Technical Contents

Engineering Guide: Cnc Machie

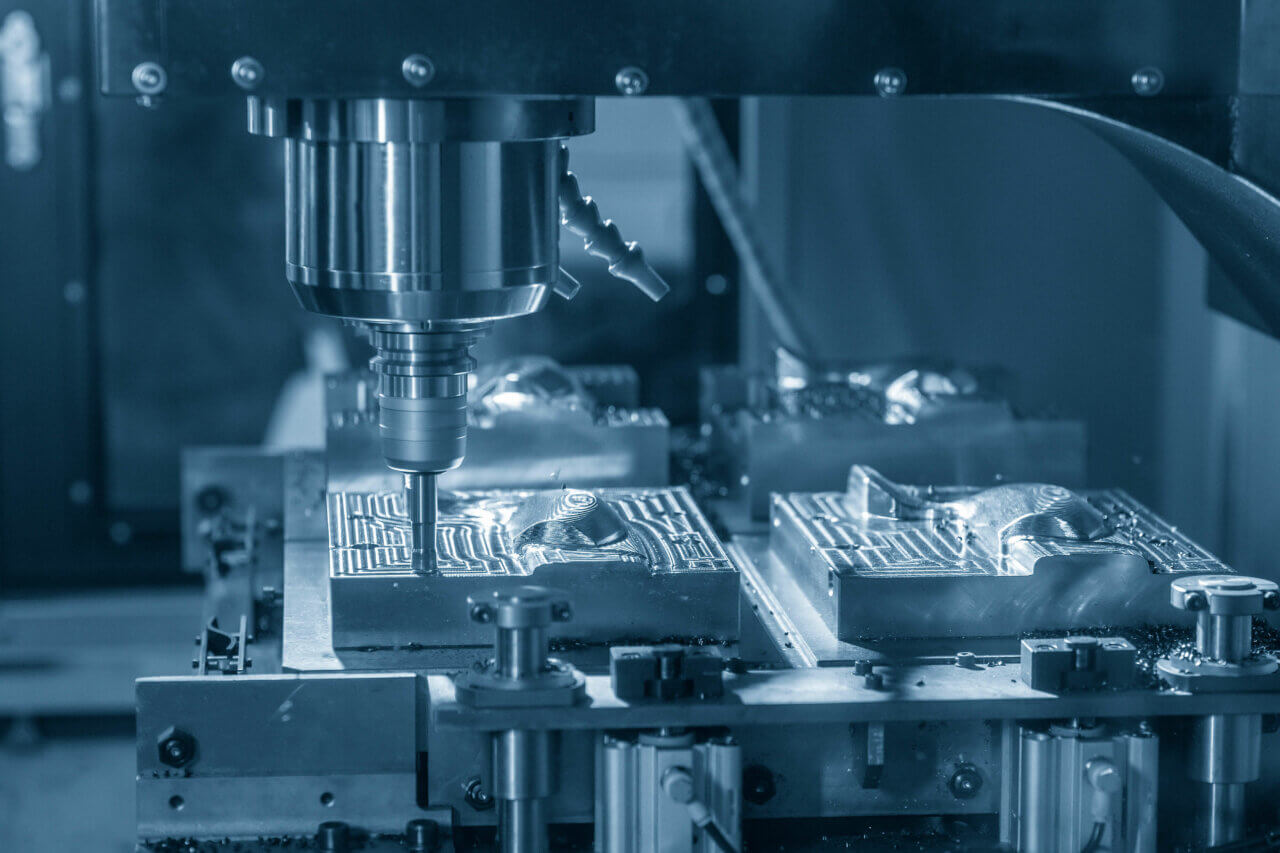

Engineering Insight The Non-Negotiable Imperative of Precision in CNC Machining

In high-stakes manufacturing sectors aerospace defense medical and advanced automation precision is not merely a quality metric it is the foundational requirement for functional integrity safety and mission success. Sub-micron deviations in critical components can cascade into catastrophic system failures rendering even the most advanced designs ineffective. The relentless pursuit of dimensional accuracy surface finish and geometric conformity defines the boundary between viable production and costly scrap. This demands far more than advanced machinery it requires an integrated engineering philosophy where material science thermal dynamics metrology and process control converge under stringent protocols. At Wuxi Lead Precision Machinery we treat precision as a strategic engineering discipline not a production outcome.

Our commitment to extreme precision is validated through mission-critical applications. We engineered and manufactured timing system components for the Beijing Winter Olympics where nanosecond synchronization accuracy was non-negotiable across global venues. Similarly our CNC-machined structural elements and sensor housings perform reliably within classified defense systems operating under extreme environmental stresses. These projects demanded adherence to AS9100 and ITAR standards alongside in-house validation processes exceeding typical industry norms. Success in such arenas stems from our holistic approach combining multi-axis machining centers with real-time thermal compensation sub-micron probing systems and a zero-defect culture rooted in statistical process control.

