Technical Contents

Engineering Guide: Cnc Machine Aluminum Cutting

Engineering Insight: CNC Machine Aluminum Cutting – The Role of Precision in High-Performance Manufacturing

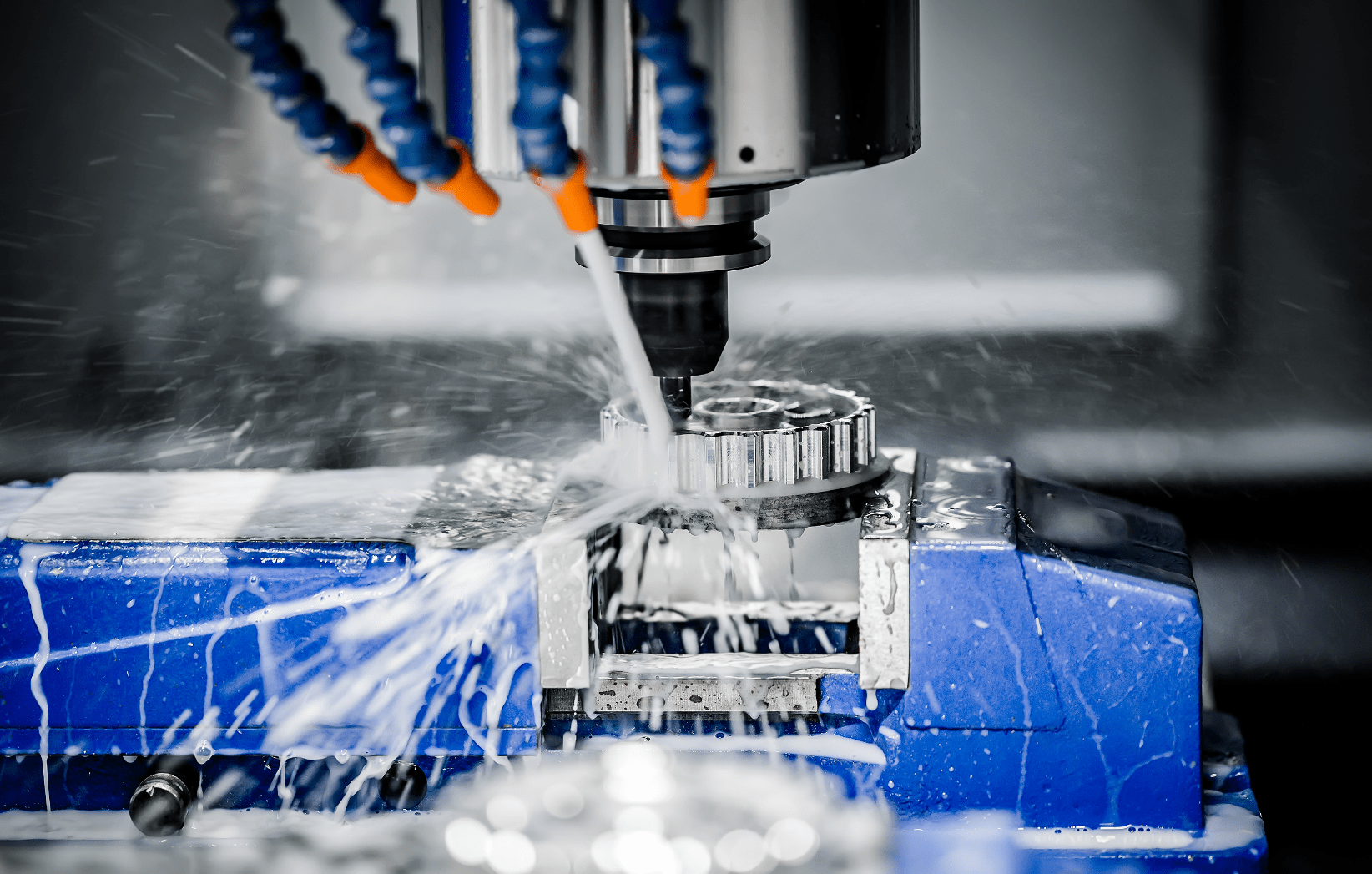

In the realm of precision CNC machining, aluminum stands out as one of the most widely used materials due to its favorable strength-to-weight ratio, excellent thermal conductivity, and superior machinability. However, achieving consistent, high-tolerance results in CNC machine aluminum cutting demands more than just capable equipment—it requires a deep understanding of material behavior, cutting dynamics, and process optimization. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a target but a foundational principle that governs every stage of production.

