Technical Contents

Engineering Guide: Cnc Aluminium Milling Machine

Engineering Insight: The Critical Role of Precision in CNC Aluminium Milling Machines

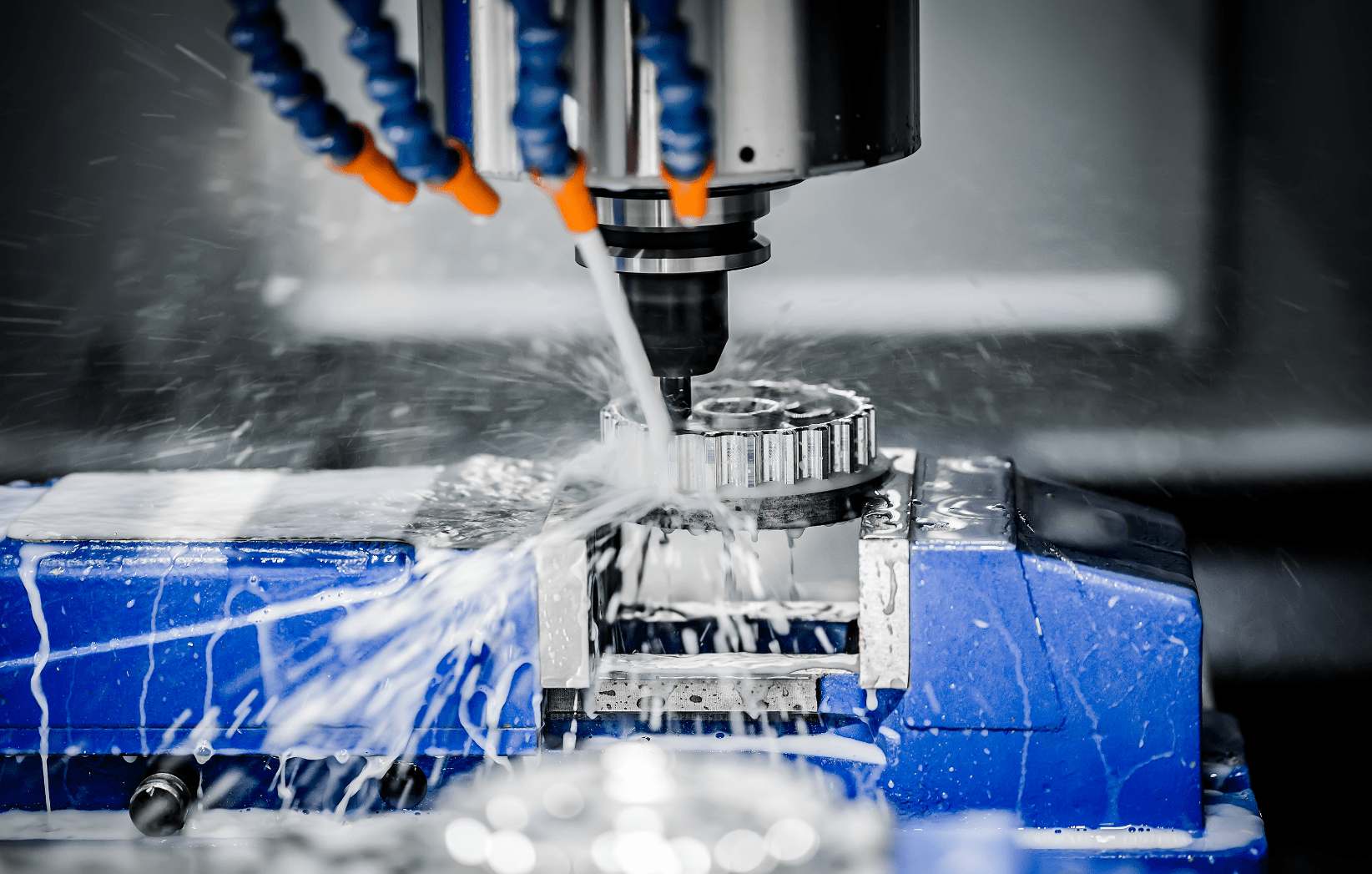

In high-performance manufacturing, the precision of a CNC aluminium milling machine is not merely a technical specification—it is the foundation of reliability, repeatability, and performance. Aluminium, while lightweight and highly machinable, presents unique challenges in high-speed milling due to its thermal conductivity, softness, and tendency to gall or burr if not processed with exacting control. Achieving micron-level tolerances consistently demands more than advanced tooling; it requires a holistic engineering approach that integrates machine rigidity, thermal stability, spindle dynamics, and real-time feedback systems.