Achieving this level of precision requires systematic rigor beyond machine capability. Our engineering team implements closed-loop feedback from coordinate measuring machines (CMMs) directly into production workflows ensuring continuous calibration. Material stability is analyzed pre-machining while adaptive cutting strategies mitigate deflection and vibration. Every process parameter from spindle harmonics to coolant dynamics undergoes validation against Geometric Dimensioning and Tolerancing (GD&T) requirements. This methodology transforms precision from an aspiration into a measurable and repeatable output.

The following table outlines the core precision capabilities inherent to our advanced CNC machining platforms:

| Specification | Performance Standard | Measurement Method |

|---|---|---|

| Positioning Accuracy | ±1.5 µm | Laser Interferometer |

| Repeatability | ±0.8 µm | Ballbar Test (ISO 230-4) |

| Volumetric Compensation | Full 3D Grid | Laser Vector Analysis |

| Surface Finish (Ra) | 0.1 – 0.4 µm | Profilometer |

| Thermal Drift Compensation | < 2 µm over 8 hours | Real-time Sensor Network |

Precision engineering at this level transcends equipment specifications. It represents a convergence of expertise process discipline and unwavering accountability. For industries where failure is not an option Wuxi Lead Precision Machinery delivers certified accuracy you can integrate with confidence. Partner with us to transform your most demanding precision challenges into reliable production reality.

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in high-precision CNC machining. As a leader in advanced manufacturing solutions, we specialize in complex, high-integrity components for industries including aerospace, medical, energy, and automation. Our core strength lies in our integration of cutting-edge 5-axis CNC machining technology with rigorous quality control processes, enabling us to deliver parts with exceptional accuracy, surface finish, and geometric complexity.

Our 5-axis CNC machining centers provide full simultaneous motion across all five axes, allowing for multi-faceted machining in a single setup. This eliminates cumulative errors from repositioning and significantly improves dimensional consistency. With advanced toolpath strategies and high-speed spindles, we achieve intricate contours and tight internal features that are unattainable with conventional 3-axis systems. Our machines are equipped with automatic tool changers, probing systems, and real-time monitoring to ensure process stability and repeatability across both prototyping and high-volume production runs.

Material versatility is a key aspect of our capability. We process a broad spectrum of engineering-grade materials, including aerospace-grade aluminum alloys, titanium, stainless and carbon steels, Inconel, and high-performance polymers. Each material is machined using optimized parameters and tooling strategies to maintain integrity, minimize thermal distortion, and achieve superior surface quality.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using state-of-the-art Coordinate Measuring Machines (CMM) with tactile and optical probing systems. Our CMM inspection process follows ISO 10360 standards and is fully integrated with CAD-based inspection software, enabling comprehensive first-article inspection reports (FAIR) and statistical process control (SPC) data for batch traceability. Additionally, in-process inspections and final visual checks ensure compliance with customer specifications and industry standards.

The table below outlines our standard machining tolerances, reflecting our commitment to precision and consistency.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.010 mm | ±0.005 mm |

| Linear Dimensions (100–500 mm) | ±0.015 mm | ±0.010 mm |

| Linear Dimensions (500–1000 mm) | ±0.025 mm | ±0.020 mm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Positional Tolerance (Hole to Hole) | ±0.012 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm (polished finishes available) |

| Geometric Tolerances (Flatness, Perpendicularity) | 0.02 mm/m | 0.01 mm/m |

All tolerances are achievable under controlled environmental conditions and are subject to part geometry, material, and fixturing requirements. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to ensure optimal outcomes without compromising performance or cost-efficiency.

With a foundation built on advanced equipment, expert programming, and uncompromising quality control, Wuxi Lead Precision Machinery delivers technical excellence in every component we produce.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting optimal materials is critical for performance, cost efficiency, and longevity in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering team evaluates material properties against application demands including load, environment, weight constraints, and regulatory requirements. Aluminum, steel, and titanium represent the most prevalent choices for high-integrity parts across aerospace, medical, and industrial automation sectors. Understanding their distinct characteristics ensures the right balance of machinability, strength, and final functionality.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and excellent thermal conductivity. Their natural corrosion resistance and ease of machining make them ideal for structural frames, heat sinks, and non-ferrous applications where weight reduction is paramount. While highly workable, aluminum requires careful toolpath strategies to prevent burring and maintain tight tolerances on thin features. Steel variants like 4140 and 17-4 PH provide superior hardness, wear resistance, and structural integrity under heavy loads. These alloys are the standard for high-stress mechanical components such as shafts, gears, and tooling fixtures. Machining steel demands robust tooling and precise coolant management to handle higher cutting forces and thermal generation compared to aluminum. Titanium, primarily Grade 5 (Ti-6Al-4V), delivers outstanding strength-to-weight performance and unparalleled corrosion resistance in extreme environments like marine or chemical exposure. However, its low thermal conductivity and tendency to gall necessitate specialized cutting parameters, rigid setups, and premium tooling to achieve dimensional accuracy without work hardening.

