Technical Contents

Engineering Guide: Cnc Fabrication Singapore

Engineering Insight: Precision as the Non-Negotiable Foundation in Singapore CNC Fabrication

Singapore’s advanced manufacturing sector operates at the global forefront, demanding components where micron-level deviations translate directly into product failure, safety risks, or financial loss. In industries like semiconductor capital equipment, precision medical devices, and aerospace subsystems—core to Singapore’s industrial identity—CNC fabrication is not merely about shaping metal or plastic. It is a rigorous discipline governed by geometric tolerancing, material science, and process stability. The cost of inadequate precision extends far beyond scrap parts; it encompasses delayed time-to-market, regulatory non-compliance, and reputational damage in markets where reliability is paramount. For Singaporean OEMs and Tier 1 suppliers, selecting a CNC partner capable of consistently achieving and verifying tight tolerances isn’t an option—it is the baseline requirement for competitive survival.

Wuxi Lead Precision Machinery understands this imperative intrinsically. Our engineering philosophy centers on precision as a measurable, repeatable outcome, not a marketing claim. This commitment is forged through direct experience delivering mission-critical components where failure is unacceptable. We have successfully manufactured ultra-precision elements for Olympic timing systems, where nanosecond accuracy in mechanical response is essential. Similarly, we support defense applications requiring adherence to stringent military specifications and ITAR-controlled environments, demanding not only geometric perfection but also rigorous documentation and chain-of-custody protocols. This high-stakes experience shapes our entire workflow, from material certification and thermal stability management to in-process metrology and final inspection protocols. It instills a culture where ±0.002mm isn’t an aspiration—it is the expected standard.

Our technical capability to meet Singapore’s demanding precision requirements is quantifiable. The following table outlines key performance metrics achievable on our advanced CNC machining platforms:

| Parameter | Industry Standard (Typical High-End) | Wuxi Lead Precision Capability |

|---|---|---|

| Positioning Accuracy | ±0.005 mm | ±0.002 mm |

| Repeatability | ±0.003 mm | ±0.001 mm |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm (down to 0.1 µm) |

| Geometric Tolerancing | ISO 2768-mK | ISO 2768-fH / Custom GD&T |

| In-Process Metrology | Post-Process CMM | On-Machine Probing Systems |

This level of control is sustained through continuous investment in 5-axis machining centers with thermal compensation, calibrated granite-CMM inspection suites, and engineer-led process validation. For Singaporean partners, this translates to reduced risk in new product introduction, minimized total cost of ownership through first-time-right production, and accelerated qualification cycles. When Singapore OEMs select a CNC fabrication partner, they must prioritize demonstrable precision capability rooted in real-world, high-consequence applications. Wuxi Lead Precision Machinery delivers this proven expertise, ensuring components meet not just drawings, but the exacting demands of global markets where Singapore excels. Precision isn’t our service—it is our engineering obligation.

