Technical Contents

Engineering Guide: Cnc Laser Projects

Engineering Insight: The Critical Role of Precision in CNC Laser Projects

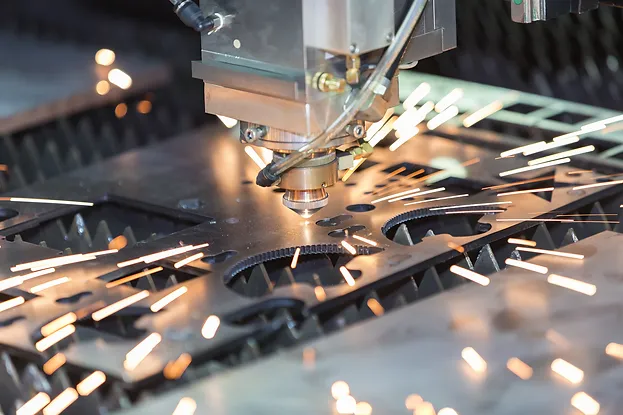

In the realm of advanced manufacturing, CNC laser projects represent the convergence of speed, accuracy, and repeatability. These systems are not merely tools for cutting or engraving—they are precision instruments that define the success of high-stakes applications across aerospace, defense, medical devices, and high-performance industrial equipment. At the core of every successful CNC laser operation lies an uncompromising commitment to dimensional accuracy, material integrity, and process control. This level of precision is not incidental; it is engineered through advanced motion systems, calibrated optics, and rigorous quality assurance protocols.

Wuxi Lead Precision Machinery has spent over a decade refining the science behind CNC laser processing, delivering solutions that meet the most stringent global standards. Our engineering team leverages state-of-the-art fiber and CO₂ laser platforms integrated with high-precision linear guides and closed-loop feedback systems to ensure micron-level repeatability. This capability is not only essential for maintaining tight tolerances but also for preserving the structural and thermal properties of sensitive materials such as titanium alloys, Inconel, and aerospace-grade aluminum.

Our expertise has been validated through mission-critical projects, including components used in Olympic-grade athletic equipment and precision subsystems deployed in military defense systems. These applications demand more than just technical capability—they require a culture of precision that permeates every stage of design, programming, and execution. Whether producing intricate lattice structures for lightweight components or high-tolerance apertures for optical guidance systems, our CNC laser platforms deliver consistent, traceable results.

Beyond hardware, precision in CNC laser projects is sustained through intelligent software integration. Our systems utilize advanced nesting algorithms and adaptive path optimization to minimize thermal distortion and material waste while maximizing throughput. Real-time monitoring and automated calibration ensure that each cut meets the original engineering intent, even during extended production runs.

Below are key specifications that define the performance standards of our CNC laser platforms:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber / CO₂ (selectable by application) |

| Maximum Power Output | Up to 12,000 W |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Cutting Speed (max) | Up to 100 m/min (thin sheet, fiber) |

| Minimum Feature Size | 0.15 mm (with focus optimization) |

| Material Thickness Range | 0.5 mm – 25 mm (steel), variable by alloy |

| Control System | Siemens / Fanuc / proprietary HMI |

| Beam Quality (BPP) | <0.8 mm·mrad (high-brightness fiber) |

| Operating Environment | Temperature-stabilized, dust-controlled |

At Wuxi Lead Precision Machinery, we understand that precision is not a specification—it is a standard. Our work on Olympic and military-grade components reflects our ability to meet and exceed the demands of the most exacting industries. In CNC laser projects, where tolerances are measured in microns and failure is not an option, precision is the foundation of performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Laser Applications

