Technical Contents

Engineering Guide: Cnc Auftragsfertigung

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Auftragsfertigung

In the demanding realm of CNC Auftragsfertigung (CNC contract manufacturing), precision transcends mere specification; it is the foundational pillar of product integrity, performance, and ultimately, market success. For German and European manufacturers sourcing high-value components, tolerances measured in microns are not academic exercises but critical determinants of assembly fit, functional reliability, and lifecycle durability. Sub-micron deviations in aerospace actuators, medical implants, or semiconductor tooling can cascade into catastrophic field failures, regulatory non-compliance, or costly recalls. True precision engineering demands a holistic system approach – encompassing advanced machinery, rigorously controlled environmental conditions, metrology-grade tooling, and deeply embedded process discipline. It is the difference between a component that merely exists and one that performs flawlessly under extreme operational stress.

At Wuxi Lead Precision Machinery, we understand this imperative at the most granular level. Our engineering philosophy is forged in the crucible of projects where failure is not an option. We have delivered mission-critical components for Olympic timing systems, where nanosecond synchronization accuracy is paramount, and supplied precision-machined elements for advanced military platforms subjected to severe shock, vibration, and environmental extremes. These engagements demanded far more than meeting nominal tolerances; they required demonstrable, auditable process capability (CpK > 1.67) and unwavering adherence to AS9100 and ITAR standards. Our facility operates under strict thermal stability protocols, utilizes only calibrated coordinate measuring machines (CMMs) traceable to national standards, and implements real-time in-process gauging for critical features. This level of micron-level accountability is not reserved for elite projects – it is the standard we apply to every order within our CNC Auftragsfertigung service.

Our commitment translates directly into tangible value for your supply chain. Partnering with a manufacturer possessing proven experience in the most exacting applications ensures your components are produced with the necessary rigor from Day One. This minimizes risk, reduces total cost of ownership through near-zero defect rates, and provides the confidence that your design intent is realized with absolute fidelity. Precision is not a cost; it is an investment in product excellence and brand reputation.

The following table outlines core production capabilities consistently achieved across our CNC machining operations for demanding sectors:

| Capability | Production Standard | Key Enabling Technology |

|---|---|---|

| Positional Accuracy | ± 0.002 mm | Siemens 840D SL Controls, Linear Encoders |

| Surface Roughness (Ra) | 0.2 – 0.8 µm | High-Precision Spindles, Polycrystalline Diamond Tooling |

| Geometric Tolerance | IT5 – IT6 (ISO 2768) | 5-Axis Simultaneous Machining, Thermal Compensation |

| Material Range | Aluminum Alloys, Titanium, Inconel, Tool Steels, Engineering Plastics | Multi-Function Mill-Turn Centers (Y-axis), High-Pressure Coolant |

| Critical Feature CpK | ≥ 1.67 | SPC Integration, Real-Time Process Monitoring, CMM Verification |

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Manufacturing

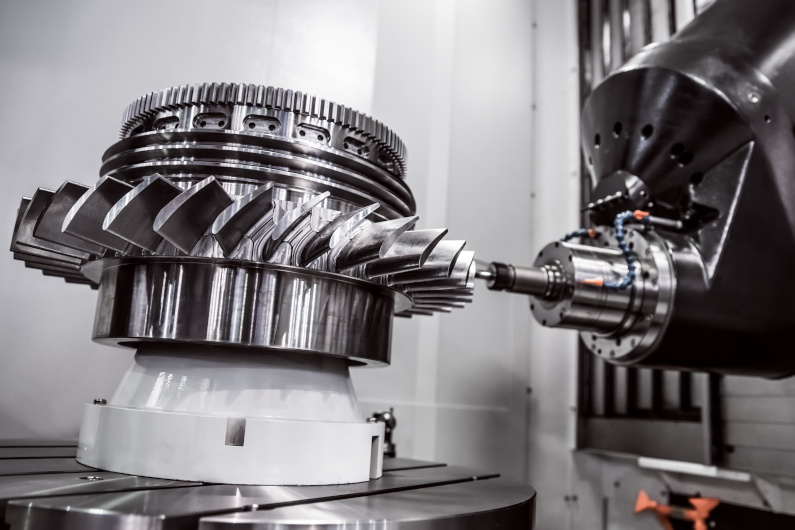

Wuxi Lead Precision Machinery delivers high-precision CNC contract manufacturing services tailored to the most demanding industries, including aerospace, medical, automotive, and industrial automation. Our technical capabilities are built around advanced 5-axis CNC machining systems, which enable us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis platforms allow simultaneous movement across five axes, significantly reducing setup times and ensuring superior part consistency. By eliminating the need for multiple fixturing stages, we maintain tighter tolerances and improve overall component integrity.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure process stability and efficiency. This enables us to work with a broad range of materials, including aluminum alloys, stainless steel, titanium, brass, and engineering plastics such as PEEK and PTFE. Whether producing low-volume prototypes or high-volume production runs, our 5-axis technology ensures repeatability, precision, and rapid turnaround.

