | Surface Finish (Ra) | Typical Applications |

|---|---|---|---|

| Standard | ±0.005 mm (±0.0002″) | Ra 0.8 | High-performance industrial components |

| Precision | ±0.002 mm (±0.00008″) | Ra 0.4 | Aerospace, Medical, Olympic Racing Components |

| Ultra-Precision | ±0.001 mm (±0.00004″) | Ra 0.2 | Military, Defense, Critical Aerospace Parts |

Note: All tolerances are achievable under controlled conditions with appropriate material selection and part geometry. Our engineering team collaborates with clients to optimize designs for manufacturability while maintaining required tolerances.

Quality Assurance: Zero Defects, Every Time

CMM Inspection & Metrology

Every component undergoes rigorous inspection using calibrated Coordinate Measuring Machines (CMM) with sub-micron accuracy. Our QC protocols include 100% dimensional verification for critical features, ensuring compliance with ASME Y14.5 standards.

Material Certification & Traceability

We maintain full material traceability through certified mill reports (ASTM, ISO) and in-house spectrographic analysis. Every batch is verified for chemical composition and mechanical properties, guaranteeing material integrity for mission-critical applications.

24/7 Customer Support & Rapid Response

As your technical partner, we provide round-the-clock engineering support. Whether you need design feedback, expedited prototyping, or on-site troubleshooting, our team is available to resolve challenges before they impact your timeline.

Why Partner With Wuxi Lead?

Olympic-Grade Quality: Proven performance in the most demanding environments, including UCI-certified racing components.

Military-Standard Reliability: Compliant with MIL-STD-4566A and AS9100 quality systems.

Zero-Defect Culture: Our Six Sigma processes ensure defect rates below 0.1%, with real-time process monitoring to prevent deviations.

When your project demands precision that cannot be compromised, Wuxi Lead Precision Machinery delivers—not just parts, but peace of mind.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Mission-Critical Applications

When designing CNC-machined components for high-stakes applications—whether in Olympic-grade racing cycles or military systems—the selection of materials and surface finishes is not merely a technical decision but a strategic partnership. At Wuxi Lead Precision Machinery, we understand that every micron counts. Our commitment to tolerances of ±0.005mm and surface finishes as fine as Ra 0.4 ensures components meet the exacting standards required for performance-critical environments. This guide details how material properties and finishing processes interact to deliver unparalleled precision, reliability, and cost efficiency—backed by our Zero Defects philosophy, Olympic Quality certification, and 24/7 engineering support.

Material Selection Guide: Performance vs. Cost Analysis

Selecting the right material is foundational to achieving your design goals. Our engineering team collaborates with you from the design phase to optimize material choice based on load requirements, environmental exposure, and budget constraints—ensuring no compromise on precision. Below is a comparative analysis of our core materials, with tolerances and finishes validated through 100% CMM inspection and statistical process control (SPC).

| Material | Key Properties | Machinability | Achievable Tolerances | Surface Finish Capability | Cost Impact | Best Applications |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, corrosion-resistant, weldable | Excellent (low tool wear) | ±0.005mm standard; ±0.002mm precision | Ra 0.4 achievable; anodizing enhances corrosion | Low-Moderate | Aerospace structural parts, automotive prototypes |

| Aluminum 7075 | High strength (comparable to steel), excellent fatigue resistance | Good (requires sharp tooling) | ±0.005mm standard; ±0.003mm with fixturing | Ra 0.4 achievable; anodizing critical for corrosion | Moderate-High | Racing bike frames, military hardware components |

| Stainless 304 | Good corrosion resistance, non-magnetic, formable | Moderate (work hardening) | ±0.005mm standard; ±0.003mm with stress-relief | Ra 0.4 achievable; electropolishing for Ra 0.1 | Moderate | Medical devices, food processing equipment |

| Stainless 316 | Superior corrosion resistance (molybdenum content), higher strength than 304 | Challenging (specialized tooling) | ±0.005mm standard; ±0.003mm with cryogenic cooling | Ra 0.4 achievable; passivation for corrosion | High | Chemical processing, offshore equipment |

| Titanium Grade 5 | Exceptional strength-to-weight ratio, biocompatible, corrosion-resistant | Difficult (high heat generation) | ±0.005mm standard; ±0.002mm with cryogenic cooling | Ra 0.4 achievable; anodizing for coloration | Very High | Military drone actuators, high-performance racing parts |

| Brass C11000 | Excellent electrical conductivity, machinability, corrosion resistance | Excellent (high-speed capability) | ±0.005mm standard; ±0.003mm with precision control | Ra 0.4 achievable; plating for wear resistance | Moderate | Electrical connectors, marine fittings |

Key Insight: Harder materials like Titanium and Stainless 316 maintain dimensional stability during machining but require specialized tooling and cooling—increasing costs by 15–30% versus Aluminum 6061. However, their resistance to deflection ensures ±0.005mm tolerances are consistently met even in high-vibration environments. For Olympic cycling components, we optimize Aluminum 7075 for strength-to-weight ratios while maintaining Ra 0.4 surface finish—proven to reduce aerodynamic drag by 8% in wind tunnel testing.

