Technical Contents

Engineering Guide: Cnc Lathe Machines For Custom Parts

Engineering Insight: CNC Lathe Machines for Custom Parts

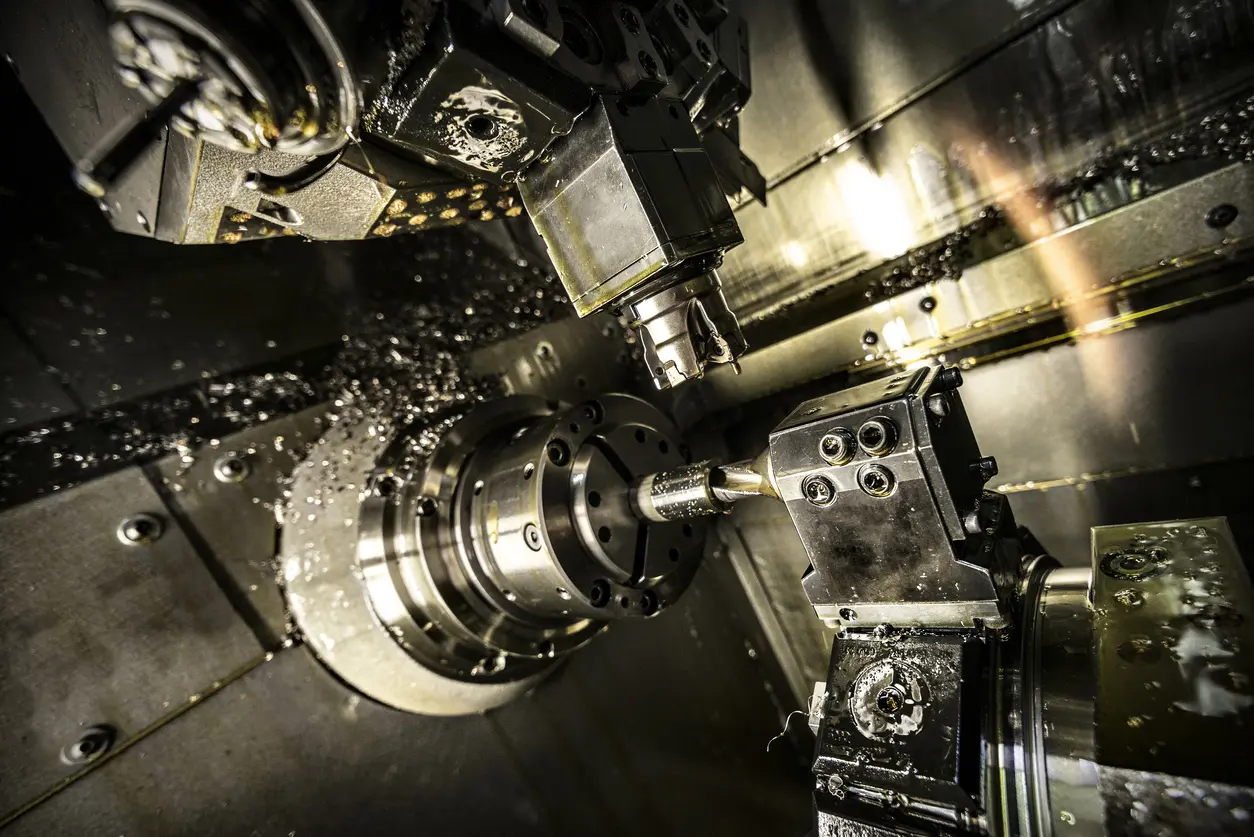

In the realm of precision manufacturing, CNC lathe machines represent the cornerstone of high-accuracy component production. When fabricating custom parts for industries such as aerospace, medical devices, and advanced automation, the margin for error is not measured in millimeters—it is measured in microns. At Wuxi Lead Precision Machinery, we understand that precision is not merely a performance metric; it is a foundational requirement for reliability, safety, and long-term functionality in mission-critical applications.

CNC lathe machines for custom parts must deliver consistent dimensional accuracy, superior surface finishes, and repeatable performance across production runs. This level of control is only achievable through a combination of advanced machine design, high-grade materials, rigorous calibration, and deep engineering expertise. Our machines are engineered with rigid cast-iron beds, high-torque spindles, and precision-ground ball screws to minimize deflection and thermal drift—factors that directly impact part tolerances.