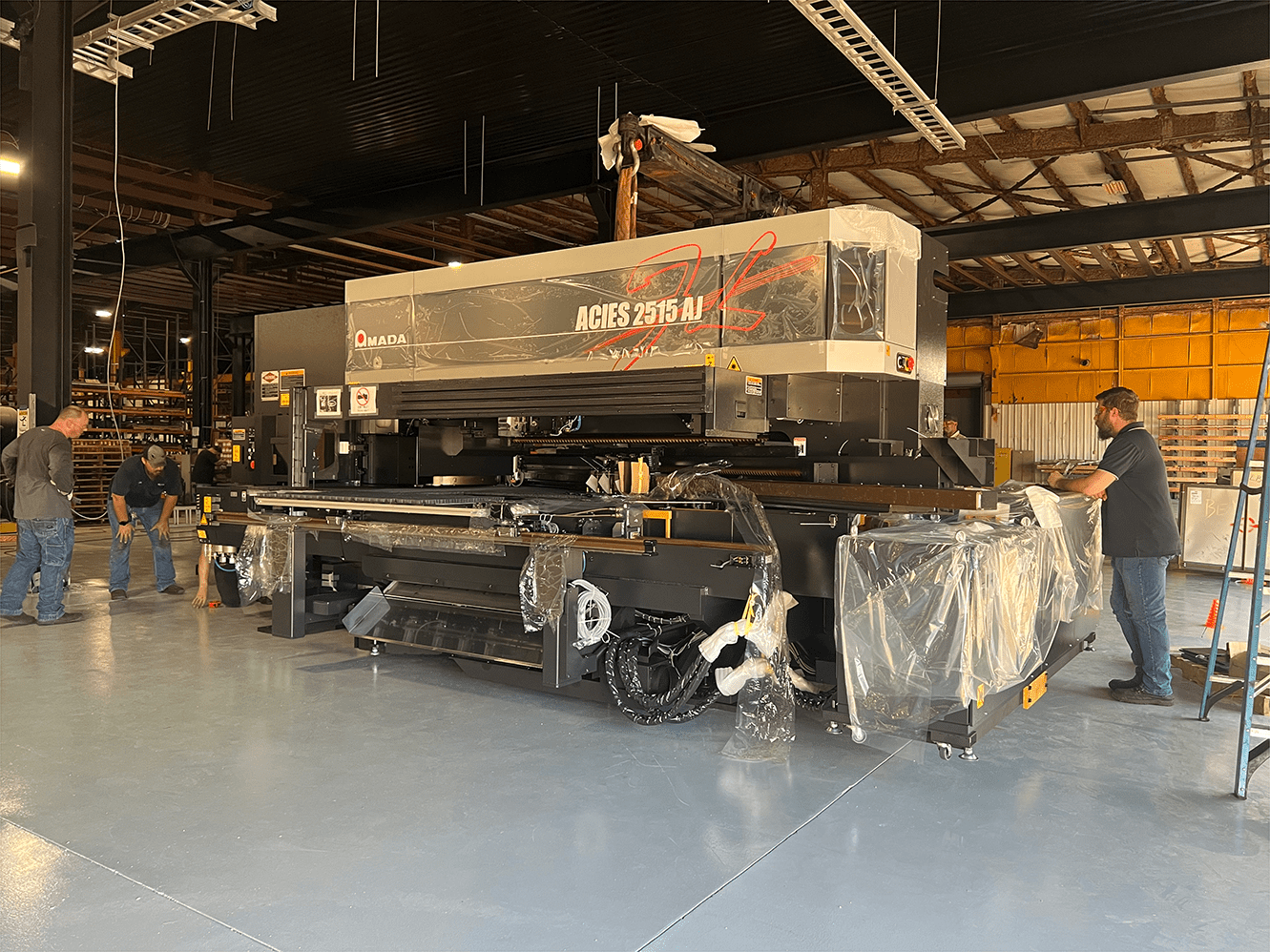

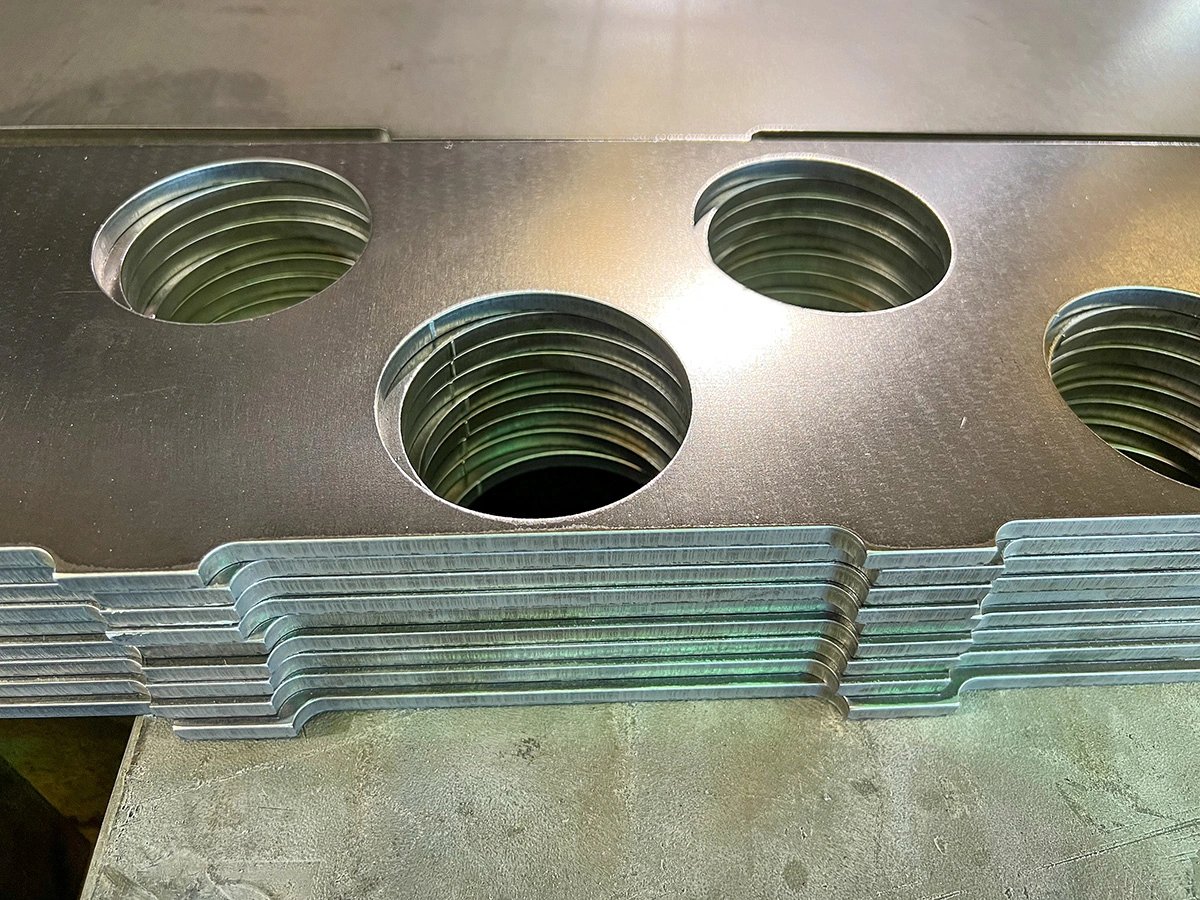

Wuxi Lead Precision Machinery delivers uncompromising precision for complex CNC laser projects through advanced multi-axis machining and rigorous quality assurance. Our core strength lies in mastering intricate geometries inherent in high-value laser system components, where micron-level accuracy directly impacts optical performance and system integration. We deploy a dedicated fleet of state-of-the-art 5-axis CNC machining centers, primarily featuring DMG MORI and MAZAK platforms, equipped with high-frequency spindles (up to 30,000 RPM) and dynamic linear motor drives. This infrastructure enables the simultaneous machining of complex 3D contours, deep cavities, and undercuts in a single setup, eliminating cumulative error from multiple fixtures. We routinely process challenging materials critical to laser applications, including aerospace-grade aluminum alloys (7075-T6, 6061), titanium (Ti-6Al-4V), Inconel 718, copper alloys, and specialized ceramics, ensuring thermal stability and structural integrity for demanding operational environments. Integrated high-precision laser measurement systems within our machining cells provide real-time tool and part verification, enhancing first-pass yield for critical features.

Quality control is non-negotiable in laser system manufacturing. Every component undergoes a comprehensive inspection protocol anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs). Our certified metrology team performs full 3D geometric dimensioning and tolerancing (GD&T) verification against ASME Y14.5 standards, generating detailed inspection reports with traceable NIST-certified calibration. This process includes critical analysis of surface finish, positional accuracy of mounting interfaces, bore concentricity for optical paths, and flatness of critical mounting surfaces – all parameters where deviations can cause beam misalignment or system failure. We implement statistical process control (SPC) at key manufacturing stages, ensuring consistent repeatability batch after batch. Our quality management system is ISO 9001:2015 certified, providing a robust framework for continuous improvement and defect prevention specific to the stringent demands of laser technology partners.

The following table details our standard and tight-tolerance capabilities for critical features in CNC laser project components:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Positional (Holes) | ±0.010 mm | ±0.003 mm |

| Angular (Bevels) | ±0.1° | ±0.02° |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm |

| Feature-to-Feature | ±0.015 mm | ±0.005 mm |

| Laser Integration | ±0.008 mm | ±0.002 mm |

Our technical team collaborates closely with client engineering departments during the design phase, providing Design for Manufacturability (DFM) feedback to optimize part geometry for precision machining and laser assembly. This proactive approach minimizes costly iterations and ensures seamless integration of machined components into final laser systems, delivering reliability you can measure in nanometers. Wuxi Lead Precision Machinery is your committed partner for turning the most exacting laser project specifications into reality.

