Technical Contents

Engineering Guide: Cnc Machien

Engineering Insight Precision as the Non-Negotiable Foundation of Modern CNC Machining

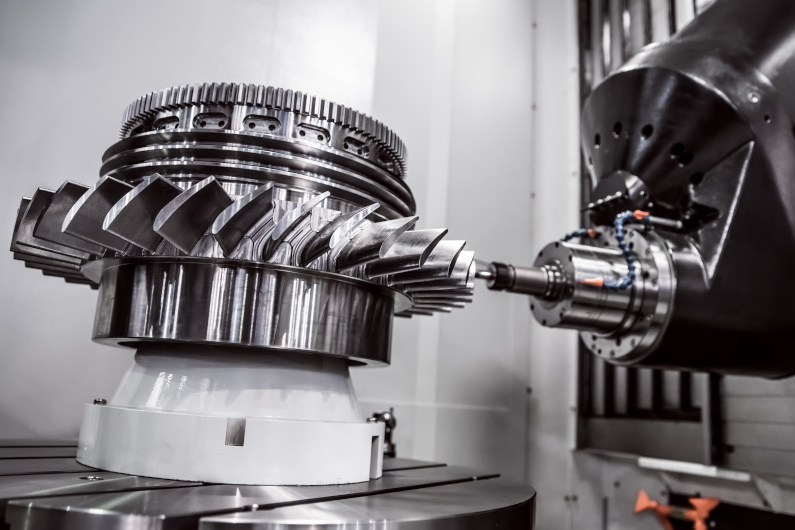

In high-stakes manufacturing sectors like aerospace defense and advanced medical technology precision is not merely a desirable attribute it is the absolute cornerstone of functionality safety and system integration. The difference between a successful mission a life-saving device and catastrophic failure often resides within microns. Modern CNC machines must deliver not only initial accuracy but also sustained repeatability under demanding production cycles thermal fluctuations and complex multi-axis operations. Achieving true precision requires an integrated approach encompassing machine tool design thermal management advanced control algorithms high-fidelity feedback systems and rigorous calibration protocols. It transcends simple dimensional conformity demanding predictable performance across thousands of parts ensuring every component meets exacting specifications without variation. This level of consistency is what transforms raw material into mission-critical hardware.

Wuxi Lead Precision Machinery has honed this capability through decades of delivering components where failure is inconceivable. Our engineering teams possess deep expertise forged in projects demanding the utmost reliability including precision subsystems for the Beijing Winter Olympics infrastructure and critical components for national defense applications. These engagements required machining tolerances consistently held below 0.005mm under stringent environmental and operational scrutiny. Such experience instills an uncompromising culture where precision is engineered into every process from material selection to final inspection not treated as a final checkpoint. We understand that in military systems a micron-scale deviation can compromise guidance accuracy and in Olympic-grade equipment it can affect performance at the elite level.

True precision engineering demands machines built to exacting standards. This involves ultra-rigid cast iron structures with optimized ribbing to minimize deflection high-precision preloaded spindle bearings with micron-level runout control linear scales for direct position feedback and sophisticated thermal compensation systems that actively counteract heat-induced growth. The control system must process complex toolpaths with nanometer resolution while maintaining exceptional surface finish. The table below outlines the core precision specifications achievable on Wuxi Lead’s flagship vertical machining centers designed for these demanding applications.

| Specification | Performance Metric | Significance |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±0.003 mm | Ensures absolute dimensional correctness of complex geometries |

| Repeatability (X/Y/Z) | ≤ 0.001 mm | Guarantees identical part quality batch after batch |

| Spindle Runout (at nose) | ≤ 0.0005 mm | Critical for fine surface finishes and tight tolerances on rotating features |

| Thermal Drift Compensation | ≤ 0.002 mm/°C | Maintains accuracy despite ambient or process-induced temperature changes |

| Volumetric Compensation | ISO 230-6 Certified | Corrects for geometric errors across the entire machine working volume |

