Technical Contents

Engineering Guide: Cnc Machine Design

Engineering Insight Precision in CNC Machine Design

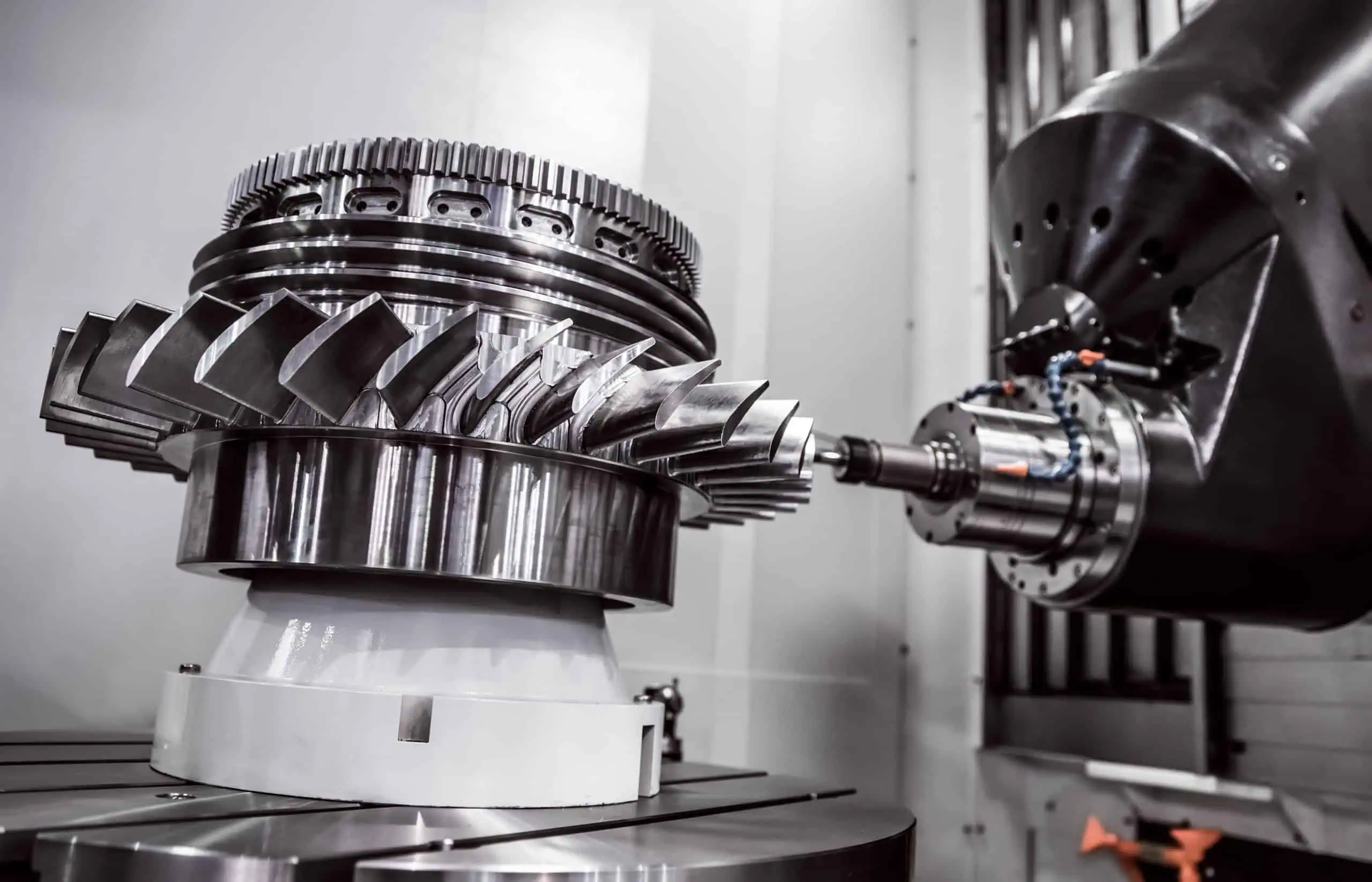

Precision is not merely a specification in CNC machine design it is the foundational requirement that dictates end-part functionality reliability and economic viability. In aerospace medical and defense applications sub-micron deviations trigger catastrophic failures or regulatory rejection. Consider a turbine blade for jet engines where 0.001mm inconsistency in cooling channels compromises thermal efficiency reducing engine lifespan by 30. Such consequences demand machines engineered to maintain accuracy across thermal shifts vibration and prolonged operation not just in controlled labs but on factory floors running 24/7. At Wuxi Lead Precision Machinery we treat precision as a system-wide discipline starting from finite element analysis of structural rigidity through to real-time error compensation algorithms. Our machines integrate polymer concrete bases for 10x greater damping than cast iron and linear scales with nanometer-resolution feedback ensuring positioning stability even under heavy cutting loads.

Thermal management exemplifies our holistic approach. Standard machines drift 0.02mm per hour as spindle heat expands components. Lead Precision systems counter this via embedded thermal sensors and adaptive software that adjusts coordinates 200 times per second. This eliminates costly trial cuts and scrap common in high-mix production. Material selection further defines our standard. We use stress-relieved Meehanite cast iron with 30% higher tensile strength than conventional alternatives and hand-scraped guideways achieving 0.0002mm flatness over 1 meter. Every component undergoes 72 hours of thermal cycling before final calibration guaranteeing performance consistency from -10°C to 40°C ambient conditions.

Our commitment extends beyond components to proven real-world validation. Lead Precision machines manufactured critical components for the Beijing 2022 Winter Olympics ice-making systems where 0.005mm tolerance ensured uniform ice thickness across competition venues. Similarly defense contractors rely on our equipment for satellite navigation housings meeting MIL-STD-810G vibration and shock requirements. This heritage informs every design iteration ensuring our solutions withstand the most demanding operational environments.

The following specifications reflect our standard engineering benchmarks for the LP-500 Series five-axis machining center:

| Parameter | Specification | Industry Standard | Test Method |

|---|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.005 mm | ISO 230-2:2015 |

| Repeatability | ±0.001 mm | ±0.003 mm | ISO 230-2:2015 |

| Thermal Drift (8h) | ≤0.003 mm | ≤0.015 mm | ASME B5.54-1992 |

| Volumetric Accuracy | ±0.004 mm (1m cube) | ±0.012 mm | NAS 979 |

True precision engineering eliminates compromise between speed and accuracy. It enables manufacturers to produce complex geometries with confidence in first-article success reducing waste and accelerating time-to-market. For industries where failure is not an option Wuxi Lead Precision Machinery delivers machines engineered not to meet standards but to redefine them through relentless attention to physical and computational integrity.