Aluminum, while softer than steel, presents unique challenges during CNC machining. Its low melting point and high ductility can lead to built-up edge (BUE), chatter, and dimensional instability if not managed with precision-engineered toolpaths and machine rigidity. Moreover, aerospace, defense, and high-performance automotive sectors demand tolerances within ±0.005 mm, requiring not only advanced 5-axis CNC systems but also real-time monitoring and adaptive control technologies. At Lead Precision, our engineering teams leverage decades of experience in mission-critical applications, including components for Olympic-standard equipment and military-grade systems, where failure is not an option.

Our approach begins with material-specific spindle tuning and optimized coolant delivery to minimize thermal expansion during high-speed aluminum cutting. We employ high-rigidity CNC platforms with linear motor drives and in-process probing to ensure geometric accuracy across complex contours. Surface finish consistency is maintained through dynamic feed adjustment and tool wear compensation algorithms, allowing us to achieve Ra values below 0.8 µm without secondary operations.

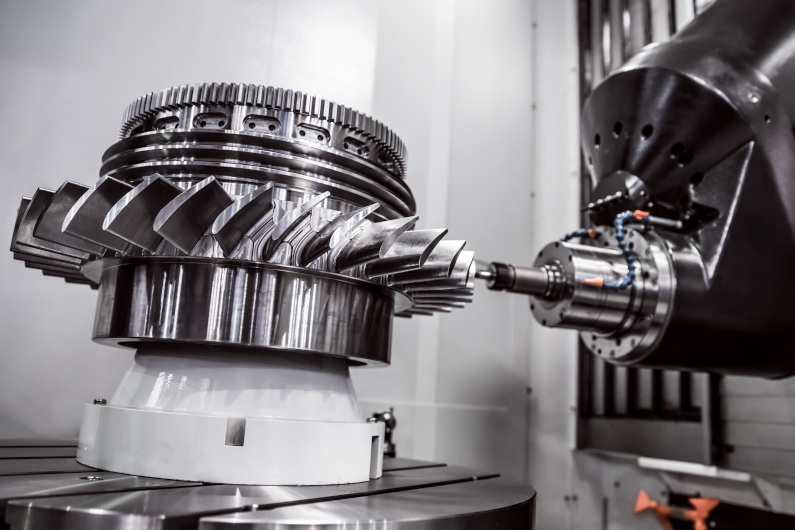

Precision also extends beyond hardware. At Wuxi Lead, we integrate simulation-driven programming using advanced CAM software to predict tool deflection, vibration modes, and chip load distribution. This digital twin methodology allows us to validate machining strategies before material contact, reducing trial runs and ensuring first-article success—critical for low-volume, high-mix production typical in defense and R&D sectors.

Our commitment to precision is validated by international quality certifications and traceable process documentation, ensuring every aluminum component meets stringent industry standards. Whether producing lightweight structural frames for unmanned aerial vehicles or high-conductivity housings for satellite systems, our CNC machining processes are engineered for repeatable accuracy under the most demanding specifications.

Below are key technical specifications that define our CNC aluminum cutting capabilities:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Spindle Speed Range | 20,000 – 42,000 RPM (HSK-E40 interface) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Tool Change Time (ATC) | < 2.5 seconds |

| Surface Finish (Typical) | Ra 0.4 – 0.8 µm |

| Tolerance Range | ±0.005 mm (standard), ±0.002 mm (tight) |

| Coolant System | High-pressure through-spindle (20–50 bar) |

| Control System | Siemens SINUMERIK 840D sl |

At Wuxi Lead Precision Machinery, precision in CNC machine aluminum cutting is not achieved by chance—it is engineered, verified, and delivered with every component we produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Machining

Aluminum’s favorable machinability, strength-to-weight ratio, and thermal properties make it a cornerstone material for demanding aerospace, medical, and industrial applications. At Wuxi Lead Precision Machinery, we leverage advanced 5-axis CNC machining centers specifically optimized for high-integrity aluminum components. Our HAAS UMC-750 and DMG MORI CTX beta 1250 platforms feature high-speed spindles (24,000 RPM standard, 42,000 RPM optional) with through-spindle coolant, enabling aggressive material removal rates while maintaining exceptional surface finishes and minimizing thermal distortion in thin-walled structures. Integrated Renishaw probing systems ensure precise workpiece alignment and in-process verification, critical for complex geometries requiring tight positional relationships across multiple features. The combination of rigid machine structures, linear motor drives on key axes, and HEIDENHAIN TNC640 controls delivers the dynamic accuracy necessary for intricate contours and micro-features common in fluidic manifolds, heat exchangers, and structural brackets.

Our process expertise extends beyond raw machine capability. We employ specialized high-performance cutting tools from suppliers like Sandvik Coromant and Iscar, utilizing optimized toolpaths generated through Mastercam and hyperMILL software. This ensures efficient chip evacuation, reduced burring, and extended tool life specifically for aluminum alloys including 6061-T6, 7075-T6, and 2024-T3. Material-specific parameters for feed rates, depths of cut, and coolant strategies are rigorously validated to prevent issues like built-up edge or chatter, guaranteeing consistent part quality across production runs. This systematic approach minimizes secondary operations and scrap rates, providing significant cost efficiency for high-value components.

