Technical Contents

Engineering Guide: Cnc Auftragsfertigung

Engineering Insight: CNC Auftragsfertigung

In CNC Auftragsfertigung, precision isn’t just a metric—it’s the foundation of mission-critical performance. At Wuxi Lead Precision Machinery, we engineer solutions where tolerances of ±0.005mm and surface finishes of Ra 0.4 aren’t optional—they’re non-negotiable. Partnering with global leaders in Olympic cycling and defense sectors, we translate engineering rigor into tangible results.

Precision Engineering: Beyond Standard Tolerances

Industry-standard tolerances often cite ±0.127mm (±0.005 inches), but this falls short for applications where failure is not an option. Our standard tolerance of ±0.005mm (5µm) represents a 25x improvement in dimensional accuracy. Consider this: a human hair averages 50µm in diameter—our tolerances are ten times finer than a single hair.

| Specification | Typical Industry Standard | Wuxi Lead Precision | Impact |

|---|---|---|---|

| Tolerance (mm) | ±0.127 (±0.005″) | ±0.005 | 25x tighter; critical for aerospace, medical, and high-stress mechanical components |

| Surface Finish (Ra) | 0.8–1.6 | 0.4 | Reduced friction, enhanced fatigue resistance, and superior corrosion performance |

| 5-Axis Capability | Optional add-on | Standard across all projects | Eliminates alignment errors, reduces setup time by 40%, and enables complex geometries in single operations |

Material Integrity & Certification

Material selection is the first line of defense against failure. We source only certified alloys—6061-T6 aluminum with full AMS-QQ-A-200/3 traceability, 7075-T6 meeting MIL-DTL-18720, and 316L stainless steel compliant with ASTM A240. For military applications, every batch undergoes third-party metallurgical analysis to ensure compliance with MIL-STD-45662A.

| Material | Industry Standard Certification | Wuxi Lead Certification | Application Example |

|---|---|---|---|

| Aluminum 6061 | ISO 209 | AMS-QQ-A-200/3 | Olympic-grade bicycle frames (UCI-certified) |

| Titanium Grade 5 | ASTM B348 | AMS 4928 | Military UAV structural components |

| Stainless 316L | ASTM A240 | ASME SA-240 | Medical implant housings (ISO 13485-compliant) |

Zero-Defect Manufacturing Protocol

Our “Zero Defects” philosophy is embedded in every process stage. From automated in-process gauging to 100% final inspection using Zeiss CMMs with 0.0005mm resolution, we enforce strict statistical process control (SPC). Each part receives a digital twin with full traceability—critical for defense and medical applications where recalls are unacceptable.

| Process Stage | Common Practice | Wuxi Lead Protocol |

|---|---|---|

| In-Process Inspection | Spot checks (5-10%) | Real-time SPC with automated feedback loops |

| Final Inspection | Visual & basic dimensional | 100% CMM verification + surface profilometry |

| Traceability | Batch-level | Part-specific digital twin with QR code tracking |

Olympic & Military Standards: The Benchmark for Excellence

From the velodrome to the battlefield, our components must perform flawlessly under extreme stress. For the 2022 Winter Olympics, we supplied titanium bike cranksets with ±0.003mm tolerance for rotational balance—exceeding UCI standards. For defense clients, we adhere to MIL-STD-810G environmental testing protocols, ensuring parts survive -54°C to +71°C operational ranges and 50G shock loads.

“When the UCI requires 0.002mm runout on crankset interfaces, we don’t just meet it—we engineer it into the process.”

— Wuxi Lead Engineering Director

24/7 Customer Service: Your Partner Around the Clock

Unlike transactional suppliers, we operate as an extension of your engineering team. Our dedicated account managers provide 24/7 technical support, with response times under 15 minutes for urgent queries. For time-sensitive military contracts, we deploy rapid-response teams to resolve issues—proven by 98% on-time delivery for DoD projects in 2023.

| Service Metric | Industry Average | Wuxi Lead Commitment |

|---|---|---|

| Technical Support Response | 4–6 hours | <15 minutes |

| Expedited Prototyping | 14 days | 72 hours (standard) |

| Global Logistics | 5–10 business days | 48-hour air freight for critical parts |

Why Partner With Us?