This commitment to measurable precision performance is why global leaders in sensitive industries specify Wuxi Lead machinery. We engineer not just for today’s tolerances but for the evolving demands of next-generation manufacturing where the margin for error continues to shrink. Partnering with a manufacturer possessing proven high-precision execution capability mitigates risk and ensures your most critical components meet the uncompromising standards required for success. Precision is the language of reliability and we speak it fluently.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered for high-complexity components across aerospace, medical, energy, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling the production of geometrically intricate parts with exceptional accuracy and surface integrity. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous movement across five planes, minimizing setup cycles and enabling single-operation completion of multi-faceted components. This results in tighter tolerances, superior part consistency, and reduced lead times—critical advantages for mission-critical applications.

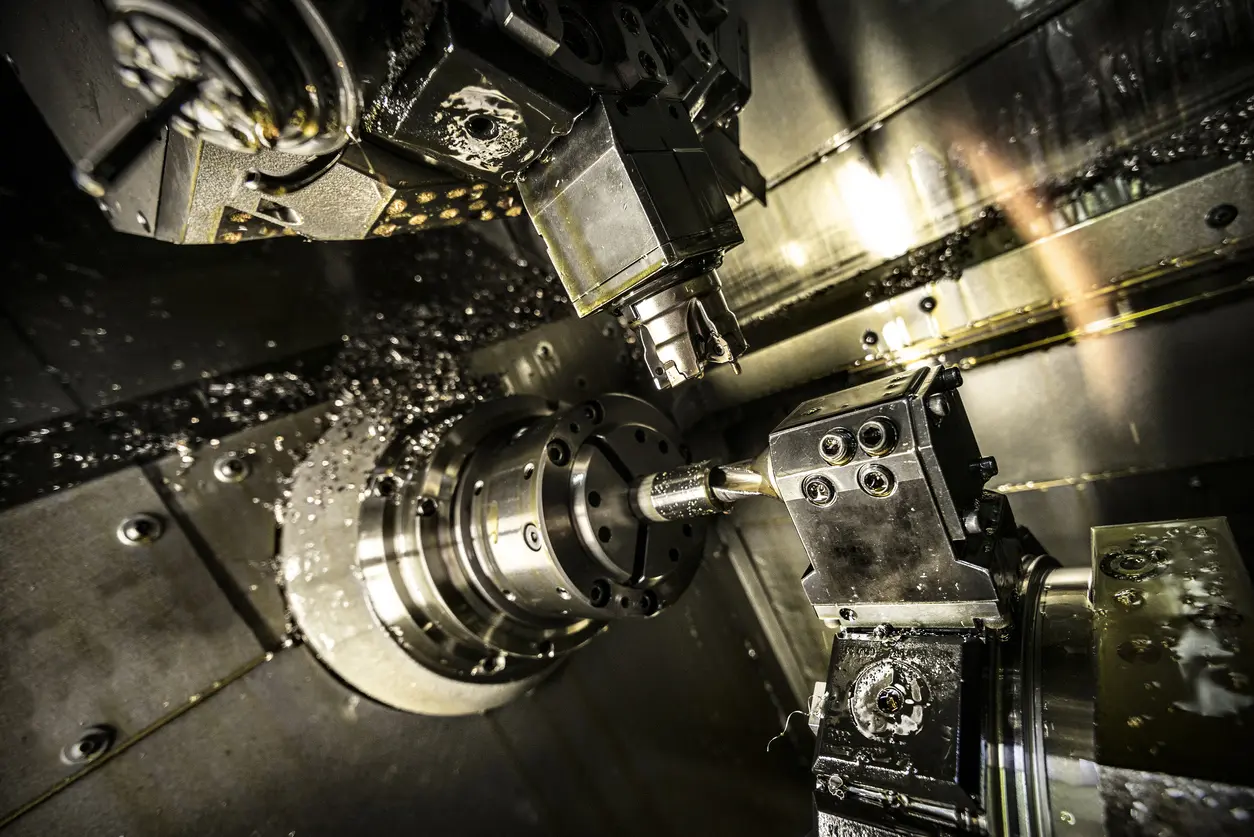

Our facility is equipped with a fleet of high-performance 5-axis machining centers from industry-leading manufacturers, featuring high-torque spindles, dynamic tool changers, and real-time monitoring systems. These machines support a broad range of materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics. Advanced CAD/CAM integration ensures seamless translation of complex digital models into precise physical components, while adaptive machining strategies optimize toolpaths for material removal efficiency and dimensional stability.

