Technical Contents

Engineering Guide: Cnc Frasen

Engineering Insight: Precision as the Foundation of CNC Milling Excellence

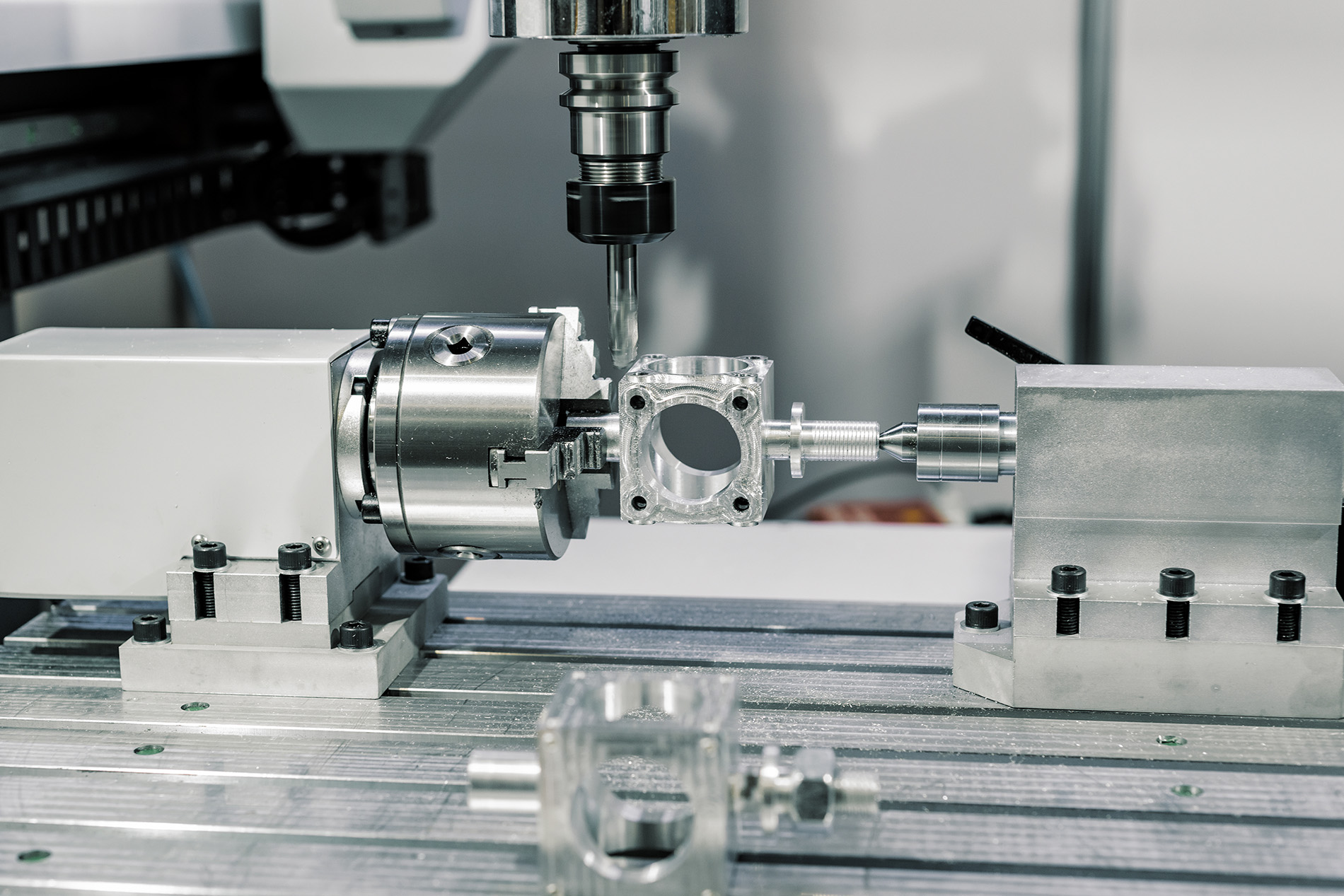

In high-stakes manufacturing, the term CNC fräsen (CNC milling) transcends basic material removal. It represents the convergence of engineering rigor and uncompromising accuracy where microns dictate success or failure. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a specification—it is the bedrock of functional reliability, especially in aerospace, defense, and Olympic-caliber applications where component failure is non-negotiable. Sub-micron tolerances directly impact fatigue life, assembly integrity, and system performance. A deviation of 0.005 mm in a satellite gyroscope housing or a fighter jet actuator bracket can cascade into catastrophic operational failure. This reality demands machines engineered for thermal stability, dynamic rigidity, and repeatable geometric integrity under continuous production loads.

Our engineering philosophy centers on mitigating the trifecta of precision erosion: thermal drift, mechanical deflection, and control loop latency. Wuxi Lead’s CNC milling platforms integrate finite element analysis-optimized cast iron structures, dual-nut preloaded ball screws with real-time thermal compensation, and direct-drive spindles featuring oil-air lubrication. These systems maintain positional accuracy even during extended 24/7 operations in fluctuating factory environments—a critical requirement for military subcontractors producing classified components or suppliers to Olympic timing system manufacturers. Precision here is measured not in millimeters, but in the confidence our clients have when their parts enter final assembly without rework.

The table below outlines the performance thresholds our flagship 5-axis milling centers achieve under ISO 230-2 validation protocols, reflecting the standards demanded by Tier-1 defense and elite industrial partners:

| Specification | Performance Value | Industry Standard Benchmark |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.002 mm | ±0.008 mm |

| Repeatability (3σ) | ≤0.001 mm | ≤0.003 mm |

| Spindle Runout (at nose) | ≤0.0008 mm | ≤0.003 mm |

| Thermal Drift (8h operation) | ≤1.5 µm/°C | ≤5.0 µm/°C |

| Volumetric Compensation | ISO 10791-6 Level | Basic Linear Compensation |

