Technical Contents

Engineering Guide: Cnc Las Vegas

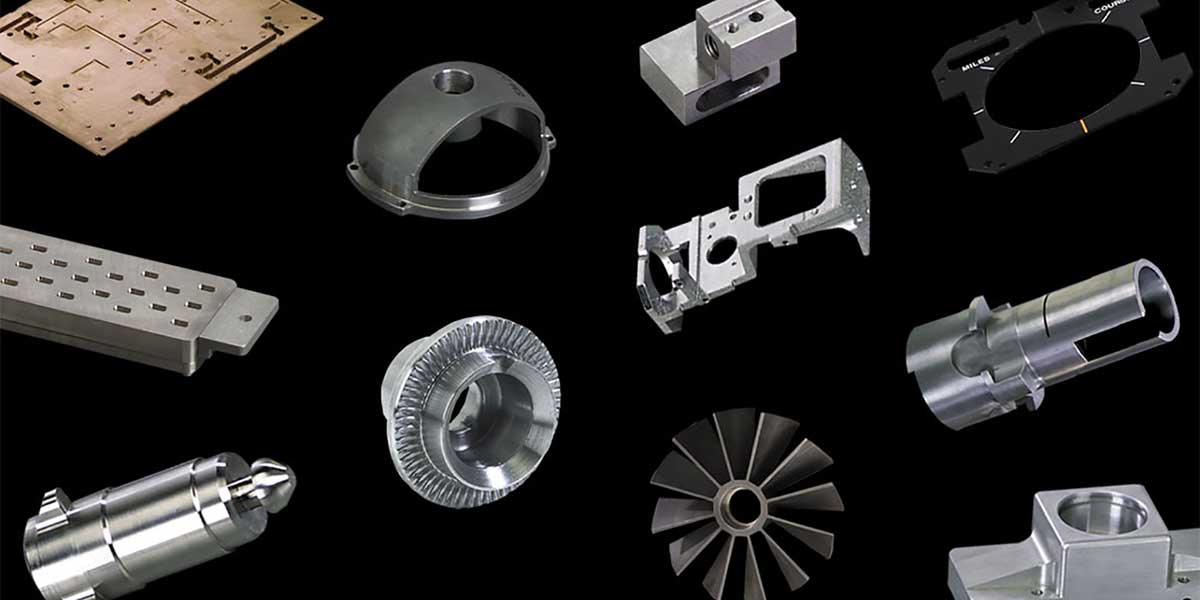

Engineering Insight: The Uncompromising Role of Precision in CNC Machining for Demanding Applications

In high-performance manufacturing environments such as those serving aerospace, defense, and elite industrial sectors, precision is not merely a specification—it is a foundational requirement. When discussing CNC machining in a context like Las Vegas, where advanced manufacturing intersects with innovation in automation, robotics, and defense technology, the margin for error collapses to microns. At Wuxi Lead Precision Machinery, we understand that achieving such levels of accuracy demands more than advanced equipment; it requires decades of engineering discipline, rigorous process control, and a culture rooted in excellence.

Our experience extends beyond commercial production. We have engineered critical components for applications tied to Olympic-standard equipment and military-grade systems—environments where failure is not an option. These projects demand not only tight tolerances but also repeatable consistency across batches, material integrity under extreme conditions, and full traceability from raw stock to final inspection. In such contexts, CNC machining becomes a convergence of art and science, where every micron matters and every surface finish is mission-critical.

Precision begins with machine stability and thermal compensation, but it extends into programming strategy, toolpath optimization, and real-time in-process measurement. At Lead Precision, our CNC machining centers operate under strict environmental controls, with multi-axis capabilities and integrated probing systems that ensure dimensional accuracy down to ±0.002 mm. We utilize high-rigidity spindles, advanced coolant management, and adaptive cutting strategies to maintain part integrity, especially when working with exotic alloys such as Inconel, titanium, and hardened tool steels.

Our engineering team applies deep process knowledge to every project, ensuring that geometric dimensioning and tolerancing (GD&T) are not just met but validated through comprehensive CMM and optical inspection protocols. This level of scrutiny is non-negotiable when producing components for high-stress applications—whether in unmanned aerial systems, precision guidance mechanisms, or high-speed automation used in next-generation manufacturing lines.