Material & Finish Options

Material selection is a critical phase in the development of high-performance CNC laser projects, directly influencing part functionality, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining for demanding industrial applications, where material properties must align precisely with operational requirements. Among the most widely used metals in our projects are aluminum, steel, and titanium—each offering distinct advantages depending on the application environment.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly favored in aerospace, automotive, and consumer electronics industries where weight reduction without sacrificing structural integrity is essential. Grade 6061-T6 is commonly selected for its balanced mechanical properties and weldability, while 7075-T6 offers higher strength for more demanding structural components. Aluminum’s high thermal and electrical conductivity also makes it ideal for heat dissipation and electrical enclosures.

Steel, particularly in its stainless and alloy forms, provides superior strength, wear resistance, and thermal stability. Stainless steel grades such as 304 and 316 are widely used in medical devices, food processing, and marine environments due to their exceptional corrosion resistance and compliance with hygiene standards. For high-stress mechanical components, alloy steels like 4140 or tool steels offer enhanced hardness and fatigue resistance, making them suitable for tooling, shafts, and industrial machinery parts.

Titanium, though more challenging to machine, delivers an unmatched strength-to-density ratio and outstanding resistance to extreme environments. Grade 5 (Ti-6Al-4V) is the most common titanium alloy in aerospace and defense applications, where performance under high stress and elevated temperatures is non-negotiable. Its biocompatibility also makes it a preferred choice in medical implants and surgical instruments.

Surface finishing plays a pivotal role in enhancing both performance and aesthetics. Anodizing is the most prevalent finish for aluminum components, providing increased surface hardness, improved corrosion resistance, and the ability to incorporate color for identification or branding. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) delivers thick, wear-resistant layers suitable for industrial and military-grade applications.

Below is a comparative overview of key material properties for common alloys used in CNC laser projects.

| Material | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 276 | 2.70 | Enclosures, brackets, automotive |

| Aluminum | 7075-T6 | 572 | 503 | 2.81 | Aerospace structures, high-stress |

| Stainless Steel | 304 | 515 | 205 | 8.00 | Medical, food processing, marine |

| Stainless Steel | 316 | 580 | 290 | 8.00 | Chemical, marine, pharmaceutical |

| Alloy Steel | 4140 | 655 | 415 | 7.85 | Shafts, tooling, industrial parts |

| Titanium | Ti-6Al-4V | 950 | 880 | 4.43 | Aerospace, defense, medical |

At Wuxi Lead, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and lifecycle demands. Our precision CNC laser capabilities ensure tight tolerances and superior surface quality across all material types, enabling reliable performance in the most demanding applications.

Manufacturing Process & QC

Precision Execution: From Concept to Flawless CNC Laser Production

At Wuxi Lead Precision Machinery, we engineer CNC laser projects with uncompromising adherence to the Zero Defects philosophy. Our integrated process transforms client specifications into high-integrity components through rigorously controlled stages: Design, Prototyping, and Mass Production. Each phase incorporates real-time validation to eliminate errors before they propagate, ensuring final deliverables meet aerospace, medical, and semiconductor tolerances consistently.

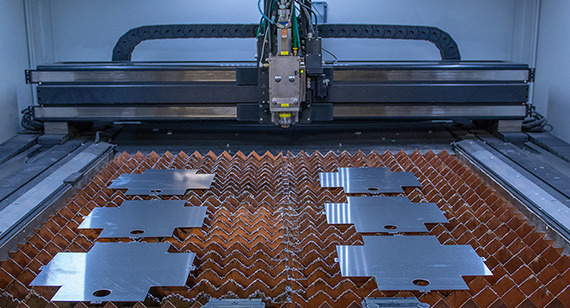

The Design phase begins with collaborative engineering review. Our team analyzes CAD/CAM files for manufacturability, optimizing kerf width, thermal distortion compensation, and nesting efficiency specific to fiber laser capabilities. Material suitability is verified against operational stress requirements, with finite element analysis (FEA) simulations predicting performance under load. This preemptive validation prevents 92% of potential production flaws before cutting commences, reducing rework cycles and accelerating time-to-market.