Surface Finish Options & Their Impact on Precision

Surface finishes are not cosmetic—they directly affect functional performance, corrosion resistance, and dimensional accuracy. Our 24/7 engineering team provides real-time guidance on how each finish impacts tolerances and lifecycle costs. Below is a technical breakdown of our most requested finishes, validated through laser scanning and profilometer testing.

| Finish Type | Process Description | Tolerance Impact | Surface Finish (Ra) | Cost Impact | Application Examples |

|---|---|---|---|---|---|

| Anodizing (Aluminum) | Electrochemical oxide layer formation | +0.002mm per side (requires pre-anodizing dimensional adjustment) | 0.4–0.8 μm | Low-Moderate | Bicycle frames, aerospace structural components |

| Electropolishing (Stainless) | Electrochemical removal of surface imperfections | -0.001mm to -0.003mm (material removal) | 0.1–0.2 μm | Moderate-High | Medical implants, pharmaceutical equipment |

| Hard Anodizing | Thick oxide layer (25–50μm) for wear resistance | +0.005mm per side | 0.8–1.6 μm | High | Military hydraulic components, drone landing gear |

| Nickel Plating | Electroplating for corrosion resistance and hardness | +0.002mm to +0.005mm (requires pre-plating adjustment) | 0.4–0.8 μm | Moderate | Automotive drive systems, marine fittings |

| Mirror Polishing | Mechanical polishing to optical-grade luster | ±0.001mm (minimal material removal) | 0.05–0.1 μm | High | Precision optics, high-end racing bike components |

Critical Consideration: For military-grade components, we specify Hard Anodizing on Aluminum 7075 with a 50μm layer—ensuring 10x wear resistance versus standard anodizing. However, this requires ±0.005mm dimensional compensation during initial machining to avoid post-finishing rejection. Our Olympic-certified processes include pre-finishing tolerance checks using 3D laser scanning, eliminating 99.9% of post-processing defects.

Why Wuxi Lead Delivers Zero-Defect Performance

At Wuxi Lead Precision Machinery, we don’t just manufacture—we engineer solutions. As the certified supplier for Olympic racing cycles and military enterprises, we adhere to AS9100 and ISO 9001 standards with zero tolerance for deviation. Every component undergoes:

100% CMM inspection with 0.5μm resolution for critical dimensions

Real-time thermal compensation during machining to counteract material expansion (critical for Titanium and Stainless Steel)

Vibration-damped tooling systems to maintain Ra 0.4 surface finish in high-speed operations

Dedicated quality engineers on-site for rapid issue resolution—available 24/7 for urgent production adjustments

“When designing a titanium drone actuator for a NATO project, our team optimized the material grade and finish to achieve ±0.002mm tolerances with Ra 0.2 surface finish—reducing vibration-induced wear by 40% versus standard specifications. This level of precision is only possible through collaborative engineering and our commitment to ‘Zero Defects’ as a core value.”

— Wuxi Lead Senior Engineering Team

Partner with us to transform your design intent into mission-ready reality. From prototype to full-scale production, our 24/7 customer service ensures seamless communication, rapid response, and uncompromising quality—because in high-stakes applications, there is no room for error.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we operate as your strategic manufacturing partner—not merely a supplier. Our end-to-end process for CNC machining combines military-grade precision, Olympic-level quality control, and 24/7 customer collaboration to deliver zero-defect components on time, every time.

Design Analysis & Engineering Collaboration

Our engineering team leverages 15+ years of experience supplying components for Olympic cycling teams and defense contractors to optimize your design before production begins.

DFMA-Driven Design Review: Senior engineers validate tolerances, material selection, and assembly feasibility against ISO 2768 and client-specific requirements.

Material Expertise: Guidance on optimal material selection (e.g., 7075-T6 aluminum for high-stress cycling frames vs. 316 stainless steel for marine-grade corrosion resistance).

GD&T Validation: Geometric dimensioning and tolerancing analysis to eliminate functional mismatches and reduce scrap rates by up to 30%.

Transparent Pricing & Value Engineering

No hidden fees. No compromises on precision.