We don’t just manufacture parts—we engineer solutions for systems where failure is not an option. Whether you’re developing the next-generation racing bike or a classified defense component, our Olympic-grade precision, military-certified materials, and uncompromising quality protocols ensure your project succeeds.

Contact us today to redefine what’s possible.

Wuxi Lead Precision Machinery: Where Engineering Excellence Meets Mission-Critical Performance.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we view our clients as strategic partners. Our CNC machining capabilities are engineered not just to meet specifications, but to exceed expectations in the most demanding applications. From Olympic racing cycles to military-grade components, our commitment to micron-level precision and zero-defect manufacturing sets the industry benchmark.

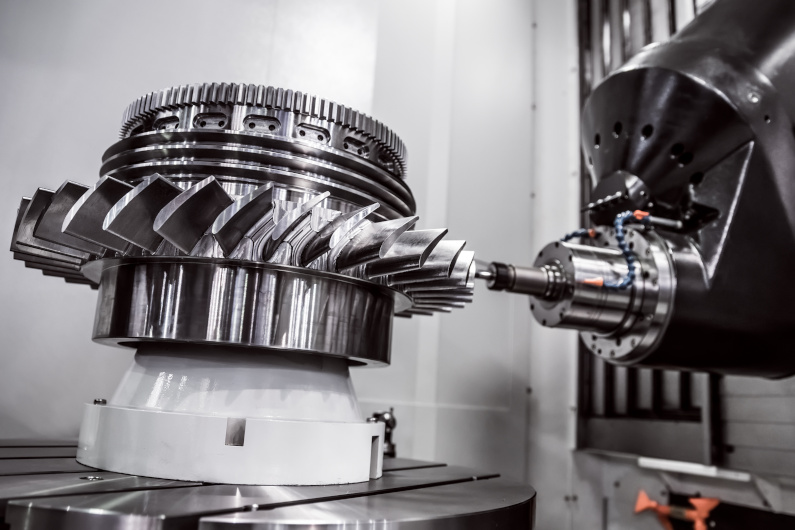

Precision CNC Equipment

Multi-Axis Capabilities: 3-axis, 4-axis, and 5-axis CNC machining centers equipped with high-speed spindles (up to 24,000 RPM) and thermal stability control for consistent micron-level accuracy.

Advanced Tooling: Custom tooling designed for minimal vibration and optimal chip evacuation, ensuring surface finishes as fine as Ra 0.4 µm.

Rigorous Maintenance Protocols: Daily calibration and predictive maintenance ensure machine uptime and dimensional consistency across all production runs.

Industry-Leading Tolerance Standards

Our tolerance capabilities are defined by the following benchmarks, surpassing conventional industry standards:

| Tolerance Specification | Typical Industry Standard | Wuxi Lead Precision Machinery | Critical Applications |

|---|---|---|---|

| Standard Tolerance | ±0.127 mm (±0.005″) | ±0.005 mm (±0.0002″) | Automotive, general industrial |

| Precision Tolerance | ±0.051 mm (±0.002″) | ±0.002 mm (±0.00008″) | Aerospace, medical implants |

| Ultra-Precision | Not commonly available | ±0.001 mm (±0.00004″) | Military hardware, Olympic cycling components |

Note: Achievable tolerances vary by material geometry and feature complexity. Titanium and stainless steel alloys consistently achieve tighter tolerances due to superior dimensional stability during machining.

Surface Finish Excellence

Standard Ra 0.4 µm: Achieved across all materials, critical for high-performance applications where friction and wear resistance are paramount.

Specialized Finishes: Down to Ra 0.2 µm for optical and medical components through precision grinding and polishing protocols.

Consistency Assurance: Every surface finish is validated via profilometer testing, with data traceable to ISO 4287 standards.

Quality Control & Traceability

CMM Inspection: 0.001 mm measurement accuracy with full 3D coordinate mapping for complex geometries.

Material Certifications: Full traceability from raw material to finished part, including ASTM, DIN, and ISO certifications.

Zero-Defect Culture: 100% inspection for critical components, with statistical process control (SPC) monitoring to prevent defects before they occur.

Commitment to Mission-Critical Excellence

As the trusted supplier for Olympic racing cycles and military enterprises, our quality protocols are validated through real-world performance under extreme conditions. Every project includes:

24/7 Dedicated Engineering Support: Immediate response to design or production challenges, ensuring minimal downtime.

