Technical Contents

Engineering Guide: Cnc Fixture Plate

Engineering Insight: The Critical Role of Precision in CNC Fixture Plates

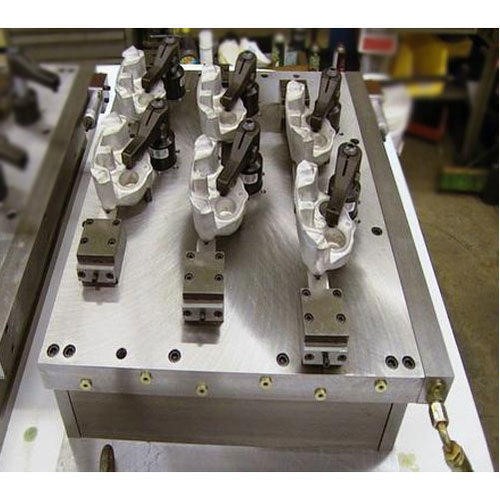

In high-precision CNC machining, the fixture plate is far more than a mounting surface—it is the foundational interface between machine, workpiece, and process repeatability. At Wuxi Lead Precision Machinery, we treat the CNC fixture plate not as a passive component, but as an engineered system integral to dimensional accuracy, tool life, and overall production efficiency. Our decades of experience in serving aerospace, defense, and high-end industrial clients have reinforced a fundamental truth: without a precisely manufactured and meticulously calibrated fixture plate, even the most advanced CNC machine cannot deliver its full potential.

Precision in fixture plate design begins with material selection and extends through every phase of manufacturing. We utilize high-grade aluminum alloys and hardened tool steels, stress-relieved and aged to eliminate internal distortions. Surface flatness is maintained within ±0.005 mm over the entire plate area, ensuring consistent workholding across multiple setups. Threaded hole positioning accuracy is held to ±0.01 mm, enabling seamless integration with modular fixturing systems and zero-point clamping solutions. These tolerances are not arbitrary—they are the result of rigorous process validation and alignment with international standards such as ISO 2768 and DIN 86126.

Our engineering team applies finite element analysis (FEA) during the design phase to anticipate thermal expansion, clamping forces, and dynamic loading conditions. This predictive modeling ensures long-term stability under continuous production cycles. Furthermore, all fixture plates undergo post-machining metrology using coordinate measuring machines (CMMs) and laser interferometry to verify geometric integrity. This closed-loop quality control process is a hallmark of our manufacturing philosophy.

Wuxi Lead Precision Machinery has supplied mission-critical fixture solutions for applications in Olympic-standard sports equipment manufacturing and precision components for military-grade systems. These projects demanded not only extreme accuracy but also full traceability, documentation, and repeatable performance under stringent operational conditions. Our involvement in such high-stakes environments reflects our capability to deliver fixture plates that meet the most exacting requirements.

Whether used in 5-axis milling, high-speed engraving, or automated pallet systems, our CNC fixture plates are engineered for longevity, interchangeability, and micron-level reliability. We understand that in modern manufacturing, setup time is cost, and inconsistency is risk. That is why every plate we produce is a commitment to precision, backed by engineering rigor and real-world performance.

| Specification | Value | Notes |

|---|---|---|

| Material Options | 7075-T6 Aluminum, 42CrMo4 Steel | Stress-relieved and aged |

| Surface Flatness | ±0.005 mm | Over full surface, measured via optical flat |

| Hole Position Accuracy | ±0.01 mm | Per ISO 2768-mK |

| Repeatability (Clamping) | ±0.003 mm | After 10,000 cycles |

| Hardness (Steel Plates) | HRC 48–52 | Through hardening and tempering |

| Surface Treatment | Anodized (Al) / Black Oxide (Steel) | Corrosion and wear resistance |

| Standard Compliance | ISO 2768, DIN 86126, GB/T 1804 | Full inspection report available |

