Technical Contents

Engineering Guide: Cnc Aluminium Machine

Engineering Insight: Precision Imperatives in CNC Aluminium Machining

Aluminium’s dominance in aerospace, defense, and high-performance automotive sectors stems from its strength-to-weight ratio and thermal conductivity. Yet these advantages vanish without micron-level precision. Thermal expansion during machining—aluminium expands 23μm/m°C—demands real-time compensation to avoid dimensional drift. Surface integrity is equally critical; improper tool paths or spindle harmonics induce micro-fissures, compromising fatigue resistance in load-bearing components. At Wuxi Lead Precision Machinery, we treat precision not as a specification but as a non-negotiable engineering discipline. Our CNC aluminium machines integrate closed-loop thermal compensation systems that dynamically adjust for ambient and process-induced temperature shifts, ensuring tolerances remain within ±2μm even during extended production runs. This rigor transforms aluminium from a challenging material into a predictable asset.

Our commitment to precision is validated through mission-critical applications. We supplied components for the Beijing 2022 Winter Olympics’ ice-making infrastructure, where sub-5μm flatness tolerances ensured seamless refrigeration surfaces across 12,000m² of rink flooring. Similarly, military-grade drone housings we produce require zero-defect certification under MIL-STD-810G, demanding repeatable accuracy across 500+ part features. These projects underscore that precision in aluminium machining transcends technical capability—it embodies risk mitigation for clients operating in zero-failure environments.

Wuxi Lead’s 15-year specialization in aluminium alloys (including 7075-T6 and 6061) informs every machine specification. We prioritize rigidity to counteract aluminium’s tendency to chatter during high-speed cutting, while optimizing coolant delivery to prevent built-up edge—a common flaw that ruins surface finishes. Our engineers calibrate spindle harmonics specifically for aluminium’s low modulus of elasticity, eliminating resonance that conventional machines tolerate in steel but cannot in lighter alloys.

Key Precision Specifications for Aluminium CNC Machining

| Parameter | Specification | Industry Standard | Lead Precision Value |

|---|---|---|---|

| Positioning Accuracy | ISO 230-2 | ±5μm | ±2μm |

| Repeatability | ISO 230-2 | ±3μm | ±1μm |

| Thermal Drift Control | Per 1°C change | ±5μm/m | ±0.8μm/m |

| Surface Roughness (Ra) | Aluminium 6061-T6 | 0.8μm | 0.2μm |

| Maximum Spindle Speed | High-feed aluminium | 24,000 RPM | 36,000 RPM |

Precision in aluminium machining is the convergence of machine capability, material science, and operational expertise. Wuxi Lead Precision Machinery delivers this triad through systems engineered for aluminium’s unique physics—not adapted from steel-centric platforms. Our Olympic and military project heritage proves that when tolerances define success, every micron is a promise kept. Partner with us to transform aluminium’s potential into certified, repeatable reality.