The following table outlines key technical capabilities that define our precision CNC machining services:

| Specification | Performance Level |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope (XYZ) | 1,200 × 800 × 600 mm |

| Spindle Speed (Max) | 24,000 rpm |

| Tolerance Range | ±0.002 mm typical |

| Surface Finish (Ra) | 0.4 μm to 1.6 μm (adjustable) |

| Materials Processed | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| CNC Axes | 3-axis, 4-axis, 5-axis simultaneous |

At Wuxi Lead Precision Machinery, we bring this level of precision to every client, regardless of sector. Whether supporting R&D initiatives in the Las Vegas tech corridor or fulfilling serial production for defense integrators, our commitment remains unchanged: deliver components where precision is proven, not promised.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

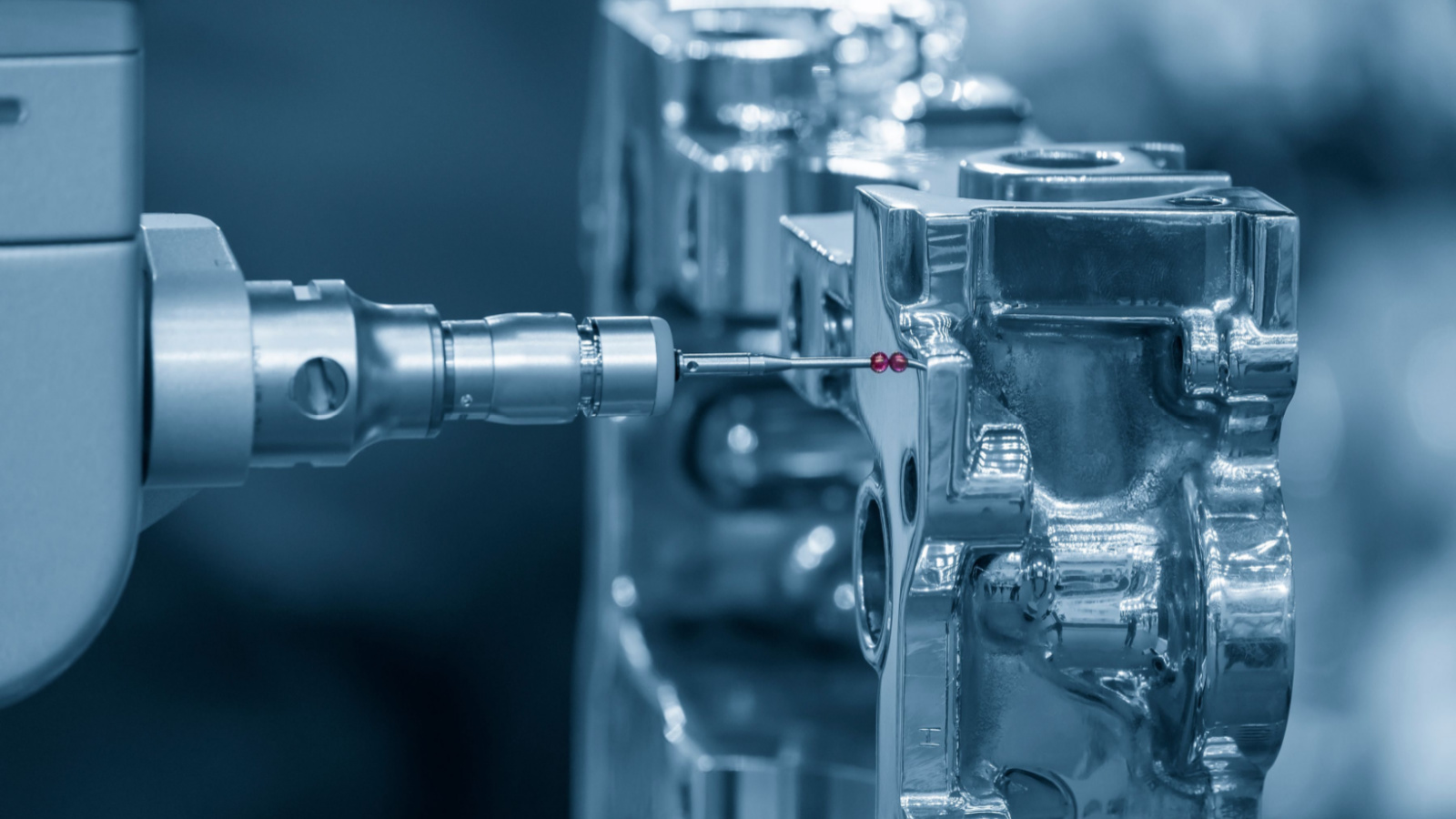

Wuxi Lead Precision Machinery delivers micron-level precision through advanced 5-axis CNC machining centers, engineered to meet the stringent demands of aerospace, medical, and energy sectors. Our HAAS UMC-750 and DMG MORI CMX 600 V eco platforms feature simultaneous 5-axis interpolation, enabling complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures while reducing lead times by up to 40%. Machines operate within a climate-controlled 20±1°C facility, utilizing high-rigidity spindles (15,000 RPM) and FANUC 31i-B5 controls for thermal stability during extended production runs. Material expertise spans titanium alloys (Grade 5), Inconel 718, 17-4 PH stainless steel, and aluminum 7075-T6, with optimized toolpaths for hard-to-machine composites.

