Technical Contents

Engineering Guide: Cnc En Ligne

Engineering Insight The Non-Negotiable Imperative of Precision in CNC Machining

Precision in CNC machining transcends mere dimensional accuracy; it is the foundational requirement for functional integrity, performance reliability, and ultimate success in advanced manufacturing. In sectors like aerospace, medical device production, and high-performance automotive, components operating under extreme stress or within intricate assemblies demand tolerances measured in microns. A deviation of even 5 micrometers can compromise structural integrity, induce catastrophic failure in flight systems, or render a life-saving medical implant unusable. True precision encompasses not only the machine’s capability to hit target dimensions consistently but also its ability to maintain surface finish quality, geometric form, and material properties throughout complex multi-axis operations. This level of control is achieved through rigorous machine calibration, advanced thermal compensation systems, superior spindle dynamics, and meticulous process validation – elements non-negotiable for mission-critical applications.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering. Our facility is certified to the highest international standards, including AS9100 for aerospace and ISO 13485 for medical devices, reflecting our systemic commitment to quality. This expertise is proven through direct contributions to projects where failure is not an option. We have manufactured precision components for Olympic-caliber sporting equipment demanding absolute consistency under peak athlete performance, and critical subsystems for defense applications requiring unwavering reliability in the most demanding environments. These engagements are not merely contracts; they are validations of our engineering discipline, process control, and unwavering focus on delivering parts that perform exactly as designed, every time.

The tangible output of our precision capability is evident in the measurable performance of our machining centers and the components they produce. Key specifications consistently achieved across our production floor include:

| Specification Parameter | Wuxi Lead Precision Capability | Industry Benchmark (High-End) |

|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±0.002 mm | ±0.005 mm |

| Repeatability (3σ) | ±0.001 mm | ±0.003 mm |

| Typical Surface Roughness (Ra) | 0.2 μm | 0.8 μm |

| Maximum Spindle Speed | 24,000 RPM | 15,000 RPM |

| Supported Critical Materials | Titanium, Inconel, Tool Steels | Aluminum, Mild Steel |

Achieving and sustaining these metrics requires more than advanced hardware. It demands deep metallurgical understanding, sophisticated fixture design to eliminate part deflection, optimized cutting strategies minimizing thermal impact, and continuous in-process metrology. For the discerning B2B manufacturer, selecting a partner like Wuxi Lead Precision Machinery means securing a direct link to proven, battle-tested precision engineering. We transform complex, high-tolerance designs into reality, ensuring your components meet the exacting demands of the most challenging global markets, backed by the credibility earned through service to the world’s most stringent programs. Precision is not our claim; it is our documented operational standard.