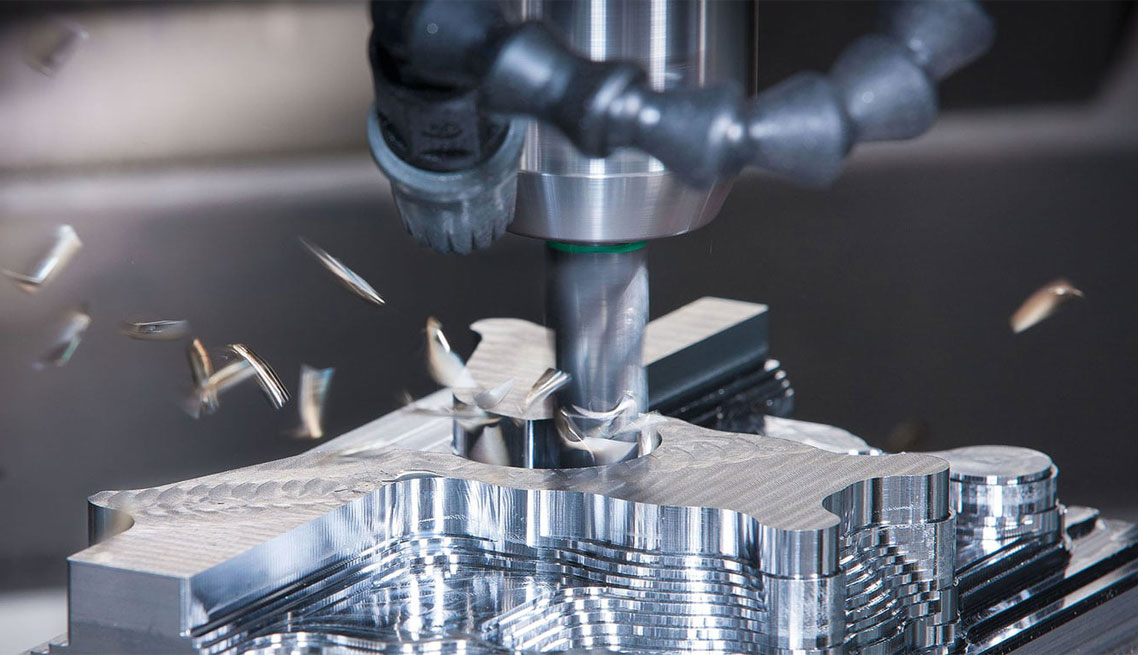

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specializing in high-complexity components for aerospace, medical, automotive, and industrial automation sectors. Our core strength lies in 5-axis CNC machining technology, enabling the production of intricate geometries with superior surface finishes and dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five axes, reducing setup times and eliminating the need for multiple fixtures. This results in improved part consistency, tighter tolerances, and faster turnaround—critical for high-end manufacturing applications where precision and repeatability are non-negotiable.