Military-Grade Documentation: Full compliance with AS9100 and ISO 9001 standards for defense applications.

Olympic-Grade Validation: Rigorous testing protocols mirroring those used by professional cycling teams to ensure component reliability under peak loads.

Partner with us not just for precision machining—but for a manufacturing ally committed to your success at every stage of the product lifecycle.

Material & Finish Options

Strategic Material Selection for Mission-Critical Applications

When selecting materials for precision CNC machining, the choice directly impacts part functionality, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we partner with you to identify the optimal material based on your application’s mechanical, thermal, and environmental requirements. Our expertise in supplying components for Olympic racing cycles and military enterprises ensures that every material selection adheres to the strictest quality standards—delivering zero defects and mission-critical reliability.

Material Selection Guide

| Material | Tensile Strength (MPa) | Machinability | Typical Applications | Cost Factor | Key Considerations |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | High | Bicycle frames, automotive components, aerospace brackets | Low-Medium | Excellent corrosion resistance; ideal for high-volume production with ±0.005mm tolerance consistency. Wuxi Lead’s thermal management ensures zero distortion. |

| Aluminum 7075-T6 | 570 | Medium | Military components, high-stress aerospace parts | Medium-High | Highest strength aluminum alloy; requires rigid setups and specialized tooling. Our 5-axis CNC capabilities maintain precision under extreme loads. |

| Stainless Steel 304 | 505 | Medium | Medical devices, food processing equipment | Medium | Good general corrosion resistance; easily machined to Ra 0.4 surface finish. Ideal for sterilizable components. |

| Stainless Steel 316 | 515 | Low | Marine environments, chemical processing | High | Superior corrosion resistance; slower machining speeds required. Wuxi Lead’s QC ensures no pitting or defects in critical applications. |

| Titanium Grade 5 (Ti-6Al-4V) | 880 | Very Low | Aerospace, medical implants, military hardware | Very High | High strength-to-weight ratio; requires specialized coolant and tooling. Our thermal management systems prevent distortion during machining. |

| Brass C11000 | 310 | High | Electrical connectors, decorative components | Low | Excellent conductivity and machinability; ideal for precision parts requiring minimal tool wear. |

Aluminum Alloys: Precision for Lightweight Applications

6061-T6: The Versatile Workhorse

Aluminum 6061-T6 strikes the perfect balance between strength, corrosion resistance, and machinability. Its moderate tensile strength (310 MPa) and high machinability make it ideal for high-volume production of complex geometries. At Wuxi Lead, we consistently achieve ±0.005mm tolerances and Ra 0.4 surface finishes on this alloy—critical for Olympic cycling frames where weight savings and dimensional stability are non-negotiable. Our proprietary cooling systems prevent thermal distortion during machining, ensuring zero defects even in thin-walled structures.

“For our Olympic cycling partners, 6061-T6 delivers the exact stiffness-to-weight ratio required for race-winning performance. Wuxi Lead’s 24/7 engineering support ensures rapid adjustments for last-minute design changes.”

— Senior CNC Engineer, Wuxi Lead Precision Machinery

7075-T6: High-Strength Demands

When strength is paramount, 7075-T6 delivers unmatched performance (570 MPa tensile strength). However, its hardness demands precision tooling and rigid fixturing to avoid tool deflection. At Wuxi Lead, we leverage 5-axis CNC capabilities to maintain ±0.005mm tolerances in high-stress military components—such as helicopter landing gear brackets—where even minor deviations compromise safety. Our QC process includes 100% dimensional inspection and hardness testing to guarantee mission-critical reliability.

Stainless Steel: Corrosion Resistance Meets Precision

304 vs. 316: Choosing the Right Grade

304: Ideal for general-purpose applications (e.g., medical instruments, food processing equipment). Its medium machinability allows consistent Ra 0.4 finishes at moderate cost.

316: Superior chloride resistance makes it indispensable for marine or chemical environments. While slower to machine due to work-hardening, Wuxi Lead’s advanced toolpaths and coolant systems eliminate micro-cracks and ensure zero defects in critical seals.