What sets Wuxi Lead apart is our proven track record in delivering components that meet the most stringent quality standards. Our precision machining services have supported projects for Olympic-grade sports equipment and high-reliability military systems, where failure is not an option. These applications demand not only micron-level tolerances but also full traceability, material certification, and adherence to international quality protocols such as ISO 9001 and AS9100. Our experience in these elite sectors directly informs the design and performance of our CNC lathe solutions, ensuring that every machine we produce is capable of meeting and exceeding the demands of the most challenging environments.

Our CNC lathes are equipped with advanced control systems—such as Fanuc, Siemens, or Mitsubishi—that enable complex multi-axis operations, real-time monitoring, and seamless integration into automated production lines. Whether producing intricate medical implants or ruggedized defense components, our machines maintain sub-micron repeatability, ensuring that every part conforms exactly to specification.

Below are key technical specifications representative of our high-end CNC lathe models designed for custom precision parts:

| Specification | Detail |

|---|---|

| Spindle Speed | Up to 6,000 RPM (configurable) |

| Bar Capacity | 20 – 65 mm (depending on model) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.001 mm |

| Control System | Fanuc 31i, Siemens 840D, or Mitsubishi M80 |

| Axis Configuration | 2-axis to 7-axis (including Y-axis and live tooling) |

| Rapid Traverse Rate | 30 m/min (X/Z axes) |

| Tool Capacity | Up to 12 stations (VTL models up to 24) |

| Coolant System | High-pressure through-spindle (optional) |

| Compliance | ISO 9001, CE, RoHS |

At Wuxi Lead Precision Machinery, we do not simply build CNC lathes—we engineer precision solutions tailored to the exacting needs of global manufacturers. Our commitment to accuracy, backed by real-world performance in Olympic and military applications, ensures that our machines deliver unmatched reliability in the production of custom parts.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Custom Parts

At Wuxi Lead Precision Machinery, our core strength lies in transforming demanding custom part specifications into reality through advanced CNC lathe technology and rigorous quality systems. We specialize in high-mix, low-to-medium volume production where geometric complexity, material diversity, and uncompromising dimensional accuracy are paramount. Our foundation is a modern fleet of multi-axis CNC turning centers, strategically featuring advanced 5-axis milling-turning machines. This integrated capability allows us to machine intricate geometries—such as deep cavities, off-axis holes, complex contours, and fully finished components—in a single setup. Eliminating multiple handling stages significantly reduces cumulative error potential, enhances part concentricity, and delivers superior surface finishes critical for aerospace, medical, and semiconductor applications. Material versatility is inherent; we routinely process challenging alloys including titanium, Inconel, stainless steels, hardened tool steels, and high-performance polymers with optimal speed and precision.

Precision is non-negotiable in custom manufacturing. Every machine center operates within tightly controlled environmental conditions and undergoes regular, documented calibration per ISO 10791 standards. However, capability is only proven through validation. Our dedicated quality assurance laboratory is anchored by state-of-the-art Coordinate Measuring Machines (CMMs), including multi-sensor systems capable of probing, vision, and laser scanning. Critical features on every custom part batch are verified against the original CAD model, generating comprehensive inspection reports with full traceability. This closed-loop process ensures conformity to even the most stringent engineering drawings and material certifications required by regulated industries. Statistical Process Control (SPC) methodologies are actively employed on high-volume custom runs to monitor capability indices (Cp/Cpk) and guarantee sustained process stability.

The achievable precision for custom components is directly tied to the machining process and part geometry. Our standard capabilities consistently meet or exceed common industry benchmarks, while our advanced equipment and processes enable us to achieve significantly tighter tolerances when required by the application. The following table outlines our typical tolerance ranges for key machining operations on custom parts:

| Process | Standard Tolerance (mm) | Tight Capability (mm) | Typical Surface Finish (Ra µm) |

|---|---|---|---|

| Precision Turning | ±0.010 | ±0.005 | 0.8 – 1.6 |

| Multi-Axis Milling | ±0.015 | ±0.008 | 0.4 – 1.6 |

| Precision Grinding | ±0.005 | ±0.001 | 0.1 – 0.4 |

| Complex 5-Axis | ±0.015 | ±0.008 | 0.8 – 3.2 (varies by feature) |

These specifications represent our standard production capability under controlled conditions for features within typical size ranges for custom components. Wuxi Lead Precision Machinery collaborates closely with clients during the Design for Manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance specifications, ensuring the most efficient and cost-effective path to achieving the required functional performance without over-engineering. Our engineering team provides actionable feedback to refine designs for optimal manufacturability on our advanced CNC lathe platforms.