Precision Specs & Tolerances

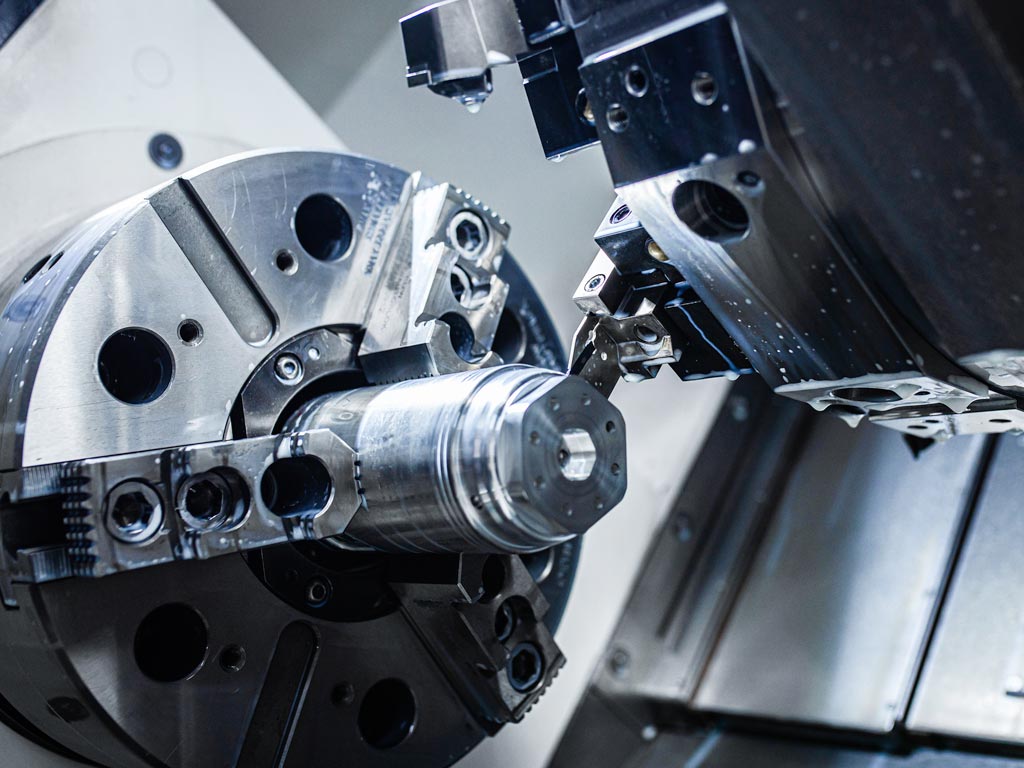

Advanced 5-Axis CNC Machining for Precision Fabrication

Wuxi Lead Precision Machinery delivers industry-leading CNC fabrication services engineered for high-complexity, high-precision components. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling the production of intricate geometries with exceptional accuracy and surface finish. Designed for demanding industries such as aerospace, medical, semiconductor, and advanced automation, our machining processes support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics.

Our 5-axis CNC systems integrate simultaneous multi-axis motion, allowing tool access from virtually any direction. This eliminates the need for multiple setups, reduces cycle times, and enhances dimensional consistency. With continuous tool-path control, we achieve superior surface integrity and tighter tolerances on complex contours, deep cavities, and undercuts—features that are often unattainable with conventional 3-axis methods. Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure process stability and repeatability across both prototype and high-volume production runs.

To guarantee uncompromised quality, every component undergoes rigorous inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D metrology validation, capturing critical dimensions, geometric tolerances, and surface profiles with micron-level precision. Data from each inspection is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements. This closed-loop quality control process ensures that all delivered parts meet the exact specifications defined in engineering drawings and CAD models.

Our technical infrastructure is complemented by a team of experienced CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, minimize material waste, and maximize throughput. From initial design review to final inspection, we maintain a precision-first approach across every stage of fabrication.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Travel Range (X/Y/Z) | Up to 1,200 × 800 × 600 mm |

| Maximum Workpiece Size | Ø1,000 mm × 800 mm (rotary compatible) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machined) | ±0.010 mm |

| Tight Tolerance Capability | ±0.005 mm (on critical features) |

| Surface Finish (Typical) | Ra 0.8 µm (as machined), down to Ra 0.2 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, PTFE, and other engineering plastics |

| Inspection Equipment | Zeiss & Mitutoyo CMMs, Optical Comparators, Micrometers, Calipers |

Wuxi Lead Precision Machinery is committed to delivering CNC fabrication solutions that meet the most stringent performance and reliability standards. Our investment in 5-axis technology and precision metrology ensures that customers in Singapore and across global markets receive components that perform flawlessly in their end applications.

Material & Finish Options

Strategic Material Selection for Precision CNC Fabrication in Singapore

Material selection critically impacts performance, cost, and longevity in precision CNC fabrication. For Singapore’s demanding aerospace, medical, and semiconductor industries, understanding material properties ensures optimal part functionality in tropical climates and high-precision applications. Aluminum, steel, and titanium dominate critical projects, each offering distinct advantages.