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Fixture Plate Manufacturing

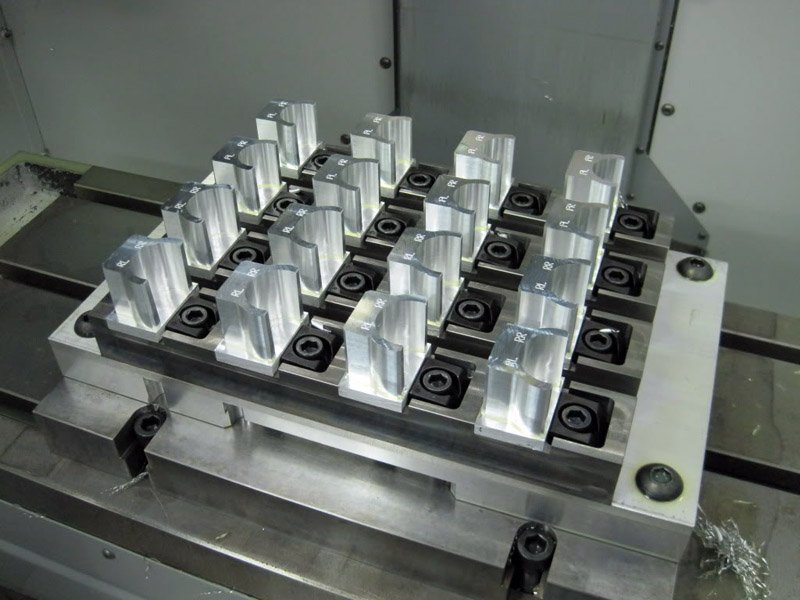

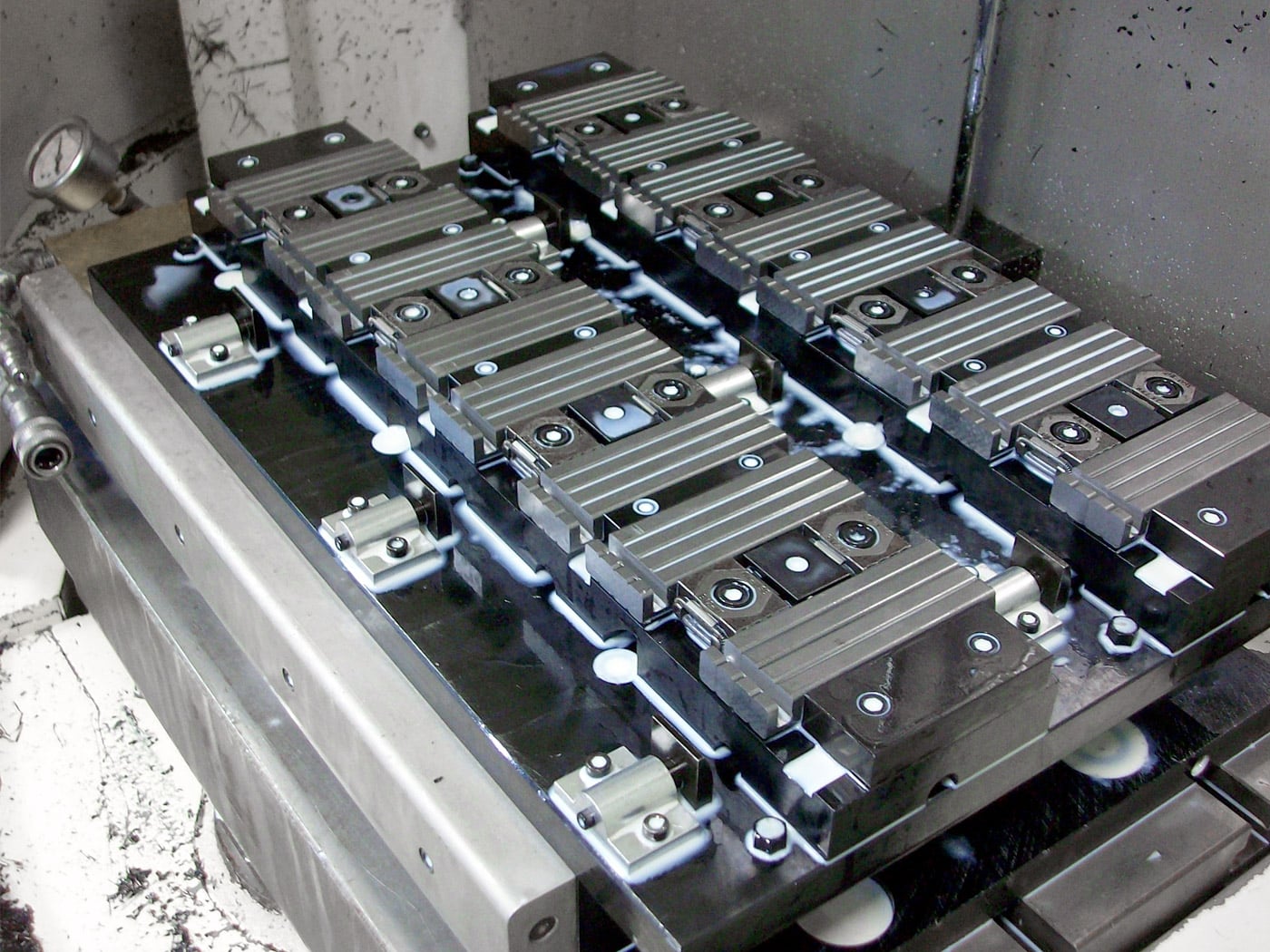

At Wuxi Lead Precision Machinery, our technical capabilities for CNC fixture plate production are engineered to meet the exacting demands of advanced manufacturing. Fixture plates serve as the critical foundation for workholding stability and repeatability in high-mix, low-volume production. We leverage state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C400 U, to achieve geometric complexity and micron-level accuracy unattainable with conventional 3-axis systems. These platforms enable simultaneous multi-surface machining, eliminating secondary setups and ensuring holistic precision across intricate T-slot patterns, vacuum channels, and custom datum features. Our integrated tooling systems and high-rigidity spindles (42,000 RPM) maintain thermal stability during extended operations, critical for plates exceeding 1,000 mm in length where cumulative error risks are significant.

Quality control is non-negotiable in fixture plate manufacturing. Every component undergoes rigorous inspection via Zeiss CONTURA G2 and Hexagon GLOBAL S CLASS Coordinate Measuring Machines (CMM), operating in a climate-controlled metrology lab (20±0.5°C). Our inspection protocol validates all critical features against ASME Y14.5 GD&T standards, with full first-article reports (FAIR) including 3D deviation mapping and surface texture analysis. Statistical Process Control (SPC) data is logged for every production run, enabling real-time adjustments to sustain capability indices (Cp/Cpk >1.67). This closed-loop system guarantees that positional tolerances and surface integrity remain consistent across batches, directly translating to reduced machine downtime and scrap rates for our clients.

