Technical Contents

Engineering Guide: Cnc Aluminium

Engineering Insight: CNC Aluminium – The Benchmark of Precision in Modern Manufacturing

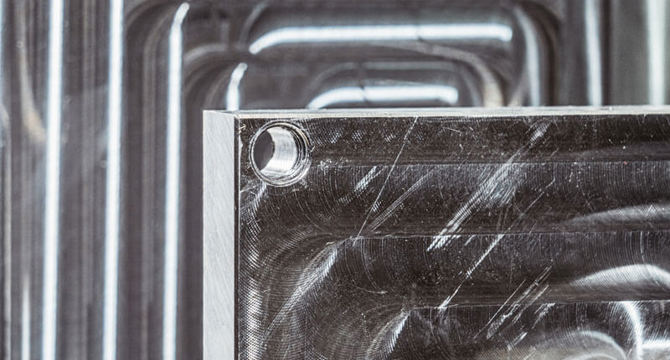

In the realm of high-performance engineering, CNC aluminium stands as a cornerstone material for industries where strength, weight efficiency, and dimensional accuracy are non-negotiable. At Wuxi Lead Precision Machinery, we recognize that machining aluminium is not merely about shaping metal—it is about achieving micron-level consistency, structural integrity, and repeatability under exacting conditions. Precision in CNC aluminium machining directly influences the performance, safety, and longevity of end-use components, particularly in aerospace, defense, medical technology, and high-end industrial automation.

Aluminium, while inherently malleable and lightweight, presents unique challenges in precision machining. Its thermal conductivity and softness require optimized cutting parameters, specialized tooling, and advanced CNC strategies to prevent deformation, burring, or surface finish degradation. At Lead Precision, our engineering protocols are built on over a decade of refinement, enabling us to maintain tolerances as tight as ±0.005 mm. This level of accuracy is not incidental—it is the result of rigorous process control, real-time monitoring, and a deep understanding of material behavior under high-speed machining conditions.

Our expertise has been validated through mission-critical applications, including components engineered for Olympic-standard sporting equipment and precision subsystems deployed in military-grade hardware. These projects demand more than technical capability; they require a culture of excellence where every micron is accounted for and every process is traceable. Whether producing intricate heat sinks for defense electronics or lightweight structural frames for high-speed automation, our CNC aluminium components are engineered to exceed functional and regulatory expectations.

Wuxi Lead Precision Machinery operates a fully integrated CNC facility equipped with multi-axis machining centers, coordinate measuring machines (CMM), and in-process inspection systems. This infrastructure ensures that each aluminium part conforms to design intent across batches, with full documentation for quality assurance. Our team of engineers applies adaptive machining techniques, including high-speed milling and deep-hole drilling, tailored specifically to aluminium alloys such as 6061, 7075, and 2024—each selected for their balance of strength, corrosion resistance, and machinability.

Below is a summary of our standard CNC aluminium machining capabilities:

| Specification | Detail |

|---|---|

| Material Types | Aluminium 6061, 7075, 2024, 5052, and custom alloys |

| Tolerance | ±0.005 mm (standard), down to ±0.002 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.4 µm (polished/precision) |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Machining Axes | 3-axis, 4-axis, and 5-axis simultaneous |

| Secondary Operations | Deburring, anodizing, laser marking, precision tapping |

| Quality Standards | ISO 9001:2015, full first-article inspection, batch traceability |

Precision in CNC aluminium is not just a technical achievement—it is a commitment to reliability, performance, and trust. At Wuxi Lead Precision Machinery, we deliver engineered solutions where accuracy is not measured in millimeters, but in microns.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Machining Excellence