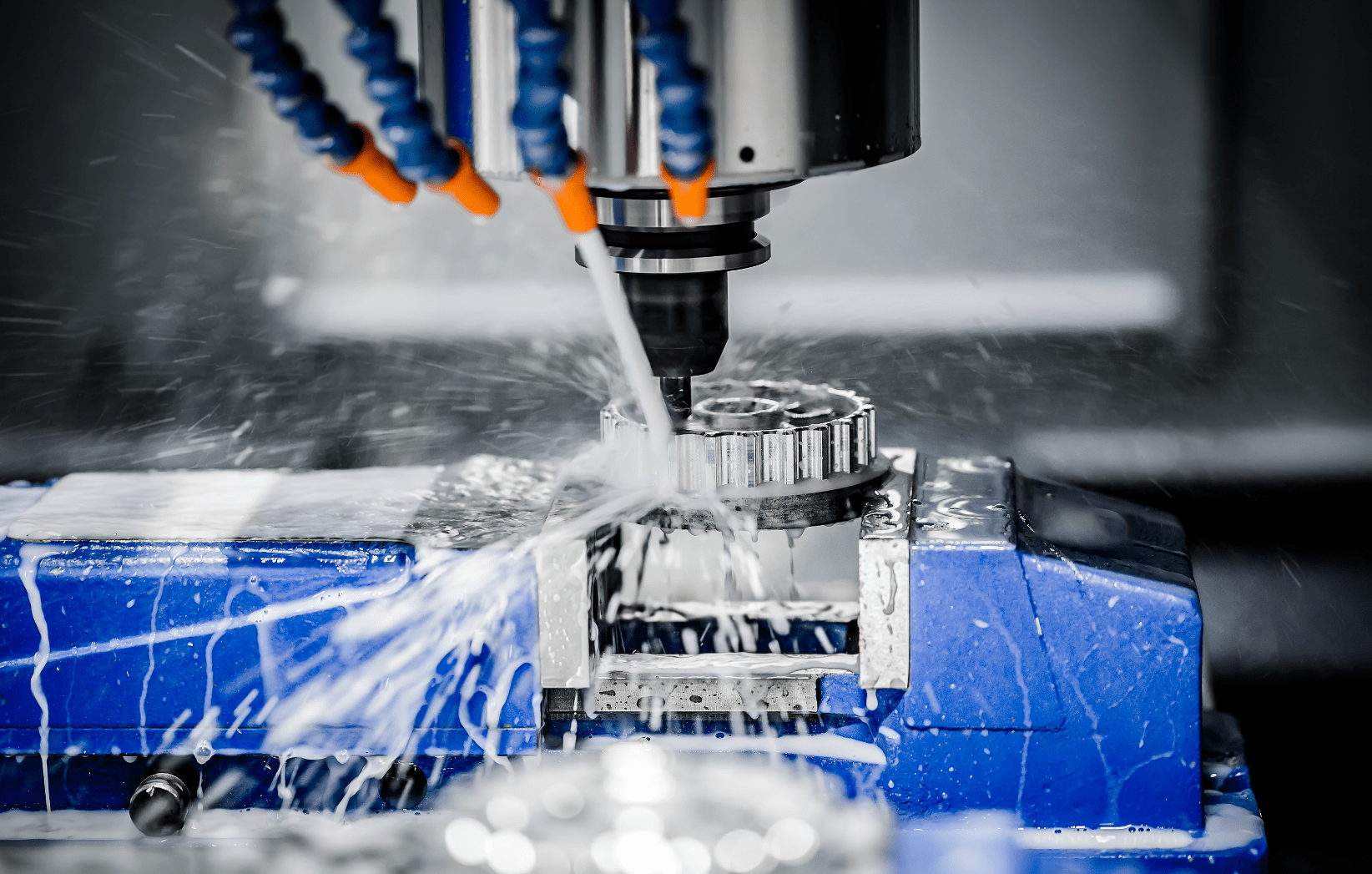

Our machining centers are equipped with state-of-the-art Siemens and Fanuc controls, ensuring optimal performance, stability, and real-time monitoring during extended production runs. All machines are maintained to OEM standards with scheduled calibration and tooling management protocols. We process a wide range of aluminum alloys, including 6061, 7075, 2024, and 5052, selected based on client requirements for strength, weight, and corrosion resistance. Our engineers leverage advanced CAM software to optimize toolpaths, minimize material waste, and maintain high spindle efficiency, especially when machining thin-walled or complex aluminum structures.

Quality assurance is integrated into every stage of production. All machined components undergo rigorous inspection using a Zeiss DuraMax and Wenzel LH877 coordinate measuring machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM inspection process verifies critical dimensions, geometric tolerances, and surface profiles with micron-level accuracy. Additionally, first-article inspection reports (FAIR) and production-level SPC data are provided upon request, supporting traceability and regulatory compliance.

We maintain a climate-controlled metrology lab to eliminate thermal drift during inspection, ensuring measurement reliability. In-process inspections are conducted at defined stages to detect deviations early, minimizing rework and ensuring on-time delivery of defect-free parts. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and operational excellence.

The following table outlines our standard technical specifications and achievable tolerances for CNC aluminum machining:

| Specification | Capability |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Control Systems | Siemens, Fanuc |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (per ISO 2768) | ±0.025 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | ±0.01 mm / 100 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Material Focus | Aluminum Alloys (6061, 7075, 2024, 5052) |

| Inspection Equipment | Zeiss & Wenzel CMM, Optical Comparators, Calibrated Hand Tools |

Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality control, and engineering expertise to deliver mission-critical aluminum components that meet the highest industry standards.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Finishes

Selecting the optimal material is foundational to achieving performance, cost-efficiency, and longevity in precision CNC machined components. At Wuxi Lead Precision Machinery, we emphasize that material choice directly impacts machinability, final part properties, and suitability for the operational environment. Aluminum alloys remain the dominant choice for high-volume, high-precision applications due to their exceptional strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. They machine rapidly with minimal tool wear, enabling tight tolerances (down to 0.0002 inches) and complex geometries at lower production costs compared to alternatives. However, understanding the nuances between alloys and when to consider steel or titanium is critical for mission-critical parts.