Precision Specs & Tolerances

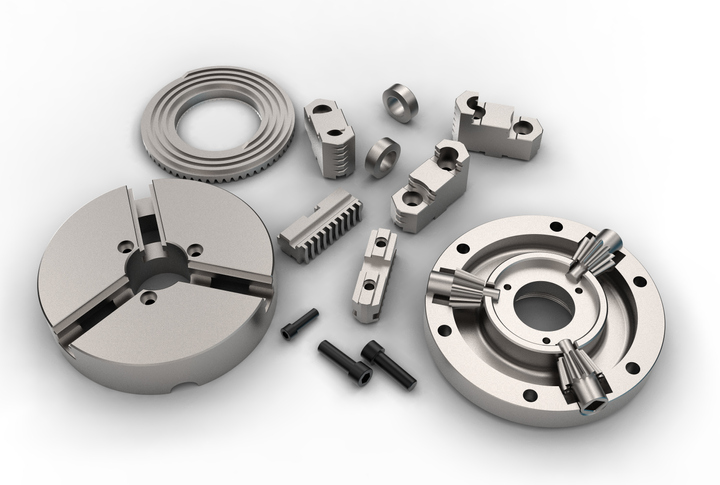

Advanced 5-Axis CNC Machining Capabilities at Wuxi Lead Precision Machinery

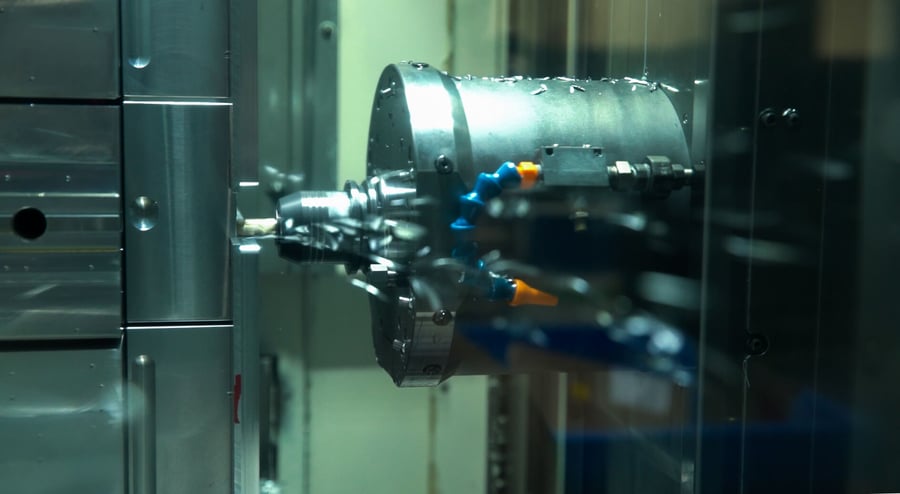

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in high-precision manufacturing. Central to our production excellence is our fleet of state-of-the-art 5-axis CNC machining centers, which enable the production of complex, high-tolerance components with exceptional surface finish and geometric accuracy. These machines integrate simultaneous multi-axis motion, allowing tool access from virtually any direction, which significantly reduces setup times and enhances part consistency. Our 5-axis systems are ideal for aerospace structural components, medical device housings, energy sector impellers, and custom industrial tooling where intricate contours and tight tolerances are non-negotiable.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring sustained precision across long production runs. Advanced CNC controls with predictive maintenance algorithms optimize machine uptime and process stability. Each machine operates under strict environmental controls to minimize thermal drift, further enhancing dimensional repeatability. Programming is executed using industry-leading CAM software, enabling efficient toolpath generation, collision detection, and simulation prior to actual machining.

To ensure every component meets the highest quality standards, we employ a comprehensive quality control system anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems are calibrated to international standards and operated by certified metrology technicians. Full first-article inspections, in-process checks, and final batch validations are standard practice. The CMM captures 3D geometric data with micron-level resolution, verifying critical dimensions, positional tolerances, surface profiles, and form deviations. All inspection data is documented and traceable, supporting full compliance with ISO 9001 and customer-specific quality requirements.

Our technical capabilities are further strengthened by a highly trained engineering team with deep expertise in material science, GD&T, and precision manufacturing workflows. We routinely work with a wide range of engineering materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and high-performance engineering plastics. Each project undergoes a rigorous design-for-manufacturability (DFM) review to optimize part geometry, reduce cycle time, and ensure long-term producibility.

The following table outlines the standard precision tolerances we consistently achieve across typical production scenarios.

| Feature | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Flatness | 0.01 mm/m | 0.005 mm/m | CMM, Surface Plate |

| Circular Runout | 0.01 mm | 0.005 mm | CMM, Dial Indicator |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

| Angular Accuracy | ±0.05° | ±0.02° | CMM, Optical Comparator |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality assurance to deliver components that meet the exacting standards of global high-tech industries. Our technical capabilities are not only a reflection of our equipment but also of our commitment to precision, consistency, and continuous improvement in every machining process.