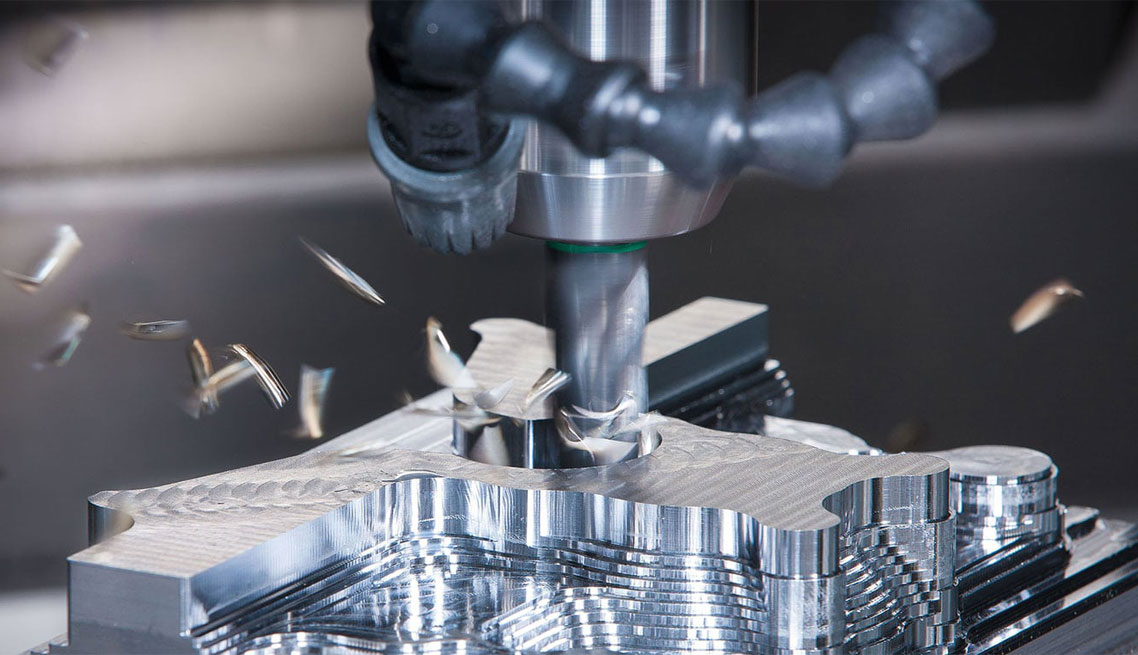

Wuxi Lead Precision Machinery delivers uncompromising precision in CNC aluminum machining, leveraging advanced multi-axis technology and rigorous quality control to meet the exacting demands of aerospace, medical, and industrial automation sectors. Our facility operates 18 state-of-the-art 5-axis CNC machining centers, including DMG MORI and MAZAK platforms, engineered for complex geometries and tight-tolerance components. These systems integrate simultaneous 5-axis interpolation, high-speed spindles (up to 24,000 RPM), and automated tool changers to eliminate secondary operations, reduce lead times by 35%, and ensure micron-level repeatability. This capability is critical for manufacturing intricate aluminum housings, fluid manifolds, and structural brackets where angular features and undercuts demand seamless single-setup machining.

Material optimization is central to our process. We specialize in 6061-T6, 7075-T6, and 2024-T3 aluminum alloys, utilizing proprietary toolpath strategies and coolant-through spindle systems to minimize thermal deformation and burr formation. Our engineers deploy adaptive roughing and high-efficiency finishing cycles tailored to aluminum’s thermal conductivity and chip evacuation challenges, achieving surface finishes down to Ra 0.4 µm without secondary polishing. All programs undergo virtual simulation via NX CAM to prevent collisions and verify tolerances before metal cutting begins.

Quality assurance is non-negotiable. Every critical dimension is validated using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with ±2.5 µm + L/300 µm accuracy, operating in a temperature-controlled metrology lab (20°C ±0.5°C). Full first-article inspection reports (FAIRs) per AS9102 standards are provided, including GD&T analysis, surface roughness mapping, and 3D deviation color plots. Statistical process control (SPC) monitors feature drift in real time, with automatic machine tool compensation triggered if deviations approach 70% of tolerance limits. This closed-loop system ensures batch consistency across production runs exceeding 10,000 units.

