Technical Contents

Engineering Guide: Cnc 5 Axis Machining

Engineering Insight: The Non-Negotiable Role of Precision in CNC 5 Axis Machining

In high-value manufacturing sectors including aerospace, medical device production, and advanced energy systems, the shift to CNC 5 axis machining is not merely an operational upgrade; it is a fundamental requirement for achieving geometric complexity and part consolidation impossible with 3-axis technology. However, the true measure of a 5 axis capability lies not in the number of rotational axes alone, but in the unwavering precision maintained throughout the entire machining envelope. Sub-micron level accuracy across all five simultaneous axes is the critical differentiator between a functional prototype and a flight-certified, life-critical component. The cost of precision failure in these applications extends far beyond scrap material, encompassing program delays, certification hurdles, and catastrophic field failures. Achieving this level of fidelity demands more than advanced hardware; it requires deep process mastery, rigorous thermal compensation strategies, and an ingrained quality culture where tolerances measured in thousandths of a millimeter are the baseline expectation, not the exception.

Wuxi Lead Precision Machinery has honed this mastery over 15 years of delivering mission-critical components where precision is non-negotiable. Our engineering teams possess proven expertise in machining complex geometries for applications where failure is not an option. This includes producing ultra-precise manifolds and structural elements for the Beijing 2022 Winter Olympics ice-making systems, operating under extreme thermal cycling conditions, and manufacturing classified aerospace components requiring AS9100-certified processes and traceability to military specifications. Our facility integrates high-stability 5 axis platforms with in-process probing, real-time tool wear compensation, and environmental controls to ensure dimensional integrity from the first chip to the final inspection report. This operational discipline translates directly to client success, minimizing costly rework and ensuring first-article approval.

The following specifications represent the baseline precision capabilities achievable on our certified 5 axis machining centers under controlled production conditions, reflecting the standard we apply to every critical component:

| Specification Parameter | Typical Performance | Measurement Standard |

|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±0.001 mm | ISO 230-2:2014 |

| Repeatability (All Axes) | ±0.0005 mm | ISO 230-2:2014 |

| Surface Finish (Ra) | 0.4 µm – 0.8 µm | ISO 4287 |

| Geometric Tolerance (GD&T) | ±0.002 mm | ASME Y14.5-2018 |

| Thermal Drift Compensation | < 0.003 mm/°C | Internal Protocol |

This level of precision is not accidental. It is the direct result of integrating machine tool performance with meticulous process engineering and continuous validation. For manufacturers developing next-generation products, partnering with a supplier possessing demonstrable experience in ultra-precision 5 axis machining—validated through projects serving the Olympics and defense sectors—eliminates technical risk and accelerates time-to-market. At Lead Precision, we understand that your component’s precision defines your product’s performance; we engineer every process to ensure it exceeds expectation.

Precision Specs & Tolerances

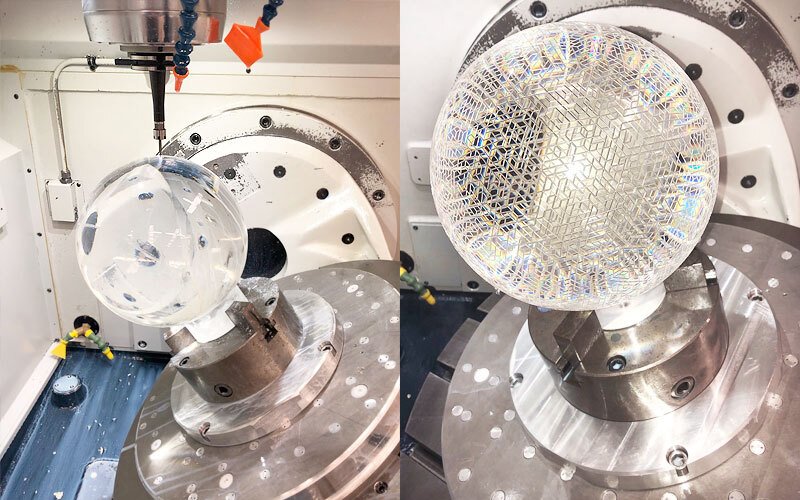

Wuxi Lead Precision Machinery delivers advanced 5-axis CNC machining capabilities designed for high-complexity, high-precision components across aerospace, medical, energy, and industrial automation sectors. Our 5-axis simultaneous machining technology enables the production of intricate geometries with superior surface finishes and reduced setup times, ensuring optimal part accuracy and repeatability. By integrating rotational and linear motion across five axes, we eliminate the need for multiple fixtures and secondary operations, significantly enhancing efficiency and dimensional consistency.

Our facility is equipped with state-of-the-art 5-axis CNC machining centers from leading global manufacturers, featuring high-torque spindles, dynamic tool compensation, and real-time error correction systems. These machines support a wide range of materials, including aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics, allowing us to meet diverse application requirements. Advanced CAD/CAM software ensures precise toolpath generation, minimizing cycle times while maximizing material removal rates and surface integrity.