Precision Specs & Tolerances

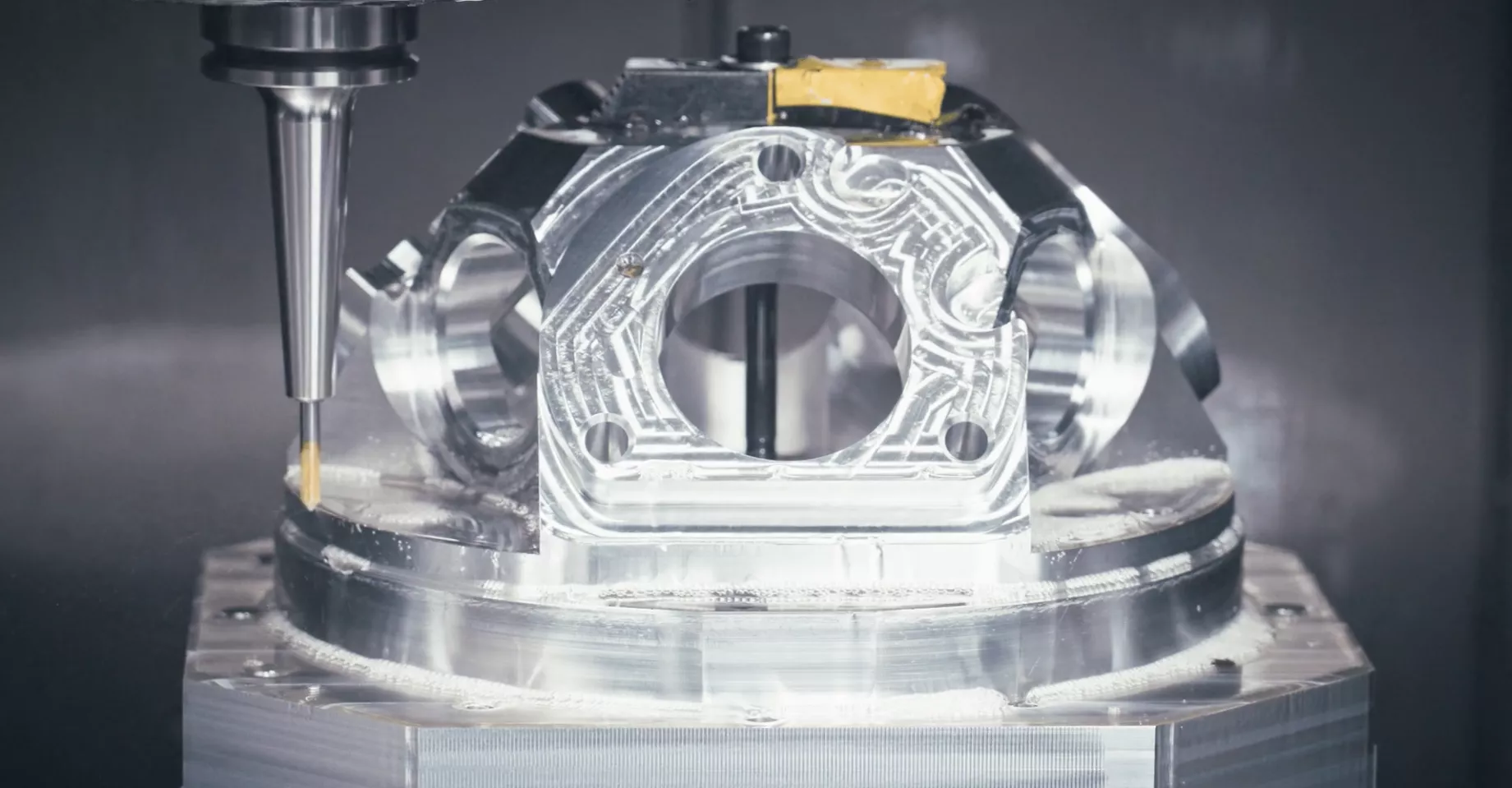

Advanced 5-Axis CNC Machining Capabilities at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our technical foundation is built upon state-of-the-art 5-axis CNC machining systems, enabling us to deliver complex, high-precision components for aerospace, medical, automotive, and industrial automation sectors. Our facility integrates advanced multi-axis technology that allows simultaneous movement across five axes, providing unparalleled flexibility in contouring and machining intricate geometries. This capability significantly reduces setup times, improves part accuracy, and ensures superior surface finishes—critical for high-performance applications where consistency and reliability are non-negotiable.

Our 5-axis machining centers are equipped with high-speed spindles, dynamic tool changers, and real-time monitoring systems to maintain optimal cutting conditions. These machines support a broad range of materials, including aluminum alloys, stainless steels, titanium, Inconel, and engineering plastics, ensuring adaptability across diverse client requirements. With full 360° rotational access to the workpiece, we achieve complex features in a single setup, minimizing human intervention and eliminating cumulative alignment errors common in 3-axis processes.

Integral to our manufacturing excellence is our comprehensive quality control infrastructure. Every component undergoes rigorous inspection using a Zeiss DuraMax and Wenzel LH877 Coordinate Measuring Machine (CMM), ensuring dimensional conformity to the tightest tolerances. Our CMM systems operate within a climate-controlled metrology lab, maintaining thermal stability for measurement repeatability down to the micron level. In addition to first-article inspections, we perform in-process and final QA checks, supported by digital reporting and full traceability for every production batch.

To ensure transparency and precision alignment with client specifications, we adhere to internationally recognized tolerance standards. The following table outlines our standard achievable tolerances across critical dimensions:

| Feature Type | Standard Tolerance | High-Precision Tolerance | Measurement Tool |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.015 mm | ±0.008 mm | CMM, Air Probes |

| Positional Tolerance | ±0.020 mm | ±0.010 mm | CMM |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm | Surface Roughness Tester |

| Angular Features | ±0.1° | ±0.05° | CMM, Optical Comparator |

All inspections are documented with detailed inspection reports, including point-cloud data when required, ensuring full compliance with ISO 9001 standards and customer-specific quality mandates. Our engineering team collaborates closely with clients during the design-for-manufacturability phase to optimize part geometry for precision, cost-efficiency, and scalability.