The table below details achievable tolerances for standard and high-precision fixture plate configurations. All values are validated per ISO 2768-mK and verified using calibrated CMM probes with uncertainty ratios ≤1:10.

| Parameter | Standard Tolerance | High-Precision Option | Measurement Method |

|---|---|---|---|

| Overall Flatness (per 300mm) | ±0.005 mm | ±0.001 mm | Optical Flat + CMM |

| Hole Positional Accuracy | ±0.010 mm | ±0.002 mm | CMM (5-point circle) |

| Hole Diameter Tolerance | H7 (+0.018/0) | G6 (+0.007/-0.004) | Air Gauge + CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Parallelism (Datum Faces) | 0.015 mm | 0.003 mm | CMM + Granite Surface Plate |

Material selection is optimized for rigidity and thermal stability, with primary use of hardened 1.2379 tool steel (58-62 HRC) and 7075-T6 aluminum. Stress-relieving cycles are integrated into our machining sequence to prevent post-fabrication distortion. For aerospace and semiconductor applications requiring ultra-stable references, we implement in-process laser interferometry to compensate for machine volumetric errors. This comprehensive approach ensures fixture plates deliver sub-micron repeatability over thousands of clamping cycles, directly enhancing end-part quality and throughput for our partners. Wuxi Lead’s fusion of 5-axis capability, metrology-grade verification, and material science expertise establishes a benchmark for mission-critical workholding solutions in global precision manufacturing.

Material & Finish Options

Material Selection for High-Performance CNC Fixture Plates

Selecting the appropriate material for a CNC fixture plate is critical to ensuring dimensional stability, longevity, and performance under production conditions. At Wuxi Lead Precision Machinery, we engineer fixture plates to meet the exacting demands of precision CNC machining environments. The three primary materials used—aluminum, steel, and titanium—each offer distinct advantages depending on the application’s mechanical, thermal, and environmental requirements.