The following table outlines achievable geometric tolerances for aluminum components under standard production conditions, validated through CMM inspection:

| Feature Type | Standard Tolerance | Precision Tolerance (Optional) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | CMM |

| Hole Diameter (Drilled) | +0.025/-0.000 mm | +0.008/-0.000 mm | Air Gage/CMM |

| Hole Position | ±0.05 mm | ±0.01 mm | CMM |

| Flatness | 0.05 mm | 0.005 mm | CMM/Height Gage |

| Perpendicularity | 0.05 mm | 0.01 mm | CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

These capabilities translate directly into client value: reduced assembly errors, extended component service life, and elimination of costly post-machining rework. By integrating 5-axis flexibility with metrology-grade verification, Wuxi Lead ensures every aluminum part conforms to print specifications while optimizing production economics. Our technical team collaborates with clients during design-for-manufacturability (DFM) reviews to identify tolerance synergies that accelerate time-to-market without compromising performance. This engineering-led approach establishes Wuxi Lead as a trusted partner for mission-critical aluminum components where precision is non-negotiable.

Material & Finish Options

Material selection is a critical decision in precision CNC machining, directly influencing component performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC aluminum machining, while also offering advanced capabilities in steel and titanium for demanding industrial applications. Understanding the mechanical properties, machinability, and finishing options of each material enables engineers and procurement specialists to make informed decisions aligned with functional requirements.

Aluminum remains one of the most widely used materials in precision CNC machining due to its favorable strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. It is particularly well-suited for aerospace, automotive, and electronics applications where weight reduction and efficient heat dissipation are paramount. Our facility primarily works with 6061-T6 and 7075-T6 aluminum alloys, which offer high machinability and dimensional stability. These grades respond exceptionally well to anodizing, enhancing surface hardness and wear resistance.

Steel, particularly alloy and stainless variants such as 4140, 17-4 PH, and 304/316, provides superior strength, hardness, and resistance to wear and high temperatures. While heavier than aluminum, steel is the preferred choice for structural components, tooling, and parts exposed to extreme mechanical stress. Its machinability is lower compared to aluminum, requiring optimized tool paths and cutting parameters—expertise we apply consistently to maintain tight tolerances and surface integrity.

Titanium, especially Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding resistance to corrosion, even in aggressive environments. It is widely used in aerospace, medical implants, and marine applications. However, titanium’s low thermal conductivity and high chemical reactivity present significant machining challenges, including tool wear and heat buildup. Our CNC machining centers are equipped with high-pressure coolant systems and rigid tooling setups to manage these challenges effectively.

Surface finishing plays a vital role in enhancing both performance and aesthetics. Anodizing is the most common post-processing treatment for aluminum components. It creates a durable, non-conductive oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) anodizing is ideal for general-purpose applications with optional dye coloring, while Type III (hardcoat) anodizing delivers thicker, harder coatings for high-wear environments.

Below is a comparative overview of key material properties and finishing options:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Recommended Finish |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 2.7 | 6061, 7075, 5052 | Aerospace, Electronics | Type II / Type III Anodize |

| Steel | 950 (17-4 PH) | 7.8 | 4140, 17-4 PH, 304 | Automotive, Tooling | Passivation, Plating |

| Titanium | 900 (Ti-6Al-4V) | 4.5 | Gr2, Gr5 | Medical, Aerospace, Marine | Anodizing, Passivation |

At Wuxi Lead Precision Machinery, we combine material science expertise with state-of-the-art CNC technology to deliver components that meet exacting international standards. Our engineering team supports clients in selecting the optimal material and finish combination based on operational environment, load conditions, and lifecycle requirements.

Manufacturing Process & QC

Precision CNC Aluminum Production: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our CNC aluminum manufacturing process is engineered for uncompromising quality and efficiency, adhering strictly to the zero-defect philosophy demanded by high-end industrial sectors. We integrate advanced engineering with rigorous quality control across three critical phases, ensuring every component meets exacting dimensional and functional requirements.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the initial design stage, utilizing advanced CAD/CAM simulation software to identify potential aluminum-specific challenges like thermal deformation, chatter, or fixturing limitations. We optimize toolpaths, select appropriate alloys (primarily 6061-T6, 7075-T6, or custom grades), and define precise tolerances per ISO 2768-mK or client-specific standards before any metal is cut. This proactive DFM stage prevents costly errors and accelerates time-to-market.