At Wuxi Lead Precision Machinery, we have engineered CNC aluminium milling solutions that meet the most stringent global standards. Our machines are developed not only for commercial applications but have been trusted in mission-critical environments, including components for Olympic-standard sports equipment and precision aerospace and defense systems. These applications demand absolute consistency under extreme conditions, reinforcing our commitment to engineering excellence.

Precision begins with the machine’s structural design. Our CNC milling platforms utilize high-grade Meehanite cast iron beds, stress-relieved and precision scraped to ensure long-term geometric stability. Linear guideways with preloaded ball screws and high-resolution encoders maintain positional accuracy across dynamic cutting cycles. To counteract thermal growth—a critical factor in aluminium machining where high spindle speeds generate heat—we integrate thermal compensation algorithms and symmetrical cooling channels in the spindle housing and column.

Our spindles are optimized for aluminium, with speeds reaching up to 24,000 RPM and HSK-E32 tooling for superior clamping force and balance. Combined with high-torque servo motors and a rigid 3-axis configuration, these spindles deliver clean cuts, minimal tool wear, and excellent surface finishes—often eliminating the need for secondary polishing.

Advanced CNC controls with predictive path optimization further enhance precision by adjusting feed rates and tool paths in real time, minimizing vibration and tool deflection. This level of control is essential when machining complex geometries such as impellers, heat sinks, or aerospace brackets, where even a micron of deviation can compromise performance.

Wuxi Lead’s decades of experience in precision engineering are reflected not only in our machine specifications but in the trust placed in us by industries where failure is not an option. Whether producing high-volume consumer electronics enclosures or low-volume, high-mix military components, our CNC aluminium milling machines deliver the accuracy, durability, and repeatability that define true manufacturing excellence.

| Specification | Value |

|---|---|

| Table Size | 1000 mm × 500 mm |

| X/Y/Z Travel | 800 / 500 / 450 mm |

| Spindle Speed | 12,000 – 24,000 RPM |

| Spindle Taper | HSK-E32 |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Control System | Fanuc 31i or Siemens 840D |

