Technical Contents

Engineering Guide: Cnc Fabrication Service

Engineering Insight Precision as the Non-Negotiable Foundation of CNC Fabrication

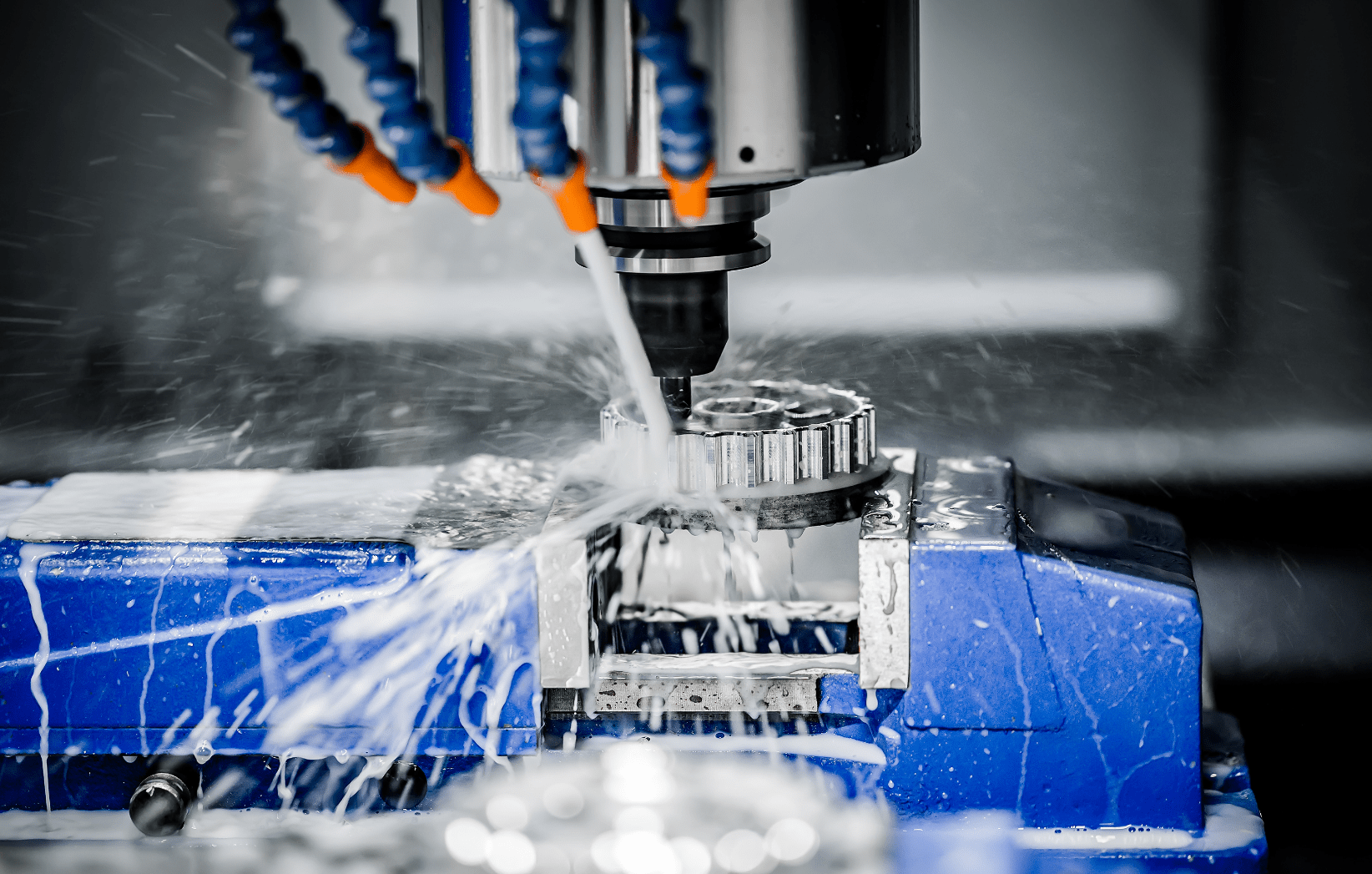

In high-stakes CNC fabrication services, precision transcends mere specification; it defines mission success, product reliability, and ultimately, client trust. The margin for error in critical aerospace components, life-saving medical devices, or advanced defense systems is measured not in thousandths of an inch, but in microns. A deviation of 0.005mm in a hydraulic manifold can lead to catastrophic system failure. An imperceptible surface finish anomaly on a satellite housing can compromise thermal management in orbit. Precision machining is the invisible safeguard ensuring that engineered intent becomes physical reality without compromise. For global manufacturers, selecting a CNC partner capable of consistently delivering micron-level accuracy across complex geometries and demanding materials is not an operational choice—it is a strategic imperative for product integrity and market leadership.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our engineering philosophy is forged in environments where failure is not an option. We bring demonstrable expertise from projects demanding the absolute pinnacle of dimensional control, including components for Olympic-grade timing systems where split-micron accuracy ensures fair global competition, and mission-critical military hardware where tolerances directly impact operational safety and effectiveness. This experience instills a rigorous, process-driven approach across our entire facility. It means implementing multi-stage verification protocols far beyond standard industry practice, utilizing temperature-stabilized metrology labs, and maintaining machine tools under continuous calibration cycles traceable to national standards. We understand that the true measure of a CNC fabrication service lies not just in achieving a tolerance on a drawing, but in guaranteeing its repeatability across every single part in a production run, regardless of complexity.

Our commitment is validated through stringent process controls and advanced capability. The table below outlines our core precision machining specifications, reflecting the baseline we consistently exceed for critical applications:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.001 mm |

| Positional Tolerance | ±0.015 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Material Range | Aluminum, Steel, Stainless, Titanium, Plastics | Inconel, Hastelloy, Tungsten Carbide |

| Machine Platform | 3-Axis Milling/Turning | 5-Axis Simultaneous Milling/Turning |

| Metrology Verification | CMM, Optical Comparator | Laser Interferometry, Roundness Tester, Surface Profilometer |

This capability is underpinned by our ISO 9001:2015 certified quality management system and a team of engineers with deep domain experience in solving the most challenging fabrication problems. When your application demands zero-defect performance, Wuxi Lead Precision Machinery transforms stringent requirements into engineered certainty. Your specifications become our engineering mandate, executed with the discipline earned through proven success in the world’s most demanding manufacturing arenas. Partner with us where precision isn’t a claim—it’s the documented outcome.