Prototyping transitions virtual designs into tangible validation. Leveraging our high-speed 5-axis machining centers, we produce functional prototypes rapidly, typically within 5-7 business days. Each prototype undergoes comprehensive metrology using蔡司 CONTURA CMMs and optical comparators, verifying critical dimensions, surface finishes, and geometric tolerances against the original CAD model. Client feedback is incorporated immediately, allowing for swift design refinements. This iterative phase ensures the final production process is de-risked and fully validated, eliminating unforeseen issues during scale-up.

Mass production executes the perfected process with unwavering consistency. Our fully automated production cells, featuring state-of-the-art Haas and DMG MORI machining centers, operate under strict environmental controls. Real-time in-process SPC (Statistical Process Control) monitors key parameters like tool wear, spindle load, and dimensional drift. Every 50th part undergoes 100% inspection against the critical characteristics defined in the prototype phase. Our integrated ERP system tracks material traceability from certified mills through every machining and inspection step, guaranteeing full auditability. The result is predictable lead times and certified zero-defect output, batch after batch.

Wuxi Lead CNC Aluminum Production Specifications

| Parameter | Capability | Standard Tolerance | Measurement System |

|---|---|---|---|

| Material | 6061-T6, 7075-T6, 2024, Custom Alloys | ±0.005 mm | Zeiss CONTURA CMM |

| Max Work Envelope | 1200 x 800 x 600 mm | Surface Finish | Ra 0.4 µm (Typical) |

| Spindle Speed | Up to 24,000 RPM | Geometric Tol. | ISO 2768-mK / GD&T |

| Positioning Accuracy | ±0.003 mm | Inspection Rate | 100% Critical Features |

| Coolant System | High-Pressure MQL / Flood | Process Control | Real-Time SPC Monitoring |

This disciplined approach—from collaborative design validation through rapid prototyping to statistically controlled mass production—ensures Wuxi Lead delivers CNC aluminum components that consistently exceed the performance and reliability expectations of aerospace, medical, and semiconductor clients. Partner with us for precision you can measure and trust.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Aluminium Machining

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer solutions that redefine performance, reliability, and scalability in high-end industrial applications. As a trusted leader in CNC aluminium machining, we specialize in transforming complex designs into high-tolerance, repeatable, and mission-critical parts for aerospace, automotive, medical, and advanced industrial sectors. Our commitment to precision, advanced technology, and customer-centric service sets us apart in a competitive global market.

When you choose to partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem backed by over 15 years of engineering expertise. Our state-of-the-art facility in Wuxi, China, is equipped with multi-axis CNC machining centers, automated inspection systems, and a quality management framework compliant with ISO 9001:2015 standards. Every aluminium component we produce undergoes rigorous dimensional verification, material certification, and surface finish validation to ensure it meets or exceeds your technical and regulatory requirements.

Our engineering team works collaboratively with clients from concept through to full-scale production. Whether you require rapid prototyping, low-volume batch runs, or high-volume manufacturing, we offer scalable solutions with fast turnaround times and competitive pricing. We support a wide range of aluminium alloys—including 6061, 7075, 2024, and 5052—each machined with optimized toolpaths and coolant strategies to maximize structural integrity and minimize thermal distortion.

We understand that in precision manufacturing, specifications matter. Below are key capabilities that define our CNC aluminium machining services.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, mill-turn |

| Tolerance | Up to ±0.005 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Surface Finish | As low as Ra 0.4 µm (polished), standard Ra 3.2 µm |

| Materials | Aluminium 6061-T6, 7075-T6, 2024-T4, 5052-H32, and custom alloys |

| Secondary Operations | Deburring, anodizing (Type II & III), powder coating, laser engraving, passivation |

| Quality Assurance | CMM inspection, first-article reporting, PPAP, FAI documentation |

Partnering with Wuxi Lead Precision Machinery means more than just sourcing a supplier—it means aligning with a long-term manufacturing ally dedicated to innovation, transparency, and operational excellence. Our global logistics network ensures timely delivery to North America, Europe, and Asia, supported by dedicated project managers who provide real-time updates and full traceability.

For engineering teams and procurement leaders seeking a reliable, high-precision partner in CNC aluminium machining, the next step is clear. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual tour of our facility. Let Lead Precision be the foundation of your next breakthrough in manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.