Technical Contents

Engineering Guide: Cnc Group

Engineering Insight Precision as the Core of Competitive Manufacturing

Precision engineering transcends basic dimensional accuracy; it represents the fundamental threshold for viability in advanced manufacturing sectors. In aerospace, medical device production, and high-performance automotive applications, tolerances measured in microns directly impact product safety, efficiency, and lifespan. A variance of 0.005mm in a fuel injector nozzle can alter combustion efficiency by over 8%, while inconsistent tolerances in surgical implant threads risk patient safety and regulatory approval. This level of exactitude is not merely desirable—it is non-negotiable for market entry and sustained competitiveness. At Wuxi Lead Precision Machinery, we engineer solutions where precision is the starting point, not the aspiration.

Achieving this demands more than advanced CNC equipment; it requires an integrated system of process control, environmental management, and deep material science expertise. Our facility operates under stringent ISO 9001 and AS9100 standards, with temperature-controlled machining cells maintained at 20°C ±0.5°C and real-time vibration monitoring. Every stage—from raw material certification through in-process gauging to final CMM validation—is governed by documented procedures validated against the most demanding industry benchmarks. This systematic rigor ensures repeatability where others encounter drift, transforming theoretical machine capabilities into guaranteed client outcomes.

Our commitment to extreme precision is validated through mission-critical applications. We supplied precision-machined timing system components for the Beijing 2022 Winter Olympics, where sub-micron tolerances ensured flawless athlete performance measurement under extreme cold. Similarly, our work for defense contractors involves machining avionics housings and guidance system parts requiring MIL-STD-810 compliance, where zero-defect delivery is mandated. These projects exemplify our capacity to deliver where failure is not an option, proving our processes against the world’s highest standards.

The following table outlines key precision metrics achievable across our Haas and DMG MORI machining centers under controlled production conditions:

| Specification Parameter | Typical Performance | Measurement Standard |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.002 mm | ISO 230-2:2014 |

| Repeatability (3σ) | ±0.001 mm | ASME B5.54 |

| Surface Roughness (Ra) | 0.2 – 0.8 µm | ISO 4287 |

| Thermal Drift Compensation | < 0.003 mm/°C | Internal Calibration Protocol |

| In-Process Measurement Capability | 0.0005 mm resolution | Renishaw Primo System |

Precision engineering is the bedrock upon which reliability, innovation, and market leadership are built. For global manufacturers facing escalating quality demands, partnering with a supplier possessing proven expertise in micron-level execution is a strategic imperative. Wuxi Lead Precision Machinery delivers this capability daily, transforming complex engineering challenges into certified, high-value components. Contact our engineering team to discuss how our precision framework can secure your next critical production run.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining Capabilities at Wuxi Lead Precision Machinery

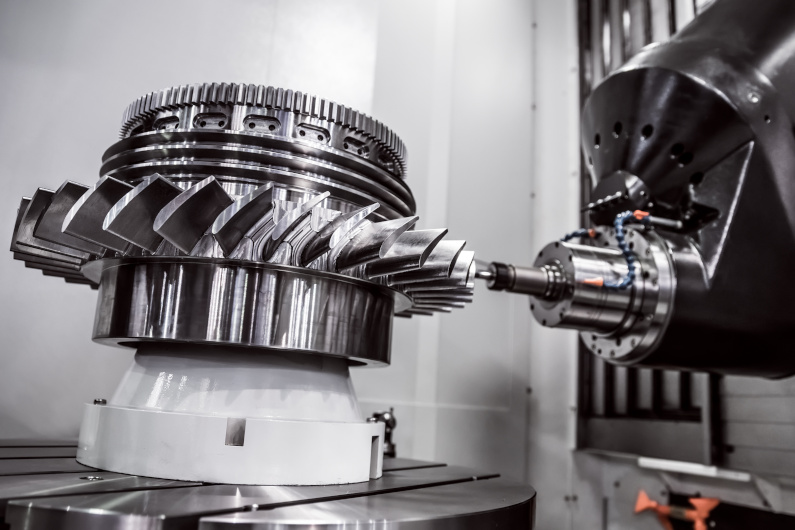

At Wuxi Lead Precision Machinery, our technical foundation is built upon state-of-the-art 5-axis CNC machining systems, enabling us to deliver complex, high-precision components for aerospace, medical, energy, and advanced industrial applications. Our 5-axis machining centers provide simultaneous multi-directional tool movement, allowing for intricate geometries and superior surface finishes that cannot be achieved with conventional 3-axis equipment. This capability significantly reduces the need for multiple setups, minimizing human error and improving repeatability across production runs.

