Technical Contents

Engineering Guide: Cnc Machine Market

Engineering Insight Precision as the Non-Negotiable Core of the CNC Machine Market

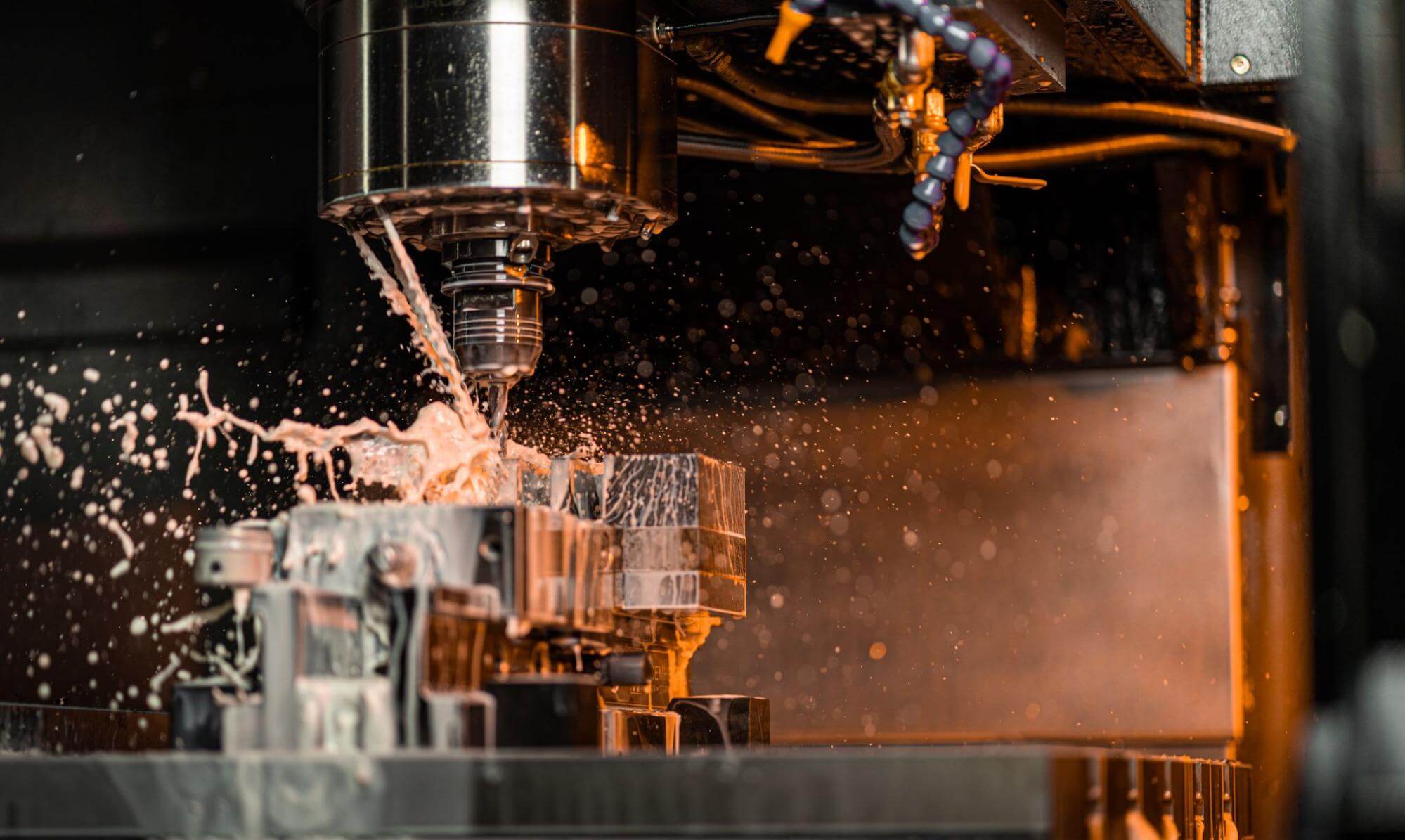

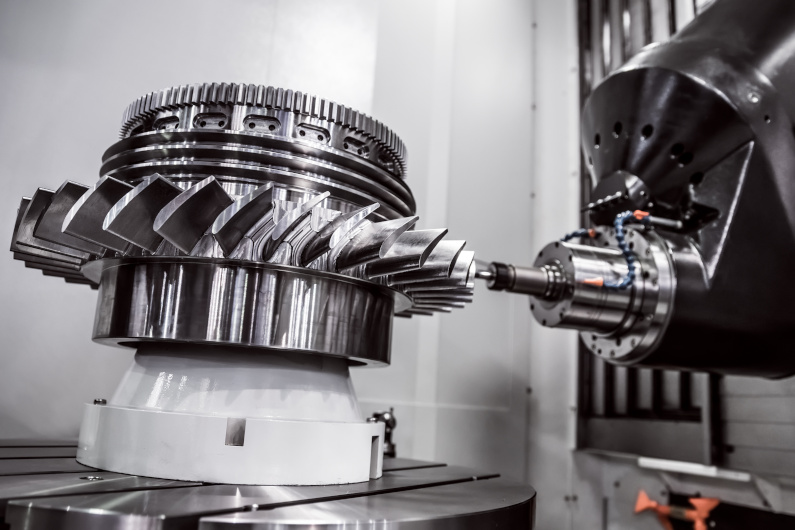

In the high-stakes arena of modern manufacturing, precision transcends mere specification; it is the fundamental determinant of product viability, performance, and market success. The contemporary CNC machine market operates under an uncompromising mandate where tolerances measured in microns directly dictate functional integrity, assembly feasibility, and the ultimate lifespan of critical components. This demand is not abstract. It manifests in aerospace assemblies where misaligned turbine blades induce catastrophic vibration, in medical implants where surface finish dictates biocompatibility, and in semiconductor tooling where sub-micron deviations render multi-million dollar systems inoperable. Precision is the silent enabler of innovation, allowing engineers to translate complex digital designs into physical reality with absolute fidelity. Without it, the promise of advanced materials, intricate geometries, and next-generation product performance remains unrealized. The market increasingly discriminates not just on raw power or speed, but on the demonstrable, repeatable capability to hold dimensional and geometric tolerances under real-world production conditions across shifts and seasons.

Wuxi Lead Precision Machinery operates at this demanding apex. Our engineering philosophy is forged in environments where failure is not an option. This includes supplying mission-critical components for international sporting events demanding flawless structural integrity under extreme loads and dynamic conditions, alongside stringent military and defense applications where component reliability is synonymous with operational safety and national security. These sectors impose validation protocols far exceeding standard industry norms, requiring not only exceptional