Key mechanical properties guide initial material screening as shown below. Real-world selection must also factor in total cost of ownership, including raw material expense, machining time, and post-processing requirements.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating (Relative) |

|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | Excellent (High) |

| Steel 4140 | 7.85 | 655 | Good (Moderate) |

| Titanium Ti-6Al-4V | 4.43 | 900 | Fair (Challenging) |

Surface finishing, particularly anodizing for aluminum, significantly enhances component durability and appearance. Type II (Sulfuric Acid) anodizing provides standard corrosion resistance and dyeability for aesthetic or moderate-duty applications. For critical wear surfaces, Type III (Hard Anodizing) creates a thicker, harder ceramic layer offering superior abrasion resistance and electrical insulation, though it requires precise dimensional allowance due to oxide layer growth into the substrate. Wuxi Lead Precision Machinery integrates material science expertise with advanced CNC capabilities to advise on optimal material-finish combinations, ensuring your components meet exacting performance criteria while maximizing production efficiency. Consult our engineering team early in the design phase to leverage material selection as a strategic advantage.

Manufacturing Process & QC

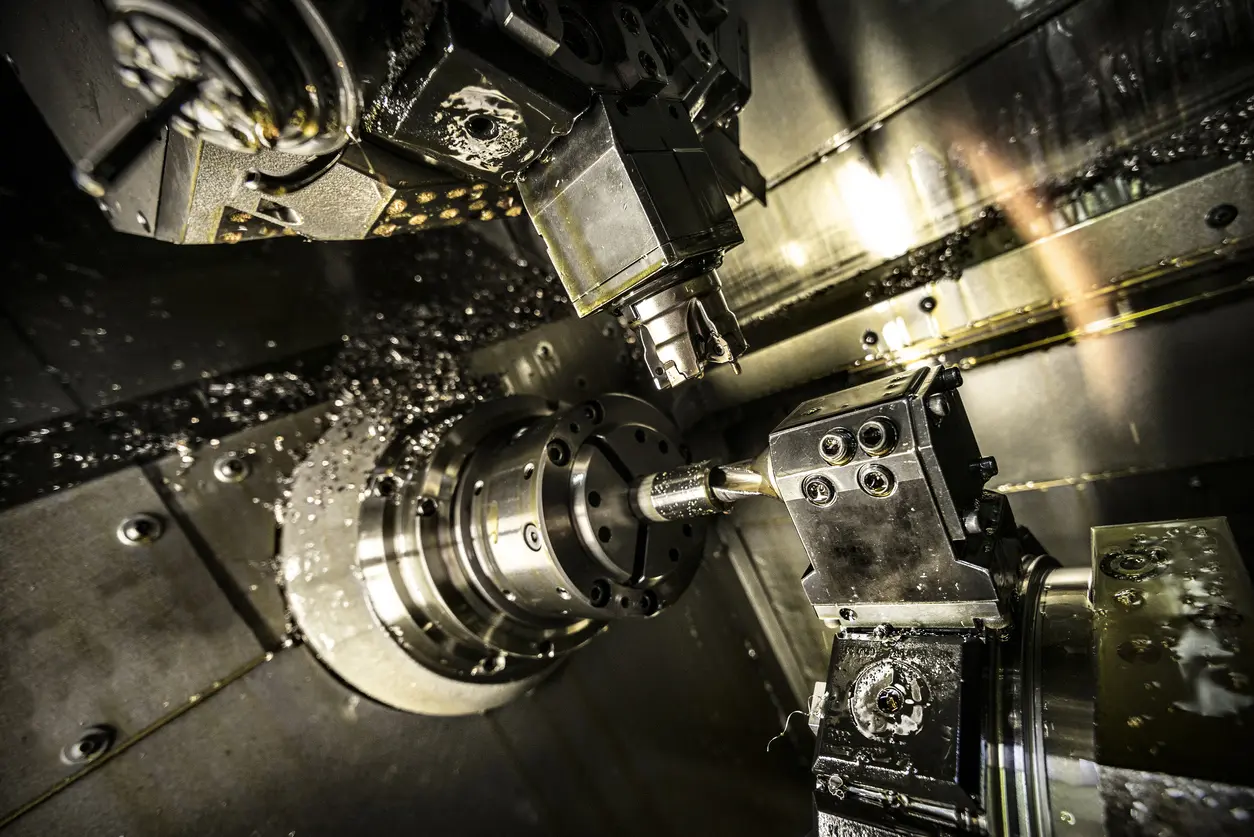

From Concept to Perfection: The Precision CNC Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence at every phase of production. Our end-to-end CNC machining process is built on a foundation of precision, consistency, and zero-defect manufacturing. From initial design to final mass production, each step is optimized to deliver components that meet the most demanding industrial standards.