Quality control is fully integrated into our manufacturing workflow. Every component undergoes rigorous inspection using a state-of-the-art Coordinate Measuring Machine (CMM), ensuring dimensional compliance with customer specifications. Our CMM system provides 3D measurement accuracy down to ±0.001 mm, enabling full traceability and certification for critical applications. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and digital micrometers to validate both macro and micro features.

All inspection data is documented and available with shipment, supporting compliance with ISO 9001 standards and industry-specific regulatory requirements. Our quality engineers work closely with design and production teams to implement proactive quality planning, including First Article Inspection (FAI) and Production Part Approval Process (PPAP), when required.

The combination of advanced equipment, skilled programming, and systematic quality assurance allows Wuxi Lead to consistently meet the most stringent technical demands. Our in-house capabilities cover milling, turning, drilling, tapping, and precision boring—all executed under controlled environmental conditions to minimize thermal variation and ensure measurement reliability.

Below is an overview of our standard machining tolerances and capabilities.

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Linear Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finish) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Maximum Work Envelope (XYZ) | 1200 x 800 x 600 mm | Custom setups available |

| Minimum Feature Size | 0.5 mm diameter | 0.2 mm with micro tools |

| CMM Measurement Accuracy | ±0.001 mm | Full report available |

Wuxi Lead Precision Machinery maintains a continuous improvement philosophy, investing in the latest CAM software, tooling technologies, and staff training to ensure we remain at the forefront of precision CNC contract manufacturing.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Auftragsfertigung

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in precision CNC contract manufacturing. At Wuxi Lead Precision Machinery, we prioritize material compatibility with both functional requirements and our advanced machining capabilities. Aluminum, steel, and titanium dominate high-specification applications, each offering distinct advantages under specific operational conditions. Understanding their mechanical properties, machinability, and finishing responses ensures your components meet rigorous aerospace, medical, and industrial standards.

Aluminum alloys, particularly 6061-T6 and 7075-T6, deliver an exceptional strength-to-weight ratio and superior thermal conductivity. They are ideal for lightweight structural components, heat sinks, and housings where weight reduction is critical. Aluminum machines efficiently at high speeds, minimizing tool wear and cycle times. Its natural corrosion resistance is significantly enhanced through anodizing, a process we specialize in for both functional and aesthetic outcomes.

Carbon and stainless steel variants like 4140, 17-4PH, and 304/316 provide unmatched tensile strength, wear resistance, and dimensional stability. These materials excel in high-load, high-temperature environments such as hydraulic systems, shafts, and tooling fixtures. While machining steel demands precise toolpath strategies and coolant management to control heat and burr formation, our ISO 9001-certified processes ensure micron-level tolerances and exceptional surface integrity.

Titanium Grade 5 (Ti-6Al-4V) is indispensable for extreme environments requiring biocompatibility, fatigue resistance, and strength at elevated temperatures. Common in aerospace landing gear and medical implants, titanium presents significant machining challenges due to low thermal conductivity and high reactivity. Our specialized tooling, rigid CNC platforms, and optimized cutting parameters prevent work hardening and maintain tight tolerances, maximizing yield on this premium material.

Critical Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Alloys | Primary Applications |

|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | 6061, 7075, 2024 | Aerospace brackets, heat sinks |

| Steel | 7.8 | 655 (4140) | 4140, 17-4PH, 304 | Hydraulic manifolds, shafts |

| Titanium | 4.4 | 900 (Ti-6Al-4V) | Ti-6Al-4V, CP Ti | Aircraft components, implants |

Anodizing: Beyond Surface Enhancement

Anodizing is not merely a cosmetic finish; it fundamentally transforms aluminum’s surface properties. Our precision anodizing process creates a durable, non-conductive oxide layer that dramatically improves corrosion and abrasion resistance. Type II (sulfuric acid) anodizing offers excellent dye receptivity for identification, while hardcoat Type III anodizing achieves thicknesses up to 50µm for severe wear environments. We strictly control electrolyte temperature, voltage, and immersion time to ensure uniform coating thickness and adhesion, critical for components operating in marine or chemical exposure scenarios. Partnering with Wuxi Lead ensures your material and finish selection aligns with both performance demands and manufacturability, reducing lead times and total cost of ownership. Contact our engineering team to validate your material strategy against your application’s lifecycle requirements.

Manufacturing Process & QC

Design Phase: Engineering Excellence from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless production begins with precision-driven design engineering. Our CNC auftragsfertigung process integrates advanced CAD/CAM software to transform client specifications into fully optimized 3D models. Every design is subjected to rigorous simulation and tolerance analysis, ensuring dimensional accuracy, material compatibility, and manufacturability. Our engineering team collaborates directly with clients to validate geometric dimensioning, surface finish requirements, and functional performance under real-world conditions. This collaborative approach minimizes iterations, reduces time-to-prototype, and establishes a zero-defect mindset from day one. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are standard, guaranteeing that every component is not only precise but also production-efficient.