machine capability but also rigorous process control, advanced metrology integration, and unwavering commitment to zero-defect manufacturing. Our experience navigating these ultra-high-precision landscapes directly informs the machine design, calibration standards, and process validation embedded within every system we engineer and deploy for our global clientele.

The tangible output of this precision focus is quantifiable. Below are key performance indicators defining the baseline capability expected from advanced CNC machining centers serving demanding sectors:

| Performance Parameter | Typical High-End Specification | Critical Impact |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±1.5 µm | Ensures correct feature location across entire work envelope |

| Repeatability (X/Y/Z) | ≤ ±0.7 µm | Guarantees consistent part-to-part quality in volume production |

| Volumetric Compensation | Full 3D laser-mapped | Corrects for geometric errors inherent in machine structure |

| Thermal Growth Compensation | Real-time sensor network | Maintains accuracy despite ambient or process temperature shifts |

| Spindle Runout (at tool) | ≤ 1.0 µm TIR | Directly influences surface finish and tool life |

Achieving and sustaining these levels requires holistic engineering. It integrates thermally stable machine structures, high-resolution feedback systems, advanced motion control algorithms, and sophisticated environmental management – far beyond basic machine construction. For manufacturers entering or competing in advanced sectors, the CNC machine is not merely a tool; it is the foundational platform upon which product excellence, yield rates, and ultimately, business reputation are built. Partnering with an engineering-led supplier possessing proven experience in the most exacting applications provides the necessary confidence that precision is not just promised, but demonstrably delivered and sustained. This is the non-negotiable standard defining the future of the CNC machine market.

