Technical Contents

Engineering Guide: Cnc Custom Cutting

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Custom Cutting

In high-stakes manufacturing, CNC custom cutting transcends mere material removal; it is the disciplined execution of geometric intent where precision defines viability. Sub-micron tolerances are not academic exercises but fundamental requirements ensuring functional integrity, assembly compatibility, and ultimate product performance. Variations beyond specified limits cascade into catastrophic failures—misaligned aerospace components inducing flight instability, medical implant interfaces causing biological rejection, or semiconductor tooling generating wafer yield loss. True precision engineering demands holistic control: thermal stability of the machine structure, rigidity of the spindle and tooling interface, advanced motion control algorithms compensating for dynamic forces, and meticulous process validation. It requires understanding that material behavior under high-speed cutting—residual stress, thermal expansion, micro-vibration—dictates the achievable accuracy envelope. Sacrificing precision for speed or cost inevitably elevates scrap rates, incurs costly rework, and damages client trust. The margin for error in critical applications is effectively zero; the machine tool and process must consistently deliver within the design’s absolute boundaries.

Wuxi Lead Precision Machinery operates at this uncompromising threshold. Our engineering heritage is forged in sectors where failure is not an option. We engineered critical timing system components for the 2022 Beijing Winter Olympics, demanding absolute synchronization accuracy under extreme environmental conditions. Similarly, our production of specialized guidance system housings for defense applications required adherence to MIL-STD-810G vibration and shock specifications, alongside micron-level dimensional stability in hardened aerospace alloys. This experience ingrained a culture where precision is measured, verified, and guaranteed—not assumed. Our facility utilizes metrology-grade CNC machining centers operating within controlled environmental chambers, coupled with in-process probing and post-production verification using coordinate measuring machines (CMMs) traceable to national standards. We translate complex engineering drawings into physical reality with documented repeatability.

The table below outlines the core precision capabilities underpinning our custom cutting services for mission-critical components:

| Specification Category | Performance Level | Relevance to Critical Applications |

|---|---|---|

| Positional Accuracy (ISO 230-2) | ±0.001 mm over 300 mm | Ensures feature alignment in multi-part assemblies |

| Repeatability (ISO 230-2) | ±0.0005 mm | Guarantees consistent part-to-part quality |

| Surface Finish (Ra) | As low as 0.4 μm | Critical for sealing surfaces, fatigue life, optics |

| Material Range | Aluminum to Inconel 718, Titanium | Supports demanding aerospace, medical, energy sectors |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates complex, large-scale precision components |

Achieving such precision requires more than advanced hardware; it demands deep process knowledge, rigorous quality protocols, and an engineering mindset focused solely on meeting the functional intent of the design. At Lead Precision, we treat every custom cutting project with the same scrutiny applied to Olympic timing systems or military hardware. This commitment ensures your components perform flawlessly in their intended application, reducing total cost of ownership through minimized waste and guaranteed reliability. Precision isn’t our goal—it’s our operational baseline.

Precision Specs & Tolerances

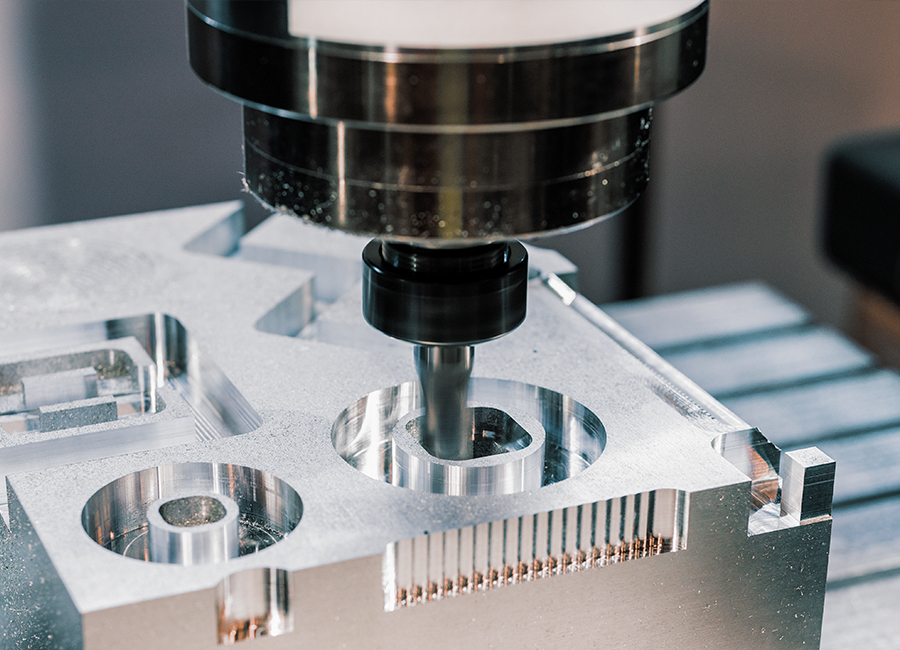

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specializing in custom cutting solutions for high-performance industries such as aerospace, medical, automotive, and energy. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across all five axes, reducing setup cycles and improving part consistency. This capability supports the production of intricate components from a single workholding setup, minimizing human intervention and enhancing repeatability.