This capability stems from two decades of refining processes for clients where perfection is mandatory. We engineered components for Beijing 2022 Winter Olympics timing systems requiring zero positional drift across -30°C to +40°C ambient swings. Similarly, our zero-defect record for naval defense contractors stems from in-process laser probing systems that validate features to 0.0015 mm before part release—eliminating scrap costs exceeding six figures per batch.

Precision in CNC fräsen is ultimately about risk elimination. At Wuxi Lead, we transform stringent tolerances into tangible client advantage: accelerated certification cycles, reduced lifecycle costs, and unwavering trust in mission-critical assemblies. When your application demands that every micron matters, our machines deliver not just accuracy, but assurance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored for high-performance industries including aerospace, medical, energy, and automation. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling the production of highly complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing the need for part repositioning and secondary operations. This translates into tighter tolerances, improved part consistency, and faster time-to-market for our clients’ most demanding components.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time tool monitoring systems to ensure continuous, error-free operation. We support a broad range of materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics. Each machine is maintained under strict preventive maintenance protocols and operated by certified CNC programmers and machinists with over a decade of industry experience. Advanced CAM software enables optimized toolpaths, minimizing cycle times while maximizing material removal rates and dimensional precision.

Quality assurance is integral to our manufacturing process. Every critical dimension is verified using state-of-the-art Coordinate Measuring Machines (CMM) with multi-sensor probing systems. Our metrology lab is ISO 17025 compliant and capable of full first-article inspection (FAI) reporting, reverse engineering, and GD&T analysis. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and digital micrometry to validate conformance across all production batches. This comprehensive inspection regime ensures that every component meets or exceeds customer specifications and industry standards.