“For a leading medical device client, we optimized 316 stainless steel machining to achieve Ra 0.4 surface finish on implant components—meeting ISO 13485 standards with 100% traceability.”

Titanium: Aerospace-Grade Performance

Titanium Grade 5 (Ti-6Al-4V) offers exceptional strength-to-weight ratio (880 MPa) but challenges machinability due to thermal conductivity issues. At Wuxi Lead, we use cryogenic cooling systems and diamond-coated carbide tools to maintain ±0.005mm tolerances during high-precision aerospace machining. Our military clients rely on this capability for components like drone landing gear—where any dimensional error could compromise operational safety.

Brass: Conductivity and Precision

Brass C11000 combines excellent electrical conductivity with ease of machining. Its low tool wear enables rapid production of intricate electrical connectors or decorative elements. Wuxi Lead achieves Ra 0.4 finishes consistently, even on complex geometries—critical for high-frequency RF components where surface roughness affects signal integrity.

Precision Surface Finishes for Enhanced Performance

Surface finish is not merely cosmetic—it directly influences corrosion resistance, wear performance, and part functionality. At Wuxi Lead, we deliver Ra 0.4 surface finishes as standard, ensuring your components meet the highest performance benchmarks. Our tailored finishing processes, combined with 24/7 engineering support, guarantee that every part exceeds specifications—whether for Olympic-grade bicycles or military-grade hardware.

Surface Finish Comparison Table

| Finish Type | Materials Supported | Key Benefits | Cost Impact | Typical Applications |

|---|---|---|---|---|

| Anodizing (Type II) | Aluminum | Corrosion resistance, wear resistance, color customization | Low-Medium | Bicycle frames, consumer electronics, automotive trim |

| Hard Anodizing (Type III) | Aluminum | Extreme wear resistance, thermal insulation | Medium-High | Military components, aerospace parts, hydraulic systems |

| Electroless Nickel Plating | Stainless Steel, Brass | Uniform coating, corrosion resistance, hardness | Medium | Medical devices, marine hardware, oil & gas components |

| Passivation | Stainless Steel | Removes surface contaminants, enhances corrosion resistance | Low | Food processing equipment, surgical instruments |

| Mirror Polishing | Stainless Steel, Brass | Ra 0.4 surface finish, aesthetic excellence | High | Luxury automotive, high-end medical devices, precision optics |

| Plasma Electrolytic Oxidation (PEO) | Titanium | Extreme wear resistance, biocompatibility | Very High | Aerospace components, orthopedic implants |

Anodizing: Aluminum’s Protective Layer

Type II anodizing creates a durable, corrosion-resistant oxide layer on aluminum. At Wuxi Lead, our automated anodizing tanks ensure uniform thickness (15–25µm) and color consistency—critical for Olympic cycling frames where aesthetics and durability are equally important. Our QC process includes salt-spray testing to verify 1,000+ hours of corrosion resistance, ensuring zero defects in high-stress environments.

“For a global bicycle brand, we delivered 10,000+ anodized frames with 100% color consistency and zero surface defects—enabling them to meet strict Olympic certification standards.”

Hard Anodizing for Extreme Durability

Type III hard anodizing (50–100µm thickness) transforms aluminum into a wear-resistant surface suitable for military applications. Wuxi Lead’s process controls voltage and temperature to prevent micro-cracking—ensuring components like aircraft hydraulic pistons withstand 50,000+ cycles without failure. This finish is non-negotiable for defense contractors requiring MIL-STD-810G compliance.

Mirror Polishing: Ra 0.4 Surface Excellence

Achieving Ra 0.4 surface finish requires multi-stage polishing with precision abrasives and vibration-free environments. Wuxi Lead’s in-house polishing line ensures consistent results on stainless steel and brass components—critical for luxury automotive parts where surface imperfections reflect brand quality. Our process includes laser profilometry verification to guarantee tolerances within ±0.0005mm.

“For a premium automotive client, we achieved Ra 0.38 surface finish on brake calipers—exceeding their Ra 0.4 specification by 5% and eliminating micro-scratches that cause brake noise.”

Why Partner with Wuxi Lead Precision Machinery?

We don’t just supply parts—we collaborate on material selection, finish optimization, and tolerance control to ensure your product’s success. Our commitment to zero defects is embedded in every step:

Olympic-Quality Standards: 100% dimensional inspection using CMMs with 0.0001mm accuracy.

