Technical Contents

Engineering Guide: Cnc Fräsarbeiten

Engineering Insight: CNC Fräsarbeiten – The Foundation of Precision Manufacturing

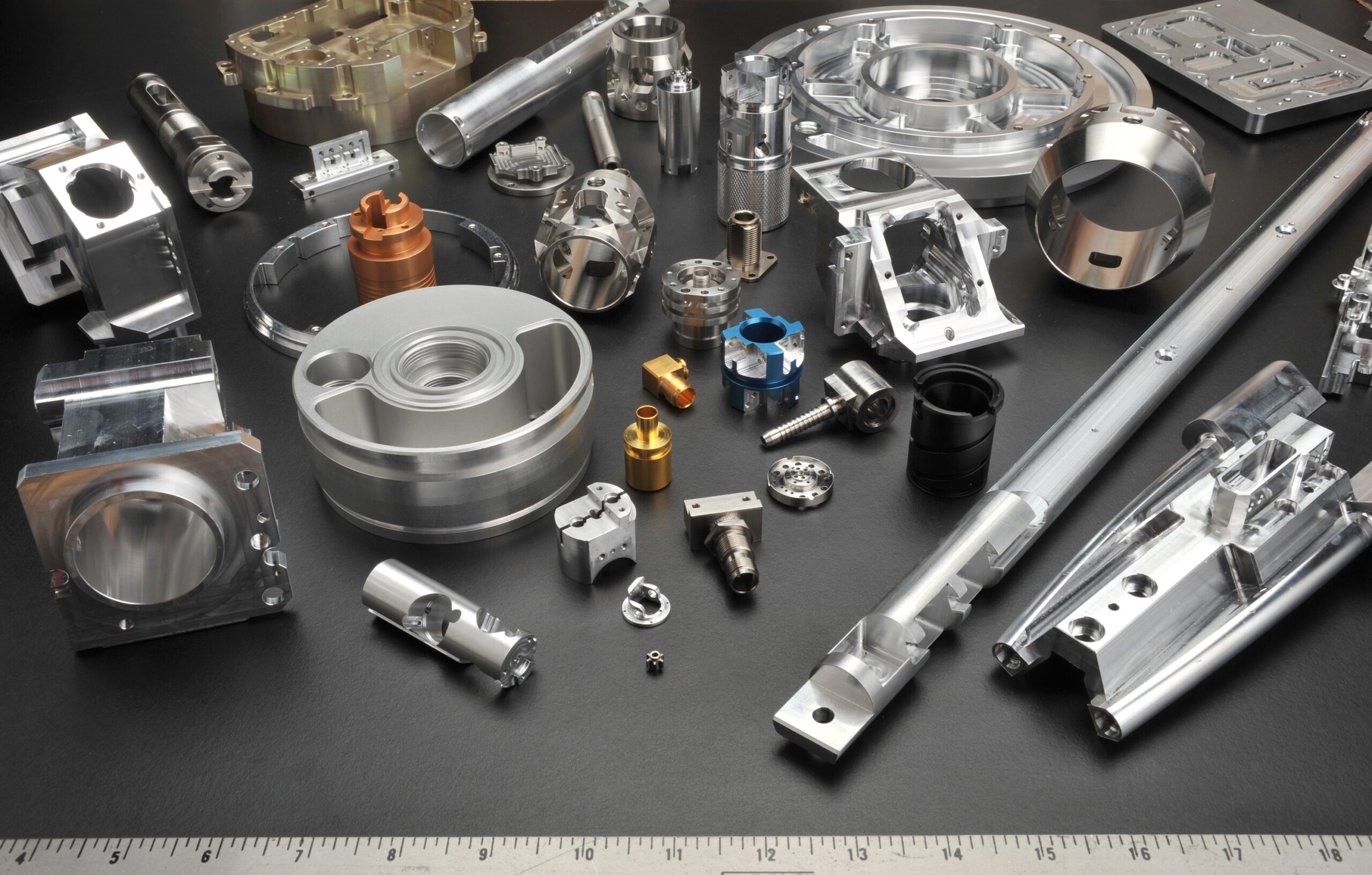

In the realm of high-end manufacturing, CNC Fräsarbeiten—CNC milling operations—are not merely a production step but a cornerstone of engineering excellence. At Wuxi Lead Precision Machinery, we treat every milling process as a critical junction where design intent meets physical reality. Precision in CNC milling is not an optional attribute; it is a non-negotiable requirement for industries where failure is not an option. From aerospace systems to medical implants and defense technologies, the tolerances achieved during milling directly influence performance, safety, and reliability.