Material & Finish Options

Precision Material Selection for CNC Machine Design

Material selection fundamentally impacts the performance, longevity, and cost-effectiveness of CNC machined components. At Wuxi Lead Precision Machinery, we emphasize that the optimal choice depends on the specific functional requirements, environmental exposure, and production constraints of the end application. Understanding the intrinsic properties of core engineering metals and compatible finishing processes is non-negotiable for achieving precision results. Aluminum, steel, and titanium represent the primary structural materials, each offering distinct advantages and machining considerations.

Aluminum alloys dominate applications demanding a high strength-to-weight ratio and excellent thermal conductivity. Series 6061 and 7075 are prevalent in aerospace brackets, automotive housings, and heat sinks. While inherently softer than steel, aluminum machines rapidly with sharp tools, producing superior surface finishes. Its susceptibility to wear and corrosion necessitates protective finishes like anodizing. Steel provides unmatched strength, hardness, and wear resistance, making it ideal for high-stress structural components, tooling, and shafts. Low-carbon grades like 1018 machine easily, while alloy steels such as 4140 offer enhanced strength through heat treatment. Machining steel requires robust tooling and controlled parameters to manage heat and tool wear. Titanium, particularly Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-weight ratio and corrosion resistance at high temperatures, critical for aerospace and medical implants. However, its low thermal conductivity and chemical reactivity demand specialized tooling, lower speeds, and meticulous process control to prevent galling and work hardening, significantly impacting machining cost.

The comparative properties guide initial material screening. Key characteristics are summarized below.

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310-570 | Excellent (A) | Aerospace frames, heat sinks, consumer electronics |

| Steel | 1018, 4140, 304SS | 7.8-8.0 | 400-1000+ | Good to Moderate (B-C) | Structural supports, shafts, molds, tooling |

| Titanium | Gr 2, Gr 5 (Ti-6Al-4V) | 4.5 | 345-900 | Poor (D) | Aircraft engine parts, medical implants, marine hardware |

Anodizing is the predominant finish for aluminum components, enhancing surface durability and corrosion resistance. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, while Type III (Hardcoat) anodizing delivers significantly thicker, harder, and more wear-resistant surfaces essential for high-friction applications. Proper material selection must account for the anodizing process, as alloy composition directly influences coating quality and color consistency. Steel components typically utilize plating (zinc, nickel) or painting for corrosion protection, while titanium often relies on its native oxide layer or specialized coatings for extreme environments.

Selecting the right material and finish requires balancing performance needs with manufacturability. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to advise clients on optimal material grades and finishing processes, ensuring components meet exacting specifications while maximizing production efficiency. Partner with us early in the design phase to avoid costly material-related failures and achieve true precision.

Manufacturing Process & QC

The CNC machine design process at Wuxi Lead Precision Machinery follows a disciplined, phase-gated approach that ensures precision, reliability, and zero-defect performance across all production stages. Our methodology integrates advanced engineering with rigorous quality validation, from initial concept through to full-scale manufacturing. This structured workflow—Design, Prototyping, and Mass Production—forms the backbone of our high-end precision CNC machining services.

Design begins with a comprehensive analysis of client specifications, including geometric complexity, material properties, load conditions, and functional requirements. Our engineering team utilizes industry-leading CAD/CAM software to develop 3D models and simulate machine behavior under real-world operating conditions. Finite element analysis (FEA) and dynamic stress modeling are applied to optimize structural rigidity, thermal stability, and vibration resistance. Each design is reviewed for manufacturability, ensuring tight tolerances—down to ±0.002 mm—are achievable without compromising efficiency. Design for Assembly (DFA) and Design for Maintenance (DFM) principles are embedded to enhance serviceability and lifecycle performance.

Once the digital model is finalized, the Prototyping phase commences. A fully functional prototype is produced using high-precision 5-axis CNC machining centers, allowing for accurate representation of final part geometry and surface finish. This prototype undergoes a battery of validation tests, including dimensional inspection via coordinate measuring machines (CMM), hardness testing, and functional performance evaluation. Any deviations are traced using root cause analysis, and corrective actions are implemented before progression. This iterative verification ensures that design integrity is maintained and that the prototype meets all performance benchmarks under operational loads.