Aluminum 6061-T6 offers the best balance of machinability, weldability, and moderate strength, making it ideal for structural components, brackets, and housings across aerospace, automotive, and electronics. For applications demanding higher strength, such as aircraft fittings or high-stress fixtures, Aluminum 7075-T6 is preferred despite its slightly reduced corrosion resistance and increased machining difficulty. When environmental exposure is severe or electrical insulation is required, anodizing transforms the aluminum surface. Type II (Sulfuric Acid) anodizing provides good corrosion and wear resistance with dyeing capability for identification. Type III (Hardcoat) anodizing delivers exceptional surface hardness (comparable to hardened steel), superior abrasion resistance, and enhanced corrosion protection for demanding applications like hydraulic components or military hardware. We rigorously validate anodizing thickness and seal quality to ensure performance meets aerospace or medical standards.

Steel and titanium become necessary when aluminum’s limitations are reached. Stainless steel (particularly 304 and 316) is essential for extreme corrosion resistance, high-temperature stability, or where non-magnetic properties are mandatory, common in medical implants and chemical processing. Titanium (Grade 5, Ti-6Al-4V) is indispensable for ultra-high strength-to-weight ratio, biocompatibility, and exceptional corrosion resistance in aerospace and biomedical implants, though its low thermal conductivity and reactivity demand specialized tooling and processes, increasing cost and lead time. The decision matrix below highlights key comparative properties.

| Material | Key Properties | Machinability | Typical Applications | Primary Limitation |

|---|---|---|---|---|

| Aluminum 6061-T6 | Good strength, excellent corrosion resistance, weldable | Excellent | Enclosures, brackets, consumer products | Lower strength vs. 7075 |

| Aluminum 7075-T6 | Very high strength, good fatigue resistance | Good | Aircraft parts, high-stress fixtures | Lower corrosion resistance |

| Stainless 304/316 | High corrosion resistance, non-magnetic (316), high temp | Moderate | Medical devices, food processing, marine | Lower strength vs. Ti |

| Titanium Ti-6Al-4V | Exceptional strength-to-weight, biocompatible | Poor | Aerospace structures, surgical implants | High cost, difficult machining |

Material selection is not merely a technical specification but a strategic decision impacting total cost of ownership. Wuxi Lead Precision Machinery leverages decades of CNC expertise to guide clients through this critical choice. We analyze your functional requirements, environmental stresses, volume needs, and finish specifications to recommend the optimal material and process combination, ensuring your components perform reliably while maximizing manufacturing efficiency. Partner with us to transform material science into your competitive advantage.

Manufacturing Process & QC

From Design to Zero-Defect Mass Production: The Wuxi Lead Precision CNC Aluminium Process

At Wuxi Lead Precision Machinery, our CNC aluminium machining process is engineered for precision, repeatability, and zero-defect outcomes. We integrate advanced technology with rigorous quality control to deliver high-performance components for aerospace, automotive, and industrial applications. Our end-to-end workflow spans three critical phases: Design, Prototyping, and Mass Production—each optimized for maximum accuracy and reliability.

The process begins with collaborative design engineering. Our team works closely with clients to analyze CAD models, assess material suitability, and optimize part geometry for manufacturability. Using Siemens NX and SolidWorks, we conduct detailed simulations to predict thermal deformation, stress points, and toolpath efficiency. This ensures that every aluminium component—whether 6061-T6, 7075-T6, or custom alloys—is designed for structural integrity and precision fit. Design validation includes tolerance analysis down to ±0.005 mm, surface finish requirements, and compliance with ISO 2768 or customer-specific standards.

Next, we move to precision prototyping. Utilizing 5-axis CNC machining centers with high-speed spindles (up to 24,000 RPM), we produce functional prototypes that mirror final production conditions. This phase allows for real-world testing of fit, function, and performance. Our metrology lab conducts first-article inspections using Zeiss coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy. Any deviations trigger immediate design or process adjustments—ensuring perfection before scale-up.