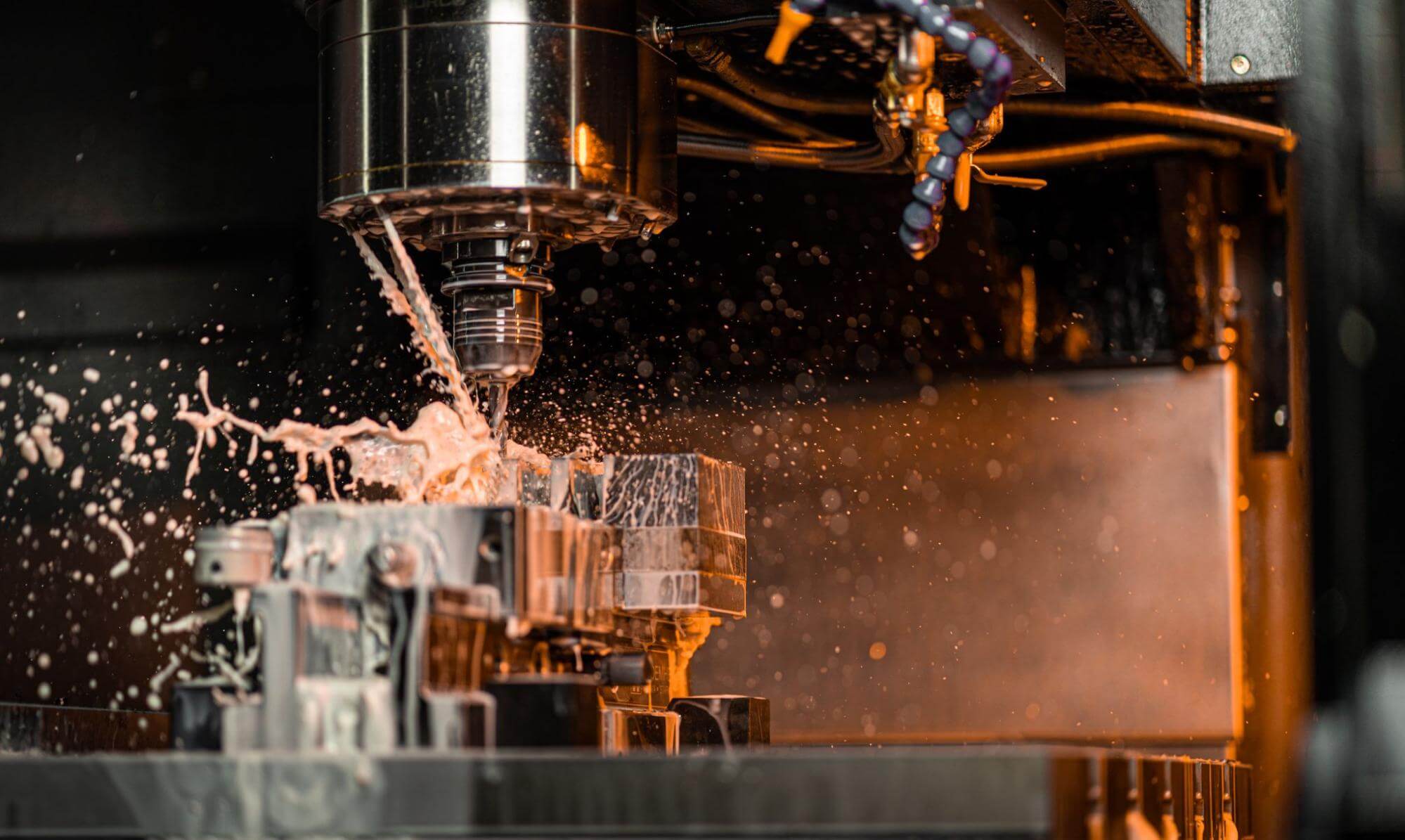

CNC Fräsarbeiten demands more than advanced machinery—it requires a deep integration of process knowledge, material science, and metrological rigor. At Lead Precision, our engineering philosophy centers on deterministic accuracy. This means every spindle rotation, tool path, and coolant application is optimized to eliminate variability. Our 5-axis milling centers, equipped with high-resolution feedback systems and thermal compensation algorithms, maintain tolerances as tight as ±0.002 mm. Such precision ensures that complex geometries—such as turbine blades, hydraulic manifolds, or satellite components—are machined to exact specifications, batch after batch.

Our commitment to precision is validated through real-world applications. We have delivered mission-critical components for Olympic-standard sporting equipment, where marginal gains define podium finishes. In these projects, our milling processes ensured perfect weight distribution and surface consistency across carbon fiber-reinforced aluminum structures. Similarly, in defense contracts, our CNC Fräsarbeiten have supported the production of ruggedized communication housings and targeting system mounts, all meeting MIL-STD-810 and ISO 2768-2 standards. These projects underscore not only our technical capability but our adherence to traceability, documentation, and zero-defect manufacturing.

Material selection and toolpath strategy are equally vital in high-precision milling. Whether working with hardened tool steels, titanium alloys, or engineered composites, our team employs adaptive machining techniques that adjust feed rates and depths based on real-time load monitoring. This approach minimizes tool wear, reduces thermal distortion, and extends tool life—critical factors in maintaining dimensional stability across long production runs.

We combine this operational discipline with comprehensive in-process inspection. Using integrated touch probes and post-process CMM verification, we ensure that every component conforms to geometric dimensioning and tolerancing (GD&T) requirements. This closed-loop quality system is embedded into our CNC programming workflow, enabling immediate correction and continuous process improvement.