Precision Specs & Tolerances

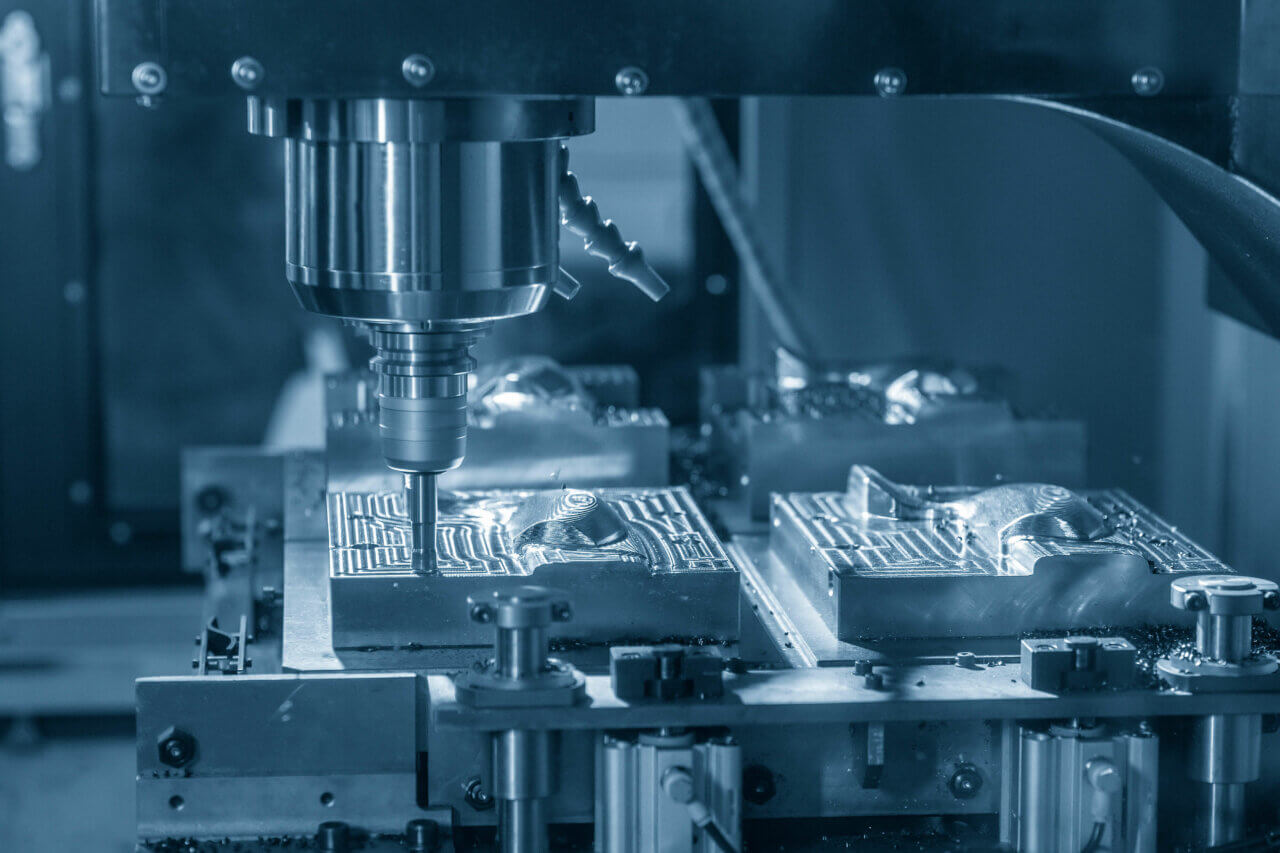

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical, energy, and advanced automation. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with superior surface finish and dimensional accuracy. Our 5-axis CNC systems operate with simultaneous multi-axis motion, allowing for intricate contours, undercuts, and deep cavity machining that are unattainable with conventional 3-axis equipment. This level of precision reduces the need for multiple setups, minimizing human error and significantly improving production efficiency.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation, ensuring consistent part quality across both prototyping and high-volume production runs. Materials processed include aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics, all machined under strict environmental controls to prevent thermal distortion. Each machine is maintained to OEM specifications and operated by certified CNC programmers and machinists with extensive experience in tight-tolerance component manufacturing.

Quality assurance is integral to our process. Every critical dimension is validated using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems. Our CMMs are calibrated to ISO 17025 standards and operated in a temperature-controlled metrology lab, ensuring measurement repeatability down to ±0.0001 inches (2.5 µm). Full first-article inspection reports (FAIR) and production batch certifications are provided upon request, supporting compliance with AS9100, ISO 13485, and other industry-specific quality management systems.