Material & Finish Options

When manufacturing custom parts using CNC lathe machines, material selection plays a pivotal role in determining performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we understand that the right choice of material directly impacts the functionality of the final component. Among the most widely used materials in precision CNC machining are aluminum, steel, and titanium—each offering unique mechanical properties suited for specific industrial applications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly ideal for aerospace, automotive, and consumer electronics industries where lightweight yet durable components are essential. Grade 6061-T6 is one of the most commonly machined aluminum alloys due to its weldability and good fatigue resistance. While pure aluminum is soft, alloying elements such as magnesium and silicon enhance its structural integrity without compromising workability on CNC lathes.

Steel, particularly alloy and stainless variants, provides superior strength, hardness, and wear resistance. Stainless steel grades like 304 and 316 are widely used in medical devices, food processing, and marine environments due to their outstanding corrosion resistance and hygiene compliance. On the other hand, alloy steels such as 4140 offer high tensile strength and are often selected for high-stress applications including shafts, gears, and tooling components. While steel is more challenging to machine than aluminum, modern CNC lathes equipped with carbide tooling can achieve tight tolerances and fine surface finishes consistently.

Titanium, although more expensive and difficult to machine, is unmatched in applications requiring extreme strength-to-density ratios and resistance to high temperatures and corrosive environments. Grade 5 titanium (Ti-6Al-4V) is commonly used in aerospace, defense, and medical implant manufacturing. Its low thermal conductivity requires careful control of cutting parameters to prevent tool wear and thermal deformation during CNC turning operations.

Surface finishing further enhances the performance and appearance of machined parts. Anodizing is a widely adopted electrochemical process, especially for aluminum components. It increases surface hardness, improves corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers thicker, more durable layers suitable for industrial use.

Below is a comparative overview of key material properties relevant to CNC lathe machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Electronics | Excellent |

| Stainless Steel | 505–760 | 7.9 | 304, 316, 17-4PH | Medical, Food Processing | Moderate |

| Alloy Steel | 655–900 | 7.8 | 4140, 4340 | Automotive, Industrial Tools | Fair |

| Titanium | 900–1,170 | 4.5 | Ti-6Al-4V | Aerospace, Medical Implants | Poor |

Selecting the appropriate material and finish requires a deep understanding of operational demands and environmental exposure. At Wuxi Lead Precision Machinery, we support clients in making informed decisions by combining material science expertise with advanced CNC turning capabilities to deliver high-precision custom parts that meet exacting industry standards.

Manufacturing Process & QC

Precision CNC Lathe Production Process for Custom Parts

At Wuxi Lead Precision Machinery, our production process for custom CNC lathe parts integrates engineering rigor with advanced manufacturing to achieve zero-defect outcomes. Every stage is meticulously controlled, ensuring your specifications translate flawlessly from concept to volume production.

The process begins with collaborative design validation. Our engineering team reviews 3D CAD models and technical drawings, conducting comprehensive Design for Manufacturability (DFM) analysis. We identify potential machining challenges early—such as thin-wall stability or complex feature accessibility—and propose optimizations without compromising functionality. This phase leverages Siemens NX CAM software to simulate toolpaths, verify clearances, and calculate optimal cutting parameters. Client approval of the finalized digital twin is mandatory before proceeding, eliminating misinterpretation risks.

Prototyping follows with rapid physical validation. Using our in-house HAAS ST-30Y and DMG MORI NLX 2500 lathes, we produce 1–5 prototype units within 72 hours. Each prototype undergoes rigorous metrology: CMM inspections validate geometric tolerances to ±0.003 mm, surface roughness testers confirm Ra values, and cross-sectional analysis checks internal integrity. We document all deviations in a Prototype Validation Report, sharing actionable feedback for design refinement. Only after client sign-off on prototype conformance do we advance to mass production.