To maintain the highest level of quality assurance, every production run undergoes rigorous inspection using a Zeiss DuraMax Bridge-Type Coordinate Measuring Machine (CMM). This metrology-grade system provides non-contact and tactile probing capabilities, delivering micron-level verification of critical dimensions, geometries, and surface profiles. Full first-article inspection reports (FAIR) and process capability (Cp/Cpk) data are generated as standard, ensuring full compliance with ISO 9001:2015 and customer-specific quality requirements. In-process inspections are also conducted to preempt deviations and maintain continuous process control.

Our commitment to precision is quantified in the tolerances we consistently achieve across diverse part configurations and material types. The following table outlines our standard and achievable tolerance specifications under controlled production conditions.

| Feature Type | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Reamed/precision bored |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm span |

| Circular Runout | 0.01 mm | 0.003 mm | Full rotation |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machined; polish optional |

All tolerances are verified under temperature-stable conditions to eliminate thermal drift effects. Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with disciplined quality control protocols to deliver components that meet the most stringent performance and reliability standards in global advanced manufacturing.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering expertise ensures informed decisions aligned with your application’s mechanical, environmental, and economic demands. Aluminum alloys, particularly 6061-T6, dominate aerospace, automotive, and prototyping due to excellent machinability, favorable strength-to-weight ratio, and seamless compatibility with anodizing. Its lower density reduces part weight significantly while maintaining adequate structural integrity for non-critical load scenarios. Steel alloys like 4140 offer superior strength, wear resistance, and durability for high-stress applications such as shafts, gears, and tooling. Though more challenging to machine than aluminum, requiring robust tooling and optimized parameters, its hardenability and fatigue resistance justify its use in demanding industrial environments. Titanium Grade 5 (Ti-6Al-4V) represents the premium solution for aerospace, medical implants, and marine components where extreme strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility are non-negotiable. Its high cost and difficult machinability—characterized by low thermal conductivity and work hardening tendencies—necessitate specialized CNC strategies and tooling, which our facility expertly executes.

Surface finishing, especially anodizing for aluminum, critically enhances functional properties. Type II (Sulfuric Acid) Anodizing provides a standard decorative and corrosion-resistant layer, while Type III (Hardcoat) Anodizing delivers a significantly thicker, harder surface (up to 70 Rockwell C) for severe wear resistance and electrical insulation. Crucially, anodizing is exclusive to aluminum; steel requires plating (e.g., zinc, chrome) or passivation, and titanium benefits from chemical passivation or specialized coatings like PVD. Selecting the wrong finish compromises performance and lifespan.

Material properties directly dictate machining strategy and final part capability. The following table summarizes key characteristics for common high-performance alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | 95% | Aerospace brackets, enclosures, prototypes |

| Steel 4140 | 7.85 | 655 | 65% | Gears, shafts, tooling, high-stress parts |

| Titanium Ti-6Al-4V | 4.43 | 900 | 30% | Aircraft components, medical implants, marine |

Wuxi Lead Precision Machinery leverages decades of CNC expertise to navigate these material complexities. We provide comprehensive consultation from initial design through final finishing, ensuring your selected material and process—whether machining 6061-T6 for rapid iteration or implementing Type III anodizing for extreme wear—delivers maximum value and reliability. Partner with us to transform material potential into precision-engineered reality.