We specialize in achieving and verifying tight tolerances across complex part features. The table below outlines our standard and precision tolerance capabilities based on feature type and material stability.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | CMM, High-Precision Micrometer |

| Angular Features | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Hole Diameter (Drilled) | ±0.01 mm | ±0.005 mm | Air Gauge, CMM |

| Hole Diameter (Reamed) | ±0.005 mm | ±0.002 mm | CMM, Plug Gauge |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Profilometer |

| Positional Tolerance | ±0.01 mm | ±0.005 mm | CMM |

| Flatness | 0.01 mm/m | 0.005 mm/m | CMM, Optical Flat |

Our technical capabilities are reinforced by a digital-first workflow, integrating CAD/CAM software with real-time machine monitoring to ensure process traceability and continuous improvement. From design support to final inspection, Wuxi Lead Precision Machinery provides a fully documented, repeatable, and scalable precision machining solution tailored to the evolving needs of the global CNC machine market.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to achieving precision, performance, and cost-efficiency in CNC-machined components. At Wuxi Lead Precision Machinery, we understand that material properties directly impact machinability, final part integrity, and suitability for demanding applications across aerospace, medical, and industrial sectors. This guide outlines key considerations for aluminum, steel, and titanium, alongside critical insights on anodizing finishes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are industry staples due to their excellent strength-to-weight ratio, superior thermal and electrical conductivity, and inherent corrosion resistance. They machine exceptionally well, allowing for high-speed cutting, tight tolerances, and complex geometries with minimal tool wear. Aluminum is ideal for structural components, housings, and parts requiring weight reduction. However, its lower hardness compared to steel necessitates careful design for high-wear applications.

Steel, encompassing both carbon steels (e.g., 1018, 1045) and stainless varieties (e.g., 304, 316, 17-4 PH), offers high strength, durability, and wear resistance. Stainless steels provide outstanding corrosion resistance, crucial for medical implants, marine hardware, and chemical processing equipment. Machining steel generally requires more robust tooling and slower speeds than aluminum due to higher hardness and work-hardening tendencies, particularly with stainless grades. Carbon steels are cost-effective for non-corrosive environments but require protective finishes.

Titanium alloys, primarily Ti-6Al-4V (Grade 5), deliver an unparalleled strength-to-weight ratio, exceptional corrosion resistance across extreme environments, and biocompatibility. These properties make titanium indispensable for critical aerospace components, surgical instruments, and high-performance automotive parts. However, titanium presents significant machining challenges: low thermal conductivity leads to heat concentration at the tool tip, high chemical reactivity risks galling, and its strength causes rapid tool wear. Success demands specialized tooling, precise coolant application, and controlled cutting parameters.

Material performance characteristics are critical for informed selection. Key comparative specifications include:

| Material (Common Grade) | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (100%) | Good |

| Stainless Steel 304 | 8.0 | 515 | Fair (45%) | Excellent |

| Carbon Steel 1045 | 7.8 | 570 | Good (65%) | Poor (Requires finish) |

| Titanium Ti-6Al-4V | 4.4 | 900 | Poor (20-30%) | Excellent |

Anodizing is a vital electrochemical finish primarily for aluminum, enhancing surface properties. Type II (Sulfuric Acid) anodizing provides good corrosion and wear resistance with dyeing capability for identification, typically yielding coatings of 5-25μm. For mission-critical applications demanding maximum hardness and abrasion resistance, Type III (Hardcoat) anodizing produces dense, thick coatings (25-50+μm) without dyes. Wuxi Lead Precision Machinery meticulously controls anodizing parameters—bath chemistry, temperature, voltage, and time—to ensure consistent coating thickness, adhesion, and performance, directly supporting your functional and aesthetic requirements.

Material choice is not merely a specification; it is an engineering decision impacting manufacturability, lifecycle cost, and end-product success. Our process engineers collaborate closely with clients during the design phase to evaluate material suitability against application stresses, environmental factors, and precision targets. Partner with Wuxi Lead to leverage our deep material science expertise and advanced CNC capabilities for optimal component realization. Contact our engineering team for a detailed material assessment specific to your project.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for excellence, integrating precision, consistency, and rigorous quality control from initial concept to full-scale delivery. Our approach follows a three-phase framework—Design, Prototyping, and Mass Production—each stage optimized to achieve zero defects and ensure compliance with the highest standards in CNC machining.

Design begins with a collaborative analysis of customer specifications, engineering drawings, and performance requirements. Our engineering team utilizes advanced CAD/CAM software to develop 3D models and simulate machining paths, ensuring dimensional accuracy and material efficiency. Finite element analysis (FEA) and tolerance stack-up studies are conducted to anticipate stress points and thermal variations, allowing for proactive design refinement. This digital-first approach minimizes human error and accelerates time-to-prototype while maintaining full traceability.