Quality assurance is central to our manufacturing philosophy. Every component undergoes rigorous inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, geometric tolerances, and surface profiles. Our CMM systems are integrated with PC-DMIS software, enabling full first-article inspection (FAI) reporting and statistical process control (SPC) data tracking. This ensures complete traceability and compliance with ISO 9001:2015 and AS9100D standards.

We maintain strict environmental controls within our metrology lab to mitigate thermal drift, ensuring measurement stability across production runs. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate all aspects of part conformance.

The following table outlines the standard technical capabilities and tolerances achievable through our 5-axis CNC machining process:

| Parameter | Specification |

|---|---|

| Machine Travel (X × Y × Z) | Up to 1,200 × 800 × 700 mm |

| Rotary Axis Range (A and B) | ±120° (A), 360° (B) |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances (Linear) | ±0.010 mm |

| Tight Tolerances (Precision) | ±0.005 mm |

| Geometric Tolerances (Flatness, Perpendicularity) | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (typical 1.6–3.2 µm) |

| Minimum Feature Size | 0.5 mm (dependent on geometry and material) |

| Maximum Part Weight | 800 kg |

With a focus on engineering collaboration, Wuxi Lead supports clients from prototyping through high-volume production, offering Design for Manufacturability (DFM) analysis and rapid turnaround times. Our 5-axis machining capabilities, combined with stringent quality control, position us as a trusted partner for mission-critical precision components in demanding global markets.

Material & Finish Options

Material Selection for Precision 5-Axis CNC Machining

Selecting the optimal material is paramount in 5-axis CNC machining, directly impacting part performance, manufacturability, cost, and final finish. Complex geometries demand materials that maintain integrity under intricate cutting paths and multi-directional forces. At Wuxi Lead Precision Machinery, our engineering team prioritizes material compatibility with 5-axis processes to ensure dimensional accuracy, surface quality, and structural reliability for demanding aerospace, medical, and industrial applications. Understanding the core properties of Aluminum, Steel, and Titanium is essential for informed decision-making.

Aluminum alloys, particularly 6061 and 7075, are industry staples for 5-axis work due to excellent machinability, high strength-to-weight ratio, and good thermal conductivity. They enable high feed rates and rapid material removal, crucial for complex contours, while minimizing tool wear. Aluminum is ideal for structural components, housings, and prototypes where weight savings are critical. Steel variants, especially 4140 and 17-4 PH stainless, offer superior strength, hardness, and wear resistance. Machining these requires robust tooling and optimized parameters to manage heat generation and tool deflection during deep cavity or thin-wall machining inherent in 5-axis operations. Steels are the choice for high-stress components like hydraulic manifolds, shafts, and tooling fixtures. Titanium alloys, notably Ti-6Al-4V, provide exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility but present significant machining challenges. Low thermal conductivity leads to heat concentration at the cutting edge, demanding precise speed/feed control, specialized tooling, and ample coolant to prevent work hardening and tool failure. Titanium is indispensable for critical aerospace structural parts and medical implants.

Anodizing is the predominant finish for aluminum 5-axis machined parts, enhancing surface durability, corrosion resistance, and aesthetic appeal. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, while Type III (Hardcoat) anodizing delivers a much thicker, harder, wear-resistant surface essential for functional components subject to abrasion. Achieving uniform anodizing on complex 5-axis geometries requires meticulous racking design and process control to ensure consistent current distribution across all intricate surfaces and internal features. Material choice fundamentally dictates the achievable surface finish and post-processing requirements.

The following table summarizes key material characteristics relevant to 5-axis machining performance:

| Material | Key Properties for 5-Axis Machining | Machinability Rating | Common 5-Axis Applications |

|---|---|---|---|

| Aluminum Alloys | Excellent thermal conductivity, Low density, Good strength | Excellent | Aerospace brackets, Enclosures, Heat sinks |

| Steel Alloys | High strength, Hardness, Wear resistance | Good | Hydraulic blocks, Precision shafts, Tooling |

| Titanium Alloys | Exceptional strength-to-weight, Corrosion resistance | Fair | Aircraft structural fittings, Medical implants |

Material selection is not merely a specification box to tick; it is an integrated engineering decision. Wuxi Lead Precision Machinery leverages deep metallurgical understanding and extensive 5-axis process expertise to guide clients towards the optimal material and finish combination. Our engineers collaborate from the design phase, ensuring material properties align with machining capabilities and final application demands, guaranteeing precision, performance, and value. Contact our technical team to discuss your specific material challenges for complex 5-axis components.

Manufacturing Process & QC

The journey of precision 5-axis CNC machining at Wuxi Lead Precision Machinery begins with a rigorous, integrated production process designed to ensure zero defects across every phase—from initial design through prototyping to full-scale mass production. Our methodology combines advanced engineering insight with state-of-the-art technology, enabling us to deliver complex, high-tolerance components for aerospace, medical, automotive, and industrial automation sectors.