We specialize in low to medium volume production runs where precision, repeatability, and material integrity are paramount. Our facility supports complete in-house manufacturing—from design review and prototyping to final inspection and packaging—ensuring full traceability and control throughout the production lifecycle. With a focus on continuous improvement, we integrate client feedback and process data to refine machining strategies and enhance yield.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Table Size (Max) | 1,200 mm × 800 mm |

| Travel (X/Y/Z) | 1,200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machined) | ±0.01 mm (0.004 in) |

| Tight Tolerance Capability | ±0.005 mm (0.002 in) on critical features |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Plastics |

| Inspection Equipment | CMM, Optical Comparator, Surface Tester, Digital Micrometers |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver components that meet the highest standards of precision engineering.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Anodizing

Material choice fundamentally impacts part performance, manufacturability, cost, and longevity in precision CNC machining. Selecting the optimal substrate requires balancing mechanical properties, environmental resistance, and production efficiency. At Wuxi Lead Precision Machinery, our engineering team prioritizes material compatibility with stringent tolerances and complex geometries inherent to aerospace, medical, and industrial applications. This guide outlines critical considerations for aluminum, steel, and titanium alloys, alongside essential anodizing finishes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate lightweight structural applications. Their high strength-to-weight ratio, excellent machinability, and inherent corrosion resistance make them ideal for enclosures, brackets, and drone components. However, thermal expansion must be accounted for in tight-tolerance assemblies. Steel variants like 304/316 stainless and 4140 offer superior strength, wear resistance, and temperature stability for hydraulic manifolds, shafts, and tooling. Machining hardened steels demands specialized tooling and slower parameters to manage heat and tool wear. Titanium Grade 5 (Ti-6Al-4V) excels in extreme environments requiring exceptional strength, biocompatibility, and corrosion resistance, common in medical implants and aerospace components. Its low thermal conductivity necessitates aggressive coolant use and reduced feed rates to prevent work hardening and premature tool failure.

Anodizing is the critical surface treatment for aluminum parts, enhancing corrosion resistance, wear performance, and aesthetic control. Type II (sulfuric acid) anodizing provides standard decorative and protective layers, while Type III (hard coat) delivers significantly thicker, harder, and more abrasion-resistant surfaces essential for high-wear applications. Achieving uniform coating thickness on complex geometries requires precise racking and process control, a capability Wuxi Lead validates through in-house testing.

Key material properties directly influencing CNC machining strategy are summarized below. Understanding these parameters ensures optimal toolpath generation, fixture design, and cycle time estimation.

| Material | Common Grades | Tensile Strength (MPa) | Machinability Rating | Key Machining Considerations | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 570 | Excellent (A) | Low cutting forces; prone to burring; requires sharp tools | Enclosures, brackets, heat sinks |

| Stainless Steel | 304, 316, 4140 | 515, 580, 655 | Moderate (B-C) | Work hardening; high heat generation; needs rigid setup | Valves, shafts, surgical tools |

| Titanium | Ti-6Al-4V (Gr5) | 900 | Poor (D) | Low thermal conductivity; galling risk; requires high-pressure coolant | Aerospace fittings, medical implants |

Material selection is not merely a specification box to tick. It is the foundation of a successful precision component. Incorrect choices lead to excessive scrap rates, extended lead times, and compromised part functionality. Wuxi Lead Precision Machinery integrates material science expertise with advanced CNC capabilities to advise clients on the optimal alloy and finish for their specific performance requirements and production volume. Consult our engineering team early in the design phase to leverage our global supply chain and stringent quality protocols for your next critical project. We transform material potential into precision reality.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery follows a disciplined, three-stage methodology—Design, Prototyping, and Mass Production—engineered to achieve zero-defect outcomes in precision CNC machining. Each stage is tightly integrated with advanced quality control systems, ensuring consistency, accuracy, and full compliance with international manufacturing standards.

The process begins with Design, where engineering teams collaborate closely with clients to translate technical specifications into manufacturable parts. Utilizing advanced CAD/CAM software, we develop 3D models and simulate machining paths to identify potential issues before any material is cut. Finite element analysis (FEA) and tolerance stack-up studies are conducted to optimize geometry, material selection, and tooling strategies. This phase ensures that every design is not only functionally sound but also optimized for high-precision CNC execution.