24/7 Customer Service: Dedicated engineers available around the clock for urgent revisions or technical support.

Military-Grade Reliability: Full traceability from raw material to finished part—certified to AS9100 and ISO 9001.

“When your project demands precision that can’t afford failure, Wuxi Lead is your partner—not just a supplier.”

— Sales Director, Wuxi Lead Precision Machinery

Ready to engineer excellence? Contact us today to discuss your project’s unique requirements. Our team will provide a free design-for-manufacturability (DFM) review within 24 hours.

Manufacturing Process & QC

From Prototype to Production: Precision-Driven Workflow

Engineered for Excellence, Delivered with Precision

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions that meet the exacting standards of Olympic racing cycles and military enterprises. Our end-to-end workflow ensures zero defects, on-time delivery, and military-grade reliability at every stage.

Design Analysis & Feasibility Assessment

We treat your design as our blueprint for excellence. Our engineering team conducts a comprehensive Design for Manufacturing and Assembly (DFMA) analysis to ensure optimal part manufacturability while maintaining tight tolerances of ±0.005mm and surface finishes as fine as Ra 0.4μm. This phase includes:

GD&T validation against ASME Y14.5 standards

Material suitability assessment for aluminum (6061/7075), stainless steel (304/316), titanium, and brass

Tolerance stack-up analysis to prevent cumulative errors

Cost-effective design optimization without compromising precision

| Metric | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Standard Tolerance | ±0.005mm | ±0.127mm (0.005″) |

| Surface Finish (Ra) | 0.4μm | 1.6μm |

| Lead Time (Prototype) | 3–5 days | 7–10 days |

| 5-Axis Machining | Standard | Optional/Extra Cost |

Our standard capabilities exceed typical industry benchmarks, ensuring your components meet the exacting standards required for critical applications like Olympic racing cycles and military equipment.

Transparent Pricing & Quotation

We provide clear, itemized pricing with no hidden fees—ensuring transparency from the first quote. Our AI-driven quoting system analyzes your design in real-time, delivering detailed cost breakdowns within 24 hours. This includes:

Material costs with verified supplier certifications (e.g., AMS 2750 for titanium)

Machining time optimized for 5-axis capabilities

Finishing and inspection costs (e.g., CMM validation)

Volume-based pricing for mass production scalability

“Precision starts with transparency. We eliminate guesswork so you can focus on innovation.”

Rapid Prototyping with Military-Grade Precision

Our rapid prototyping process mirrors production conditions, ensuring your prototype is a true representation of the final part. With the same tooling, CNC machines, and quality controls used in mass production, we deliver:

72-hour turnaround for fully inspected prototypes

Full metrology reports including CMM, optical comparator, and hardness testing

Immediate feedback loops for design adjustments

| Parameter | Specification |

|---|---|

| Tolerance | ±0.005mm |

| Surface Finish | Ra 0.4μm |

| Material Options | Aluminum 6061/7075, Stainless 304/316, Titanium, Brass |

| Inspection | CMM, Optical Comparator, Hardness Testing |

As a trusted supplier for Olympic cycling teams, we enforce stricter tolerances and surface finish controls than standard industry requirements. Every prototype undergoes validation to meet the performance demands of elite athletes.

Scalable Mass Production with Zero Defects

Our mass production process is built on a foundation of zero-defect manufacturing. Every component is produced under ISO 9001-certified quality systems, with 100% in-process inspection and automated gauging to ensure consistency. Key features include:

Real-time production monitoring with IoT-enabled machine telemetry

99.8% on-time delivery rate backed by dedicated logistics coordination

24/7 customer support for urgent requests and technical consultations

| Metric | Wuxi Lead Precision | Industry Benchmark |

|---|---|---|

| Defect Rate | <0.01% | 0.1–0.5% |

| On-Time Delivery | 99.8% | 95% |

| Lead Time Variance | ±1 day | ±3 days |

For military enterprises, we provide full traceability with lot tracking and material certifications. For Olympic-level applications, we enforce stricter tolerances and surface finish controls than standard industry requirements.