Our 5-axis machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring continuous precision across long production runs. These machines are capable of machining a wide range of materials, including aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics, meeting the demanding requirements of mission-critical applications. The integration of high-resolution encoders and thermal compensation systems further ensures dimensional stability under varying operational conditions.

Quality control is embedded throughout our manufacturing process. Every component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machines (CMM) equipped with tactile and optical probes. Our CMM systems provide full 3D geometric dimensioning and tolerance (GD&T) verification, ensuring compliance with ISO 1101 and ASME Y14.5 standards. All inspection data is digitally archived for full traceability, supporting quality audits and production consistency across batches. In addition to post-machining inspection, we employ in-process probing on select CNC machines to verify critical features during machining, allowing for immediate correction and reduced scrap rates.

We maintain strict environmental controls in our metrology lab, including temperature stabilization at 20°C ±0.5°C and vibration-dampened foundations, ensuring measurement accuracy down to the micron level. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and customer satisfaction.

The following table outlines the standard tolerances achievable through our precision CNC custom cutting processes:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.015 mm | ±0.008 mm | CMM, Air Gages |

| Positional Tolerance | ±0.020 mm | ±0.005 mm | CMM (GD&T Analysis) |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm | Surface Profilometer |

| Angular Features | ±0.05° | ±0.01° | CMM, Optical Comparator |

| Flatness | 0.01 mm | 0.003 mm | CMM, Precision Blocks |

These capabilities, combined with our engineering expertise, enable Wuxi Lead Precision Machinery to deliver CNC custom cutting solutions that meet the highest standards of precision, reliability, and repeatability.

Material & Finish Options

Material Selection for Precision CNC Custom Cutting

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in precision CNC custom cutting. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your application’s mechanical, thermal, and environmental demands. Aluminum, steel, and titanium represent the core alloys for high-integrity components, each offering distinct advantages. Understanding their characteristics ensures your design translates into a reliable final product.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. These grades machine efficiently, minimizing tool wear while maintaining tight tolerances. Aluminum’s natural corrosion resistance is further enhanced through anodizing, critical for parts exposed to moisture or chemicals. Its lower density reduces inertia in moving assemblies, a key factor in dynamic applications.

Steel variants like 4140 and 304 stainless steel deliver superior hardness, wear resistance, and structural integrity under high loads. 4140 excels in shafts, gears, and tooling where fatigue resistance is paramount, while 304 stainless offers unmatched corrosion resistance for medical or marine environments. Steel’s higher density provides stability in precision instrumentation but requires robust tooling strategies to manage heat generation during machining.

Titanium Grade 5 (Ti-6Al-4V) is indispensable in extreme conditions—think aerospace actuators or biomedical implants. Its unparalleled strength-to-weight ratio, biocompatibility, and resistance to saltwater and high temperatures justify its premium cost. However, titanium’s low thermal conductivity demands specialized cutting parameters to prevent work hardening and tool deflection, underscoring the need for expert CNC programming and rigid machine setups.

Anodizing is the definitive surface treatment for aluminum components, transforming the outer layer into a durable, corrosion-resistant ceramic oxide. Type II (sulfuric acid) anodizing provides standard protection and dye acceptance for aesthetics, while Type III (hard coat) delivers exceptional abrasion resistance for high-wear interfaces. Both processes maintain dimensional stability when controlled precisely—a capability Wuxi Lead ensures through in-house anodizing oversight and metrology validation.

Material properties directly influence machining strategy, lead time, and final part cost. The table below summarizes critical specifications for common alloys:

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Excellent (70) | Enclosures, brackets, heat sinks |

| Steel 4140 | 655 | 7.85 | Good (65) | Shafts, gears, tooling |

| Stainless 304 | 515 | 8.0 | Moderate (45) | Medical devices, marine hardware |

| Titanium Grade 5 | 900 | 4.43 | Fair (35) | Aerospace fittings, implants |

Strategic material selection balances performance requirements with manufacturability. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced CNC capabilities to guide clients from material specification to finished component, ensuring every cut meets the uncompromising standards of high-end industrial applications. Partner with us to transform your design intent into precision reality.