Prototyping: Validating Precision Before Scale

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art 5-axis CNC machining centers. This phase is critical for verifying form, fit, and function. Each prototype is machined from the intended production-grade material—whether aluminum 7075, stainless steel 316L, or titanium Ti-6Al-4V—ensuring realistic performance testing. Dimensional inspection is conducted via coordinate measuring machines (CMM), optical scanners, and surface roughness testers, with all data logged and compared against original CAD specifications. Any deviation triggers immediate root-cause analysis and process correction. Client feedback is incorporated at this stage, allowing for micro-adjustments before committing to full-scale production. This closed-loop validation process ensures that only fully approved designs advance, eliminating costly errors downstream.

Mass Production: Consistency Through Automation and Control

With prototype approval, Wuxi Lead transitions seamlessly into high-volume CNC manufacturing. Our production floor operates under strict ISO 9001-certified protocols, integrating automated tool management, in-process gauging, and real-time spindle monitoring to maintain micron-level tolerances across thousands of parts. Each batch undergoes statistical process control (SPC), with random samples inspected at defined intervals to verify consistency. Our lean manufacturing layout minimizes handling, reduces cycle times, and prevents contamination or damage. Traceability is ensured through serialized part marking and digital production logs, enabling full auditability from raw material to final shipment.

Material and Tolerance Specifications

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Surface Roughness | Ra 0.2 µm to Ra 3.2 µm, customizable |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 316L), Titanium (Ti-6Al-4V), Brass, PEEK, Delrin |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis), 2000 x 1000 x 800 mm (3-axis) |

| Production Capacity | 1 to 50,000+ units per order |

| Quality Standards | ISO 9001:2015, 100% First-Time Yield Target |

Zero defects are not a goal—they are our standard. Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers CNC auftragsfertigung that meets the highest demands of aerospace, medical, and industrial automation sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising German-Grade CNC Contract Manufacturing

When precision demands exceed standard capabilities and supply chain resilience becomes non-negotiable, global manufacturers turn to Wuxi Lead Precision Machinery. We are not merely a CNC contract manufacturer; we are your engineered solution partner, delivering German-level quality standards from our state-of-the-art facility in China. Our integrated approach combines advanced multi-axis machining centers, rigorous metrology protocols, and deep engineering collaboration to transform complex designs into flawless production realities. We understand the exacting requirements of German Auftragsfertigung – tolerances held consistently within microns, material integrity preserved through optimized processes, and traceability embedded at every stage. This commitment is validated by our ISO 9001:2015 and IATF 16949 certifications, alongside documented 99.8% on-time delivery performance for critical aerospace, medical, and automotive components.

The complexities of modern supply chains necessitate a partner who mitigates risk while elevating quality. Lead Precision eliminates the perceived trade-offs often associated with offshore manufacturing. Our dedicated engineering team engages during your design phase, providing actionable DFM feedback to optimize manufacturability without sacrificing performance. We implement closed-loop process control on every job, utilizing in-process gauging and final inspection on calibrated CMMs, optical comparators, and surface profilers. This proactive quality management ensures first-article approval success and sustained production stability, directly protecting your brand reputation and reducing total cost of ownership. You gain transparent project management, real-time production updates, and a single point of accountability – transforming procurement into a strategic advantage.

Our technical capabilities are engineered to meet the highest European specifications. The following table details core production parameters relevant to demanding CNC Auftragsfertigung requirements:

| Capability Category | Specification Detail | Relevance to German Manufacturing Standards |

|---|---|---|

| Machining Tolerances | ±0.002 mm (standard), ±0.001 mm (critical) | Exceeds typical DIN ISO 2768-mK requirements |

| Material Expertise | Titanium, Inconel, Stainless Steel (316L, 17-4PH), Aluminum Alloys, Engineering Plastics | Full compliance with EN material standards |

| Equipment Fleet | 45+ CNC Centers (DMG MORI, MAZAK), 5-Axis Milling/Turning, Swiss-type Lathes | Equivalent technology to Tier 1 German suppliers |

| Quality Assurance | Full CMM Reporting, GD&T Analysis, Material Certificates (EN 10204 3.1), 100% Dimensional Inspection on critical features | Meets stringent automotive (VDA 6.3) and aerospace (NADCAP) mandates |

| Lead Time Reduction | Average 25% faster than European benchmarks for complex components | Addresses critical supply chain volatility |

Choosing Lead Precision means selecting a partner invested in your long-term success, not just fulfilling a purchase order. We operate with the precision mindset German engineering demands, backed by the operational scale and cost efficiency of a leading Chinese manufacturer. Our engineering team is prepared to review your most challenging CNC Auftragsfertigung requirements immediately. Contact us directly to initiate a technical consultation and receive a detailed capability assessment tailored to your specific project. Reach out to our global sales engineering team at [email protected] to secure your precision manufacturing advantage today. Let us demonstrate how Lead Precision becomes the invisible asset in your production chain.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.