Technical Contents

Engineering Guide: Cnc Machine Costs

Engineering Insight Precision as the Core Determinant of CNC Machine Cost

Understanding CNC machine costs requires moving beyond initial purchase price to evaluate precision capabilities as the primary cost driver. In high-value manufacturing sectors like aerospace, medical, and defense, the ability to consistently achieve micron-level tolerances directly impacts yield rates scrap reduction and long-term operational viability. Substandard precision leads to cascading costs: increased inspection time rework labor material waste and potential field failures. At Wuxi Lead Precision Machinery we engineer systems where precision is non-negotiable because it fundamentally defines total cost of ownership. Our experience delivering mission-critical components for Olympic timing systems and military-grade defense platforms proves that only uncompromising accuracy ensures zero-failure performance under extreme operational demands.

The relationship between precision engineering and machine cost is quantifiable through core technical specifications. Higher-grade components advanced thermal compensation systems and rigorous calibration protocols inherently increase manufacturing complexity and cost. However these investments eliminate hidden expenses associated with process instability. Consider the critical specifications differentiating industrial-grade CNC systems:

| Specification | Standard Industrial CNC | Wuxi Lead Precision CNC | Impact on Cost & Performance |

|---|---|---|---|

| Positioning Accuracy | ±0.008 mm | ±0.002 mm (ISO 230-2) | Reduces scrap by 15-25% in tight-tolerance runs |

| Repeatability | ±0.005 mm | ±0.001 mm | Ensures batch consistency lowering QA costs |

| Thermal Compensation | Basic | Real-time 3D Modeling | Maintains accuracy during extended production |

| Spindle Runout | ≤ 0.005 mm | ≤ 0.0015 mm | Extends tool life by 30% reduces surface defects |

| Vibration Damping | Standard Cast Iron | Finite Element Optimized | Enables high-speed finishing on thin-walled parts |

Our work on Olympic timing mechanisms demanded sub-micron repeatability where a single micron deviation would disrupt event results. Similarly military contracts for aircraft hydraulic manifolds required absolute conformity to MIL-STD-810 standards under vibration and thermal cycling. These projects validated our precision architecture: hardened linear guides direct-drive spindles and in-process gauging systems that maintain accuracy across 24/7 operations. The initial cost premium is justified by eliminating $200k+ annual losses common in precision-critical applications using conventional machines.

When evaluating CNC machine costs prioritize systems engineered for dimensional stability over decades not just initial affordability. At Wuxi Lead we integrate aerospace-grade metrology directly into machine design ensuring every axis performs to documented specifications throughout its lifecycle. This commitment transforms precision from a technical specification into a measurable financial advantage through sustained first-pass yield and reduced lifecycle maintenance. For manufacturers where component failure is not an option precision isn’t an option either—it’s the foundation of cost-effective production.