Manufacturing Process & QC

Design Engineering: The Foundation of Precision

At Wuxi Lead Precision Machinery, the CNC machining process begins with meticulous design engineering. Our team collaborates closely with clients to transform conceptual ideas into manufacturable, high-precision components. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we ensure every geometric detail, tolerance, and surface finish is optimized for performance and manufacturability. Design for Manufacturability (DFM) analysis is conducted early to identify potential production challenges, reduce material waste, and streamline downstream processes. All designs are validated through simulation tools to predict stress points, thermal behavior, and structural integrity under operational conditions. This proactive approach ensures that the final product meets both functional requirements and international quality standards such as ISO 9001:2015.

Prototyping: Validating Performance Before Scale

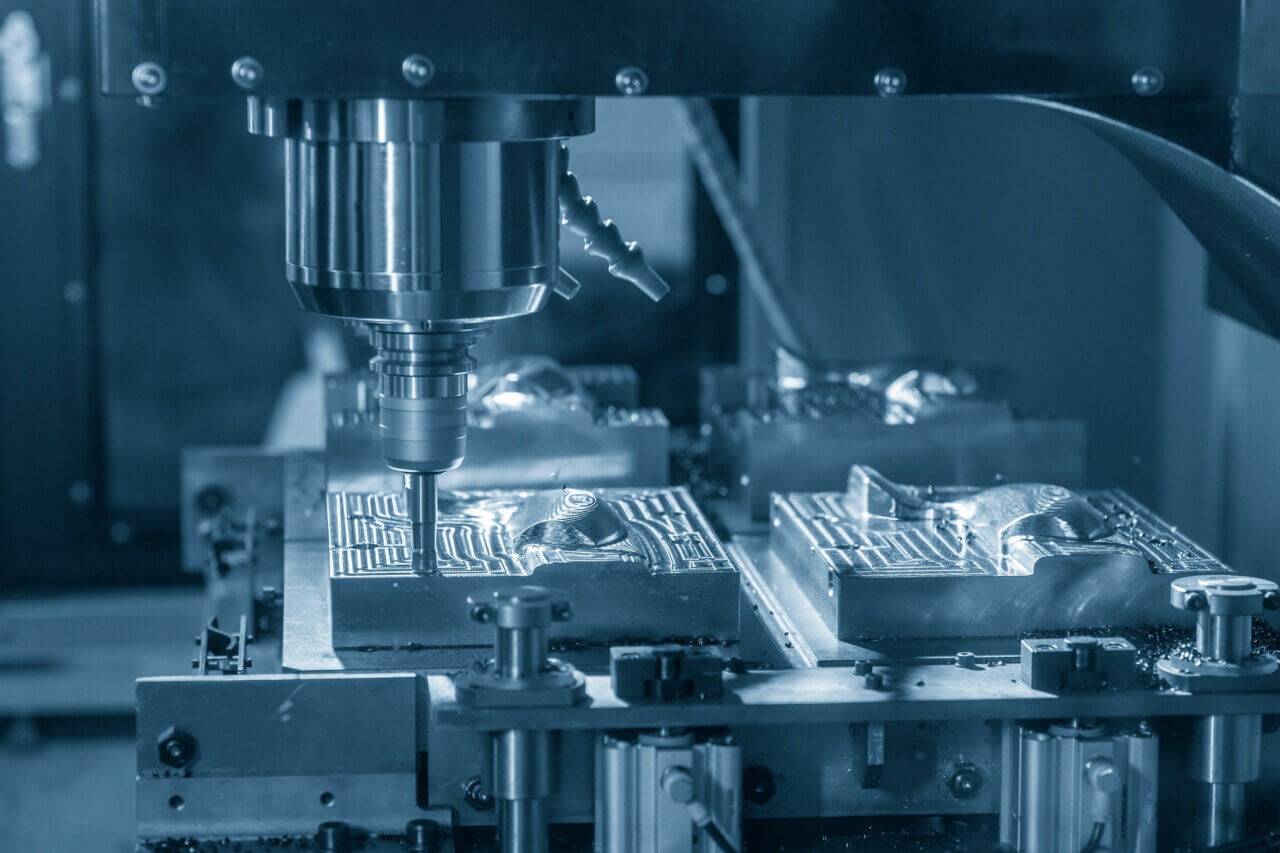

Once the design is finalized, we move into the prototyping phase—a critical step in our zero-defect philosophy. Using high-speed 3-axis, 4-axis, and 5-axis CNC machining centers, we produce functional prototypes that mirror the final production parts in both material and precision. Prototypes are typically manufactured from the same stock—aluminum, stainless steel, titanium, or engineering plastics—as the end-use component to ensure accurate performance testing. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy is verified against the original CAD model using GD&T (Geometric Dimensioning and Tolerancing) principles. Feedback from client testing is incorporated into any necessary design refinements, ensuring full alignment before transitioning to mass production.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we initiate scalable mass production under a fully controlled manufacturing environment. Our CNC machining cells operate with automated tool changers, real-time tool wear monitoring, and in-process gauging to maintain consistency across production runs from hundreds to tens of thousands of parts. Each stage of machining—milling, turning, drilling, threading, and finishing—is governed by documented work instructions and standard operating procedures. Statistical Process Control (SPC) is implemented to monitor critical dimensions and detect process drift before defects occur. Every batch is subject to first-article inspection and periodic quality audits. Our traceability system logs machine parameters, operator IDs, and inspection data for full accountability.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Max Work Envelope (XYZ) | 1200 x 800 x 600 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (PEEK, Delrin) |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

| Quality Standards | ISO 9001:2015, RoHS, Full Inspection Reports |

Through integrated design, precision prototyping, and defect-prevention systems, Wuxi Lead delivers CNC-machined components that consistently meet the highest industrial standards.