Precision Specs & Tolerances

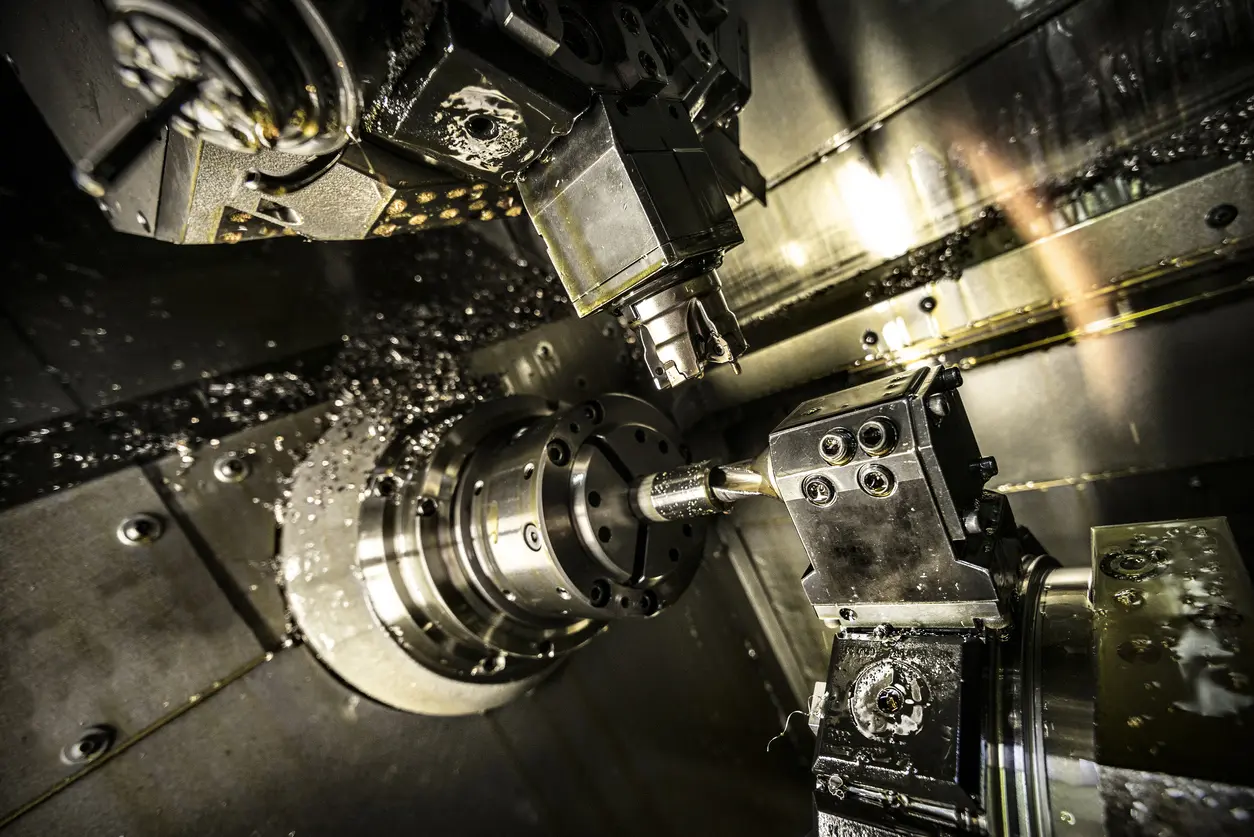

Wuxi Lead Precision Machinery delivers advanced CNC fabrication services engineered for high-complexity components across aerospace, medical, energy, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce intricate geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across X, Y, Z, and two rotational axes (A and B), minimizing setup cycles and ensuring superior part consistency. This dynamic range of motion supports undercuts, compound angles, and organic contours—features commonly found in turbine blades, surgical instruments, and high-performance fluid dynamics components.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring prolonged precision during extended production runs. Materials processed include aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 2, Grade 5), brass, and engineering plastics such as PEEK and PTFE. Each machine operates under strict environmental controls to mitigate thermal drift, maintaining dimensional stability throughout the machining cycle.

Quality assurance is integrated at every stage of production. All critical dimensions are verified using Coordinate Measuring Machines (CMM) with sub-micron resolution. These systems employ tactile probing and advanced software algorithms to generate comprehensive inspection reports, including GD&T analysis, form deviation mapping, and first-article inspection documentation. Our CMM cells are calibrated annually to ISO 17025 standards and operated by certified metrology technicians.

In addition to CMM validation, we utilize optical comparators, surface roughness testers, and hardness gauges to ensure full conformance to customer specifications. Every component undergoes a final inspection before shipment, with traceability maintained through serialized part tracking and digital quality records.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled production conditions.

| Feature | Standard Tolerance | Precision Tolerance (Optional) | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or honed |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Per GD&T (ISO 1101) |

| Angular Tolerance | ±0.1° | ±0.05° | Measured via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achievable with fine finishing passes |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm | Verified on granite surface plate |

| Runout (Concentricity) | 0.05 mm | 0.01 mm | Critical for rotating components |

All tolerances are achievable on first-run production and sustained across batch sizes ranging from prototypes to mid-volume runs. Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver CNC-fabricated components that meet the most demanding engineering requirements.