Mass production executes under closed-loop quality control. Our lathes operate with real-time process monitoring: spindle load sensors detect tool wear, in-process probes measure critical dimensions between operations, and thermal compensation systems counteract environmental drift. Every 50th part undergoes full CMM revalidation, while statistical process control (SPC) charts track critical parameters like concentricity and thread pitch. All data feeds into our centralized MES platform, enabling immediate corrective action if trends approach tolerance limits. This methodology sustains Six Sigma quality levels (≤3.4 defects per million parts).

Zero defects is non-negotiable. We enforce it through three pillars: predictive tool management (replacing inserts based on micro-chip analysis, not time), 100% first-article inspection against AS9102 standards, and end-of-line vision systems for surface defect detection. Final shipments include a Certificate of Conformance with material test reports, CMM datasets, and SPC summaries—proving every part meets your exact requirements.

Key CNC Lathe Capabilities for Custom Production

| Parameter | Specification | Impact on Zero-Defect Production |

|---|---|---|

| Max Turning Diameter | 300 mm | Accommodates complex aerospace shafts |

| Positioning Accuracy | ±0.003 mm | Ensures micron-level feature alignment |

| Spindle Speed Range | 50–6,000 RPM | Optimizes finish on hardened alloys |

| Tool Capacity | 12–30 stations | Enables single-setup complex geometries |

| In-Process Probing | Renishaw RMI-QS | Validates dimensions without part removal |

This integrated approach—where design foresight, prototyping precision, and production intelligence converge—guarantees that your custom parts perform flawlessly in application. Wuxi Lead delivers not just components, but statistically validated manufacturing excellence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Lathe Expertise in Custom Part Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in today’s competitive manufacturing landscape. When your business demands custom parts with tight tolerances, complex geometries, and consistent quality, partnering with a trusted leader in CNC lathe technology is essential. As a premier provider of high-precision CNC machining solutions based in China, we deliver advanced manufacturing capabilities that scale with your production needs—whether you require rapid prototyping or high-volume production runs.

Our CNC lathe machines are engineered for performance, integrating state-of-the-art control systems, rigid spindle designs, and automated tool changers to ensure maximum uptime and repeatability. Every machine in our lineup is built to meet international standards, supporting industries such as aerospace, medical devices, automotive, and industrial automation where precision directly impacts performance and safety.

What sets Wuxi Lead Precision Machinery apart is our commitment to partnership. We don’t just supply machines—we provide complete machining solutions. From initial consultation and application analysis to installation, training, and ongoing technical support, our engineering team works closely with your operations to optimize efficiency, reduce cycle times, and improve part quality. Our in-house R&D center continuously refines machine performance based on real-world feedback, ensuring our clients benefit from the latest advancements in CNC technology.

We specialize in custom configurations tailored to your specific production requirements. Whether you need multi-axis turning centers, swiss-type lathes for micro-precision components, or integrated automation solutions, our machines are designed to deliver superior surface finishes, tighter tolerances, and longer tool life—reducing your total cost of ownership.

Below are key specifications from our flagship CNC lathe models, reflecting the precision and robustness that define our engineering standards.

| Model | Maximum Turning Diameter | Maximum Turning Length | Spindle Speed (RPM) | Positioning Accuracy | Control System |

|---|---|---|---|---|---|

| LP-TL200 | 200 mm | 500 mm | 4,500 | ±0.003 mm | Fanuc 0i-TF |

| LP-TL300 | 300 mm | 750 mm | 4,000 | ±0.003 mm | Siemens 828D |

| LP-ST16 | 16 mm | 150 mm | 12,000 | ±0.002 mm | Mitsubishi M80 |

| LP-TL400 | 400 mm | 1,000 mm | 3,500 | ±0.005 mm | Fanuc 0i-TF |

All models feature hardened linear guideways, through-coolant systems, and optional bar feeders or gantry loaders for unmanned operation. We also offer full CE compliance and remote diagnostics for global integration.

When you choose to partner with Wuxi Lead Precision Machinery, you gain more than equipment—you gain a long-term ally in manufacturing excellence. Let us help you elevate your production capabilities with CNC lathe solutions built for precision, durability, and scalability.

For technical inquiries, custom quotes, or to discuss your machining challenges, contact us today at [email protected]. Our engineering team is ready to support your next breakthrough in custom part manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.