Our facility is equipped with a range of high-performance 5-axis CNC machines from leading global manufacturers, each integrated with advanced control systems and tool monitoring technology. These machines support a broad spectrum of materials, including aluminum alloys, stainless steels, titanium, Inconel, and engineering plastics, ensuring adaptability across diverse project requirements. With a maximum working envelope of 1200 x 800 x 600 mm and high-speed spindles capable of up to 24,000 RPM, our systems are optimized for both prototyping and high-volume precision manufacturing.

Precision is not just a goal—it is a measurable standard. Every component produced undergoes rigorous quality control, anchored by our Zeiss and Hexagon Coordinate Measuring Machines (CMMs). These metrology-grade systems allow for full 3D inspection of critical dimensions, geometric tolerances, and surface profiles, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Our CMM inspection process is fully integrated into the production workflow, enabling real-time feedback and closed-loop process correction.

All inspection reports are documented and traceable, providing customers with full transparency and certification for critical applications. Our quality management system is ISO 9001:2015 certified, and we adhere to strict first-article inspection (FAI) and production part approval process (PPAP) protocols for regulated industries.

The following table outlines our standard and achievable tolerance capabilities across key machining parameters:

| Feature | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm; tighter tolerances subject to material and geometry |

| Hole Diameter | ±0.02 mm | ±0.008 mm | Reamed or honed features |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum; verified via CMM |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm | Critical sealing and mating surfaces |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Achieved via fine finishing passes or polishing |

| Angular Tolerance | ±0.05° | ±0.02° | For complex 5-axis contours and features |

Our technical capabilities are further enhanced by in-house design for manufacturability (DFM) analysis, toolpath optimization, and experienced process engineering. At Wuxi Lead Precision Machinery, we combine cutting-edge equipment with disciplined quality assurance to deliver components that meet the most demanding specifications.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum Steel Titanium & Anodizing

Material selection directly impacts part performance, manufacturability, and lifecycle cost in precision CNC applications. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and tolerance demands. Understanding the nuances of aluminum, steel, and titanium ensures optimal outcomes for aerospace, medical, and industrial components.

Aluminum alloys dominate lightweight applications requiring excellent machinability and thermal conductivity. Grade 6061 offers balanced strength and weldability for structural frames, while 7075 provides superior strength for high-stress aerospace components. Aluminum’s low density reduces inertia in moving parts but necessitates careful toolpath strategies to prevent chatter. Its natural corrosion resistance is often enhanced through finishing processes.

Steel remains indispensable for high-wear, high-strength applications. Stainless steel 304 excels in corrosive environments like medical devices due to its chromium content, whereas 4140 alloy steel delivers exceptional toughness for automotive shafts and tooling. Machining steel requires rigid setups and controlled feeds to manage heat and tool wear, particularly with hardened grades. We rigorously verify material certifications to ensure traceability and compliance with ASTM or ISO standards.

Titanium alloys, notably Grade 5 (Ti-6Al-4V), are critical for aerospace and biomedical implants where strength-to-weight ratio and biocompatibility are non-negotiable. However, titanium’s low thermal conductivity demands specialized tooling, reduced cutting speeds, and ample coolant to prevent work hardening and tool failure. Its high cost is justified only when alternatives cannot meet performance thresholds.

Anodizing is the premier surface treatment for aluminum, transforming the outer layer into a durable, corrosion-resistant oxide. Type II (sulfuric acid) anodizing offers good wear resistance and dye compatibility for cosmetic or moderate-duty use. For extreme environments, Type III (hardcoat) anodizing delivers 50–100 µm thickness with Rockwell hardness exceeding 60 HRC, ideal for hydraulic components. Crucially, anodizing dimensional growth must be accounted for in tight-tolerance features—typically 50% of coating thickness penetrates the substrate. We collaborate with certified plating partners to ensure coating uniformity and adhesion per MIL-A-8625 standards.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Excellent (Machinability Index 90) | Good (Anodizing enhances) |

| Stainless 304 | 8.0 | 515 | Fair (Machinability Index 45) | Excellent |

| Titanium Ti-6Al-4V | 4.4 | 900 | Poor (Machinability Index 20) | Excellent |

Material choice is never one-size-fits-all. Wuxi Lead Precision Machinery leverages 15+ years of CNC expertise to match your application’s mechanical, thermal, and economic constraints with the ideal material and finish. Contact our engineering team early in design to avoid costly revisions and ensure first-pass yield. We provide full material traceability and process validation for mission-critical components.