Material & Finish Options

Material Selection Guide for Precision CNC Fabrication

Selecting optimal materials is critical for achieving performance, cost efficiency, and longevity in CNC-machined components. At Wuxi Lead Precision Machinery, our engineering team evaluates mechanical properties, environmental resistance, and manufacturability to align material choice with your application’s demands. Below we detail key considerations for aluminum, steel, and titanium, alongside essential finishing insights.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. Grade 6061-T6 offers balanced machinability, weldability, and corrosion resistance, making it ideal for structural brackets and housings. Its lower density reduces inertia in moving parts while maintaining rigidity. However, aluminum’s softer surface requires protective finishes like anodizing for wear resistance in high-friction environments.

Steel remains indispensable for high-stress applications requiring durability and hardness. Alloy 4140 provides superior tensile strength and fatigue resistance for shafts, gears, and tooling. Stainless steel 304 excels in corrosive or sanitary settings like medical devices and marine hardware. While steel machining demands rigid setups and specialized tooling to manage heat and tool wear, its versatility across load-bearing applications justifies the investment.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), are engineered for extreme conditions. With strength comparable to steel at 45% less weight and unmatched corrosion resistance, titanium is standard in aerospace actuators and biomedical implants. Its low thermal conductivity challenges machining, requiring controlled feeds/speeds and coolant strategies to prevent work hardening. Despite higher material and processing costs, titanium’s fatigue performance in cyclic loads delivers lifecycle value.

Anodizing is the premier finish for aluminum components, enhancing surface hardness and corrosion protection. Type II (sulfuric acid) anodizing creates a porous layer for dyeing and moderate wear resistance, suitable for consumer electronics. Type III (hard coat) anodizing yields thicker, denser coatings (50–100 µm) for aerospace or military parts exposed to abrasion. Both processes improve adhesion for paints or lubricants while maintaining dimensional stability—critical for precision assemblies.

Material properties directly impact CNC programming, tool selection, and throughput. Our team leverages decades of production data to optimize these variables, ensuring your design intent translates flawlessly into finished parts. Consult Wuxi Lead’s engineers early in the design phase to evaluate trade-offs between performance, lead time, and cost.