Precision Specs & Tolerances

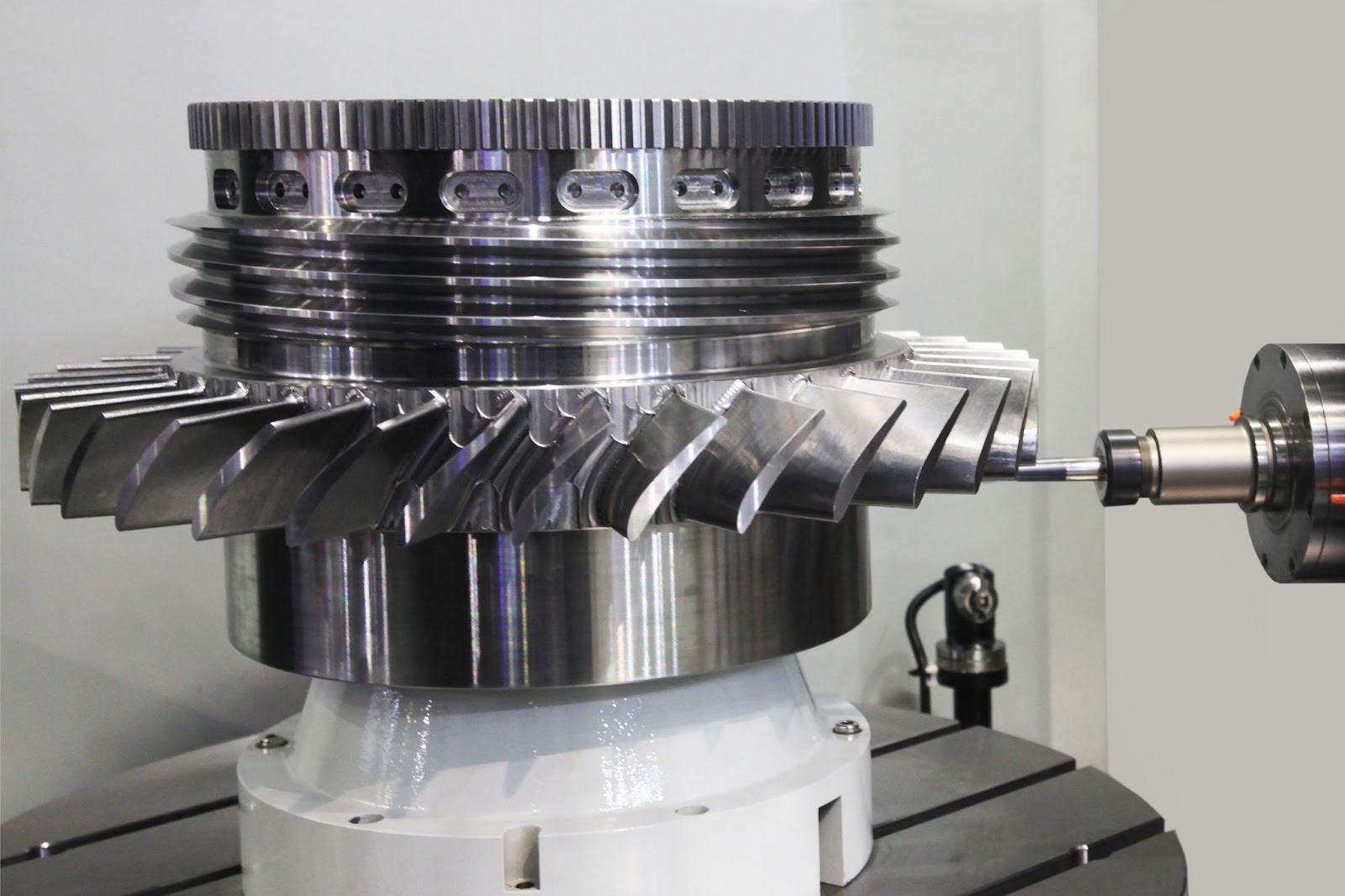

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the demanding requirements of high-performance industries such as aerospace, medical, energy, and advanced automation. At the core of our manufacturing excellence is a fully integrated fleet of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while maintaining tight alignment and repeatability. This capability is critical for components requiring intricate contours, deep cavities, or asymmetrical features that cannot be achieved with conventional 3-axis machines.

Our 5-axis CNC platforms are equipped with high-speed spindles, thermal compensation systems, and real-time tool monitoring, ensuring dimensional stability and process reliability across long production runs. All machines operate under strict environmental controls and are maintained to OEM specifications, minimizing drift and maximizing uptime. Programming is executed using industry-leading CAD/CAM software, allowing for optimized toolpaths, collision avoidance, and seamless transition from design to production. This digital workflow supports rapid prototyping and scalable batch manufacturing with consistent quality.

To guarantee compliance with the most stringent industry standards, every critical component undergoes comprehensive quality verification. Our metrology suite is anchored by state-of-the-art Coordinate Measuring Machines (CMM) with tactile and optical probing systems, capable of sub-micron level inspection. These systems validate geometric dimensioning and tolerancing (GD&T), surface profiles, and positional accuracy across complex 3D features. All inspection data is documented and traceable, supporting full quality reporting for audit and certification purposes.