Quality assurance is non-negotiable. Every component undergoes rigorous validation via Zeiss CONTURA G2 CMM systems with VAST XXT scanning probes, achieving measurement uncertainties of ±1.9 + L/300 µm. First-article inspections include full GD&T analysis per ASME Y14.5 standards, while in-process checks leverage Renishaw OMP60 probes for real-time tool wear compensation. Our ISO 17025-accredited lab performs surface roughness verification (Ra 0.4 µm achievable), hardness testing, and metallurgical analysis to ensure conformance to MIL-STD-883 and ASTM F2924 specifications. Traceability is maintained through integrated MES software, logging machine parameters, tool life data, and inspection results for full production transparency.

Critical dimensional tolerances are consistently maintained across production volumes as detailed below:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | CMM / Optical Comparator |

| Positional (Holes) | ±0.05 mm (±0.002″) | ±0.01 mm (±0.0004″) | CMM with Scanning Probe |

| Angular | ±0.1° | ±0.02° | CMM / Sine Bar |

| Surface Roughness | Ra 1.6 µm (63 µin) | Ra 0.4 µm (16 µin) | Profilometer |

| Flatness | 0.05 mm (0.002″) | 0.01 mm (0.0004″) | CMM / Granite Surface Plate |

Our process excellence extends beyond equipment. Dedicated engineering teams collaborate during DFM stages to optimize part orientation, minimize secondary operations, and recommend cost-saving material allowances without compromising integrity. All operators complete 200+ hours of certified training on 5-axis programming (Mastercam Multiaxis) and geometric tolerance interpretation. For mission-critical components, we implement SPC charting on key characteristics, with CpK ≥1.67 guaranteed. This integrated approach ensures zero-defect delivery for components requiring absolute geometric fidelity—whether producing turbine blades with 0.008 mm profile tolerances or surgical implant threads with M6x1 precision. Partner with confidence knowing your most complex designs are manufactured to the highest global standards.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

In high-precision CNC machining, material selection directly impacts performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining critical components from aluminum, steel, and titanium—each offering unique mechanical properties suited to specific industrial applications. Understanding the strengths and limitations of these materials ensures optimal part functionality across aerospace, automotive, medical, and industrial sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is commonly used in structural and prototyping applications due to its weldability and moderate strength. For higher performance demands, 7075-T6 offers superior strength, making it ideal for aerospace components. Aluminum’s low density reduces part weight without sacrificing rigidity, a critical factor in dynamic systems.

Steel, particularly alloy and stainless variants, delivers high tensile strength, wear resistance, and thermal stability. 4140 steel is frequently selected for high-stress mechanical components such as shafts and gears, thanks to its hardenability and fatigue resistance. Stainless steel 304 and 316 are preferred in medical and food-processing equipment due to their excellent corrosion resistance and compliance with hygiene standards. While heavier than aluminum, steel provides unmatched durability under extreme loads and elevated temperatures.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for mission-critical applications where strength, light weight, and resistance to extreme environments are paramount. Its exceptional performance in high-temperature and corrosive environments makes it indispensable in aerospace, defense, and biomedical implants. However, titanium’s low thermal conductivity and high chemical reactivity present machining challenges, requiring specialized tooling and precise process control—expertise that Wuxi Lead Precision Machinery has perfected over years of high-tolerance production.

Surface Finish: Enhancing Performance with Anodizing

For aluminum components, anodizing is the preferred surface treatment to improve wear and corrosion resistance. Type II (sulfuric acid) anodizing provides a durable, decorative finish with the option for color dyeing, commonly used in consumer-facing and industrial enclosures. Type III, or hard anodizing, produces a thicker, harder oxide layer, significantly enhancing surface hardness and abrasion resistance—ideal for aerospace and automotive parts exposed to high friction.

Our CNC machining process integrates material expertise with advanced finishing techniques, ensuring components meet exact mechanical, thermal, and aesthetic requirements. By pairing the right base material with appropriate surface treatment, we deliver precision parts that perform reliably in the most demanding environments.

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Machinability |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, automotive, enclosures | Excellent |

| Steel | 4140, 304, 316 | 655–900 | 7.8–8.0 | Shafts, medical devices, tools | Moderate |

| Titanium | Ti-6Al-4V (Gr 5) | 900–1,000 | 4.4 | Aircraft, implants, defense | Challenging |

Manufacturing Process & QC

Precision Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability, specifically designed to meet the stringent demands of aerospace, medical, and defense sectors served through platforms like CNC Las Vegas. We implement a rigorously controlled closed-loop system spanning Design, Prototyping, and Mass Production, with Zero Defects as the non-negotiable outcome.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the CAD/CAM phase, utilizing advanced simulation software to identify potential machining challenges, optimize toolpaths, and ensure geometric feasibility before any material is cut. This proactive approach eliminates costly errors downstream, validates tolerance stack-ups, and confirms that the design aligns with our high-precision capabilities and material constraints. Critical features are flagged for enhanced inspection protocols at this stage.