Comparative Material Specifications

| Property | Aluminum 6061-T6 | Steel 4140 | Titanium Ti-6Al-4V |

|————————-|——————|——————|——————–|

| Density (g/cm³) | 2.7 | 7.85 | 4.43 |

| Tensile Strength (MPa) | 310 | 655 | 900 |

| Yield Strength (MPa) | 276 | 415 | 830 |

| Hardness (Brinell) | 95 | 200 | 360 |

| Machinability Rating | Excellent (70) | Good (65) | Fair (30) |

| Corrosion Resistance | Moderate | Low (uncoated) | Exceptional |

Material selection is not merely a technical checkbox but a strategic decision affecting total cost of ownership. Partner with Wuxi Lead to transform specifications into precision-engineered realities.

Manufacturing Process & QC

From Concept to Completion: The CNC Fabrication Service Workflow at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our CNC fabrication service is engineered for precision, consistency, and zero-defect outcomes. We follow a disciplined production process that transforms design concepts into high-performance, mission-critical components. This process is structured in three core phases: Design Evaluation, Prototyping, and Mass Production—each governed by strict quality control protocols to ensure flawless execution.

The journey begins with Design Evaluation, where our engineering team collaborates closely with clients to analyze CAD models, material specifications, and functional requirements. We perform comprehensive Design for Manufacturability (DFM) reviews to identify potential challenges, optimize geometries, and select the most suitable alloys or composites. This stage ensures that every component is not only manufacturable but also cost-efficient and performance-optimized.

Next, we move to Prototyping, a critical validation phase. Using advanced 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes that mirror final production conditions. These prototypes undergo rigorous metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Dimensional accuracy, material integrity, and fit-for-assembly are verified to confirm design intent. Client feedback is incorporated at this stage, allowing for rapid iteration without impacting the production timeline.

Once the prototype is approved, we transition seamlessly into Mass Production. Our facility leverages automated CNC cells, robotic part handling, and real-time process monitoring to maintain consistency across high-volume runs. Every production batch is subjected to in-process inspections and final QA audits, ensuring compliance with ISO 9001:2015 and client-specific quality standards. Statistical Process Control (SPC) is implemented to detect and correct deviations instantly, guaranteeing zero-defect output.

Our commitment to precision is reflected in our technical capabilities, which support demanding industries such as aerospace, medical devices, and advanced automation.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Configurations | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Engineering Plastics (PEEK, Delrin) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Quality Standards | ISO 9001:2015, GD&T compliant, Full inspection reporting |

| Production Capacity | Low-volume to high-volume runs with scalable automation |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered solutions with uncompromising quality. From initial design to full-scale production, our CNC fabrication service is built on a foundation of technical excellence and operational discipline.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

Selecting a CNC fabrication partner demands more than technical capability—it requires a strategic ally committed to your success from prototype to production. At Wuxi Lead Precision Machinery, we engineer partnerships grounded in precision, reliability, and unwavering transparency. Our ISO 9001-certified facility in Wuxi, China, merges advanced 5-axis machining with rigorous quality control to transform complex designs into mission-critical components for aerospace, medical, and industrial sectors. We eliminate supply chain uncertainty through end-to-end accountability, ensuring every part meets your exact specifications without hidden costs or communication barriers.

Our technical infrastructure supports the most demanding applications, as demonstrated in the core capabilities below:

| Specification | Capability Detail |

|---|---|

| Machining Tolerance | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 750 mm (47 x 31 x 30″) |

| Material Expertise | Aluminum, Titanium, Stainless Steel, Inconel, Plastics |

| Surface Finish | Ra 0.4 µm (16 µin) to Ra 0.8 µm (32 µin) |

| Quality Assurance | CMM, Optical Comparator, GD&T Reporting |

| Lead Time | 7–15 days for production batches |

Beyond machinery, our value lies in proactive engineering collaboration. Our team engages early in your design phase to optimize manufacturability, reduce waste, and accelerate time-to-market—without compromising integrity. Unlike transactional vendors, we assign dedicated project managers fluent in English and technical documentation standards, ensuring seamless coordination across time zones. Every shipment includes full traceability records and first-article inspection reports, providing audit-ready compliance for regulated industries.

Global manufacturers choose Lead Precision because we treat your deadlines as our own. When prototyping medical implants or aerospace subsystems, a single deviation risks cascading delays. Our zero-defect culture—validated through third-party audits—means you receive components that integrate flawlessly into your assembly line, reducing rework and safeguarding your reputation. We invest in your success through flexible capacity allocation, real-time production updates, and post-delivery support to refine future iterations.

Initiate a partnership where precision is non-negotiable. Contact our engineering team directly at [email protected] to discuss your project requirements. Include your CAD files or technical drawings for a rapid feasibility assessment and customized quotation. Our specialists respond within 24 business hours to align on tolerances, materials, and delivery milestones. Trust Wuxi Lead Precision Machinery to become the cornerstone of your high-stakes manufacturing ecosystem—where exceptional quality meets uncompromising partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.