With a commitment to technical mastery and continuous improvement, Wuxi Lead Precision Machinery stands as a trusted partner for mission-critical CNC machining, where precision, repeatability, and on-time delivery define success.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material choice directly impacts part performance, manufacturability, and lifecycle cost in high-precision CNC applications. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, mechanical properties, and end-use requirements. Aluminum alloys dominate aerospace and electronics due to their favorable strength-to-weight ratio and thermal conductivity. 6061-T6 offers excellent weldability and corrosion resistance for structural components, while 7075-T6 delivers superior strength for high-stress applications like aircraft fittings. Steel remains indispensable for durability; 4140 alloy steel provides exceptional toughness for tooling and shafts, and 304/316 stainless steels ensure corrosion resistance in medical or marine environments. Titanium Grade 5 (Ti-6Al-4V) is critical for extreme conditions, offering unmatched strength-to-weight ratio and biocompatibility in aerospace and medical implants, though its abrasive nature demands specialized tooling and slower machining parameters.

Surface finishes further define functionality and longevity. Anodizing is the premier finish for aluminum, enhancing wear resistance and corrosion protection while enabling color coding. Type II (sulfuric acid) anodizing provides standard decorative and protective layers, while Type III (hardcoat) delivers thicker, denser coatings for severe abrasion resistance in hydraulic or military components. Proper anodizing thickness (typically 12–50 μm) must align with part geometry to avoid dimensional interference on critical tolerances.

Material selection must account for CNC process implications. Aluminum machines rapidly with high feed rates but requires sharp tools to prevent built-up edge. Steel demands rigid setups and controlled coolant to manage heat during deep cuts. Titanium necessitates low RPM, high-pressure coolant, and carbide tooling to combat work hardening and galling. Misalignment between material properties and machining strategy increases scrap rates and lead times.

Below is a comparative overview of key materials for precision CNC work:

| Material | Key Grades | Tensile Strength (MPa) | Machinability Rating (1-10) | Best For |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 8–9 | Lightweight structures, heat sinks |

| Steel | 4140, 304/316 SS | 655–965 | 6–7 | High-strength tooling, medical |

| Titanium | Grade 5 (Ti-6Al-4V) | 900–1,000 | 3–4 | Aerospace, medical implants |

Optimal material and finish selection requires analyzing operational stress, environmental exposure, and geometric complexity. Wuxi Lead Precision Machinery leverages decades of CNC expertise to recommend materials that maximize part integrity while minimizing production costs. Consult our engineering team early in the design phase to validate material suitability against your performance criteria and tolerance demands. Our ISO 9001-certified processes ensure consistent execution from prototype to volume production.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful CNC machining project begins with a rigorous design phase. This stage is not merely about geometry; it is a comprehensive analysis of material behavior, dimensional tolerances, functional requirements, and manufacturability. Our engineering team collaborates closely with clients to convert conceptual ideas into detailed 3D CAD models, ensuring every feature aligns with both performance goals and production feasibility. Using advanced simulation software, we conduct structural and thermal analyses to anticipate stress points, deformation risks, and assembly compatibility. This proactive approach eliminates costly revisions later in the process. All designs are reviewed against international standards and client-specific specifications, establishing a zero-defect mindset from the outset.

Prototyping: Validating Performance and Precision

Once the design is finalized, we proceed to prototyping—a critical checkpoint before mass production. Utilizing high-accuracy 5-axis CNC machines, we fabricate initial samples with the same material and process parameters intended for full-scale manufacturing. This ensures the prototype accurately reflects the final product’s behavior under real-world conditions. Each prototype undergoes a full metrology cycle using coordinate measuring machines (CMM), optical scanners, and surface finish testers. We validate dimensional accuracy, geometric tolerances, and surface integrity against the original CAD model. Functional testing, including fit checks and environmental exposure where applicable, confirms performance reliability. Client feedback is integrated at this stage, allowing for minor refinements without disrupting production timelines. This iterative validation is central to our zero-defect philosophy.