Dimensional accuracy is non-negotiable in precision manufacturing. Our processes consistently achieve the following tolerances on machined aluminum parts, verified through comprehensive inspection protocols:

| Feature | Standard Capability | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Geometric Tolerances | ±0.025 mm | ±0.008 mm |

| Positional Accuracy | ±0.015 mm | ±0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

Rigorous quality control is embedded throughout production. All critical dimensions undergo 100% inspection using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), programmed to ISO 10360 standards. This metrology-grade verification provides full traceability and detailed reports, including GD&T analysis against customer CAD models. First-article inspections and in-process checks using calibrated hand tools and optical comparators further ensure conformance before final CMM validation. This multi-layered quality assurance framework, combined with our optimized 5-axis machining processes, delivers aluminum components that meet the stringent demands of Tier-1 aerospace suppliers and medical device OEMs, where precision directly impacts performance and safety.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material is critical in high-performance CNC machining applications, particularly when balancing strength, weight, thermal conductivity, and cost. At Wuxi Lead Precision Machinery, we specialize in precision CNC aluminum cutting, while also offering advanced capabilities in steel and titanium machining for demanding industrial sectors such as aerospace, automotive, and medical device manufacturing. Each material presents distinct advantages depending on the functional requirements of the final component.

Aluminum remains the most widely used material in CNC machining due to its excellent strength-to-weight ratio, high thermal and electrical conductivity, and superior machinability. Grade 6061-T6 is a popular choice for structural and mechanical components, offering good corrosion resistance and weldability. For more demanding applications, 7075-T6 provides higher strength, often used in aerospace systems where weight savings are paramount. Aluminum’s low density reduces inertia in moving parts, making it ideal for dynamic systems. However, its lower hardness compared to steel and titanium requires careful toolpath optimization and cutting parameter control to maintain dimensional accuracy and surface finish.

Steel, particularly alloy and stainless variants such as 4140, 17-4 PH, and 304/316 stainless, offers superior strength, wear resistance, and durability. These materials are preferred in high-stress environments, including hydraulic systems, tooling, and industrial machinery. While steel is more challenging to machine due to higher cutting forces and heat generation, our CNC platforms are equipped with high-torque spindles and advanced cooling systems to ensure precision and tool longevity. The trade-off in machinability is justified where long-term reliability and resistance to deformation are critical.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments such as aerospace and biomedical implants. It offers an exceptional strength-to-density ratio and unparalleled corrosion resistance, even at elevated temperatures. However, titanium’s low thermal conductivity leads to heat concentration at the cutting edge, increasing tool wear. Our specialized tooling strategies, including reduced cutting speeds and high-pressure coolant delivery, ensure consistent results in titanium machining.

Surface finishing plays a pivotal role in enhancing performance and longevity. For aluminum components, anodizing—particularly Type II (sulfuric acid) and Type III (hard coat anodizing)—is widely used. Anodizing improves surface hardness, wear resistance, and corrosion protection while allowing for color dyeing for identification or aesthetic purposes. Hard anodizing (Type III) can achieve coating thicknesses up to 50 µm with a hardness approaching that of sapphire, making it ideal for high-wear applications.

Below is a comparative overview of key material properties relevant to CNC machining.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Common CNC Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | 167 | Enclosures, brackets, heat sinks |

| Aluminum 7075-T6 | 572 | 2.8 | 130 | Aerospace fittings, structural |

| Steel 4140 | 655 | 7.85 | 42.6 | Shafts, tooling, machinery parts |

| Stainless 316 | 580 | 8.0 | 16.2 | Medical devices, marine hardware |

| Titanium Ti-6Al-4V | 900 | 4.43 | 6.7 | Aircraft components, implants |

At Wuxi Lead Precision Machinery, we combine material expertise with state-of-the-art CNC technology to deliver components that meet exacting performance standards. Our engineering team collaborates closely with clients to select the optimal material and finish for each application, ensuring reliability, efficiency, and cost-effectiveness across the product lifecycle.

Manufacturing Process & QC

Precision Aluminum CNC Production: From Concept to Flawless Volume

At Wuxi Lead Precision Machinery, our CNC aluminum cutting process is engineered for absolute reliability, transforming client specifications into zero-defect components through a rigorously controlled sequence. We eliminate downstream failures by embedding quality at every phase, starting with Design. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis, scrutinizing CAD models for potential machining challenges specific to aluminum alloys. This includes optimizing wall thicknesses to prevent chatter, verifying tool access paths, and adjusting tolerances to match aluminum’s thermal behavior. Early collaboration with the client ensures geometric dimensioning and tolerancing (GD&T) align with functional requirements and achievable process capabilities, preventing costly revisions later. This proactive design validation is the critical foundation for defect prevention.