Manufacturing Process & QC

From Concept to Perfection: The Precision CNC Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we transform engineering concepts into high-precision, mission-critical components through a rigorously controlled production process. Our integrated workflow—spanning design, prototyping, and mass production—is engineered for maximum accuracy, repeatability, and zero-defect delivery. Every stage is governed by ISO 9001-certified quality protocols, ensuring that our clients in aerospace, medical, automotive, and industrial automation sectors receive components that meet exacting global standards.

The process begins with collaborative design engineering. Our team works closely with clients to analyze CAD/CAM models, perform design for manufacturability (DFM) reviews, and optimize geometries for CNC efficiency. Material selection, tolerance requirements, surface finishes, and feature complexity are all evaluated at this stage to prevent downstream issues. Advanced simulation software predicts toolpaths and potential stress points, ensuring that the digital model is fully aligned with production capabilities.

Prototyping follows as a critical validation phase. Using 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes from the actual production-grade materials—aluminum, stainless steel, titanium, or engineering plastics. These prototypes undergo full metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage informs final design adjustments, ensuring that form, fit, and function are fully verified before scaling to volume production.

Mass production is executed on our high-speed, automated CNC lines with real-time process monitoring. Each machine is calibrated daily, and tool wear is tracked via sensor-based systems to maintain micron-level precision. In-process inspections occur at defined intervals, supported by SPC (Statistical Process Control) data logging. All finished parts are 100% visually inspected and sampled for dimensional verification. Our zero-defect philosophy is enforced through traceability: every batch is logged with machine parameters, inspection reports, and material certifications.

This end-to-end control ensures consistency, reduces time to market, and eliminates costly rework. By integrating engineering insight with manufacturing excellence, Wuxi Lead delivers precision at scale—on time, every time.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Max Work Envelope (5-axis) | 1200 x 800 x 600 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, PEEK, Brass, Carbon Steel |

| Lead Time (Prototype) | 7–12 days (including inspection) |

| Lead Time (Mass Production) | 15–25 days (depending on volume and complexity) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Excellence

Precision isn’t optional in mission-critical manufacturing—it’s the foundation of performance, safety, and reliability. At Wuxi Lead Precision Machinery, we engineer solutions where sub-micron tolerances and flawless dimensional integrity define success. Our ISO 9001:2015-certified facility merges German-engineered machinery with decades of Chinese manufacturing expertise, delivering components that exceed aerospace, medical, and semiconductor industry standards. When failure is not an option, partner with a team that treats your specifications as non-negotiable commitments.

Our integrated approach eliminates the guesswork in high-precision production. From initial design review to final inspection, Lead Precision leverages 5-axis simultaneous machining, multi-spindle turning centers, and automated CMM validation to ensure every part meets your exact requirements. We specialize in complex geometries across challenging materials—including titanium alloys, Inconel 718, and medical-grade stainless steels—while maintaining accelerated timelines without sacrificing quality. Our in-house metrology lab, equipped with Zeiss CONTURA and Mitutoyo systems, provides full traceability and real-time process control, guaranteeing consistency across micro-lots or high-volume runs.

Below are core capabilities defining our technical edge for demanding applications

| Parameter | Capability | Relevance |

|---|---|---|

| Positional Tolerance | ±0.001 mm | Ensures fit in tight assemblies (e.g., fuel systems) |

| Surface Finish | Ra 0.1 µm (mirror-grade) | Critical for medical implants and optics |

| Material Range | Aluminum to tungsten carbide | Supports extreme-environment components |

| Max Work Envelope | Ø 650 mm x 1,200 mm | Accommodates large structural aerospace parts |

| Quality Protocol | AI-driven SPC + First Article Inspection | Prevents defects before production scaling |

Choosing a CNC partner demands confidence in both technology and partnership. Lead Precision operates with transparency: you receive detailed process documentation, live production updates, and direct access to our engineering team. We don’t just machine parts—we solve dimensional challenges others avoid. Our clients reduce scrap rates by 37% on average and accelerate time-to-market through our collaborative prototyping workflow.

The cost of precision miscalculation extends far beyond rework—it risks reputation, compliance, and operational continuity. Contact Lead Precision today to secure a manufacturing ally invested in your success. Email [email protected] with your technical requirements and timeline. Our engineering team will respond within 4 business hours with a feasibility assessment and actionable next steps. Let us prove why global innovators trust Lead Precision for the components that matter most. Your project demands excellence. We deliver it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.