Mass Production: Consistency at Scale

With design and prototype approval, we transition to mass production under a tightly controlled manufacturing protocol. Each CNC machine is calibrated daily, and tool wear is monitored in real time using in-process measurement systems. Our production lines operate under ISO 9001-certified quality management procedures, with full traceability from raw material to finished component. Statistical process control (SPC) is implemented to detect deviations before they affect output quality. Every batch is subjected to first-article inspection and periodic sampling, ensuring continuous compliance. Automated documentation captures machining parameters, inspection results, and operator inputs for audit readiness.

The following table outlines key capabilities supporting our production process:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Max Work Envelope (5-axis) | 1200 x 800 x 600 mm |

| Inspection Equipment | CMM, Optical Comparator, Surface Tester, Laser Scanner |

| Quality Standard | ISO 9001:2015, Full FAI & SPC Compliance |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers components that meet the highest standards of precision and reliability—ensuring zero defects and complete client satisfaction.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership with Wuxi Lead Precision Machinery

In the demanding landscape of high-precision component manufacturing, selecting the right CNC machining partner is a strategic decision impacting product quality, time-to-market, and operational resilience. Wuxi Lead Precision Machinery stands as your dedicated engineering ally, engineered to deliver uncompromising precision for mission-critical applications across aerospace, medical, energy, and advanced industrial sectors. We transcend the role of a standard contract manufacturer; we integrate as an extension of your engineering team, applying decades of specialized expertise to solve complex machining challenges and ensure your components exceed stringent performance requirements. Our commitment begins with a deep understanding of your application’s functional demands, translating into meticulously optimized manufacturing processes that guarantee repeatability and reliability at scale.

Our advanced manufacturing ecosystem is built upon a foundation of cutting-edge technology and rigorous quality systems. We operate a comprehensive suite of multi-axis CNC equipment, maintained to exacting standards and supported by statistically validated process controls. This infrastructure, combined with our ISO 9001:2015 and IATF 16949 certified quality management system, ensures every component meets the most demanding geometric and dimensional specifications. The table below outlines our core machining capabilities, reflecting our capacity to handle your most intricate projects with confidence.

| Capability Parameter | Specification Detail |

|---|---|

| Machine Types | 5-Axis Milling Centers, Multi-Tasking Turn-Mill Centers, High-Speed 3-Axis Mills, Precision Grinding Centers |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-Axis); Ø600 x 1000 mm (Turn-Mill) |

| Positioning Accuracy | ±0.003 mm (ISO 230-2) |

| Repeatability | ±0.002 mm |

| Typical Tolerances Achieved | ±0.005 mm (Critical Features), ±0.02 mm (General) |

| Spindle Speed Range | Up to 24,000 RPM (Milling), Up to 6,000 RPM (Turning) |

| Primary Materials Handled | Aerospace Alloys (Ti-6Al-4V, Inconel), Medical Stainless Steels (316L, 17-4PH), High-Performance Plastics, Tool Steels, Exotic Alloys |

True partnership at Lead Precision means proactive engineering collaboration from prototype through volume production. Our experienced applications engineers engage early in your design phase, providing actionable Design for Manufacturability (DFM) feedback to optimize part geometry, material selection, and process efficiency—reducing cost and accelerating validation without sacrificing performance. We implement robust First Article Inspection (FAI) protocols per AS9102 standards and maintain full traceability through integrated ERP and MES systems, providing you with transparent, real-time production data and comprehensive quality documentation. This meticulous approach minimizes risk and ensures seamless integration into your supply chain.

The competitive advantage lies not just in our machines, but in our people and processes. Our team of senior CNC programmers, master machinists, and quality specialists possess the nuanced understanding required for zero-defect execution on complex, low-volume/high-mix production runs. We prioritize clear, responsive communication and technical transparency, ensuring you are informed and confident at every project milestone. When your application demands the absolute pinnacle of precision, reliability, and engineering partnership, Wuxi Lead Precision Machinery delivers the results that define industry leadership.

Initiate a conversation with our engineering team to discuss how our precision capabilities can directly support your next critical project. Contact us today at [email protected] to schedule a technical consultation and receive a detailed capability overview tailored to your specific manufacturing requirements. Let us demonstrate the Lead Precision difference.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.