Prototyping is not merely a validation step; it is the critical proving ground for our Zero Defects commitment. Using the exact production-grade Haas and DMG MORI CNC machining centers intended for volume runs, we manufacture initial parts under full production parameters. Every prototype undergoes exhaustive metrology-grade inspection using Zeiss CMMs, optical comparators, and surface finish testers against the original CAD model and client specifications. First-article inspections (FAI) per AS9102 standards are standard practice. Data from this phase refines the process, confirms capability indices (Cp/Cpk > 1.67), and establishes the definitive inspection plan for mass production. Only when the prototype batch consistently meets all specifications with zero deviations do we proceed.

Mass Production leverages the validated process with relentless statistical process control (SPC). Real-time monitoring of critical parameters—tool wear, spindle load, temperature, and positional accuracy—is integrated directly from our CNC machines. Automated in-process gaging at key stages provides immediate feedback, triggering automatic tool compensation or process adjustment before non-conformities can occur. Every component undergoes 100% dimensional verification of critical features using calibrated instruments, with full traceability from raw material lot to finished part. Our ISO 9001 and AS9100 certified quality management system ensures every action is documented, auditable, and focused on preventing defects, not merely detecting them. This systematic execution guarantees statistically validated process capability and consistent zero-defect output.

Key Production Capabilities for Zero-Defect Manufacturing

| Parameter | Capability Range | Measurement Standard | Process Control Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.0002″ (5µm) standard | Zeiss CMM, Optical Comparator | Real-time SPC, Automated Gaging |

| Surface Finish | Ra 0.1 µm (4 µin) achievable | Profilometer | In-process verification |

| Materials | Aluminum, Titanium, Inconel, Stainless Steels, Plastics | Material Certificates (MTR) | Lot traceability, Pre-use verification |

| Inspection Coverage | 100% Critical Features | AS9102 FAI, PPAP Level 3 | Automated data collection |

| Process Capability | Cp/Cpk ≥ 1.67 sustained | Statistical Analysis | Real-time machine monitoring |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence in Las Vegas

When your manufacturing operations in Las Vegas demand precision, consistency, and speed, partnering with Wuxi Lead Precision Machinery ensures you gain a competitive edge. As a globally recognized leader in high-end CNC machining solutions, we deliver advanced manufacturing capabilities tailored to the rigorous demands of aerospace, medical, automotive, and industrial equipment sectors. Our engineering expertise, combined with state-of-the-art production facilities in China, positions us as the ideal strategic partner for U.S.-based enterprises seeking reliable, scalable, and precision-driven component manufacturing.

At Lead Precision, we understand that success in modern manufacturing hinges on precision tolerances, rapid turnaround, and unwavering quality control. Our CNC machining centers operate with micron-level accuracy, supported by ISO 9001-certified processes and real-time inspection protocols. Whether you require complex 5-axis milling, high-speed turning, or multi-axis Swiss machining, our team engineers every project with your end application in mind. We specialize in low-volume prototyping to high-volume production runs, ensuring seamless scalability without compromising quality.

Our commitment extends beyond machining. We offer comprehensive DFM analysis, material sourcing, surface treatment integration, and just-in-time logistics to support your supply chain efficiency. By leveraging our advanced automation and ERP-integrated workflow, we maintain full traceability and transparency from quote to delivery—critical for industries where compliance and repeatability are non-negotiable.

For Las Vegas and broader North American clients, Lead Precision bridges the gap between Chinese manufacturing capacity and Western engineering standards. We eliminate the traditional barriers of distance and communication through dedicated project managers, real-time reporting, and English-first customer support. Our clients benefit from reduced lead times, cost-effective production models, and a partner who aligns with U.S. quality expectations and delivery timelines.

Explore the technical capabilities that define our service excellence:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis to 5-axis milling, turning, Swiss machining, multi-tasking |

| Tolerance | Up to ±0.001 mm |

| Materials | Aluminum, stainless steel, titanium, brass, plastics (PEEK, Delrin), and exotic alloys |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), turning up to Ø300 mm |

| Surface Finishes | As-machined, anodizing, plating, powder coating, passivation |

| Quality Standards | ISO 9001:2015, full CMM inspection, first-article reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means choosing a team that treats your projects as mission-critical. We are committed to delivering precision, on time, every time. For engineering collaboration, quotations, or technical consultation, contact us today at [email protected]. Let Lead Precision become your trusted extension in high-performance CNC manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.