| Rapid Traverse (X/Y/Z) | 48 / 48 / 42 m/min |

| Tool Magazine Capacity | 24T (optional 30T) |

| Machine Weight | Approx. 6,800 kg |

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Aluminum Milling

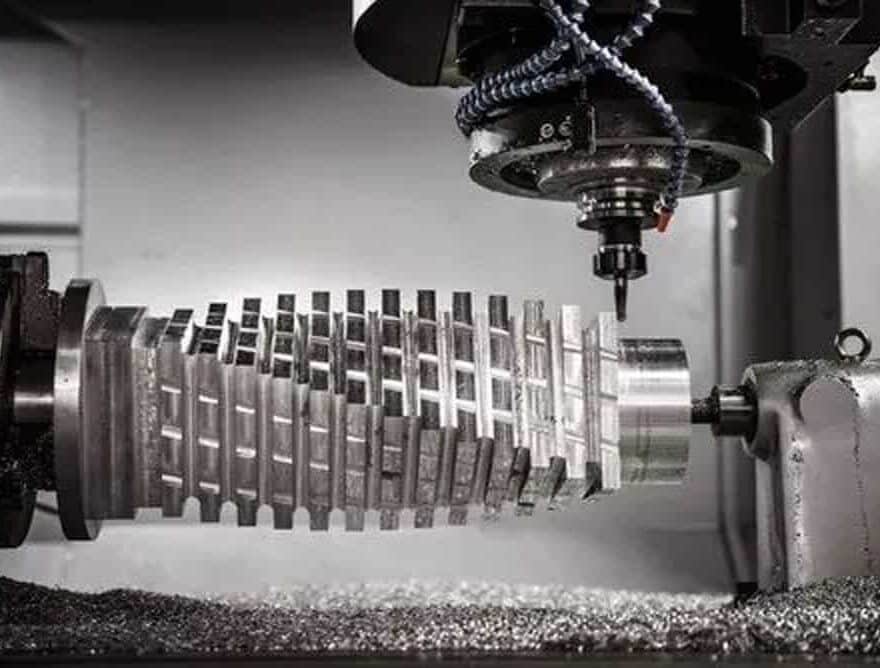

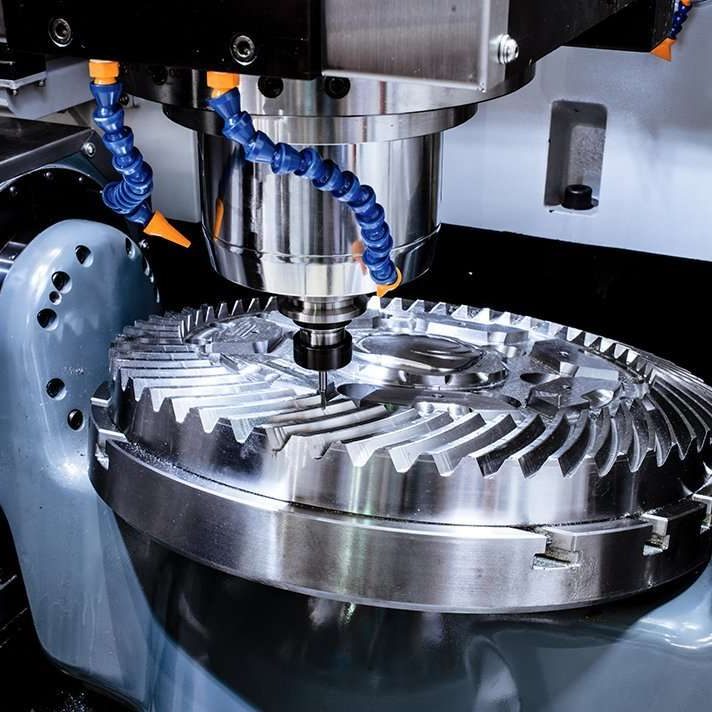

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding aluminum components through advanced 5-axis CNC milling technology. Our core manufacturing capability centers on high-speed, multi-axis machining optimized specifically for aluminum alloys, enabling the production of complex geometries with exceptional surface integrity and dimensional accuracy. We utilize state-of-the-art 5-axis CNC machining centers featuring rigid construction, high-torque spindles (up to 30,000 RPM), and Fanuc or Siemens controls. This equipment foundation allows for simultaneous 5-axis interpolation, eliminating the need for multiple setups and significantly reducing cumulative error sources inherent in 3+2 axis operations. The result is superior part accuracy, improved surface finish, and the ability to machine intricate features such as deep cavities, undercuts, and organic contours in a single operation – critical for aerospace, medical, and high-performance automotive applications.

Our process is meticulously engineered for aluminum. High-speed machining parameters are precisely calibrated to manage chip evacuation efficiently and minimize heat generation, preventing work hardening and thermal distortion that can compromise dimensional stability. Advanced toolpath strategies ensure consistent material removal rates and optimal tool life, while integrated coolant systems maintain thermal equilibrium during extended production runs. Crucially, every component undergoes rigorous post-machining verification using calibrated Coordinate Measuring Machines (CMM). Our quality control protocol involves comprehensive first-article inspection and statistical process control (SPC) sampling on production batches. CMM data is meticulously analyzed against the original CAD model, providing full traceability and objective confirmation that all critical features meet specified tolerances before shipment.

The precision achievable with our integrated 5-axis machining and CMM inspection system is consistently maintained within the following standard tolerance ranges for aluminum components. These capabilities represent our standard production capability under controlled environmental conditions; tighter tolerances are achievable for critical features upon engineering review.

| Feature Category | Capability Description | Standard Tolerance Range |

|---|---|---|

| Linear Dimensions | Overall size, hole positions, slot widths | ±0.005 mm (±0.0002″) |

| Angular Features | Bevels, tapers, compound angles | ±0.005° |

| Geometric Form | Flatness, roundness, cylindricity | 0.008 mm (0.0003″) |

| Surface Finish (Ra) | Machined surfaces (as-machined) | 0.8 µm (32 µin) |

| Hole Concentricity | Relative position of multiple bores | Ø0.010 mm (Ø0.0004″) |

| Profile Tolerance | Complex contours relative to datum system | ±0.010 mm (±0.0004″) |

This documented precision capability, backed by systematic CMM validation, ensures that parts manufactured by Wuxi Lead integrate seamlessly into final assemblies, reducing scrap, minimizing post-machining rework, and guaranteeing functional performance. Our commitment extends beyond mere specification adherence; we partner with clients during the design phase to optimize manufacturability, ensuring the highest yield and cost-effectiveness for complex aluminum components. Trust Wuxi Lead Precision Machinery for mission-critical aluminum parts where dimensional integrity is non-negotiable.