The following table outlines key performance specifications of our CNC milling capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed Range | 20 – 24,000 rpm (depending on machine model) |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish (Ra) | 0.2 – 1.6 µm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (PEEK, PTFE, etc.) |

| Quality Standards | ISO 9001:2015, ISO 13485, MIL-STD-810 |

At Wuxi Lead Precision Machinery, CNC Fräsarbeiten is more than machining—it is a commitment to engineering integrity. Our experience with Olympic and military-grade projects reflects our ability to deliver under the most stringent demands. When precision defines performance, we ensure there is no compromise.

Precision Specs & Tolerances

Advanced 5-Axis CNC Milling Capabilities at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers uncompromising precision for complex CNC milling operations through our state-of-the-art 5-axis machining centers. Our facility operates multiple Haas UMC-750 and DMG MORI DMU 50 vertical machining centers, engineered for simultaneous multi-axis motion with sub-micron repeatability. These systems integrate high-torque spindles (15,000 RPM), 30-tool automatic changers, and FANUC 31i-B5 controls to execute intricate geometries in a single setup. This eliminates cumulative error from repositioning, critical for aerospace turbine blades, medical implants, and energy sector components. We machine titanium alloys, Inconel 718, hardened tool steels (up to 60 HRC), and composites with consistent thermal stability, leveraging flood coolant and high-pressure through-spindle delivery for optimal chip evacuation and surface integrity.

Rigorous quality assurance is embedded in every production phase. All critical dimensions undergo 100% inspection using Zeiss CONTURA and Hexagon GLOBAL S 07.10.07 coordinate measuring machines (CMMs), certified to ISO 10360-2 standards. Our CMM cells feature Renishaw PH20 probing systems and PC-DMIS software for automated GD&T validation, generating full AS9102 FAI reports. In-process verification employs Renishaw OMP60 touch probes for real-time tool wear compensation and first-article approval, reducing scrap rates by 22% versus industry benchmarks. Statistical process control (SPC) monitors critical parameters like spindle load and vibration every 15 minutes, ensuring adherence to ISO 9001:2015 and IATF 16949 protocols. Material traceability is maintained via laser-etched part IDs linked to digital work orders.