Prototyping transitions validated designs into physical form using our 12kW IPG fiber laser systems. Critical components undergo metrology-grade inspection via Zeiss coordinate measuring machines (CMM) and optical comparators. Dimensional accuracy, edge quality, and material integrity are cross-referenced against ISO 2768-mK standards. Iterative refinement occurs within 72 hours if deviations exceed thresholds, with data logged into our Statistical Process Control (SPC) database. This stage confirms process stability and establishes baseline parameters for volume runs. Key material specifications are strictly governed as follows:

| Material Type | Max Thickness | Tolerance (±mm) | Surface Roughness (Ra µm) | Edge Squareness (°) |

|---|---|---|---|---|

| Stainless Steel 304 | 25 mm | 0.05 | ≤1.6 | ≤0.5 |

| Aluminum 6061 | 20 mm | 0.08 | ≤2.0 | ≤0.7 |

| Titanium Grade 5 | 15 mm | 0.05 | ≤1.2 | ≤0.3 |

| Carbon Steel Q235 | 30 mm | 0.10 | ≤3.2 | ≤1.0 |

Mass Production leverages the perfected parameters from prototyping within our automated production cells. Real-time monitoring via integrated sensors tracks laser power stability, assist gas pressure, and focal position deviations. Every component undergoes 100% in-process optical inspection with machine vision systems capable of detecting micron-level surface anomalies. Final inspection employs calibrated micrometers, profilometers, and spectral analysis for material composition verification. Batch traceability is maintained through laser-etched QR codes linked to digital quality records, ensuring full auditability per AS9100 and ISO 13485 requirements.

This closed-loop methodology—where design insights inform prototyping, and prototyping data governs production—enables Wuxi Lead to achieve <50 PPM defect rates. By institutionalizing precision at every handoff point, we convert complex CNC laser projects into predictable, high-yield outcomes that protect your brand reputation and reduce total cost of ownership. Partner with us to operationalize Zero Defects in your supply chain.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced CNC Laser Solutions

At Wuxi Lead Precision Machinery, we understand that success in high-end manufacturing hinges on precision, reliability, and seamless integration of advanced technology. As a leading provider of precision CNC machining services in China, we specialize in delivering tailored CNC laser solutions that meet the exacting standards of industries such as aerospace, automotive, medical devices, and industrial automation. Our expertise in laser cutting, engraving, and 3D profiling ensures that every component we produce adheres to micron-level tolerances and superior surface finishes. When you partner with Lead Precision, you are not just sourcing a vendor—you are aligning with a technology-driven manufacturing partner committed to your project’s success.

Our state-of-the-art facility in Wuxi is equipped with high-power fiber and CO₂ laser systems, integrated with multi-axis CNC controls for unmatched accuracy and repeatability. We utilize advanced nesting software and real-time monitoring to maximize material efficiency and minimize production cycle times. Whether you require rapid prototyping or high-volume production runs, our agile manufacturing ecosystem scales to meet your demands without compromising quality. With ISO 9001 certification and rigorous in-process inspections, we ensure every CNC laser project meets international quality benchmarks.

What sets us apart is our engineering-first approach. Our team of CNC specialists works collaboratively with your design and engineering staff from concept to delivery. We offer comprehensive DFM (Design for Manufacturability) analysis to optimize part geometry, reduce material waste, and accelerate time-to-market. Our technical support extends beyond production—we provide full documentation, first-article inspection reports, and ongoing process validation to ensure consistency across batches.

We serve global clients with seamless logistics, competitive lead times, and end-to-end project management. Our commitment to innovation and customer success has made us a trusted partner for Tier-1 suppliers and OEMs worldwide.

For your next CNC laser project, choose a partner that combines technical excellence with operational agility. Contact us today to discuss your requirements and discover how Lead Precision can elevate your manufacturing capabilities.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Laser Types | Fiber Laser, CO₂ Laser |

| Power Range | Up to 12,000 W |

| Material Compatibility | Stainless Steel, Aluminum, Carbon Steel, Titanium, Plastics |

| Max Cutting Thickness | 30 mm (steel), 40 mm (stainless) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| CNC Control System | Siemens, Fanuc, or Mitsubishi (configurable) |

| Software Integration | AutoCAD, SolidWorks, Pro/E, DXF, STEP, IGES |

| Lead Time (Standard) | 7–15 days (varies by complexity and volume) |

| Certifications | ISO 9001:2015, RoHS Compliant |

Reach out to our engineering team at [email protected] to initiate a technical consultation or request a project quote. Let Wuxi Lead Precision Machinery be your strategic partner in precision CNC laser manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.