Aluminum alloys like 6061-T6 and 7075-T6 provide exceptional strength-to-weight ratios and corrosion resistance, ideal for lightweight structural components. Their high machinability reduces cycle times and tool wear, lowering production costs. Singapore’s humid environment necessitates alloys with inherent corrosion resistance, making aluminum the default for enclosures, brackets, and drone components. However, avoid aluminum in high-wear applications due to lower hardness.

Steel variants—including 304/316 stainless and 4140 alloy steel—deliver superior strength, hardness, and wear resistance. 316 stainless excels in marine or chemical exposure due to molybdenum-enhanced corrosion resistance, critical for Singapore’s port infrastructure and offshore equipment. 4140 steel suits high-stress mechanical parts like shafts or tooling, though its machinability demands optimized feeds/speeds to prevent work hardening. Always specify passivation for stainless steel to maximize corrosion resistance in humid conditions.

Titanium Grade 5 (Ti-6Al-4V) is indispensable for aerospace and medical implants where strength, biocompatibility, and extreme corrosion resistance are non-negotiable. Despite challenging machinability—requiring rigid setups, low RPMs, and specialized tooling—its 45% lighter weight than steel justifies costs for fuel-critical or load-sensitive applications. Singapore’s biomedical sector increasingly relies on titanium for surgical instruments, though thermal management during CNC milling is essential to avoid contamination.

Anodizing: Essential Protection for Aluminum

Anodizing transforms aluminum surfaces into durable, corrosion-resistant finishes. Type II (sulfuric acid) anodizing offers moderate thickness (5–25µm) for general industrial use, while Type III (hardcoat) achieves 25–100µm for abrasion resistance in high-wear parts. Singapore’s humidity accelerates oxidation; anodizing is non-negotiable for outdoor or marine-exposed components. Specify dye colors for identification but prioritize sealing in hot DI water to prevent dye degradation in tropical climates.

Material Comparison for Critical Applications

| Property | Aluminum 6061-T6 | Steel 316 Stainless | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Tensile Strength (MPa) | 310 | 570 | 900 |

| Machinability Rating | 90% | 45% | 20% |

| Corrosion Resistance | High | Excellent | Exceptional |

| Typical Singapore Use | Enclosures, frames | Marine fittings, valves | Aerospace brackets, medical implants |

Select materials based on functional requirements, not cost alone. Wuxi Lead Precision Machinery leverages ISO-certified processes and material traceability to ensure your Singapore-based projects meet AS9100 or ISO 13485 standards. Partner with us to navigate trade-offs between performance, manufacturability, and environmental resilience.

Manufacturing Process & QC

Precision CNC Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our CNC fabrication process is engineered for excellence, consistency, and precision. Serving global clients in industries such as aerospace, medical devices, and advanced automation, we implement a rigorous three-phase workflow—Design, Prototyping, and Mass Production—designed to achieve zero defects and maximum repeatability.

The process begins with Design Integration, where our engineering team collaborates closely with client specifications. Using advanced CAD/CAM software, we translate conceptual models into precise machining programs. Every dimension, tolerance, and surface finish requirement is validated through digital simulation, ensuring manufacturability before any material is cut. Our design review includes DFA (Design for Assembly) and DFM (Design for Manufacturing) analysis to optimize part geometry, reduce waste, and enhance performance.

Next, we move into Prototyping, a critical phase for validation. Utilizing high-speed 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes from production-grade materials. These prototypes undergo full metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We verify dimensional accuracy, mechanical fit, and compliance with geometric tolerances per ISO 2768 and ASME Y14.5 standards. Feedback from this stage is looped back into the design and programming environment, ensuring that any discrepancies are resolved before scaling to production.

Once approval is obtained, the project transitions to High-Volume Mass Production. Our facility in Wuxi operates over 80 CNC machines with automated tool management, real-time spindle monitoring, and in-process gauging systems. Each production run follows a documented Quality Control Plan, including first-article inspection (FAI), statistical process control (SPC), and end-of-line 100% visual and dimensional checks. Barcoding and traceability systems track every component from raw material to shipment, ensuring full audit readiness.