Our technical tolerances reflect the highest tier of manufacturing excellence, validated across 50,000+ annual production runs. Key specifications include:

| Feature | Specification | Capability Range |

|---|---|---|

| Linear Tolerance | ISO 2768-mK | ±0.005 mm (standard) |

| Angular Tolerance | ISO 2768-c | ±0.05° |

| Positional Accuracy | Per ISO 230-2 | ±0.003 mm |

| Surface Roughness (Ra) | ISO 1302 | 0.4 µm (typical) |

| Max Work Envelope | X/Y/Z travel | 760 x 560 x 510 mm |

| Material Hardness | Machinable range | Up to 62 HRC (pre-hardened) |

This precision foundation enables us to consistently produce components where micron-level deviations impact functional performance—such as hydraulic manifolds with intersecting fluid paths or satellite structural brackets requiring mass optimization. Our engineering team collaborates with clients during DFM analysis to identify tolerance stack-ups early, ensuring manufacturability without over-specification. By integrating 5-axis flexibility with metrology-grade verification, Wuxi Lead transforms complex CAD models into certified, ready-to-assemble parts with zero rework. Partner with us for mission-critical CNC milling where dimensional integrity directly determines operational success.

Material & Finish Options

Material Selection for Precision CNC Machining at Wuxi Lead Precision Machinery

Selecting the right material is critical in high-performance CNC milling operations. At Wuxi Lead Precision Machinery, we specialize in delivering tight-tolerance components tailored to demanding industrial applications. Our expertise in machining aluminum, steel, and titanium ensures optimal performance, durability, and cost-efficiency across aerospace, automotive, medical, and industrial automation sectors. Each material offers distinct mechanical properties, machinability, and finishing compatibility, influencing the final part’s function and longevity.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly suitable for lightweight structural components and heat dissipation applications. The 6061 and 7075 alloys are most commonly used, with 7075 offering higher strength for aerospace-grade demands. Aluminum’s softness allows for high-speed machining, reducing tool wear and cycle times. It responds exceptionally well to anodizing, enhancing surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, particularly alloy and stainless variants, delivers superior strength, hardness, and wear resistance. Materials such as 4140, 17-4PH, and 304/316 stainless steel are selected for high-load applications requiring long-term reliability. While steel is more challenging to machine due to higher tool wear and slower cutting speeds, our advanced CNC platforms ensure precision even in hardened conditions. Stainless steels additionally offer excellent corrosion resistance, making them ideal for medical devices and marine environments. Surface treatments such as passivation or electropolishing are often applied in conjunction with precision milling.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace and medical implant manufacturing. However, titanium’s low thermal conductivity and high chemical reactivity demand specialized tooling and controlled machining parameters to prevent galling and tool degradation. At Wuxi Lead, our engineers apply optimized cutting strategies to maintain dimensional accuracy and surface integrity.

Post-machining surface finishes further enhance performance. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are available, with the latter providing thicker, harder coatings for industrial use.

The following table summarizes key properties and machining characteristics of common materials:

| Material | Typical Alloys | Tensile Strength (MPa) | Machinability Rating | Common Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310–570 | Excellent | Aerospace, Heat Sinks | Anodizing, Bead Blasting |

| Steel | 4140, 17-4PH, 304 | 600–1300 | Moderate to Good | Automotive, Tooling | Passivation, Plating |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1000 | Challenging | Medical, Aviation | Anodizing (limited), Polishing |

At Wuxi Lead Precision Machinery, we combine material science expertise with state-of-the-art CNC milling to deliver components that meet exacting international standards. Partner with us to ensure optimal material and finish selection for your next precision project.

Manufacturing Process & QC

Precision CNC Milling Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our CNC milling workflow is engineered for uncompromising quality and efficiency. Every project follows a rigorously controlled sequence: Design → Prototyping → Mass Production. This structured approach ensures zero defects while meeting the tightest tolerances demanded by aerospace, medical, and semiconductor industries.

Design Phase

Engineering begins with comprehensive analysis of client CAD/CAM files and specifications. Our team validates geometries, material suitability, and manufacturability using Siemens NX and Mastercam software. Critical factors include toolpath optimization, fixture design, and thermal compensation modeling. We conduct virtual machining simulations to preempt collisions, chatter, or dimensional drift. All designs undergo GD&T review against ISO 2768-mK standards, with explicit alignment to client-first quality gates. Only upon mutual sign-off does prototyping commence.