Aluminum is the most widely used material for CNC fixture plates due to its favorable strength-to-weight ratio, excellent machinability, and good thermal conductivity. 6061-T6 and 7075-T6 aluminum alloys are particularly popular in high-precision applications. 6061-T6 offers balanced mechanical properties and weldability, making it ideal for modular and reconfigurable setups. 7075-T6, while more expensive, provides higher tensile strength and is suitable for high-load or aerospace-grade tooling. Aluminum plates are often anodized to enhance surface hardness and corrosion resistance, particularly in environments exposed to coolants and machining fluids.

Steel fixture plates, typically fabricated from hardened tool steels such as 4140 or 1045, are selected when maximum rigidity and wear resistance are required. These materials maintain dimensional accuracy under heavy clamping forces and prolonged use. Steel plates are commonly used in high-volume production lines where long-term durability outweighs the need for lightweight handling. While heavier than aluminum, steel offers superior resistance to deformation and is less prone to galling when threaded features are frequently engaged.

Titanium, specifically Grade 5 (Ti-6Al-4V), is used in specialized applications where extreme strength, corrosion resistance, and low weight are paramount. Though significantly more expensive and challenging to machine, titanium fixture plates are employed in aerospace and medical manufacturing where non-magnetic properties and performance in harsh environments are essential. Due to its low thermal expansion and high fatigue strength, titanium maintains accuracy across wide temperature ranges and cyclic loading.

Surface finishing plays a crucial role in extending the service life of fixture plates. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is the preferred finish for aluminum plates. Type II anodizing provides moderate wear and corrosion resistance with aesthetic appeal, while Type III delivers a harder, thicker oxide layer suitable for industrial environments. Hardcoat anodizing can achieve surface hardness up to 60 HRC, significantly improving abrasion resistance without altering dimensional tolerances.

Below is a comparative summary of key material properties for CNC fixture plate selection.

| Material | Alloy/Grade | Tensile Strength (MPa) | Density (g/cm³) | Hardness (HB) | Typical Finish | Primary Use Case |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | 95 | Type II/III Anodizing | General-purpose, modular fixtures |

| Aluminum | 7075-T6 | 572 | 2.8 | 150 | Type III Anodizing | High-strength, aerospace tooling |

| Steel | 4140 (Hardened) | 950–1200 | 7.85 | 280 | Zinc Plating, Passivation | Heavy-duty, high-volume production |

| Steel | 1045 | 600–700 | 7.85 | 200 | Black Oxide, Paint | Cost-effective production fixtures |

| Titanium | Ti-6Al-4V | 900–1000 | 4.43 | 360 | As-machined, Passivated | Aerospace, medical, corrosive env. |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on operational demands, lifecycle cost, and precision requirements. Our engineering team provides tailored solutions to ensure maximum efficiency and repeatability in CNC workholding systems.

Manufacturing Process & QC

CNC Fixture Plate Production Process: Achieving Zero Defects

Our production process for precision CNC fixture plates follows a rigorously controlled sequence from initial design through to mass production, engineered to eliminate defects before they occur. This methodology ensures every plate meets the exacting standards demanded by high-precision manufacturing applications. The journey begins with comprehensive design engineering, where we integrate client specifications with deep manufacturing knowledge. Engineers conduct thorough Design for Manufacturability (DFM) analysis and Finite Element Analysis (FEA) simulations to optimize structural integrity, minimize thermal distortion, and ensure optimal clamping force distribution. Material selection is critical; we specify only certified aerospace-grade 4140 or 1045 steel, verified for homogeneous grain structure and minimal internal stress. Every geometric feature, tolerance band, and datum reference frame is defined against ISO 2768 medium or tighter standards, with explicit consideration for the end-use machining environment and machine tool interface.

Prototyping serves as the essential validation stage before committing to volume production. We fabricate initial prototypes using the exact same CNC machining centers and tooling intended for series production. This allows for real-world verification of the design’s functionality and manufacturability. Each prototype undergoes exhaustive metrology: full 3D scanning on a calibrated CMM validates geometric accuracy against the nominal CAD model, while surface profilometry confirms critical flatness and finish requirements. Functional testing on the target machine tool verifies repeatability under actual cutting loads and coolant conditions. Any deviation triggers immediate root cause analysis and design or process refinement. Only when the prototype consistently demonstrates zero non-conformances against all acceptance criteria does the design lock for production release.