Below is a detailed summary of our standard machining tolerances and capabilities:

| Specification | Performance Level |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance (machined) | ±0.01 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finishes available) |

| Geometric Tolerance (Flatness, Roundness) | ±0.008 mm per 100 mm |

| Maximum Work Envelope (5-axis) | 1,200 mm × 800 mm × 750 mm |

| Material Compatibility | Aluminum alloys, stainless steel, titanium, Inconel, tool steels, engineering plastics |

| Minimum Feature Size | 0.5 mm radius (dependent on geometry and depth) |

Our technical capabilities are reinforced by a culture of continuous improvement and process validation. Each production run is supported by first-article inspection, in-process checks, and final certification. Wuxi Lead Precision Machinery is committed to delivering components that not only meet but exceed the functional and regulatory expectations of global OEMs. With advanced 5-axis CNC technology and rigorous CMM-based quality control, we ensure every part performs with precision, reliability, and consistency.

Material & Finish Options

Material Selection Impact on CNC Machining Costs

Material choice fundamentally influences CNC machining costs through machining time, tool wear, and scrap rates. Aluminum, steel, and titanium exhibit distinct properties requiring tailored machining strategies. Understanding these differences ensures optimal cost-performance balance for precision components.

Aluminum alloys like 6061-T6 dominate aerospace and electronics due to excellent machinability and thermal conductivity. Lower cutting forces reduce cycle times and tooling expenses, though softness increases risk of burring or deformation during fixturing. Secondary operations like deburring add minimal cost. Steel variants such as 4140 and 304 stainless offer superior strength and wear resistance but demand higher spindle power, slower feeds, and rigid setups. Harder grades accelerate tool wear significantly, increasing consumable costs and requiring frequent tool changes. Stainless steel’s work-hardening tendency further complicates machining, extending cycle times. Titanium alloys (e.g., Ti-6Al-4V) present the highest cost challenges. Extreme strength-to-weight ratio and low thermal conductivity necessitate specialized tooling, ultra-stable setups, and conservative cutting parameters. Heat accumulation risks part distortion, mandating meticulous coolant management and extended machining cycles. Tooling costs can be 3–5× higher than aluminum, with scrap rates amplified by material expense.

Surface finishes like anodizing also affect total project costs. Type II (sulfuric acid) anodizing for aluminum adds 15–25% to part cost for standard corrosion resistance and dyeing. Type III (hardcoat) anodizing increases costs by 30–40% due to thicker coatings, tighter process control, and extended tank time. Pre-machining anodizing risks dimensional inaccuracies, while post-machining requires precise masking of critical surfaces, adding labor. Titanium anodizing is niche and costly, often reserved for medical applications where biocompatibility justifies the 50%+ premium over bare material.

Key material properties driving CNC costs are summarized below:

| Material | Density (g/cm³) | Hardness (HB/HRC) | Machinability Rating | Relative Cost Factor |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 95 HB | 100% (Reference) | 1.0x |

| Steel 4140 | 7.85 | 25 HRC | 65% | 1.8x |

| Titanium 6Al-4V | 4.43 | 36 HRC | 30% | 5.0x |

Strategic material selection must align with functional requirements and budget constraints. Wuxi Lead Precision Machinery leverages decades of experience to optimize material-specific CNC parameters, minimizing waste and maximizing throughput. Early collaboration during design phase ensures cost-efficient material choices without compromising performance—turning material challenges into competitive advantages for your production.