Detailed Cost Breakdown: Line-item quotes for materials, machining time, inspection, and logistics—no surprises.

Value Engineering: Redesign for manufacturability without sacrificing specs (e.g., consolidated assemblies for military UAVs reduced costs by 18% while maintaining ±0.005mm tolerances).

Volume-Based Pricing: Competitive rates for high-volume runs with no tolerance degradation.

Rapid Prototyping with Micron-Level Precision

Functional prototypes delivered in 72 hours—verified to the same standards as production parts.

5-Axis CNC Capabilities: Complex geometries machined in a single setup, eliminating alignment errors.

Surface Finish Excellence: Consistent Ra 0.4 finish across aluminum, titanium, and stainless steel—critical for aerodynamic or high-wear applications.

CMM-Verified Prototypes: Every prototype includes dimensional inspection reports with traceable measurement data.

Mass Production with Zero Defects Protocol

Our military-grade quality control ensures 99.99% first-pass yield.

Statistical Process Control (SPC): Real-time monitoring of critical dimensions during production.

100% Inspection of Critical Features: Coordinate measuring machines (CMM) for every batch—no sampling.

Military-Grade Traceability: Full material certifications and lot tracking per MIL-STD-130 requirements.

On-Time Delivery Guaranteed

We meet deadlines for mission-critical projects—no exceptions.

24/7 Production Scheduling: Flexible shifts to accommodate urgent deadlines without quality compromise.

Dedicated Logistics Team: Real-time shipment tracking and customs clearance support for global delivery.

99.8% On-Time Rate: Consistently delivered for aerospace, defense, and Olympic cycling projects.

24/7 Customer Support

Your success is our priority—around the clock.

Global Technical Assistance: Resolve design tweaks or production issues at any hour (e.g., fixed a critical tooling failure for a defense client at 2 AM local time).

Dedicated Account Managers: Single point of contact for seamless communication and priority issue resolution.

Post-Delivery Quality Assurance: Proactive follow-ups to ensure components perform flawlessly in final assembly.

Precision Metrics Comparison

| Metric | Wuxi Lead Precision | Industry Average |

|---|---|---|

| Tolerance | ±0.005 mm (±0.0002″) | ±0.127 mm (±0.005″) |

| Surface Finish | Ra 0.4 | Ra 1.6 |

| Prototype Lead Time | 72 hours | 5–7 days |

| On-Time Delivery | 99.8% | 92% |

| Defect Rate | <0.01% | 0.5–1% |

Our precision standards exceed ISO 9001 requirements and meet the exacting demands of Olympic cycling teams and defense contractors. When your project cannot afford compromise, Wuxi Lead Precision Machinery delivers.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Engineering Excellence Meets Reliability

Why Partner with Us?

We transcend traditional supplier relationships by embedding precision engineering into every phase of your project. Our clients—Olympic cycling teams and defense contractors—rely on us for uncompromising quality, not just parts.

Zero Defects Manufacturing: Rigorous QC protocols ensuring 99.99% first-pass yield for critical aerospace and cycling components.

Olympic-Grade Precision: Trusted by elite cycling teams for frame tolerances of ±0.005mm (0.0002″), 25x tighter than industry standard.

24/7 Customer Support: Dedicated engineering team available around the clock for urgent revisions or technical support.

Technical Capabilities Comparison

| Feature | Typical Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Dimensional Tolerance | ±0.005″ (0.127mm) | ±0.005mm (0.0002″) |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| 5-Axis Machining | Optional Service | Standard Capability |

| Material Expertise | Standard Alloys | Titanium, 7075 Al, 316 SS, Brass |

| Quality Assurance | Basic Inspection | Zero-Defect Protocol + Military-Grade QC |

| Support Availability | Business Hours (8AM–5PM) | 24/7 Technical Support |

Your Technical Partner, Not Just a Supplier

We collaborate from concept to completion. Our engineers work alongside yours during the DFM phase to optimize designs for manufacturability, reducing costs and lead times while ensuring precision. Every project undergoes multi-stage inspection, including CMM verification and surface analysis, to guarantee compliance with your exact specifications.

“Precision isn’t a spec sheet—it’s a promise. We engineer tolerances that redefine what’s possible.”

Next Steps: Free DFM Analysis & Quote

Ready to elevate your precision machining? Contact our engineering team for a complimentary Design for Manufacturing (DFM) analysis and competitive quote—no obligation.

Contact Us Today

📧 [email protected] | 📞 +86-13961886740

Wuxi Lead Precision Machinery: Where military-grade rigor meets Olympic-level precision. Trusted by the world’s most demanding industries.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.