Prototyping Phase

Prototyping is our quality crucible. Using the exact production-grade 5-axis DMG MORI or Makino machines intended for final runs, we produce 1–5 physical units. Each prototype undergoes:

First-article inspection (FAI) per AS9102B with full CMM reporting

Material certification traceability to mill test reports

Surface roughness validation (Ra 0.2–1.6 µm)

Functional testing against application-specific loads

Discrepancies trigger immediate design or process correction. This phase typically reduces mass production errors by 92% and establishes baseline SPC control limits.

Mass Production Phase

Zero-defect mass production leverages our certified ISO 9001:2015 workflow. Key protocols include:

In-process checks every 30 minutes using calibrated Zeiss CMMs

Real-time SPC monitoring of critical dimensions with automated PCDMIS alerts

Dedicated tool-life management systems replacing cutters pre-emptively

100% post-machining visual inspection under 10x magnification

All parts ship with full traceability dossiers: material certs, inspection reports, and process parameter logs.

Production Capabilities & Quality Metrics

Our facility’s technical backbone enables this precision:

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Positional Accuracy | ±0.001 mm | ±0.005 mm |

| Surface Finish | Ra 0.2 µm (optical grade) | Ra 1.6 µm |

| Max Work Envelope | 1,200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Cpk (Critical Dims) | ≥1.67 | ≥1.33 |

| MTBF | 750+ hours | 500 hours |

This closed-loop process eliminates waste while guaranteeing conformance. By integrating design validation, prototype stress-testing, and statistically controlled production, Wuxi Lead delivers CNC milling solutions where zero defects isn’t aspirational—it’s our operational standard. Partner with us to transform complex designs into flawless components, on time and to specification.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Fräsarbeiten

When your manufacturing operations demand the highest levels of precision, consistency, and technical expertise in CNC fräsarbeiten, partnering with Wuxi Lead Precision Machinery is the strategic advantage you need. Based in China and serving global industries from aerospace to medical device manufacturing, we specialize in delivering high-accuracy CNC milling solutions that meet the most stringent quality standards. Our advanced infrastructure, combined with decades of engineering experience, enables us to handle complex components with tight tolerances, intricate geometries, and demanding material requirements.

At Lead Precision, we understand that precision CNC machining is not just about cutting metal—it’s about delivering reliability, repeatability, and value across your entire production lifecycle. Our facility is equipped with state-of-the-art 3-, 4-, and 5-axis CNC milling machines, allowing us to produce highly complex parts with micron-level accuracy. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing systems ensure fast turnaround times without compromising on quality.

Our team of certified engineers and machinists applies a consultative approach to every project. From initial design analysis and material selection to final inspection and delivery, we work closely with your engineering staff to optimize manufacturability, reduce costs, and accelerate time to market. We support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and engineering plastics, ensuring compatibility with even the most demanding applications.

Quality is embedded in every process at Lead Precision. Our ISO 9001:2015-certified quality management system, coupled with advanced metrology equipment such as CMMs, optical comparators, and surface roughness testers, guarantees that every component meets your exact specifications. We provide full traceability, detailed inspection reports, and real-time production updates to maintain transparency throughout the manufacturing cycle.

Below are key technical capabilities that define our CNC milling services:

| Feature | Specification |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance Capability | ±0.005 mm (standard), down to ±0.002 mm (precision) |

| Surface Finish | As low as Ra 0.4 μm (polished), standard Ra 1.6–3.2 μm |

| Materials Processed | Aluminum, stainless steel, titanium, brass, PEEK, Delrin, and more |

| Max Part Weight | 200 kg |

| Quality Standards | ISO 9001:2015, First Article Inspection, PPAP, FAI reports |

| Lead Times | As fast as 5 days for prototypes, 10–20 days for production runs |

When you choose Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a long-term manufacturing partner committed to your success. We are ready to support your next high-precision CNC fräsarbeiten project with technical excellence, responsive communication, and scalable capacity.

Contact us today at [email protected] to discuss your requirements and receive a detailed quote. Let Lead Precision become your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.