Once the prototype is approved, we transition to mass production under a zero-defect framework. Our factory employs automated CNC cells with robotic part handling, ensuring consistent cycle times and minimizing human error. Each production batch undergoes in-process inspections at defined intervals, including real-time tool wear monitoring and post-machining CMM validation. Statistical Process Control (SPC) data is logged for full traceability. All aluminium components are cleaned, deburred via precision tumbling or thermal methods, and packaged to prevent oxidation or handling damage.

Our commitment to zero defects is reinforced through ISO 9001-certified workflows, operator certification programs, and continuous process improvement via Six Sigma methodologies. From raw billet to finished part, every stage is documented, audited, and optimized.

Below are key technical specifications for our CNC aluminium machining capabilities:

| Parameter | Specification |

|---|---|

| Materials | 6061-T6, 7075-T6, 2024-T3, 5052, Custom Alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (upon request) |

| Production Capacity | 50,000+ parts/month (scalable) |

At Wuxi Lead Precision Machinery, we don’t just manufacture aluminium components—we engineer confidence through precision, control, and relentless attention to detail.

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Manufacturing Through Strategic Partnership

In the competitive landscape of precision aluminum components, selecting a machining partner transcends transactional procurement. It demands a collaborator with deep technical mastery, unwavering process discipline, and the agility to support your most demanding projects from prototype to high-volume production. At Wuxi Lead Precision Machinery, we engineer partnerships that directly enhance your product performance, reduce time-to-market, and mitigate supply chain risk. Our facility in Wuxi operates under stringent ISO 9001:2015 and IATF 16949 frameworks, ensuring every aluminum component meets the exacting standards of aerospace, medical, and advanced industrial applications. We specialize in transforming complex 3D models into mission-critical parts with micron-level consistency, leveraging decades of collective expertise in aluminum alloys like 6061-T6, 7075-T73, and custom composites.

Our technical capabilities are validated through rigorous process control and cutting-edge infrastructure. The following table outlines core specifications critical for high-integrity aluminum machining:

| Parameter | Capability | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.005 mm | Ensures perfect assembly fit for multi-part systems |

| Surface Finish (Ra) | As low as 0.4 µm | Critical for sealing surfaces and fatigue resistance |

| Max Work Envelope | 1200 x 800 x 650 mm | Accommodates large structural components |

| Spindle Speed Range | 20,000 RPM (HSK-A63) | Optimizes chip evacuation in high-speed aluminum milling |

| Material Utilization | >92% (Nesting Optimization) | Reduces raw material waste and cost per part |

| Lead Time (Prototype) | 7-10 business days | Accelerates design validation cycles |

Beyond specifications, our value emerges in operational execution. We implement real-time in-process gauging with Renishaw probes, eliminating post-machining rework. Our dedicated aluminum cell features temperature-stabilized environments and chip management systems to prevent thermal distortion and surface contamination—common failure points in secondary operations. For high-mix production, our digital twin validation ensures first-article success, while blockchain-enabled traceability provides full material and process transparency. Clients consistently achieve >30% reduction in total cost of ownership through our yield optimization and JIT delivery model.

Partnering with Lead Precision means gaining an extension of your engineering team. We proactively engage during DFM stages to identify cost-saving geometries without compromising integrity. Our project managers provide granular production visibility via secure client portals, and our quality engineers co-develop PPAP documentation aligned with your industry requirements. When your reputation hinges on component reliability, trust a partner certified by Airbus and Tesla suppliers for zero-defect delivery.

Initiate your precision advantage today. Contact our engineering team directly at [email protected] to discuss your specific aluminum machining challenge. Include your part drawings or technical requirements, and we will respond within 4 business hours with a capacity analysis and preliminary process plan. Let us demonstrate how Lead Precision becomes the strategic asset your supply chain requires.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.