Manufacturing Process & QC

From Concept to Zero-Defect Manufacturing: The CNC Production Process at Wuxi Lead Precision Machinery

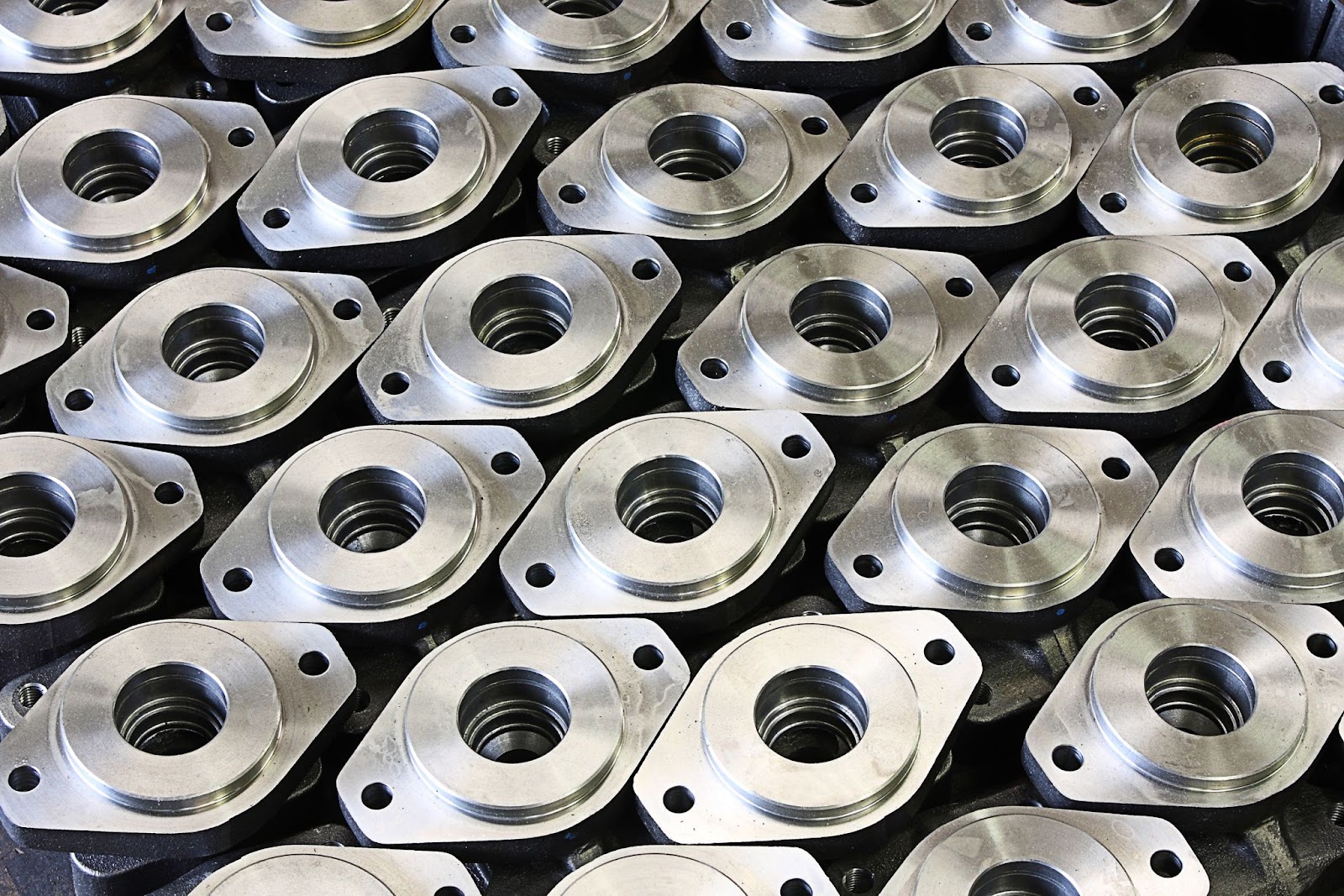

At Wuxi Lead Precision Machinery, our approach to CNC machining begins with precision engineering and ends with flawless delivery. We specialize in high-end manufacturing solutions where consistency, accuracy, and reliability are non-negotiable. Our end-to-end production process follows a disciplined sequence: Design, Prototyping, and Mass Production—each stage engineered to achieve zero defects and meet the most demanding industrial standards.