Why Choose Wuxi Lead Precision

Strategic Partnership for Precision Manufacturing Excellence

Wuxi Lead Precision Machinery stands as your definitive partner for mission-critical CNC machining solutions where uncompromising accuracy, repeatability, and technical mastery define success. We transcend conventional manufacturing by integrating advanced multi-axis technology with rigorous quality protocols, engineered specifically for industries demanding zero-defect delivery— aerospace, medical devices, energy systems, and high-performance automation. Our facility operates under ISO 9001:2015 and IATF 16949 standards, with full traceability from raw material certification to final inspection, ensuring every component meets the most stringent global specifications. Partnering with Lead Precision means accessing a dedicated engineering team that collaborates from design validation through production scaling, eliminating costly iterations and accelerating time-to-market without sacrificing integrity.

Our technical capabilities are built on a foundation of cutting-edge infrastructure and process discipline. The table below outlines core specifications governing our production ecosystem:

| Parameter | Capability | Verification Method |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Laser interferometer calibration |

| Repeatability | ±0.0005 mm | Statistical process control (SPC) |

| Material Range | Titanium, Inconel, 17-4PH, PEEK, ceramics | Material test reports (MTRs) |

| Max Work Envelope | 1200 x 800 x 650 mm | CMM validation |

| Surface Finish | Ra 0.2 µm (mirror-grade) | Profilometer measurement |

| Secondary Operations | Deburring, anodizing, passivation, laser marking | In-house certified processes |

This precision is sustained through real-time thermal compensation systems, 100% in-process metrology, and a climate-controlled production environment. Unlike volume-focused workshops, we prioritize complex geometries and tight-tolerance assemblies where failure is not an option. Our engineers proactively identify manufacturability risks during RFQ review, providing actionable DFM feedback that reduces scrap rates by up to 35%—a critical advantage when prototyping or producing low-volume, high-value components.

Initiate your project with a partner committed to your operational success. Contact our engineering team directly at [email protected] to discuss technical requirements, capacity planning, or confidential NDA-protected collaboration. Include your part specifications, target volumes, and quality benchmarks for a tailored capability assessment within 24 business hours. Wuxi Lead Precision Machinery delivers not just machined parts, but engineered confidence—where every micron is a promise kept.

Elevate your supply chain resilience. Reach out today to secure precision that performs under the most demanding conditions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.