Mass production leverages the validated process under stringent Statistical Process Control (SPC). Every plate is manufactured on dedicated, pre-calibrated 5-axis machining centers with in-process probing for real-time feature verification. Our production floor implements a closed-loop quality system: automated optical inspection checks hole patterns and critical surfaces after milling, with data fed directly into SPC charts monitoring key process parameters. Full traceability is maintained via laser-etched serial numbers linked to material certs, machine logs, and individual inspection reports. Final acceptance requires 100% verification of critical dimensions using calibrated CMMs against the approved prototype baseline. This integrated approach—design rigor, prototype validation, and SPC-driven production—ensures zero defects are not aspirational but the operational standard, guaranteeing fixture plates that deliver unwavering repeatability and extend tool life in your production cell.

Critical Fixture Plate Specifications & Verification

| Parameter | Specification | Verification Method |

|---|---|---|

| Material | ASTM A335 P11 / 4140 HT | Mill Cert + Spectrographic Analysis |

| Overall Flatness | ≤ 0.010 mm over 300 mm | 3D CMM Scanning (ASME B89.4.1032) |

| Hole Pattern Accuracy | ± 0.005 mm positional | Optical Comparator + CMM (GD&T) |

| Surface Finish (Machined) | Ra 0.8 μm max | Portable Surface Roughness Tester |

| Hardness | 28-32 HRC (case) | Rockwell Hardness Tester (ASTM E18) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in CNC Fixture Plate Solutions

At Wuxi Lead Precision Machinery, we understand that precision, repeatability, and efficiency are non-negotiable in high-end CNC machining. As a trusted leader in the field of precision manufacturing, we specialize in engineered CNC fixture plates that meet the exacting demands of aerospace, automotive, medical device, and industrial equipment industries. Our commitment to quality, innovation, and customer collaboration sets us apart as a strategic partner in your production success.

When you partner with Lead Precision, you gain access to more than just a component supplier — you align with a team of seasoned CNC engineers and manufacturing specialists who are dedicated to optimizing your workflow. Every fixture plate we produce is designed with purpose: to enhance clamping accuracy, reduce setup time, and ensure consistent part quality across high-volume runs. We leverage advanced 3D modeling, finite element analysis (FEA), and in-house five-axis machining capabilities to deliver fixture solutions that integrate seamlessly into your existing production environment.

Our manufacturing process adheres to ISO 9001:2015 standards, and we utilize premium-grade materials such as 6061-T6 and 7075-T6 aluminum, as well as hardened tool steels, depending on your application requirements. Whether you need modular tombstone configurations, vacuum chucks, or custom poka-yoke designs, our team works closely with you from concept to final inspection to ensure every detail meets your operational needs.

We pride ourselves on fast turnaround times without compromising precision. Our agile production floor is equipped with state-of-the-art CNC machines, coordinate measuring machines (CMM), and automated inspection systems that guarantee tolerances down to ±0.002 mm. This level of control ensures that every fixture plate performs reliably under real-world machining conditions.

Below are key specifications that define the performance and reliability of our CNC fixture plates:

| Specification | Detail |

|---|---|

| Material Options | 6061-T6, 7075-T6 Aluminum, Hardened Steel, Stainless Steel |

| Standard Tolerances | ±0.002 mm |

| Surface Flatness | ≤ 0.01 mm per 100 mm |

| Hole Position Accuracy | ±0.003 mm |

| Drilling Options | Threaded inserts, dowel pin holes, T-slots, counterbores |

| Finishes Available | Anodizing (Type II & III), Hardcoat, Passivation, Powder Coating |

| Max Working Size | 2000 mm × 1200 mm × 800 mm |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

Partnering with Wuxi Lead Precision Machinery means investing in long-term manufacturing excellence. We don’t just deliver parts — we deliver solutions engineered for performance, durability, and seamless integration. Let us help you elevate your CNC operations with fixture plates built to lead the industry.

Contact us today at [email protected] to discuss your project requirements. Our engineering team is ready to collaborate and provide a customized quote tailored to your precision needs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.