Manufacturing Process & QC

From Concept to Perfection: The CNC Custom Cutting Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer precision into every stage of the CNC custom cutting process. Our end-to-end workflow—spanning design, prototyping, and mass production—is built on a foundation of zero-defect manufacturing, ensuring that every component meets the exacting standards of high-performance industries such as aerospace, medical devices, and advanced automation.

The process begins with collaborative design engineering. Our team works closely with clients to translate technical drawings, 3D models, and functional requirements into optimized machining plans. Using advanced CAD/CAM software, we simulate toolpaths, analyze material stress points, and select the most suitable alloys or composites. This phase is critical for identifying potential manufacturing constraints early, reducing lead times, and eliminating costly revisions downstream.

Once the design is finalized, we proceed to precision prototyping. Utilizing high-speed 5-axis CNC machining centers, we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous in-house inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We validate dimensional accuracy, fit, and performance under real-world conditions. Client feedback is incorporated at this stage, ensuring full alignment before scaling to volume production.

Mass production is executed on our automated CNC production lines, where consistency and repeatability are paramount. Each machine operates under strict process controls, with real-time monitoring of cutting parameters such as spindle load, tool wear, and thermal expansion. Our quality management system follows ISO 9001 standards, and every production batch is subject to first-article inspection and statistical process control (SPC). We maintain full traceability for materials, tooling, and inspection data, enabling rapid root-cause analysis if deviations occur.

To support zero-defect manufacturing, we integrate preventive maintenance schedules and operator training into daily operations. Our engineers conduct regular process audits and capability studies (Cp/Cpk) to ensure sustained performance. This proactive approach minimizes variability and ensures that every part shipped meets tolerances as tight as ±0.005 mm.

The result is a seamless transition from concept to high-volume output—without compromising on precision, reliability, or delivery timelines.

Typical CNC Custom Cutting Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Tolerance Range | ±0.005 mm (standard), ±0.002 mm (tight) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, PEEK, Brass, Carbon Steel |

| CNC Equipment | 3-axis, 4-axis, 5-axis Machining Centers |

| Production Capacity | 1 to 50,000+ units per order |

| Quality Standards | ISO 9001:2015, Full CMM Inspection Reports |

Through disciplined process control and advanced technology, Wuxi Lead Precision Machinery delivers CNC custom cutting solutions that combine scalability with uncompromised quality—ensuring zero defects and total client confidence.

Why Choose Wuxi Lead Precision

Elevate Your Production with Lead Precision Partnership

At Wuxi Lead Precision Machinery, we transform complex CNC custom cutting challenges into competitive advantages. With over 15 years of specialization in high-tolerance machining for aerospace, medical, and energy sectors, our facility operates at the intersection of German engineering discipline and Chinese manufacturing agility. We deploy ISO 9001-certified processes across 30+ HAAS and DMG MORI centers, ensuring every component meets stringent global standards. Our partnership model eliminates the guesswork in precision manufacturing—delivering certified quality, on-time execution, and technical collaboration from prototype to volume production.

What distinguishes Lead Precision is our commitment to dimensional integrity under real-world conditions. While many suppliers advertise theoretical capabilities, we engineer solutions around material behavior, thermal dynamics, and toolpath optimization. Our engineers proactively identify potential failure points in your designs, reducing scrap rates by up to 35% through preemptive process refinement. This is precision engineering as a value driver, not just a specification checkbox.

Technical Capabilities at a Glance

| Capability | Specification | Application Impact |

|---|---|---|

| Maximum Work Envelope | 2000 x 1200 x 1000 mm | Large-scale structural components |

| Positional Accuracy | ±0.0025 mm (0.0001 inches) | Critical sealing surfaces |

| Spindle Speed Range | 20 – 24,000 RPM | Titanium, Inconel, composites |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Hydraulic/pneumatic components |

| Material Range | Aluminum to hardened tool steel | Single-source material flexibility |

Partnering with us means accessing more than machinery—it means embedding our expertise into your supply chain. Our dedicated project managers provide real-time production analytics via secure client portals, while our in-house metrology lab (equipped with Zeiss CMMs) validates every critical dimension against your prints. For time-sensitive projects, we offer accelerated prototyping with 72-hour turnaround on qualified designs, backed by full FAI documentation. We understand that in high-stakes industries, a missed tolerance isn’t just a rework cost—it’s a reputational risk. That’s why we build redundancy into our quality loops, with triple-stage inspection protocols for mission-critical parts.

Initiate your precision journey with a partner who treats your specifications as non-negotiable commitments. Contact our engineering team to discuss your next project’s technical requirements, volume needs, and compliance framework. We’ll respond within 4 business hours with a tailored capability assessment—not a generic brochure.

Contact [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.