Prototyping is executed using the same high-precision CNC equipment deployed in mass production, eliminating variability between sample and final output. Each prototype undergoes comprehensive metrological validation using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Functional testing is performed under simulated operational conditions to verify fit, form, and performance. Customer feedback is integrated at this stage, and design modifications are rapidly implemented through our agile revision system. This closed-loop process ensures that only fully validated designs advance to production.

Mass Production leverages automated CNC machining centers with real-time process monitoring. Our facility operates ISO 9001-certified workflows, with statistical process control (SPC) applied at every critical operation. In-process inspections occur at predefined intervals, and final inspection includes 100% visual checks and sampling based on ANSI/ASQ Z1.4 standards. All components are serialized for full traceability, and material certifications are maintained throughout the supply chain. Our zero-defect philosophy is enforced through predictive maintenance, operator certification programs, and automated defect detection systems.

Wuxi Lead Precision Machinery’s investment in technology and process discipline ensures repeatability, scalability, and uncompromised quality. Whether producing low-volume prototypes or high-volume runs, our production ecosystem is designed to deliver precision-engineered components on time and to exacting specifications.

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-axis Swiss machining |

| Tolerance Capability | ±0.002 mm (±0.00008 in) |

| Surface Roughness | As low as Ra 0.2 µm (8 µin) |

| Materials Processed | Aluminum, stainless steel, titanium, brass, plastics (PEEK, Delrin), and exotic alloys |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), IATF 16949 (automotive) |

| Inspection Equipment | CMM, optical comparators, laser scanners, roughness testers, vision systems |

| Production Capacity | Up to 500,000 units/month (depending on complexity) |

| Lead Time (Prototype) | 7–15 days |

| Lead Time (Mass Production) | 15–30 days (scalable with demand) |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Precision Through Strategic Partnership

In the high-stakes realm of precision CNC machining, component integrity directly impacts your product performance, regulatory compliance, and market reputation. Wuxi Lead Precision Machinery transcends the role of a standard supplier; we function as your dedicated engineering extension, embedding decades of aerospace, medical, and energy sector expertise into every partnership. Our commitment begins with understanding your unique tolerances, material challenges, and production scalability requirements—not selling machines, but delivering certified micron-level solutions that eliminate scrap, reduce cycle times, and ensure first-article success. When your project demands sub-5-micron repeatability under thermal load or complex 5-axis contouring for titanium alloys, our engineered systems become your competitive leverage.

Our technical differentiation is quantifiable across critical performance metrics. Below reflects standard capabilities achievable with our LEADPRO Series platforms, validated through ISO 10791-2 testing protocols:

| Specification | Lead Precision Standard | Typical Industry Baseline |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.002 mm | ±0.005 mm |

| 3D Volumetric Repeatability | 0.0015 mm | 0.004 mm |

| Spindle Runout (at nose) | ≤0.0008 mm | ≤0.002 mm |

| Thermal Growth Compensation | Real-time dual-sensor | Single-point calibration |

| Automation Integration | FMS-ready (MTConnect) | Custom retrofit required |

This precision foundation is sustained through our proactive support ecosystem. Unlike transactional vendors, Lead Precision assigns a dedicated applications engineer during onboarding to optimize G-code strategies, tooling interfaces, and process validation for your specific components. Our global service network ensures 95% spare parts availability within 72 hours, while remote diagnostics preempt 83% of potential downtime scenarios through predictive spindle health monitoring. We integrate seamlessly with your existing MES infrastructure, providing traceable data streams for AS9100 or FDA 21 CFR Part 11 compliance without workflow disruption.

The cost of precision miscalculation extends beyond rework—it erodes client trust and market position. Partnering with Lead Precision means aligning with a team that treats your quality targets as non-negotiable engineering mandates. Our collaborative development process includes pre-installation tolerance mapping, in-process Cpk validation, and post-delivery yield analysis to guarantee ROI beyond machine acquisition.

Initiate your precision assessment today. Email Contact [email protected] with your component specifications and throughput requirements. Our engineering team will respond within 4 business hours with a tailored capability analysis, including feasibility validation for your most stringent geometries. Do not compromise on the foundation of your manufacturing excellence—let Lead Precision become the certified partner your critical components demand.

Contact [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.