Material & Finish Options

When selecting materials for precision CNC milling applications, understanding the mechanical properties, machinability, and final application requirements is essential. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC aluminum milling machines designed to handle a range of aerospace, automotive, and industrial components. Among the most frequently used materials in our production environment are aluminum, steel, and titanium—each offering distinct advantages depending on performance demands.

Aluminum remains the preferred choice for lightweight, high-strength applications where thermal conductivity and corrosion resistance are critical. Grade 6061-T6 is widely used for structural components due to its excellent weldability and moderate strength, while 7075-T6 offers superior strength-to-density ratios, making it ideal for aerospace parts. Aluminum’s low melting point and high chip evacuation rate allow for faster cutting speeds, reducing cycle times and tool wear on CNC milling machines.

Steel, particularly alloy steels like 4140 and 4340, provides exceptional tensile strength, hardness, and wear resistance. These properties make steel suitable for high-load mechanical components such as gears, shafts, and tooling fixtures. However, steel’s higher density and abrasive nature demand robust spindle systems and carbide tooling. Our CNC aluminum milling machines are engineered with high-torque spindles and rigid bed structures to maintain precision when transitioning between softer aluminum and harder steel alloys.

Titanium, specifically Grade 5 (Ti-6Al-4V), is favored in extreme environments such as aerospace and medical implants due to its outstanding strength-to-weight ratio and resistance to high-temperature oxidation. Despite its benefits, titanium poses significant machining challenges. It has low thermal conductivity, leading to heat concentration at the cutting edge, and high chemical reactivity with tool materials, increasing the risk of galling. Successful titanium milling requires precise control of feed rates, coolant application, and tool geometry—capabilities embedded in Wuxi Lead’s advanced CNC systems.

Post-machining surface finishes further enhance part performance and longevity. Anodizing is the most common finish for aluminum components. Type II (sulfuric acid) anodizing improves corrosion and wear resistance while allowing for color dyeing for identification. Type III (hardcoat) anodizing produces a thicker, denser oxide layer suitable for high-wear environments. Both processes are compatible with tight-tolerance parts when properly accounted for in design.

Below is a comparative overview of key material properties relevant to CNC milling operations.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 95 | 167 | Enclosures, brackets, heat sinks |

| Steel 4140 | 7.85 | 655 | 197 | 42.6 | Shafts, tooling, structural parts |

| Titanium Ti-6Al-4V | 4.43 | 900 | 340 | 6.7 | Aerospace, medical implants |

Selecting the right material and finish ensures optimal performance, cost-efficiency, and longevity of machined components. Wuxi Lead Precision Machinery’s CNC systems are built to deliver consistent accuracy across this full spectrum of engineering materials.

Manufacturing Process & QC

Precision Aluminum Milling: The Zero Defects Production Process at Wuxi Lead

Achieving true zero defects in high-volume CNC aluminum machining demands a rigorously controlled, integrated process from initial concept to final part shipment. At Wuxi Lead Precision Machinery, we execute this through three distinct, interdependent phases: Design for Manufacturability, Rigorous Prototyping Validation, and Statistically Controlled Mass Production. This seamless workflow embeds quality at every step, eliminating waste and ensuring absolute conformance to your specifications.

The foundation is our collaborative Design for Manufacturability (DFM) phase. Our engineering team works directly with your CAD models using Siemens NX, performing comprehensive analysis to optimize geometry for milling efficiency and dimensional stability in aluminum alloys. We identify potential stress points, thin-wall challenges, and fixture requirements before metal cutting begins. Critical tolerances are scrutinized against our machine capabilities and material behavior, with proactive suggestions for minor design refinements that prevent future production defects. This upfront engineering rigor ensures the design is not just functional, but inherently manufacturable to zero-defect standards on our precision equipment.

Prototyping transitions validated design into physical reality under full production conditions. We machine initial prototypes on the exact same 5-axis DMG MORI or MAZAK platforms designated for your series run, using identical tooling, fixturing, and proven CNC programs. Every prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards. Dimensional verification utilizes Zeiss CONTURA CMMs and on-machine probing systems, measuring critical features to micron-level accuracy. Crucially, prototypes undergo functional testing and, where applicable, destructive material analysis to confirm mechanical properties and surface integrity. Only after 100% validation against your print and successful client sign-off does the process advance. This phase is non-negotiable; it proves the process capability and catches any latent issues invisible in simulation.