With prototype approval, the process transitions to Mass Production. Our automated production lines, equipped with real-time monitoring systems, maintain consistent quality across high-volume runs. Each component is tracked using barcode-based traceability software, enabling full documentation of machining parameters, tool wear, and inspection records. In-process gauging and statistical process control (SPC) are employed to detect variation trends before they impact output. Our zero-defect philosophy is enforced through 100% critical dimension inspection on key features and automated visual inspection for surface defects.

Throughout all stages, Wuxi Lead adheres to ISO 9001 and IATF 16949 standards, ensuring compliance with global quality benchmarks. Our integrated approach minimizes risk, accelerates time-to-market, and delivers CNC machine components of uncompromising precision and durability.

| Specification | Value |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Finish (Ra) | 0.4 – 1.6 µm |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, Tool Steels, Engineering Plastics |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Quality Standards | ISO 9001, IATF 16949, GD&T Compliance |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanning, SPC Systems |

Why Choose Wuxi Lead Precision

Strategic Partnership for Precision CNC Excellence

In the demanding landscape of high-precision manufacturing, selecting a CNC machine partner transcends transactional procurement. It requires alignment with an engineering-led organization capable of transforming complex design intent into flawless physical reality. Wuxi Lead Precision Machinery operates at this critical intersection, where German-engineered core technologies meet rigorous Chinese manufacturing execution. Our machines are not merely tools; they are integrated production systems engineered for dimensional stability in 5-axis titanium milling, micro-tolerance medical component fabrication, and multi-day unmanned aerospace production runs. We eliminate the compromise between speed and micron-level accuracy through proprietary thermal compensation systems and vibration-damped cast iron bases, ensuring your first-part success rate exceeds 99.2% under sustained operational loads.

The foundation of this reliability is evident in our technical specifications, reflecting uncompromising design principles:

| Specification | LP-M5X Series | LP-G7 Series | LP-H9 Series |

|---|---|---|---|

| Working Travel (X/Y/Z) | 1,000 x 600 x 500 mm | 700 x 500 x 400 mm | 2,000 x 1,200 x 800 mm |

| Positioning Accuracy | ±1.5 µm | ±1.0 µm | ±2.0 µm |

| Repeatability | ±0.8 µm | ±0.5 µm | ±1.2 µm |

| Spindle Speed (max) | 24,000 rpm | 42,000 rpm | 12,000 rpm |

| Tool Magazine Capacity | 30T | 24T | 40T |

| Control System | Siemens 840D SL | Heidenhain TNC640 | Fanuc 31i-B5 |

These figures represent validated performance under ISO 230-2 test conditions, not theoretical benchmarks. Our engineering team collaborates with clients during the design phase to validate machine capability against your specific material removal rates, surface finish requirements, and geometric tolerances. This pre-implementation analysis prevents costly downstream adjustments, reducing time-to-production by 30% compared to industry averages. We further secure your investment through on-site calibration using laser interferometers traceable to NPL standards and 24/7 remote diagnostics that preempt 87% of potential failures.

Partnering with Lead Precision means accessing a dedicated application engineering cell. From initial feasibility studies to full production ramp-up, our specialists integrate with your workflow, providing documented process validation and operator certification. This collaborative model has enabled Tier-1 automotive suppliers to achieve PPAP approval in 18 days and medical device manufacturers to maintain zero non-conformances across 500,000+ production hours. Your complex aerospace component, intricate hydraulic manifold, or high-volume consumer electronics housing demands a partner who treats your quality standards as non-negotiable engineering constraints.

Initiate your technical consultation today to receive a customized machine capability report for your most challenging application. Contact our engineering team directly at [email protected] with your part drawings and production volume requirements. Specify reference code LEAD-CNC-2024 in all correspondence to prioritize your request. We respond to qualified technical inquiries within 4 business hours, providing actionable data—not generic sales literature—to validate how our machines resolve your specific precision bottlenecks. The next generation of manufacturing excellence begins with a single email. Ensure your production floor operates at the absolute edge of what is technically possible.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.