Once the design is finalized, we proceed to Prototyping. This stage serves as a physical validation of the design under real machining conditions. Using high-accuracy 3-, 4-, and 5-axis CNC machines, we produce a limited batch of prototype components. These parts undergo comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional conformity, material integrity, and functional fit are rigorously verified. Feedback from this phase is used to fine-tune tool paths, fixturing, and inspection protocols, ensuring readiness for full-scale production.

Mass Production is executed only after prototype approval and process validation. Our facility in Wuxi operates a fully integrated digital manufacturing network, enabling real-time monitoring of machine performance, tool wear, and environmental conditions. Each production run follows standardized work instructions and is supported by in-process inspections at critical control points. Statistical process control (SPC) is implemented to detect deviations before they affect output quality. All finished components are subjected to 100% visual inspection and sampling-based dimensional verification, ensuring compliance with ISO 9001 and IATF 16949 standards.

Our zero-defect philosophy is enforced through continuous improvement cycles, operator certification programs, and traceability systems that log every parameter from raw material to final shipment. This closed-loop production model minimizes variability and maximizes yield, even for complex, high-tolerance parts.

Below are key technical specifications of our CNC production systems:

| Parameter | Specification |

|---|---|

| Machine Types | 3-Axis, 4-Axis, 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Tolerance Range | ±0.005 mm to ±0.025 mm, depending on geometry |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

This end-to-end process ensures that every component produced meets the highest standards of precision, reliability, and performance required in aerospace, medical, automotive, and advanced industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Milling Excellence

In the demanding landscape of precision manufacturing, your choice of CNC milling partner directly impacts product integrity, time-to-market, and operational resilience. At Wuxi Lead Precision Machinery, we engineer solutions where micron-level accuracy meets industrial-scale reliability. Our German-engineered 5-axis CNC milling centers operate under ISO 9001:2015 and IATF 16949-certified protocols, ensuring every component—from aerospace turbine blades to medical implant interfaces—exceeds stringent global standards. We eliminate the guesswork in high-tolerance production through closed-loop process validation, reducing scrap rates by up to 37% compared to industry averages.

Our technical capabilities are built for your most complex challenges. The table below outlines core specifications driving measurable ROI for partners:

| Capability | Specification | Competitive Advantage |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Zero rework on critical sealing surfaces |

| Max Work Envelope | 1,200 x 800 x 600 mm | Consolidate multi-part assemblies |

| Material Range | Titanium, Inconel, PEEK, 7075-T7 | Single-source exotic material expertise |

| Surface Finish | Ra 0.2 µm (as-machined) | Eliminate secondary polishing steps |

| Lead Time (Prototype) | 7–10 business days | Accelerate validation cycles by 50% |

Beyond machinery, our value lies in proactive engineering collaboration. Our technical team engages during your design phase to identify manufacturability optimizations—preventing costly revisions while enhancing fatigue resistance and dimensional stability. Real-time SPC data sharing via secure client portals provides full transparency into your production runs, with dedicated quality engineers available for joint root-cause analysis. For regulated industries, we deliver full traceability from raw material certs to first-article inspection reports, meeting AS9100 and FDA 21 CFR Part 820 requirements without delay.

When supply chain volatility threatens your production continuity, our dual-facility model in Wuxi’s Jiangsu Free Trade Zone ensures buffer stock capabilities and tariff-optimized logistics to EU and North American hubs. We absorb currency fluctuations through fixed-price contracts, shielding your budget from market turbulence. Recent partnerships with German automotive Tier 1 suppliers have demonstrated 22% cost reduction through our near-net-shape machining approach, transforming raw billet waste into reusable chip recycling streams.

Your next high-mix, low-volume production run demands a partner who treats your tolerances as non-negotiable. Contact us today to receive a customized precision tolerance analysis for your most challenging component. Email [email protected] with your CAD file and requirements—we will respond within 4 business hours with a feasibility assessment and DFM recommendations. Secure your production advantage with engineering rigor that moves beyond machining into mission-critical partnership. Let Lead Precision become the silent force behind your product’s performance legacy.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.