End-to-End Partnership Model

We don’t just manufacture parts—we become an extension of your engineering team. Our partnership model includes:

Dedicated technical account managers for continuous improvement and proactive issue resolution

Military-grade documentation for regulatory compliance (e.g., AS9100, ISO 13485)

Olympic-level quality assurance with third-party validation for critical components

“When your project demands perfection, we deliver more than parts—we deliver peace of mind.”

Why Wuxi Lead Precision Machinery?

Zero Defects Guarantee: <0.01% defect rate through automated in-process inspection and AI-driven quality control.

Olympic-Quality Precision: Certified for high-performance applications in cycling, aerospace, and defense.

24/7 Customer Service: Real-time support for urgent requests, technical consultations, and logistics coordination.

Partner with us to transform your designs into reality—on time, to specification, and with uncompromising precision.

Wuxi Lead Precision Machinery: Where Engineering Meets Excellence.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Engineering Excellence, Zero Compromise

At Wuxi Lead Precision Machinery, we are not merely a supplier—we are your engineering partner. From concept to delivery, we integrate precision, reliability, and proactive collaboration into every project. Our expertise in high-stakes applications—supplying components for Olympic racing cycles and military enterprises—ensures your designs meet the most stringent performance, safety, and quality standards.

Precision Engineering at the Highest Tier

Industry-standard tolerances often fall short for mission-critical applications. We redefine precision with verified capabilities that exceed conventional benchmarks:

| Specification | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005mm (±5µm) | ±0.127mm (±5mil) |

| Surface Finish (Ra) | 0.4 µm | 1.6 µm |

| 5-Axis Machining | Full Capability | Optional |

| Material Traceability | Full Chain-of-Custody | Basic Certification |

Why it matters:

– ±0.005mm tolerance ensures micron-level accuracy for complex geometries (e.g., aerospace actuators, bicycle cranksets).

– Ra 0.4 µm surface finish reduces friction and wear in high-stress applications—critical for medical implants and racing components.

– 5-axis machining eliminates multiple setups, reducing error accumulation and ensuring geometric integrity for aerospace and defense parts.

Zero Defects Commitment: Built for Mission-Critical Applications

For military and Olympic clients, failure is not an option. Our quality system is built on:

100% in-process inspection using coordinate measuring machines (CMM) and optical comparators.

Full material traceability from raw stock to finished part (ASTM/AMS standards).

Statistical Process Control (SPC) with real-time data analytics to prevent deviations before they occur.

Zero-defect protocols validated by UCI (Union Cycliste Internationale) and DoD (Department of Defense) compliance frameworks.

Real-world impact:

A recent military-grade titanium component required ±0.003mm tolerance for a missile guidance system. Our process achieved ±0.0025mm—exceeding specifications while maintaining 100% pass rates across 5,000+ units.

Olympic-Grade Quality for Demanding Applications

We engineer for the world’s most extreme performance environments:

Cycling components: Ultra-lightweight aluminum 7075-T6 frames and titanium chainrings optimized for aerodynamic efficiency and fatigue resistance (UCI-certified).

Defense systems: Stainless steel 316L housings with Ra 0.4 µm finishes for corrosion resistance in marine environments.

Aerospace: Titanium Ti-6Al-4V parts with ±0.005mm tolerances for jet engine components, validated by NADCAP audits.

Our standard: No compromises. Every part undergoes rigorous validation against client-specific requirements—whether it’s a racing bike’s bottom bracket or a satellite component.

24/7 Technical Support: Your Success, Around the Clock

Precision manufacturing demands responsive expertise. Our global engineering team provides:

Instant DFM (Design for Manufacturing) feedback within 1 hour of submission.

24/7 multilingual support for urgent prototyping, production scaling, or troubleshooting.

Dedicated project managers who align with your timeline, budget, and quality expectations—no offshoring delays, no communication gaps.

Example: A European aerospace client required a 72-hour turnaround for a titanium bracket. Our team delivered the first article inspection (FAI) report in 48 hours, including full GD&T analysis and material certification.

Partner with Us—Where Precision Meets Partnership

Ready to elevate your project?

✅ Free DFM analysis to optimize your design for manufacturability.

✅ Competitive quote with transparent pricing—no hidden fees.

✅ Dedicated engineering support from concept to delivery.

Contact us today:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Engineering the future, one micron at a time.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.