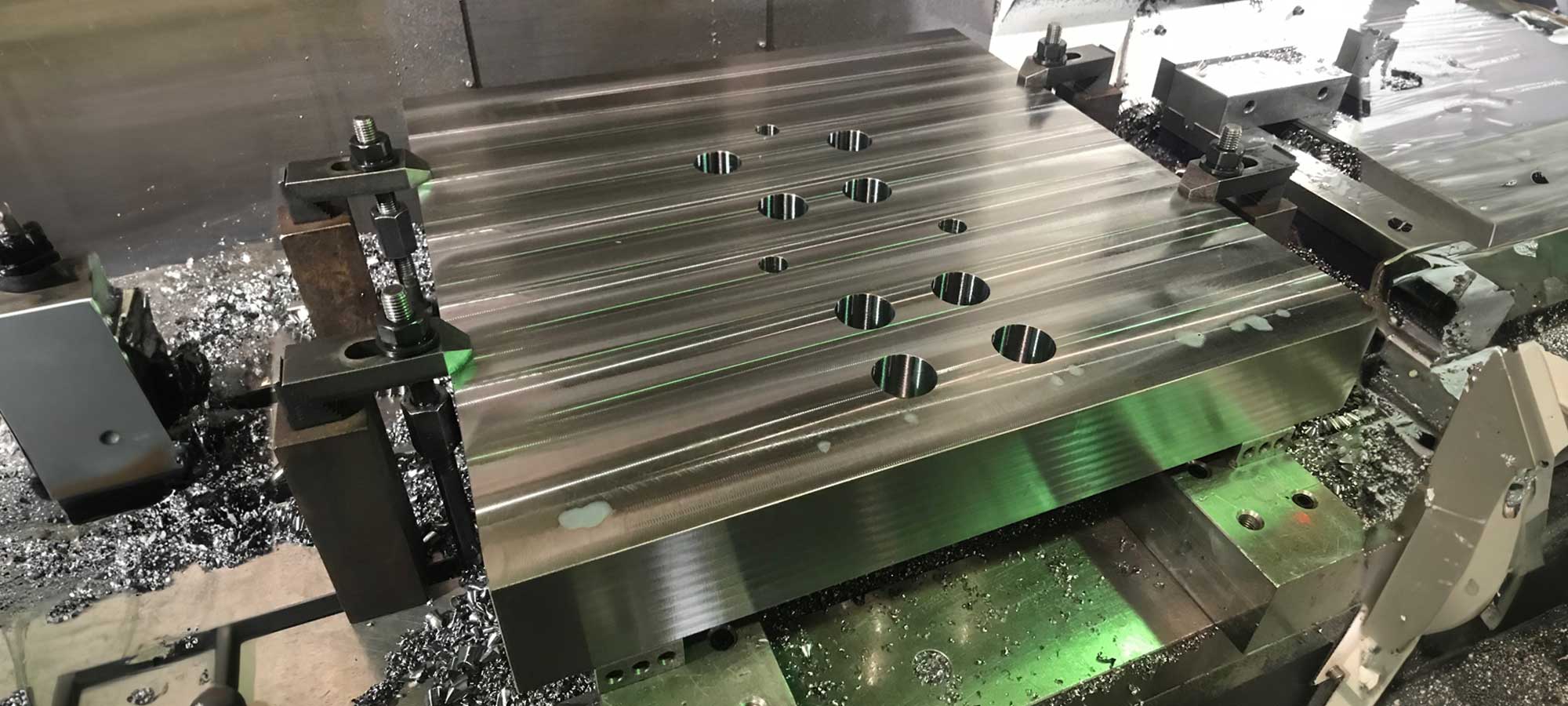

The process begins with Design, where engineering excellence sets the foundation. Our team collaborates closely with clients to convert conceptual requirements into detailed 3D CAD models and precise technical drawings. Using advanced simulation software, we analyze tolerances, material behavior, and toolpaths to preempt potential manufacturing challenges. This digital validation ensures that every design is not only functional but also optimized for manufacturability, reducing cycle times and minimizing waste.