Mass production leverages the perfected process under stringent statistical process control (SPC). Our networked CNC machines feed real-time data on tool wear, spindle loads, and thermal conditions into our centralized MES. Automated in-process gaging at defined intervals verifies critical dimensions without halting the line. SPC charts monitor key characteristics, triggering immediate corrective action before any parameter drift could cause non-conformance. Operator expertise is augmented by standardized work instructions and visual aids derived directly from the validated prototype run. Every batch includes final inspection using calibrated CMMs and optical comparators, with full traceability from raw billet to finished part. This closed-loop system, built on the foundation of DFM and prototyping, ensures consistent output where deviations are statistically improbable, not merely inspected out.

Our core machine capabilities directly enable this zero-defects outcome, as detailed below:

| Parameter | Specification | Relevance to Zero Defects |

|---|---|---|

| Positioning Accuracy | ±0.002 mm (ISO 230-2) | Ensures micron-level feature placement |

| Repeatability | ±0.001 mm (ISO 230-2) | Guarantees consistent part-to-part conformity |

| Thermal Compensation | Real-time 3D System | Eliminates drift from ambient temperature changes |

| On-Machine Probing | Renishaw RMP60 | Enables automated in-process dimensional verification |

| Spindle Runout | < 0.001 mm (TIR) | Critical for fine surface finishes and tight tolerances |

| Vibration Control | Active Damping System | Prevents chatter marks and dimensional errors |

This integrated approach transforms zero defects from an aspiration into a measurable, sustainable outcome. By perfecting the process upstream and controlling it relentlessly downstream, Wuxi Lead delivers aluminum components where quality is inherent, not incidental, minimizing your total cost of quality and ensuring supply chain reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced CNC Aluminium Milling Solutions

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and efficiency are non-negotiable in high-end manufacturing. As a trusted leader in CNC machining technology, we specialize in delivering high-performance CNC aluminium milling machines engineered to meet the rigorous demands of aerospace, automotive, medical, and industrial sectors. When you partner with Lead Precision, you gain more than equipment—you gain a strategic advantage in production capability, process optimization, and long-term cost efficiency.

Our CNC aluminium milling machines are designed with cutting-edge control systems, high-torque spindles, and rigid structural frames to ensure micron-level accuracy and exceptional surface finishes. Every machine is built to handle the unique challenges of aluminium machining, including high-speed cutting, chip evacuation, and thermal stability. With optimized tool paths and advanced cooling systems, our solutions maximize material removal rates while minimizing tool wear and cycle times.

We go beyond equipment by offering comprehensive support throughout the lifecycle of your machine. From initial consultation and customization to installation, training, and ongoing maintenance, our team of engineers and technicians ensures seamless integration into your production environment. Whether you require a standard configuration or a fully customized milling solution, we work closely with you to align performance with your specific manufacturing goals.

At Wuxi Lead, innovation is driven by customer success. Our R&D department continuously refines machine dynamics, software integration, and automation compatibility to keep pace with evolving industry standards. We are committed to sustainable manufacturing practices, incorporating energy-efficient components and smart monitoring systems that reduce downtime and improve operational transparency.

For global partners seeking a reliable, high-precision CNC machining source in China, Wuxi Lead Precision Machinery delivers unmatched quality and service. Our machines are ISO 9001 certified and tested under real-world conditions to ensure durability and performance across diverse applications.

To elevate your manufacturing capabilities with a machine built to lead, contact us today. Reach out to our sales engineering team at [email protected] to discuss your requirements, request a technical consultation, or schedule a virtual demonstration. Let us help you achieve precision, productivity, and performance—on time, every time.

| Model | Spindle Speed (RPM) | Table Size (mm) | X/Y/Z Travel (mm) | Rapid Traverse (m/min) | Control System |

|---|---|---|---|---|---|

| LP-MV850 | 8,000 | 900 × 500 | 850 × 500 × 500 | 36 | FANUC 0i-MF |

| LP-MV1060 | 10,000 | 1,100 × 600 | 1,000 × 600 × 600 | 42 | Siemens 828D |

| LP-HM1270 | 12,000 | 1,300 × 700 | 1,200 × 700 × 700 | 48 | Heidenhain TNC530 |

Contact [email protected] to begin your partnership with Wuxi Lead Precision Machinery—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.