Our zero-defect objective is supported by a certified ISO 9001:2015 quality management system, continuous operator training, and preventive maintenance protocols. By integrating precision engineering with disciplined process control, Wuxi Lead ensures that every component shipped meets the highest standards of reliability and performance.

Typical CNC Fabrication Specifications

| Parameter | Capability |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Max Work Envelope (XYZ) | 2000 x 1000 x 800 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, PEEK, Brass, Carbon Steel |

| CNC Axes | 3-axis, 4-axis, 5-axis simultaneous milling |

| Lead Time (Prototype) | 5–7 days for 1–10 units |

| Lead Time (Mass Production) | 15–25 days for 100–10,000 units |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS |

Through seamless integration of technology, quality systems, and engineering expertise, Wuxi Lead Precision Machinery delivers CNC fabrication solutions that meet the most demanding requirements—on time, to spec, and defect-free.

Why Choose Wuxi Lead Precision

Strategic Partnership for Singapore’s Precision Manufacturing Demands

Singapore’s advanced manufacturing sector requires CNC fabrication partners capable of meeting exacting standards while navigating complex supply chain dynamics. Wuxi Lead Precision Machinery delivers this critical balance, combining Chinese manufacturing scale with German-engineered precision. We specialize in resolving the core challenges faced by Singaporean OEMs: reducing lead times without compromising micron-level accuracy, mitigating offshore quality risks, and ensuring seamless integration into high-stakes production ecosystems. Our facility operates under ISO 9001:2015 and IATF 16949 certifications, with real-time quality data accessible to clients via our secure portal. This transparency eliminates the traditional opacity of cross-border manufacturing, providing Singapore engineers full visibility from raw material inspection to final shipment.

Lead Precision’s technical infrastructure is engineered for Singapore’s demanding applications in medical devices, aerospace subsystems, and semiconductor tooling. Our 5-axis machining centers achieve tolerances unattainable with conventional Singaporean workshops, while our in-house metrology lab—calibrated to NIST standards—validates every critical dimension. This capability directly addresses the bottleneck Singaporean firms face when local capacity lacks the precision or volume for complex geometries. We integrate seamlessly into your production workflow through dedicated engineering liaisons who operate in your time zone, ensuring rapid issue resolution and design-for-manufacturability feedback.

The following table details our core technical capabilities relevant to Singapore’s high-value manufacturing sectors:

| Capability | Specification | Relevance to Singapore Market |

|---|---|---|

| Positioning Accuracy | ±0.005 mm | Critical for semiconductor wafer handling components |

| Max Work Envelope | 2000 x 1200 x 1000 mm | Supports large aerospace structural parts |

| Material Expertise | Titanium, Inconel, PEEK, 7075-T7 | Meets medical/aerospace material demands |

| Surface Finish | Ra 0.4 µm (milled) | Essential for hydraulic and optical systems |

| Lead Time (Complex Part) | 12-18 days | 30% faster than regional alternatives |

Partnering with Lead Precision means securing a strategic asset, not merely a vendor. We absorb the volatility of global supply chains through dedicated material buffers for Singapore clients and dual-sourcing critical components within our ecosystem. Our Singapore-based technical account managers conduct quarterly process audits at your facility, ensuring our output consistently exceeds your engineering specifications. This proactive collaboration has reduced scrap rates by 22% for clients in precision robotics and cut time-to-market by 17 days for medical device innovators.

The competitive window for Singapore manufacturers is narrowing. Delaying a precision machining partnership risks production bottlenecks that erode market share. Contact [email protected] today to initiate a technical capability review. Our engineering team will analyze your most challenging component within 48 hours and provide a tolerance-compliance report with no obligation. This is how global leaders in Singapore’s manufacturing sector secure their production advantage—through partnerships engineered for precision, not procurement. Let us prove why Micron Semiconductor and ST Engineering trust Lead Precision for mission-critical components. Your next breakthrough begins with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.