Prototyping transitions validated designs into physical reality under full production conditions. We machine initial units using the exact CNC programs, tooling, and material lots designated for volume production. Each prototype undergoes stringent metrology: multi-axis CMM verification against nominal CAD data, surface roughness analysis, and critical feature inspection per AS9102 First Article requirements where applicable. Crucially, we perform thermal stability testing on aluminum parts, measuring dimensional drift after simulated operational temperature cycles. Any deviation triggers immediate root cause analysis—adjusting coolant concentration, spindle RPM, or fixturing—before mass production commences. This phase is not merely fit-checking; it is process certification.

Mass production leverages closed-loop process control to sustain zero defects. Our Haas and DMG MORI machining centers operate with real-time tool wear monitoring and in-process probing, automatically compensating for thermal drift and tool deflection unique to aluminum cutting. Every 50th part undergoes 100% automated optical inspection against master CAD models, while statistical process control (SPC) tracks critical dimensions from every batch. Material traceability is maintained from raw billet to finished part, with full documentation including heat treatment certificates and in-process inspection reports. This integrated system, combined with operator expertise trained in aluminum-specific best practices, ensures consistent output meeting the tightest tolerances without scrap.

Critical Aluminum CNC Machining Specifications at Wuxi Lead

| Parameter | Typical Capability (6061-T6) | Typical Capability (7075-T6) | Standard Compliance |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.008 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.4 – 1.6 µm | 0.8 – 3.2 µm | ISO 1302 |

| Feature Position | ±0.010 mm | ±0.015 mm | ASME Y14.5 GD&T |

| Max Work Envelope | 1200 x 800 x 600 mm | 1000 x 600 x 500 mm | Custom Configurable |

| Coolant Concentration | 8-12% | 10-15% | OEM Specifications |

This disciplined progression—from intelligent design validation through physics-based prototyping to closed-loop volume production—ensures Wuxi Lead delivers aluminum components where dimensional integrity and surface perfection are non-negotiable. We transform complex requirements into consistently flawless outcomes, minimizing client risk and maximizing operational uptime.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Aluminum Machining Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end manufacturing. When your operations demand flawless aluminum components—whether for aerospace, automotive, medical, or industrial automation—partnering with a trusted CNC machining expert is essential. We are not just a supplier; we are your strategic manufacturing partner, delivering engineered precision with on-time execution.

Our CNC aluminum cutting capabilities are built on decades of engineering expertise, state-of-the-art 3-, 4-, and 5-axis machining centers, and a relentless commitment to quality. Every component we produce adheres to strict ISO 9001:2015 standards, with full traceability, in-process inspections, and final QA validation. From prototype to high-volume production, we ensure consistency, tight tolerances, and superior surface finishes that meet or exceed your design requirements.

Aluminum presents unique challenges—high thermal conductivity, softness at elevated temperatures, and chip evacuation sensitivity—requiring optimized toolpaths, specialized tooling, and precise coolant strategies. Our engineers leverage advanced CAM software and real-time monitoring systems to fine-tune every cut, minimizing tool wear and maximizing throughput. Whether you’re working with 6061, 7075, or custom aluminum alloys, our processes are tailored to maintain dimensional stability and structural integrity.

We go beyond machining. Our integrated services include precision milling, turning, drilling, tapping, deburring, and optional surface treatments such as anodizing or powder coating. With in-house design support and DFM analysis, we help you optimize parts for manufacturability, reducing lead times and lowering total cost of ownership.

Our facility in Wuxi, China, is equipped for global delivery, serving clients across North America, Europe, and Asia with responsive communication, secure data handling, and scalable capacity. We pride ourselves on transparency—every project includes detailed progress updates, inspection reports, and packaging customized to your logistics needs.

Why choose Lead Precision? Because we combine German-level engineering discipline with the agility and cost efficiency of Chinese manufacturing—without compromising on quality.

Explore how we can elevate your production standards. Contact us today at [email protected] to discuss your next project with our engineering team.

| Specification | Detail |

|---|---|

| Machine Types | 3-Axis, 4-Axis, 5-Axis CNC Machining Centers |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Tolerance Capability | ±0.005 mm (standard), ±0.002 mm (tight-tolerance) |

| Spindle Speed | Up to 24,000 RPM |

| Tooling System | High-performance carbide and diamond-coated tools |

| Materials Processed | Aluminum 6061, 7075, 5052, 2024, and custom alloys |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.4 µm (precision finish) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days (varies by volume) |

| Surface Treatments | Anodizing (Type II, Type III), Powder Coating, Passivation |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.