Design is the cornerstone of our process. Our engineering team collaborates closely with clients to analyze CAD/CAM models, ensuring manufacturability, material suitability, and geometric accuracy. We conduct comprehensive Design for Manufacturing (DFM) reviews, identifying potential issues such as tool access, wall thinning, or thermal deformation before any metal is cut. Using Siemens NX and Mastercam software, we simulate the entire 5-axis toolpath in virtual space, eliminating collisions and optimizing cutting strategies for maximum precision and efficiency.

Following design validation, we proceed to prototyping. This stage is critical for verifying functionality, fit, and surface integrity. Utilizing our DMG MORI and Hermle 5-axis machining centers, we produce functional prototypes in the same material and under the same conditions as final production parts. Each prototype undergoes full metrological inspection using a Zeiss DuraMax and portable CMM systems, ensuring dimensional compliance within ±0.005 mm. Feedback from this phase is integrated into final process adjustments, guaranteeing that design intent is perfectly translated into physical form.

Mass production is executed under a disciplined quality management system aligned with ISO 9001:2015 standards. Our facility employs automated tool measurement, in-process probing, and real-time spindle monitoring to maintain consistency across production runs. Every component is traceable through our digital manufacturing execution system (MES), which logs machine parameters, inspection data, and operator inputs. Statistical Process Control (SPC) is applied to detect trends and preempt deviations, ensuring zero-defect output even over extended batches.

Our commitment to perfection is reflected in the precision and reliability of every part we produce. By integrating advanced technology with meticulous process control, Wuxi Lead Precision Machinery ensures that clients receive components that meet the highest standards of performance and quality.

| Specification | Detail |

|---|---|

| Machine Types | DMG MORI, Hermle, MAZAK 5-axis CNC centers |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1,200 x 800 x 600 mm |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, PEEK, engineering plastics |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Tolerance Range | ±0.005 mm to ±0.01 mm typical |

| Quality Standards | ISO 9001:2015, full first-article inspection, SPC monitoring |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising 5-Axis Excellence

In the demanding landscape of high-precision manufacturing, selecting a CNC machining partner transcends mere equipment capability. It demands proven engineering rigor, unwavering process control, and deep sector-specific expertise. Wuxi Lead Precision Machinery stands as your strategic ally for mission-critical 5-axis machining, where tolerances measured in microns define success and failure. We engineer solutions for industries where precision is non-negotiable: aerospace structural components, medical implant systems, energy turbine assemblies, and advanced defense subsystems. Our commitment extends beyond delivering parts; we integrate seamlessly into your supply chain as an extension of your engineering team, solving dimensional nightmares and accelerating time-to-market.

Our technical foundation rests on a rigorously maintained fleet of state-of-the-art 5-axis machining centers, operating within climate-controlled environments under ISO 9001:2015 certified processes. Every spindle run, tool change, and measurement cycle adheres to protocols exceeding industry standards. The table below details the core capabilities underpinning our service:

| Specification Category | Performance Metric | Industry Relevance |

|---|---|---|

| Positioning Accuracy | ±0.003 mm | Critical for multi-feature alignment in turbine blades |

| Repeatability | ±0.002 mm | Ensures batch consistency for medical implants |

| Surface Finish | Ra 0.4 μm (as-machined) | Meets stringent aerospace fluid dynamics requirements |

| Work Envelope (Max) | 1200 x 800 x 600 mm | Accommodates large structural aircraft components |

| Material Capability | Titanium Ti-6Al-4V, Inconel 718, 17-4PH SS, CFRP | Supports high-temp, high-strength applications |

| In-Process Metrology | On-machine probing with Renishaw systems | Eliminates setup errors for complex geometries |

| Lead Time Reduction | 25% vs. industry average | Accelerates prototyping and low-volume production |

Why Partner With Lead Precision? We move beyond transactional machining. Our engineers engage early in your design phase through Design for Manufacturability (DFM) collaboration, identifying potential precision pitfalls before metal is cut. Our dedicated project managers provide transparent, real-time progress tracking via secure client portals, including comprehensive first-article inspection reports (FAIRs) and material certifications. We invest in continuous operator certification and proprietary fixturing methodologies that minimize non-value-added time while maximizing geometric accuracy. This integrated approach consistently delivers complex components requiring simultaneous 5-axis contouring, deep cavity milling, or micro-feature detailing – often where competitors reach their technical limits.

The cost of precision failure in your sector is catastrophic. Partnering with Lead Precision mitigates this risk through demonstrable technical mastery and process transparency. We transform your most challenging 5-axis requirements from engineering obstacles into competitive advantages. Initiate your precision project with confidence. Contact our engineering team directly at [email protected] to discuss your specific tolerances, materials, and volume requirements. Include your part drawings or CAD files for a rapid capability assessment and actionable quotation. Let us prove why global leaders in aerospace, medical technology, and energy trust Wuxi Lead Precision Machinery for their most exacting 5-axis machining needs. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.