The journey begins with Design and Engineering Analysis. Our team collaborates closely with clients to review technical drawings, 3D CAD models, and performance requirements. Using advanced simulation software, we conduct dimensional analysis, material suitability checks, and manufacturability assessments. This ensures that every design is not only functional but also optimized for CNC machining efficiency. Our engineers validate tolerances, surface finishes, and geometric complexities before proceeding, minimizing downstream risks.

Next is the Prototyping Phase, where theoretical designs become tangible realities. Utilizing high-precision 3-, 4-, and 5-axis CNC machines, we produce functional prototypes that mirror final production quality. This stage allows for real-world testing, fit checks, and performance validation. Our rapid prototyping capability reduces development cycles while maintaining micron-level accuracy. Clients receive detailed inspection reports, including first-article inspection (FAI) data and GD&T verification, ensuring full traceability and compliance.

Once the prototype is approved, we transition seamlessly into Mass Production. Our facility in Wuxi operates a fully integrated production line equipped with automated tooling systems, real-time monitoring, and in-process gauging. Every component is machined under strict environmental controls to prevent thermal drift and maintain dimensional stability. We employ statistical process control (SPC) to monitor critical parameters continuously, enabling predictive adjustments before deviations occur.

Quality is not a final checkpoint—it is embedded throughout. Our zero-defect philosophy is enforced through multi-stage inspections using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Each batch undergoes 100% critical dimension checks and random sampling for full conformance. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence.

The result is a production process that guarantees repeatability, reliability, and regulatory compliance across industries such as aerospace, medical devices, and advanced automation.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.01 mm (custom down to ±0.001 mm) |

| Surface Finish (Ra) | 0.8 μm standard, down to 0.2 μm achievable |

| Max Work Envelope (XYZ) | 2000 x 1200 x 1000 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, PEEK, Inconel |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9100D |

At Wuxi Lead Precision Machinery, precision is not achieved—it is engineered, verified, and guaranteed.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Excellence

In high-stakes manufacturing sectors like aerospace, medical devices, and advanced energy systems, component precision isn’t optional—it’s existential. Tolerances measured in microns, complex geometries, and zero-defect delivery define your success. At Wuxi Lead Precision Machinery, we engineer CNC solutions that transform these demands from challenges into competitive advantages. Our machines aren’t merely tools; they are force multipliers for your production integrity, built on 15 years of obsessive refinement in ultra-precision engineering.

We understand that your supply chain resilience hinges on partners who deliver beyond specifications. That’s why every Lead Precision machine undergoes 72 hours of continuous thermal stability testing and 100% laser interferometer calibration before shipment. Our proprietary motion control algorithms eliminate step-loss errors, while rigid铸铁 bases and hydrostatic guideways ensure sub-micron repeatability across shifts, seasons, and production volumes. This isn’t theoretical performance—it’s quantified in the ISO 230-2 certified data below:

| Specification | Lead Precision LP-5X Series | Industry Standard |

|---|---|---|

| Positioning Accuracy | ±1.5 µm | ±5.0 µm |

| Repeatability | ±0.8 µm | ±2.0 µm |

| Spindle Runout (TIR) | ≤0.5 µm | ≤2.0 µm |

| Thermal Compensation | Real-time 3D mapping | Basic linear |

| Surface Finish (Ra) | 0.05 µm achievable | 0.2 µm typical |

This level of control translates directly to your bottom line: reduced scrap rates, elimination of secondary operations, and accelerated time-to-market for next-generation components. Our clients in semiconductor manufacturing report 37% faster cycle times on titanium optics mounts, while medical OEMs achieve zero non-conformities on cobalt-chromium hip joints—metrics that redefine industry benchmarks.

Partnering with Lead Precision means embedding our engineering DNA into your workflow. Our global technical team provides not just installation support, but deep process optimization: material-specific cutting strategies, fixture design validation, and predictive maintenance protocols tailored to your production rhythm. We don’t sell machines; we co-engineer reliability.

Your next breakthrough component demands a foundation of absolute precision. Initiate your precision partnership today. Contact our engineering sales team at [email protected] to schedule a confidential process audit. Include your target tolerances, material specifications, and production volume—we’ll respond within 4 business hours with a customized capability analysis. For urgent RFQs, reference code LP-CTA2024 to expedite technical review.

Lead Precision: Where Microns Define Mastery.

Wuxi Lead Precision Machinery Co. Ltd. | ISO 9001:2015 Certified | Global Support Network

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.