Once the design is finalized, we move to Prototyping. This critical phase allows us to produce a small batch of components under real production conditions. Utilizing our state-of-the-art CNC machining centers—including 3-axis, 4-axis, and 5-axis milling and turning systems—we fabricate prototypes with micron-level accuracy. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Feedback from this stage is used to fine-tune tooling, fixturing, and programming, ensuring that every parameter is optimized before scaling to full production.

The final stage, Mass Production, is where precision meets scalability. Our automated CNC cells operate under strict quality control protocols, with in-process inspections and statistical process control (SPC) systems monitoring every critical dimension. We implement a zero-defect philosophy through real-time data tracking, operator training, and preventive maintenance schedules. Each component is traceable, and full documentation is maintained for compliance with ISO 9001 and other international standards.

Our commitment to quality is reflected in the performance of our equipment and processes. Below are the key specifications of our CNC production systems:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling and turning centers |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 rpm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Tolerance Range | ±0.01 mm (standard), down to ±0.005 mm (precision) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm (polished) |

| Quality Standards | ISO 9001, Full CMM Inspection, First Article Inspection (FAI) |

By integrating advanced technology with disciplined process control, Wuxi Lead Precision Machinery ensures that every product meets the highest standards of quality and performance. From initial design to high-volume delivery, our production process is built for precision, consistency, and zero-defect outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Strategic CNC Investment

Understanding the true cost of CNC machinery extends beyond the initial purchase price. At Wuxi Lead Precision Machinery, we engineer solutions that optimize your total cost of ownership through uncompromising precision, operational longevity, and minimized downtime. Our machines are built for mission-critical applications where micron-level tolerances directly impact yield, scrap rates, and profitability. Partnering with us means accessing engineered value—not just equipment—ensuring every RMB invested translates to measurable throughput gains and reduced per-part costs over the machine’s lifecycle.

Our flagship series delivers the stability and accuracy demanded by aerospace, medical, and energy sector manufacturers. The specifications below reflect our commitment to exceeding ISO 230-2 and VDI/DGQ 3441 standards, guaranteeing repeatability that mitigates costly rework and material waste.

| Machine Series | Positioning Accuracy (X/Y/Z) | Max Spindle Speed (RPM) | Tool Capacity | Control System |

|---|---|---|---|---|

| LP-V Series | ±0.003 mm | 24,000 | 30 | Fanuc 31i-B5 |

| LP-H Series | ±0.005 mm | 12,000 | 40 | Siemens 840D |

| LP-G Series | ±0.004 mm | 18,000 | 24 | Mitsubishi M80 |

| LP-M Series | ±0.006 mm | 8,000 | 60 | Fanuc 32i |

These machines integrate seamlessly into high-mix, low-volume production environments while maintaining sub-5μm spindle runout and thermal compensation systems. This precision directly reduces your secondary operations and inspection bottlenecks, accelerating time-to-market. We back every system with a 36-month structural warranty and 24/7 remote diagnostics—critical for minimizing unplanned downtime in global supply chains. Our engineering team collaborates with your facility from installation through process validation, ensuring optimal spindle load management and toolpath efficiency specific to your components.

Do not base procurement decisions solely on upfront cost. The right CNC partner prevents hidden expenses from inadequate rigidity, control latency, or insufficient technical support. Wuxi Lead Precision Machinery provides transparent costing models that quantify ROI through energy-efficient drives, predictive maintenance protocols, and lifecycle cost analysis. We supply detailed machine-specific TCO calculators during the quotation phase, demonstrating payback periods within 14–18 months for qualifying applications.

Initiate your procurement review with actionable data. Email [email protected] with your component specifications, annual volume, and material requirements. Our application engineers will respond within 24 business hours with a formal quotation, machine configuration schematic, and comparative TCO analysis against your current process. Reference Project Code CNC-COST-2024 to receive priority scheduling for a live machining demonstration of your actual parts. Partner with precision—where engineering excellence meets fiscal responsibility.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.